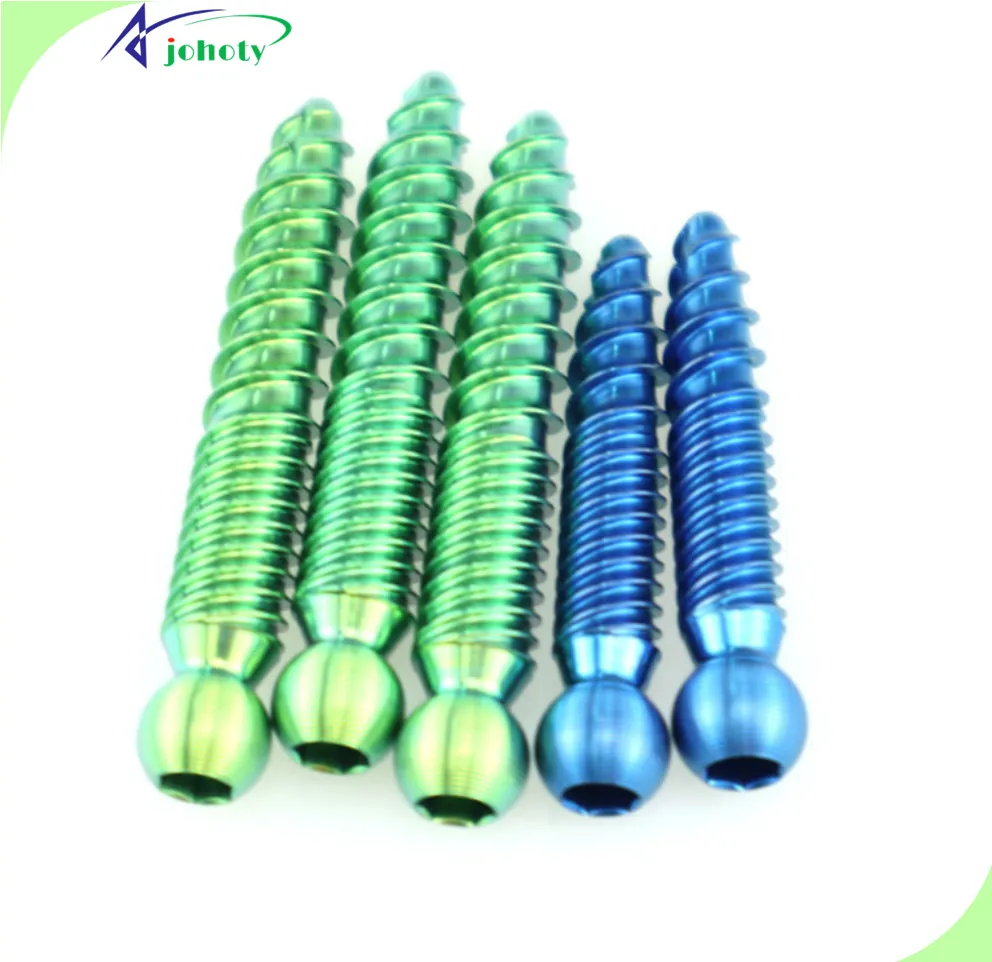

Best Medical Screws China Manufacturer

Medical Parts are ultra-precision, human body fit, safe and durable, and zero error. Titanium alloy and stainless steel are used as raw materials for orthopedic implants and dental instruments. Johoty can guarantee quality, shorten delivery time, help you improve efficacy, optimize costs, and ensure supply.

Product Features:

- Precise fit with bones.

- Aseptic material safety.

- Strength exceeds the standard.

- Ergonomic Design.

- Stable corrosion resistance.

- Personalized, customization.

Medical Screws Series:

There are many different series of medical screws, each series used for different parts. Some are used for the spine, some for joints, and some for repairing fractures. And they are very specially designed tools tailored for the body! Approximately 5 million spinal surgeries require the use of these screws worldwide each year! They are like small helpers customized for bones, helping doctors repair bones and ensure fast and stable recovery!

Category |

Description |

|---|---|

| Product Types | Including orthopedic screws (Cortical, Cancellous, Locking, Lag, Intramedullary Locking, Self-tapping), spinal screws (Pedicle, Polyaxial Pedicle, Self-tapping Pedicle, Locking Spinal, Cross-link), dental implant screws (Root-form, Mini, Cover, Healing, Self-tapping Dental Screws), and implant screws (Hip Fixation, Knee Fixation, Wrist Implant, Shoulder Fixation, Thumb Fixation, Ankle Fixation Screws). |

| Target Customers | Ideal for surgeons, hospitals, medical equipment suppliers, and procurement managers specializing in orthopedics, dental implants, spinal surgery, and other implant markets. |

| Applications | Fracture fixation, spinal stabilization, and dental implants, orthopedics, spinal surgery, and maxillofacial surgery. |

| Function & Specs | Self-tapping, self-locking, corrosion-resistant properties, and safety. ±0.005 mm accuracy tolerances. |

| Brand Info | Johoty has a legacy of quality and innovative solutions for “Caring for Life” |

| Price Range | Prices vary by specifications and material quality from $5 to $500 per screw. |

| Quality Standards | ISO 13485 and CE certification, ASTM F138, and ISO 5832-1 standards. |

| Purchasing | Available through Johoty website (https://johoty.com), Johoty CFT team ([email protected]). |

| Customer Services | Round-the-clock 24/7 support, postoperative support, and long-term warranty programs. |

| User Feedback | Good adaptability in surgery. Improved procedural stability, and a reduced rate of revision surgeries. |

| Advantages & Disadvantages | Strict quality standards and an established brand reputation. Premium pricing though competitive in the high-end market due to durability and safety. |

Reliable Quality

Cost-Effective

Fast Delivery

Customized Service

Why Choose Johoty’s Medical Screws?

Our medical screws have a strict quality inspection, cost-effective, fast delivery, and high custom. Contact us today!

Medical Screws Applications:

Fracture treatment

Spinal surgery

Pelvic fracture repair

plastic operation

Medical Screws Advantages:

Accelerated healing:

Easy to operate:

Strong corrosion resistance:

High Precision:

FAQ

- Medical screws materials are titanium alloy, stainless steel, and biodegradable materials.

- Titanium alloy is widely used due to its excellent biocompatibility, lightweight, and strength, but it’s relatively costly.

- Stainless steel offers good mechanical performance and cost-effectiveness, however, its biocompatibility isn’t as good as titanium alloy.

- Biodegradable materials slowly decompose in the body, removing the necessity for follow-up surgery to extract the medical screws. However, mechanical properties of biodegradable materials are worse than metal screws.

-

Medical screws ensure stability and safety inside the body through Johoty's precise design and production processes.

-

This includes optimized screw thread design and surface treatment to enhance their grip in bone and promote bone integration.

-

Moreover, using quality materials and strict standards ensure the usage safety and corrosion resistance of the medical screws.

-

This can greatly reduce the risk of in-body reactions and complications.

- Self-tapping screws have special screw threads, they can directly cut into bone without the need for pre-drilling.

- However, self-drilling screws come equipped with drilling features at their tips, they can penetrate bone without pre-drilling.

- Both aims are to reduce surgery time and minimize damage to bone.