Best Pogo Pin Connector China Manufacturer

Pogo Pin Connector has high precision, long lifespan, and high stability. It uses brass, beryllium copper, copper alloy, and stainless steel as core materials, and is widely used in medical equipment and communication electronics fields. Johoty provides you with diverse and flexible customization, fast delivery, and strict quality assurance to help you stand out.

Product Features:

- High precision contact

- Long wear-resistance, lifespan

- Stable low contact impedance

- Adapt to multiple scenarios

- Waterproof, corrosion-resistant

- Support high current, magnetic attachment

Pogo Pin Connector Series:

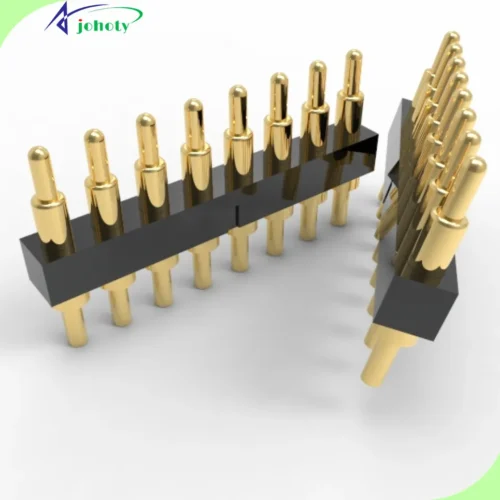

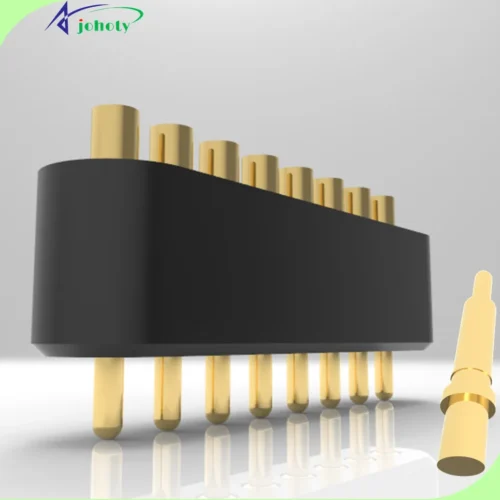

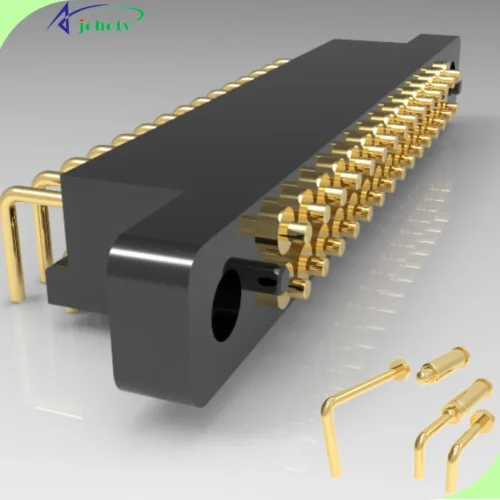

Johoty’s Pogo Pin Connector, PIN is ≥2, By Shape: standard, ball-head, magnetic, waterproof, high-current, RF, miniature, single-row, double-row, multi-row, etc. Installation: SMT, DIP, double-end, solder-up, right-angle, bending, etc. Application: Test probe (for IC, ICT, FCT), charging, signal, medical, automotive, industries, aerospace, consumer electronics, etc. Johoty always supports you with what you want!

Category |

Description |

|---|---|

| Types | Pogo Pin Connector contains any Pogo Pin shapes you want, PIN is ≥2. Includes: Magnetic connector, 2 pin connector, 3 pin connector, 4 pin connector, etc |

| Target Customers | Electronics, automotive, medical sectors, and consumer electronics sectors, as well as OEMs seeking connectivity solutions for advanced and custom electronic devices. |

| Applications | Battery charging, data transfer, testing, and connectivity in handheld devices, medical diagnostics, automotive assemblies, wearables, etc. |

| Function & Specs | Stable contact, high cycle life, corrosion resistance, and customizable. Resistance > 15 mΩ, >10,000 mating cycles. |

| Brand | Johoty is a trusted brand delivering quality, pricing, durable connectors, innovation, and client-focused custom. |

| Price Range | Ranges from $0.20 to $200.00 per piece based on your order size, materials, and customization; ideal for bulk and specialized applications. |

| Quality Standards | ISO 9001, RoHS, Lead-free, and REACH. |

| Where to buy | Johoty’s official website (https://johoty.com), and Johoty CFT team ([email protected]) for easy procurement. |

| Customer Support | Technical support & reference, customized consultations, and ASS addressing your concerns. |

| User Feedback | Durability, easy integration, ability to meet complex needs, and recommended by engineers for high-stakes projects. |

| Advantage & Disadvantage | Cost-effective, longevity and resilience, wear-prone, and high-frequency usages. Higher upfront costs but outweighed by lower maintenance expenses over time. |

Guaranteed Exceptional Quality

Cost-Effective Choice

Fast Delivery for Urgent Needs

We can help you with timely receipt of pogo pin connector, reduce waiting time, improve the response-ability to emergencies, reduce reliance on large quantities of inventory, lower storage costs & inventory management pressure, meet the needs of end users on time, enhance brand reputation, and support emergency projects & rapid iteration.

Flexbile Custom Solutions

We can help you customize size & shape, optimize current carrying capacity, contact resistance, and signal transmission speed, choose high temperature-resistant, corrosion-resistant, or high-strength materials, provide multiple installation methods including surface mount, direct insertion, or magnetic suction, design waterproof, dustproof, or earthquake resistant, extend the lifespan of connectors, and reduce maintenance costs.

Why Choose Johoty's Pogo Pin Connector?

Johoty's Pogo Pin Connector, 20% costs, ships to you in < 2 weeks, flexible custom. Contact Johoty today!

Pogo Pin Connector Applications:

Mobile Devices

Wearable Devices

Automotive Electronics

Aerospace

Pogo Pin Connector Advantages:

Seismic Resistance

Temperature Adaptability

Compact design

The pogo pin connector is compact in size, and the pitch can be designed as low as 1.0mm. Even if it is a common 6-pin, 12-pin, or 40-pin, its volume is not much. At the same time, pogo pins can also be designed as double-row, triple-row, or multi-row, which can greatly reduce the overall size.

The pogo pin is especially suitable for aviation equipment with limited space, and smart wearables. Small size design not only saves circuit board space but also makes the overall device design more compact. Johoty's poro pin connector is suitable for the lightweight needs of today's electronic products.

Easy to install:

FAQ

>100%, yes, It differs depending on the model and its specific design. Johoty's Pogo Pin connector, with special design and encapsulation, can achieve a certain level of waterproofing, such as IP67. It is suitable for applications requiring waterproofing.

Price differences are usually related to the connector's performance indicators. Johoty always utilizes precious metal coating including gold, silver, platinum, platinum, palladium, rhodium, ruthenium, etc. Manufacturing precision, and additional features, such as waterproofing, and high-frequency transmission capability. The Pogo pin connector needed for high-end applications typically commands higher prices. Sure, you can get discounts for your mass-production order

For projects with limited budgets, it's recommended to clearly define core performance requirements and non-essential additional features. Then, Johoty can design a cost-effective solution while keeping the complete function you want to get. Choose cost-effective models without reducing key performance. Additionally, consider contacting multiple suppliers, and comparing quotations and minimum order quantities to find the most cost-effective solution. One point is high quality is surely determined by high cost!