Pogo Pin Connector, we welcome to its Ultimate Guide! Whether you’re seeking high-reliability connectivity solutions or precise positioning within tight spaces. Even if you’re from the most complex aerospace electronic systems. Our goal is to provide you with a solution that is precisely what you need, nothing less.

Pogo Pin connector is a precise electronic connection solution known for its reliability and flexibility. This guide will delve into the workings, design features, and customization options to meet complex needs. Whether your project requires high-density wiring, precise positioning, or operation in harsh environments. The Pogo Pin connector can meet your requirements.

Learn how to utilize the Pogo Pin connector to furnish you with the most suitable resolution imaginable!

Introduction: Pogo Pin Connector Ultimate Guide to Tailor to Complex Needs

- Welcome here! In today’s increasingly intricate and diverse landscape of electronic devices. The Pogo Pin connector is emerging as a top choice for pretty many customers. Thanks to their distinctive design and flexibility. Whether in industrial automation or aerospace electronic systems, Pogo Pin connectors have showcased unparalleled performance and versatility.

- In this manual, we’ll explore an array of features and benefits of the Pogo Pin connector. We’ll explore adapting them to address intricate needs and preferences. Whether you’re seeking a highly reliable connectivity solution or aiming for precise positioning within limited space, we’ve got you covered.

- Through this guide, you’ll gain comprehensive insights into the working principles and design characteristics. And applications of the Pogo Pin connector across various complex scenarios.

- Join me as we set sail on this voyage, uncovering the limitless opportunities of Pogo Pin connectors. Our goal is to offer you flawless, personalized solutions designed just for you!

Principles and Structure: Pogo Pin Connector

Principles:

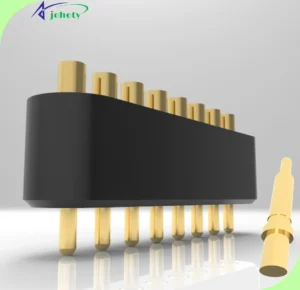

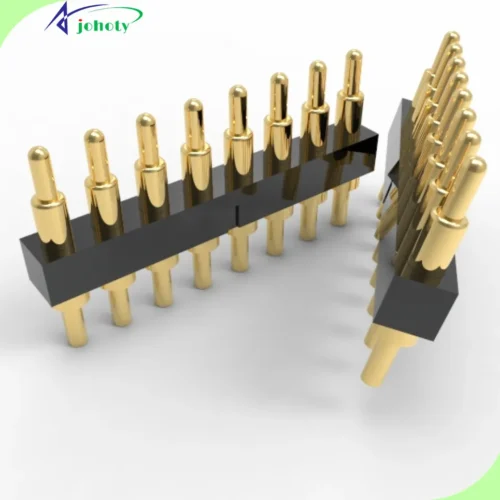

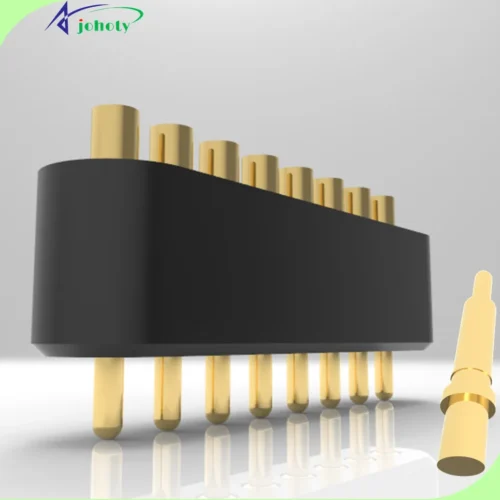

- The Pogo Pin connector is an electronic connector based on spring contact, functioning similarly to spring-loaded sockets. It consists of pogo pins made from spring material. Which provides an electrical connection through elastic deformation with the target socket or pad.

- This design allows Pogo Pin connectors to maintain stable electrical connections during insertion and removal. Even in vibrating or moving environments.

Structure:

- The basic structure comprises a conductive pogo pin and an outer protective housing. Pogo pins are typically made from highly elastic metal materials, such as copper, steel, or alloys. The outer protective housing is used to secure the pogo pins and provide the connection interface.

- In the electronics industry, the Pogo Pin connector holds a significant position and has extensive applications. Its versatility extends from mobile technology to medical devices, from industrial machinery to automotive and aerospace electronics, serving a wide array of industries.

- It has the characteristics of high reliability, quick connection, and precise positioning. This makes the Pogo Pin connector an indispensable component of electronic devices. Providing reliable electrical connection solutions for various complex applications.

Design Features: Pogo Pin Connector Ultimate Guide to Tailor to Complex Needs

Spring Contact Design:

- The Pogo Pin connector utilizes a spring contact design, ensuring stable electrical connections during insertion and removal. This design guarantees reliability and stability, maintaining a solid connection even in mobile or vibrating environments.

High Reliability:

- The Pogo Pin connector is crafted with a strong focus on reliability. Its Pogo pins are often made from highly elastic metal materials, such as copper, steel, or alloys.

- You can rely on these materials for their outstanding conductivity and durability, ensuring long-term stable operation of the connector.

Precise Positioning:

- Pogo Pin connectors often feature precise positioning capabilities to ensure proper alignment. This precise positioning helps avoid connection issues caused by misalignment.

- It’s particularly well-suited for applications that necessitate high connection accuracy.

High Density Wiring:

- Due to the fine and flexible leads of Pogo Pin connectors, it can achieve high-density wiring. This allows Pogo Pin connectors to connect multiple electronic components within a limited space. This facilitates compact device designs.

Adaptability:

- The Pogo Pin connector typically exhibits good adaptability and can operate normally in various conditions. Even in harsh environments, they maintain stable connectivity performance admirably.

Customization Capability:

- Johoty often offers customization services for the Pogo Pin connector tailored to specific customer needs. This allows customers to select the appropriate size, shape, material, and characteristics based on their application requirements. Achieving optimal connection results.

Reliable Connection and Precise Positioning of Pogo Pin Connector

Reliability of Spring-loaded pin:

- The spring contact design ensures stable electrical connections during insertion and removal.

- The elasticity and durability of the spring-loaded pin allow pogo pin connectors to maintain excellent connectivity performance for extended periods.

Precise Positioning Function:

- The precise positioning feature of the Pogo Pin connector ensures correct alignment.

- Precise positioning is crucial, especially for applications requiring high-precision wiring and alignment.

Material and Process Advantages:

- The Pogo Pin connector employs high-quality materials and advanced processes, including five-axis CNC, to ensure stability and reliability.

- Materials and processes have a significant impact on the electrical performance, durability, and environmental adaptability of connectors.

Various Complex Applications:

- The Pogo Pin connector suits medical equipment, industrial control systems, automotive electronic systems, aerospace electronic systems, and more.

- The Pogo Pin connector fully meets customers’ requirements for reliable connections and precise positioning in these scenarios. This enhances equipment performance and reliability.

Customization Services:

- Johoty provides comprehensive and professional customization services. Such as customizing connector dimensions, shapes, materials, and characteristics according to customer requirements.

- These services help customers meet specific demands and provide the best connection solutions.

High-Density Wiring and Usage in Harsh Environments of Pogo Pin Connector

Advantages of High-Density Wiring:

- The Pogo Pin connectors enable high-density wiring, leveraging its compact design and narrow lead spacing.

- The benefits of high-density wiring include space savings, increased equipment integration, and enhanced performance.

Pogo Pin Design and Lead Spacing:

- The pogo pin design and spacing of Pogo Pin connectors facilitate high-density wiring and stable connections.

- The fine and flexible pogo pin design of the Pogo Pin connectors allows for high-density wiring within limited space.

Characteristics for Adapting to Harsh Environments:

- Pogo Pin connectors can operate in high temperatures and corrosive, dusty, and humid environments.

- The material selection and process advantages of the Pogo Pin connector enable it to maintain stable performance in harsh environments.

Dustproof and Waterproof Design:

- The dustproof and waterproof design of the Pogo Pin connectors ensures reliable operation in harsh environments.

- Dustproof and waterproof design is crucial for outdoor, industrial, and other harsh environments, safeguarding the stable operation of customers’ equipment.

Challenges of Complex Requirements for Pogo Pin Connectors

High-Density Wiring Demand:

- Modern electronic devices require high-density wiring, such as aerospace electronic systems, smartphones, tablets, medical equipment, etc. This needs to connect numerous electronic components within a limited space.

- Traditional connectors face challenges in high-density wiring, being bulky with thick leads.

Precise Alignment Requirement:

- Some applications necessitate precise alignment, such as medical equipment, industrial control systems, etc.

- Traditional connectors struggle with precise alignment, leading to misalignment between plugs and sockets.

Usage Demands in Harsh Environments:

- Certain special environments require maintaining stable performance, like high temperature, humidity, corrosion, etc.

- Traditional connectors face challenges in reliability and stability when used in harsh environments.

Diverse Application Requirements:

- Modern electronic devices have diverse applications across different industries and fields, like automotive electronics, medical equipment, industrial control systems, etc.

- Traditional connectors are limited in their adaptability to various applications.

Customization Needs:

- Many customers require customized Pogo pin connectors, with customization requests in dimensions, shapes, materials, characteristics, etc.

- Traditional connectors struggle to meet customization needs, often failing to keep up with customers’ latest project application requirements.

Why Use Johoty’s Customized Pogo Pin Connector?

Meeting Specific Needs:

- Different customers have varied requirements for connectors, necessitating customized solutions to meet specific application needs.

- We’re adept at fashioning the tailor-made Pogo Pin connectors to precisely match the individual specifications of our customers. Including dimensions, shapes, materials, characteristics, etc., to achieve optimal connection results.

Enhancing Performance and Reliability:

- The customized Pogo Pin connector offers distinct advantages over standard connectors in terms of performance and reliability.

- They can better adapt to specific applications, improving equipment performance and reliability.

Solving Complex Issues:

- Some complex issues may not be resolved by standard connectors, requiring customized connection solutions.

- The customized Pogo Pin connectors can help customers address complex problems, enhancing equipment performance and reliability.

Providing Personalized Services:

- Our customized services, including design consultation, sample production, customized manufacturing, etc., can provide customers with a personalized service experience.

- Personalized services are crucial for meeting customer needs and enhancing customer satisfaction.

Innovation and Competitive Advantage:

- The customized Pogo Pin connectors can help customers achieve innovation and competitive advantage, driving product development and improvement.

- By offering unique product solutions, we enhance customers’ competitiveness in the market.

Success Stories of Pogo Pin Connector

Smartphone Industry

- Challenge: Limited internal space in smartphones requires high-density wiring and reliable electrical connections.

- Solution: Utilizing compact, high-density Pogo Pin connectors to efficiently connect multiple functional modules.

- Outcome: The Pogo Pin connectors provide stable electrical connections, reducing connection issues caused by tight spaces. Our focus is on amplifying the efficiency and trustworthiness of smartphones, delivering top-tier performance.

Medical Devices

- Challenge: Medical devices require high-precision and high-reliability connections, often used in high-humidity and sterilization environments.

- Solution: Our customized Pogo Pin connectors are made from corrosion-resistant, high-temperature materials with dustproof and waterproof features. Ensuring stable performance in harsh conditions.

- Outcome: These connectors ensure the high reliability and precision of medical devices, meeting the healthcare industry’s demand for high-standard connection solutions.

Automotive Electronic Systems

- Challenge: Automotive electronic systems operate in harsh environments with high temperatures and vibrations, requiring connectors with high durability and stability.

- Solution: Implementing high-temperature and vibration-resistant Pogo Pin connectors with specialized designs to enhance adaptability in harsh conditions.

- Outcome: The customized Pogo Pin connector provides stable and reliable connections in automotive electronic systems, enhancing system safety and durability.

Industrial Control Systems

- Challenge: Industrial control systems require reliable connections in high-density electrical environments and stable operation under high current and voltage conditions.

- Solution: Through customized designs, the Pogo Pin connectors meet the demands for high current and voltage while achieving a compact layout.

- Outcome: The Pogo Pin connectors improve wiring efficiency and connection reliability in industrial control systems, enhancing system stability and safety.

Our Technical Support and Services of Pogo Pin Connector

Customized Design Support:

- We offer tailored design support with our professional engineering team, addressing specific requirements. Such as dimensions, shapes, materials, or unique application scenarios. We provide expert advice and customized solutions to meet our customers’ needs.

Sample Production:

- We provide sample production services, allowing customers to validate the feasibility and performance of designs. Our priority is to guarantee both the quality and performance of samples meet customers’ expectations. Serving as reliable references for subsequent production.

Technical Training and Support:

- Our services encompass technical training and continuous support to help customers better understand the working principles, and design features. As well as application scenarios of the Pogo Pin connector. Our dedicated team provides comprehensive technical support to address various technical challenges.

Production Support:

- We offer production support to ensure that product quality and delivery schedules meet customers’ requirements. We collaborate closely with customers to ensure smooth production processes and promptly address their feedback and needs.

After-Sales Service:

- Our CFT team provides professional ASS, including product quality assurance and technical support. We actively respond to customer queries and requirements, delivering timely solutions to ensure customer satisfaction with our products and services.

Conclusions: Pogo Pin Connector Ultimate Guide to Tailor to Complex Needs

The Importance of Customized Solutions:

- The customized Pogo Pin connector plays a crucial role in meeting complex requirements. Through customized design and professional services, we can provide customers with the best connectivity solutions tailored to specific needs.

The Value of Technical Support and Services:

- Technical support and services are immensely important throughout the entire process. Our lineup of services encompasses a broad range of options to suit every need.

- Including customized design support, sample production, technical training, and after-sales service. Assisting customers in achieving project success and product optimization.

The Wide Application and Enormous Potential of Pogo Pin Connector:

- The Pogo Pin connector has a wide application across various industries and holds enormous potential. Whether it’s in smartphones, medical devices, automotive electronic systems, or industrial control systems.

- The Pogo Pin connector can provide high-performance, highly reliable connectivity solutions.

Future Development Trends:

- The future development trends of the Pogo Pin connector lean towards miniaturization, higher density, and increased reliability. Customized services and technological innovations play a key role in future developments.

Appreciation and Outlook:

- We sincerely appreciate your attention and support, and we look forward to deeper cooperation and mutual development in the future. Through relentless effort and continuous innovation.

- You can rely on us to maintain our standard of excellence by providing top-quality products. Competitive prices, fast logistics, and professional services, aiming for mutual success.