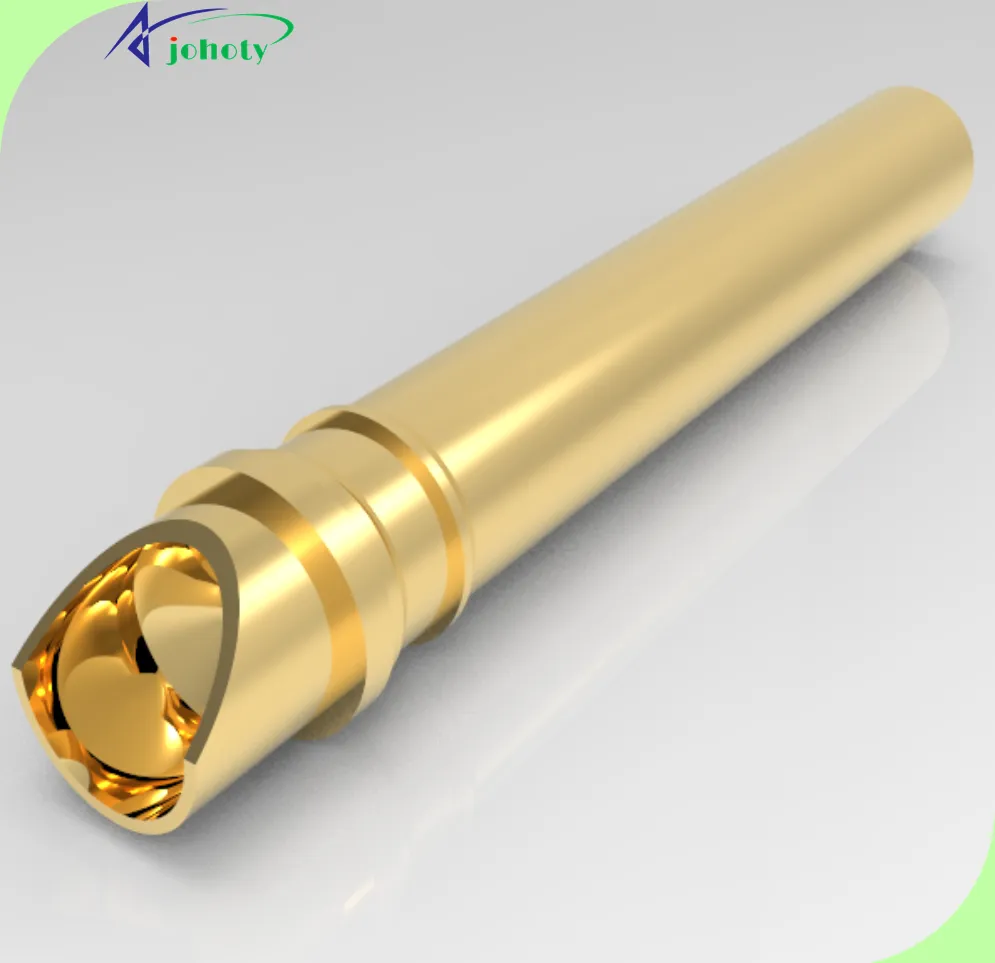

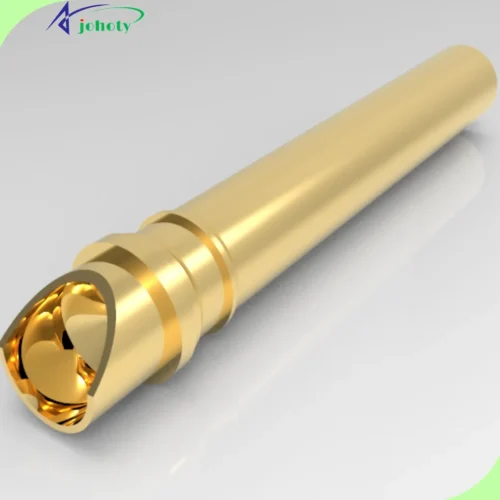

Solder Cup Pogo Pin Description:

Solder Cup Pogo Pin Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact Resistance: ≥ 15 mΩ, Custom. |

| Current Rating: 0.5A – 50A, Custom. | |

| Voltage Rating: 3.3V – 50V, Custom. | |

| Mechanical: | Diameter: 0.50 mm to 20.00 mm, Custom. |

| Length: 5.00 mm to 50.00 mm, Custom. | |

| Spring Force: ≥ 20 gf at nominal working height. | |

| Working stroke: 0.20 mm to 10.00 mm, Custom. | |

| Full stroke: 0.50 mm to 15.00 mm, Custom. | |

| Durability (Life Cycle): 10,000 ~ 500,000 cycles. | |

| Operating Temperature: -40°C to +125°C | |

| Materials: | Plunger: Brass, tellurium copper, or beryllium copper. ≥ 0.25um. Plating of gold, Ag, Pd, Pt, Rh, Ru, Custom. |

| Barrel: Brass, beryllium copper, tellurium Copper. Plating of gold, Ag, Pd, Pt, Rh, Ru, Custom. | |

| Spring: Stainless steel, music wire, Custom. | |

| Installation: | Soldering methods: Wave soldering, reflow, manual, laser, and ultrasonic soldering. Custom. |

| Cup shapes: Straight, conical, grooved, open, closed. Custom. | |

| Cup sizes: Diameter is 0.30-3.00mm, depth is 0.5mm-2.5mm, wall thickness tolerance is ± 0.02mm, hole size is AWG18-AWG30, standard pitch is 1.00mm-2.54mm. Custom. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s Solder Cup Pogo Pin?

Johoty’s solder cup pogo pin has 5 types of shapes and soldering methods, flexible custom of sizes. Johoty is trustworthy!

Solder Cup Pogo Pin Benefits:

Meet Various Application Requirements, Strong Compatibility

Excellent Soldering Strength and Conductivity, High Reliability

Shorten Production Cycle and Improve Efficiency

Reduce Costs, Flexible Process Selection

Solder Cup Pogo Pin Applications:

Automotive Electronics

Medical Equipment

Robot Control System

Communication Equipment

Consumer Electronics Products

Computer Hardware

Battery Charging System

Virtual Reality Devices

Solder Cup Pogo Pin Advantages:

Multiple Soldering Methods are Compatible

Stable Electrical Performance

High Strength Spring Design

Strong High Temperature Resistance

FAQ

An electronic connector secures and connects bare wires through soldering. It finds widespread use in situations necessitating trustworthy electrical links. Notably in cutting-edge electronic appliances, aerospace applications, military hardware, and industrial automation setups.

The particular demands of the application must be carefully evaluated. Encompassing elements such as dimensions, configuration, material selection, electrical performance criteria, environmental factors, and budgetary limitations.

Solder cup pogo pin optimizes signal transmission by reducing contact resistance and providing stable physical connections. Selecting the appropriate pogo pins and proper installation are essential in optimizing signal quality.