Best Pogo Pins, China Manufacturer

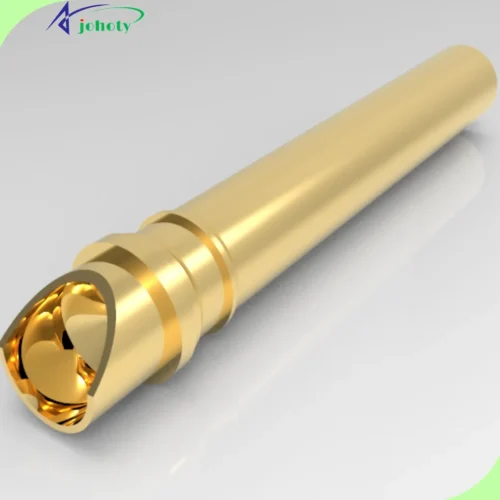

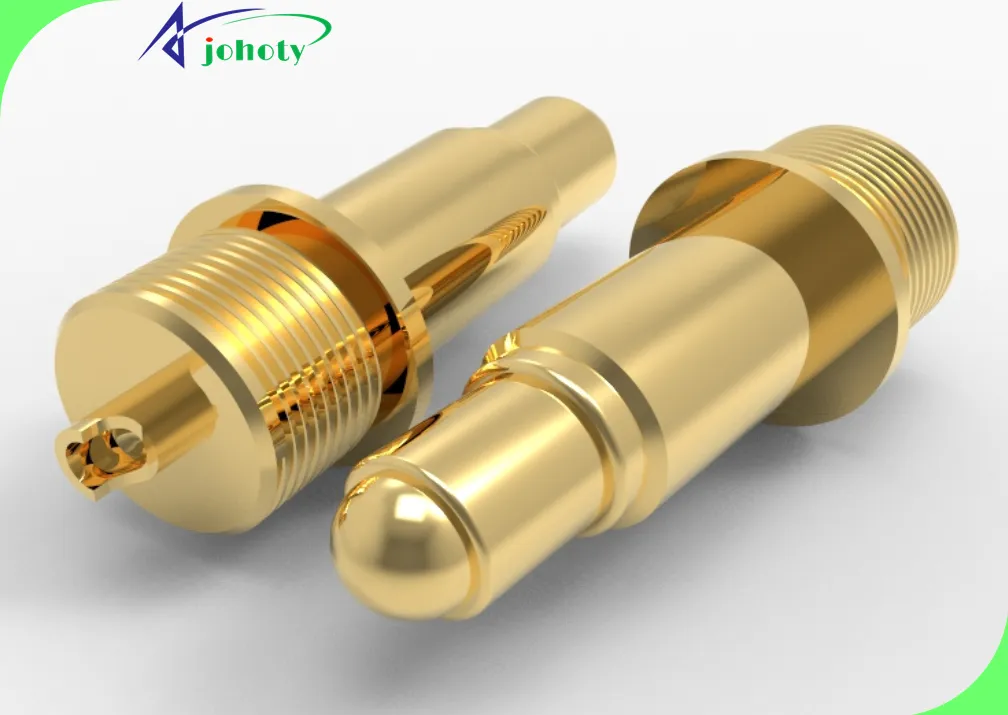

Pogo Pins have high-precision connections, high reliability, long durability, and a wide range of applications. Raw materials: brass, beryllium copper, tellurium Copper, gold-plating. Application areas: consumer electronics, medical devices, etc. Johoty provides you with cost-effective, fast delivery, flexible custom, and high-quality assurance.

Product Features:

-

Efficient electrical connection.

-

Long life cycle, wear-resistant.

-

Precision, high elasticity.

-

Stable, reliable, not loose.

-

Waterproof, corrosion-resistant.

-

Eco-friendly lead-free materials.

.

Pogo Pins Series:

Johoty’s Pogo Pins series, By Function: Waterproof, High-current, RF, Solder-Cup, Low-resistance, High-temp. etc. Installation: SMT, DIP, Double-end, Right-angle, Bending, Threaded, Solder-up, etc. Sizes: Micro, Standard, Large, Precision, Long, Short, Low Profile, Custom Size, etc. By Shape: Flat, Pointed, Ball, Tapered, Ring, Cup, Crown, Multi-Contact, Special Shape, etc. By Usages: Test probe (for IC, ATE, ICT, FCT), Charging, Signal, Aerospace, Medical, Consumer Electronics, Automotive, Industries, etc. You can find any Pogo Pins you want at Johoty!

Category |

Description |

|---|---|

| Pogo Pin Category | 10 types: IC Test Probe, ICT/FCT Test Probe, Through Hole, Surface Mount, High Current, Thread, Solder Cup, Double-ended, Bend type, and Right Angle. |

| Target Customers | Electronics manufacturers, automotive companies, medical device makers, consumer electronics companies, industrial automation, etc. |

| Applications | Electronic devices, charging docks, medical instruments, smartphones, gaming controllers, testing equipment, wearables, aerospace, robotics, industrial automation, etc. |

| Function & Spec | Excellent conductivity, compact design, and durability through many mating cycles. Low contact resistance (≥15 mΩ) and wide temp range (-40°C to +85°C), etc. |

| Brand Info | Johoty, known for its various precision connectors, provides you with flexible connectivity solutions. High quality, cost-effectiveness, and trusted choice for a long time. |

| Price Range | Priced between $0.10 and $100.00 each, depending on type, specifications, and order size. cost-effective for large orders. |

| Quality Standards | ISO 9001, RoHS, REACH, Lead Free, AISI, etc |

| Purchasing | You can buy Pogo Pins through Johoty website (https://johoty.com), CFT team ([email protected]), or WhatsApp (+86 18007608187), Skype (alfredyou2013), WeChat (+86 18007608187). |

| Customer Service | Technical help, Pogo Pins selection advice, ASS, keep the post. etc |

| User Feedback | Reliability, ease of use, durability, cost-effectiveness. durability and consistent electrical connections in demanding environments. |

| Advantages & Disadvantages | High-quality pogo pins, and excellent customer support. However, competition with lower-cost alternatives can be a disadvantage, although the superior quality justifies the price. |

Top Quality

Johoty can offer you stable electrical connections, reduce frequent maintenance, minimize poor contact, reduce disconnection or signal interference, achieve a stable and fault-free experience, provide reliable performance in different working environments, low and stable contact resistance, and ensure the integrity and clarity of high-frequency signals.

Cost-Effective

We can help you with a Long lifespan, reduce replacement costs, lower maintenance and downtime costs, offer the advantage of unit price in bulk procurement, reduce product repair rates due to poor contact or damage, improve production and testing efficiency, reduce additional investment in environmental adaptability, enhance product market competitiveness and user reputation, and achieve long-term investment returns.

Fast Delivery

We can help you with faster completion of product assembly and launch, avoid downtime due to lack of pogo pins, place orders on demand and reduce inventory management costs, reduce production interruption risks caused by delivery delays, better serve your end customers & improve customer satisfaction, reduce unexpected expenses, and optimize project management.

Custom Service

Why Choose Johoty's Pogo Pins?

Johoty's Pogo Pins, 20% cost-saving, ships in < 2 weeks, flexible and perfect custom. Contact Johoty today!

Pogo Pins Applications:

Robot battery connection

Car charging dock

Computer interface

Smart Watch Charging

Pogo Pins Advantages:

Compact in size

Structural flexibility

The structural design of Pogo Pins is very flexible, Johoty can customize their sizes and shapes according to device requirements. Each pogo pin is like a transformer, it can adapt to various device requirements. So, our spring loaded pin has a very high adaptation rate!

Low contact resistance

High conductivity

FAQ

1. How do Pogo Pins work?

Pogo Pins rely on built-in spring force to maintain a highly stable electrical connection between the plunger tip and its contact point. When compressed, the spring compresses, you can see reliable physical and electrical contact. Then, you can get a stable signal or power transmission.

2. What are the typical applications of Pogo Pins?

Johoty's Pogo Pins are used in various electronic devices and smart systems. Including medical instruments, consumer electronics, the charging ports of smartphones and tablets, testing and measurement equipment, and automotive electronics. Wearable devices, military and aerospace electronics, and robotics technology.

3. How to choose the right Pogo Pins?

When you select the appropriate pogo pin, you kindly think about the required current carrying, and operating frequency dimensions. For example, diameter and length. Pin shapes, working stroke, contact resistance, voltage rating, rating current, environmental conditions, temperature range, and waterproofing. It varies based on your applications.

Pogo Pins rely on built-in spring force to maintain a highly stable electrical connection between the plunger tip and its contact point. When compressed, the spring compresses, you can see reliable physical and electrical contact. Then, you can get a stable signal or power transmission.

Johoty's Pogo Pins are used in various electronic devices and smart systems. Including medical instruments, consumer electronics, the charging ports of smartphones and tablets, testing and measurement equipment, and automotive electronics. Wearable devices, military and aerospace electronics, and robotics technology.

When you select the appropriate pogo pin, you kindly think about the required current carrying, and operating frequency dimensions. For example, diameter and length. Pin shapes, working stroke, contact resistance, voltage rating, rating current, environmental conditions, temperature range, and waterproofing. It varies based on your applications.