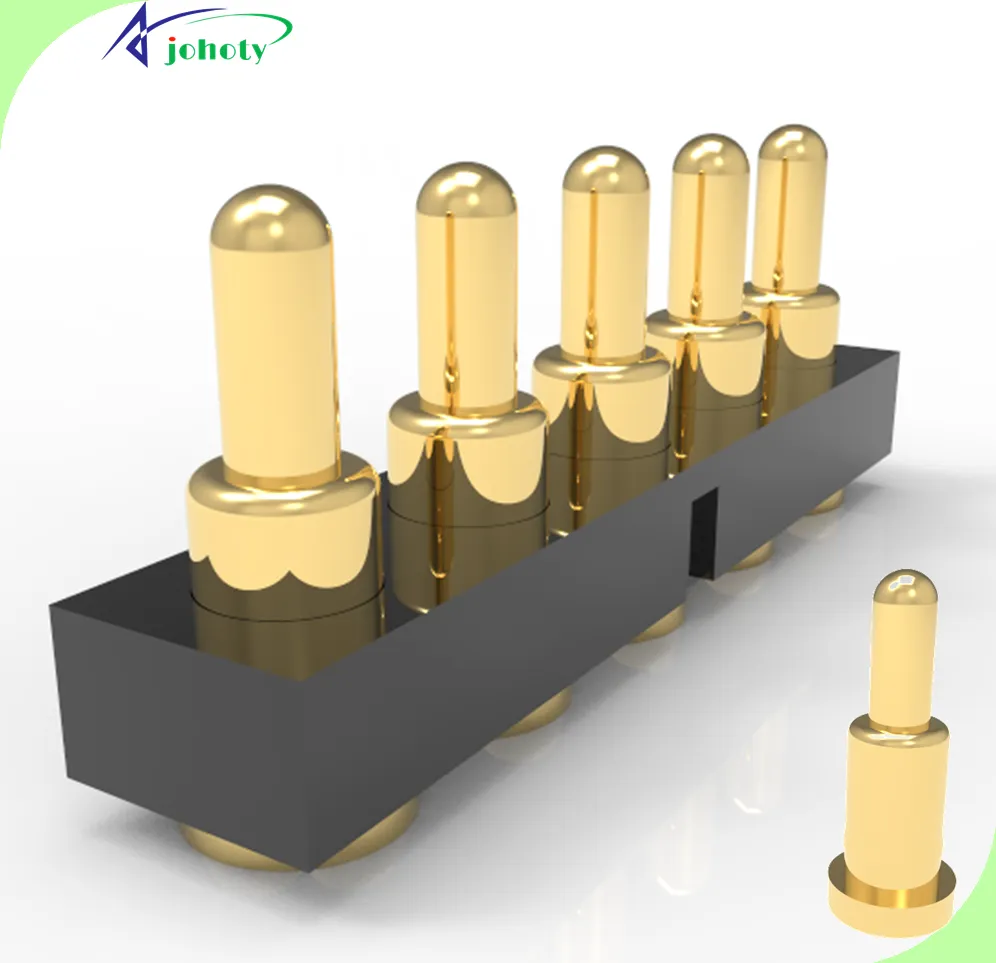

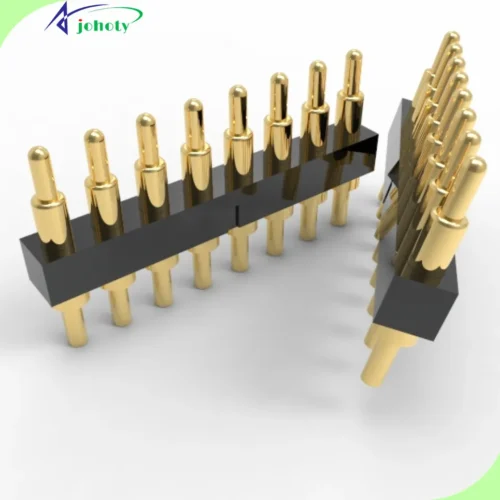

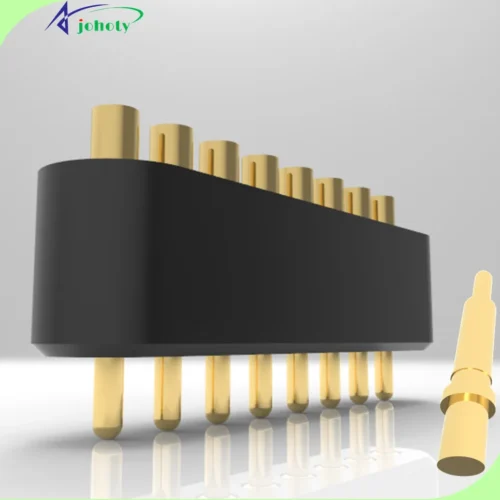

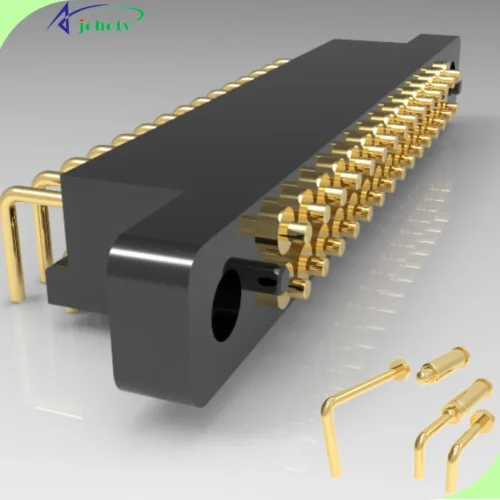

5 Pin Connector Description:

5 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: 0.015 Ω ~ 0.20 Ω, Custom. |

| Rated current: 0.05 A to 20 A, Custom. | |

| Rated voltage: 3.3 V to 500 V, Custom. | |

| Insulation impedance: 100 MΩ to 1000 MΩ, Custom. | |

| EMI: Can be compatible. Custom. | |

| Working frequency: From MHz to GHz, Custom. | |

| Mechanical: | Shapes: Single/dual rows, round, SMT, DIP, Double-ended, Right-Angle, Solder-cup, Bending type, Custom. |

| Contact force: ≥15gf, no upper limit, Custom. | |

| Pitch: ≥1.27mm, Custom. | |

| Stroke: ≥0.50mm, Custom. | |

| Length: ≥2.50mm, Custom. | |

| Barrer diameter: ≥0.50mm, most is >1.00mm, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, for female connector, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: 10,000 ~ 200,000 times, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Contact materials: Copper alloys (beryllium copper, phosphor copper), stainless steel, gold, etc. |

| Housing materials: Aluminum alloy, plastic (nylon, PA66, PTE, PPS, PBT), etc. | |

| Insulation materials: PI, PTFE, PBT, Nylon, etc. | |

| Spring materials: Gold-plated, music steel, stainless steel, etc. | |

| Ball materials: Steel, zirconium, ceramic, Custom. | |

| Sealing materials: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating materials: Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering materials: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, L/F, H/F, etc. | |

| Flammability rating: UL94 V-0, etc. | |

| Installation: | Surface mount: SMT, Automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin is available, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact. | |

| Embedded: High waterproof and sealing. | |

| Quick assembly: Testing equipment. | |

| Locking: Screws, nut, outside fixation force. | |

| Slot: High connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 5 Pin Connector?

5 Pin Connector is compact, EMI, IP68, magnetic connection. High precision and user feel, durability, and reliability. Johoty is trustworthy!

5 Pin Connector Benefits:

Improve Reliability of Product Connections

Johoty helps you improve signal stability, resist external environmental influences, has strong anti-vibration capabilities, has a long lifespan for cyclic use, reduces assembly errors, is compatible with high current and high-speed signals, is easy to maintain and replace, has a small size and lightweight, and meet the needs of modern equipment.

Support More Efficient Multifunctional Circuit Design

We can help you support efficient circuit modular design, support high-density circuit design, enhance connection reliability, and multifunctional signal transfer capability, improve product reliability and life cycles, enhance circuit performance, and meet multi-industry applications.

Meet the Miniaturization Needs of High-end Equipment

We can help you achieve compact designs, save space, lightweight designs suitable for portable devices, support high-density connections, highly customized, improve manufacturing and assembly efficiency, adapt to various miniaturization, reduce losses, strong earthquake resistance, high/low temp resistance, and have both beauty and practicality.

Provide Long Lifespan and High Durability

Johoty helps you extend your equipment lifespan, reduce repair costs, and ensure long-term reliability with stable electrical performance. Corrosion resistance, high/low temp resistance, dust and dirt prevention, earthquake and impact resistance, mechanical wear resistance, long-lasting conductivity, and low contact resistance.

5 Pin Connector Applications:

Connection of High-end Medical Equipment

Signal Transmission of Aerospace Equipment

Miniaturization Design of 5G Communication Base Stations

Module Connection of New Energy Vehicle Batteries

Efficient Operation of Smart Home Appliances

Data Interface of Wearable Devices

High Speed Communication of Drones

Precise Control of Industrial Automation Equipment

5 Pin Connector Advantages:

Flexible Customized Design

Stable Signal Transmission

Excellent Lifespan and Durability

Miniaturization Meets the Demand for High-end Equipment

FAQ

Very good. With its spring-loaded designs, Johoty 5 pin connector can maintain a stable electrical connection, even in situations with significant vibrations.

Keep in mind the distinct needs of the application. Including current and voltage requirements, required plug life, operating environment, and space constraints.

Key parameters include current and voltage ratings, contact resistance, length, stroke, spring force, life expectancy, and operating temperature range. Dimensional specifications, and the need for a waterproof or dustproof design.