Spring Force 5gf Pogo Pin Delivers Consistent Compression and High Contact Accuracy for IC Validation. Power Your Design Confidence. View Specs!

Introduction:

Spring force 5gf pogo pins are constantly updated in modern electronic design. It can adapt to the improvement of IC packaging accuracy, the popularization of BGA/LGA packaging structure, and the extreme compression of testing redundancy space. How to achieve low loss and repeatable connections in high-density arrays? This has become a core challenge in R&D, testing, and quality management.

During the IC verification phase, engineers may encounter repeated plug connections, accumulation of small deviations in errors, and overstress losses. Spring force 5gf pogo pins often determine the key to whether a prototype testing system can run stably for a long time.

At this critical point, Johoty’s spring force 5gf pogo pin has ultra-low voltage connection, precise displacement control, and extremely high cycle life. It has gained attention in high-end chip manufacturing and testing in Norway.

Johoty will analyze the application logic, structural design, materials, and data performance of Spring Force 5gf pogo pins. Focus on how to accurately respond to the real pain points of R&D engineers, structural designers, and IC testing experts. As research samples of Johoty technology team, we would like to showcase its usage feedback and performance to you.

Role and challenges of Spring force 5gf pogo pins in IC verification

Traditional probes often use spring needles with elasticity ranging from 20gf to 80gf to pursue contact stability. However, in IC verification/ATE/precision detectors, excessive spring force brings some negative effects:

- BGA solder ball deformation or cracking affects the welding strength and subsequent packaging reliability.

- Micro Pad compression injury leads to reduced signal integrity.

- Signal distortion or reflection enhancement on high-speed testing platforms >3GHz.

- Accumulated structural fatigue during frequent plugging and unplugging processes.

- It isn’t easy to fulfill high-precision positioning and floating docking compensation in high-density areas.

More than 67% of structural engineers have provided feedback that they would like to use pogo pins with elasticity less than 10gf. It can reduce mechanical interference and structural stress in precision verification platforms. Based on this requirement, Johoty R&D team has designed micro pogo pins with a spring force of 5gf for Norwegian customers. These pins are suitable for testing 220-pin high-density IC chips with 2Gbpi and low interference.

How to achieve precise contact control under 5gf spring force?

Many procurement experts and R&D engineers may question whether a decrease in elasticity will reduce contact stability? Johoty has optimized pogo pin design to address this core issue:

3 stage gold plating treatment ensures low resistance contact.

- The thickness of the gold plating on the plunger can reach up to 5μm, while the industry standard ranges from 0.1μm to 0.125μm.

- The inner wall of the Barrel is polished to the highest level after 5-axis CNC machining, improving the smoothness of dynamic fit.

- Plunger tip and spring precision polishing process to reduce insertion force fluctuations.

After 10,000 compression cycles, contact impedance fluctuation range is <2mΩ, with an industry average of >6.5mΩ, effectively controlling signal loss.

Spring Material Optimization: Precise Spring Force Curve and Low Fatigue Index

- Spring adopts high-performance SUS304V or SWB-P, which has excellent recovery deformation characteristics.

- The elastic curve undergoes a three-stage buffering design, with the first pressure zone providing flexible absorption, the middle section forming a platform zone to maintain constant force, and the tail section slowly recovering.

This curve design can maintain a stable compressive force between 4.8gf and 5.2gf under a displacement error of ±0.10mm. Johot’s spring force 5gf pogo pins are far superior to traditional linear force curves.

Advantages of spring force 5gf pogo pins in high-frequency and low current testing

High frequency signal integrity:

In millimeter wave signal testing, any mechanical deviation or fluctuation in contact resistance may cause high reflection or signal degradation.

S-parameter test conducted by Johoty on spring force 5gf pogo pins is as follows:

| Test frequency | Return loss (S11) | Insertion loss (S21) |

|---|---|---|

| 1GHz | -28dB | -0.15dB |

| 3GHz | -22dB | -0.30dB |

| 6GHz | -17dB | -0.42dB |

Maintaining good signal integrity in the frequency range below 6GHz can meet the majority of IC verification and onboard debugging requirements.

Consistency of small current:

For some CMOS sensors, operational amplifier chips, or low-power SoCs, precise sampling at <1mA current is required during verification phase. Ordinary spring loaded pins often experience contact resistance offset under microcurrent conditions.

Johoty’s spring force 5gf pogo pins have been subjected to low stress contact control and silver coated gold finishing on the contact surface. Maintain contact stability within 0.1mA-10mA, with offset fluctuations less than 0.5%.

Life and reliability: Large scale modulus measurement and verification before reflow soldering

Johoty Laboratory conducted 100,000 compression tests on spring force 5gf pogo pins using a mechanical fatigue cycle testing system:

- Spring force attenuation <2.5%.

- The increase in contact resistance is less than 1.8mΩ.

- The displacement difference rate of the warhead is less than ±3μm.

After 200 cycles of high and low temperature testing between 40℃ and 125℃, there were no metal fatigue cracks or coating peeling. Fully meet the AEC-Q200 connector environmental testing standards for automotive grade components.

Engineering adaptation suggestions for Spring force 5gf pogo pins:

According to a large number of cooperative customer feedback, Spring Force 5gf pogo pins have been recommended by customers in the following applications:

- IC encapsulation validation socket.

- Semiconductor Test Fixture.

- Module functional socket.

- LGA, BGA probe holder automatic loading platform.

- Manually adjust the fixture before reflow soldering.

- Temporary measurement point for military/aviation micro high-speed signal transmission.

In the automated probe switching system, a 5gf spring force can effectively reduce the alignment stress of the loading and unloading equipment. Improve contact consistency and reduce misjudgment risk.

Material options and customization: Johoty’s engineering collaboration

Johoty doesn’t provide a universal configuration, but designs models based on customer needs. Suggestions for precise selection of crimping space and signal requirements.

The scope of customization support includes:

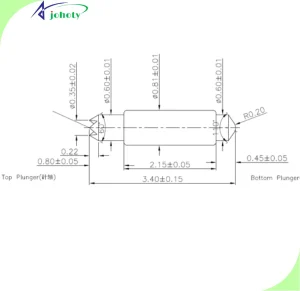

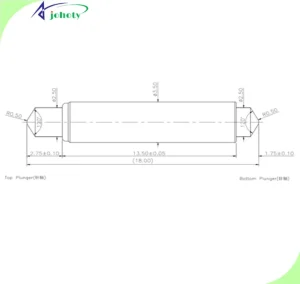

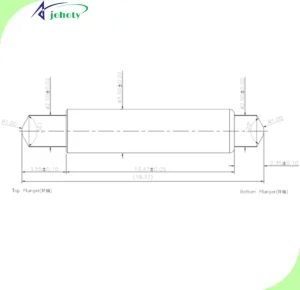

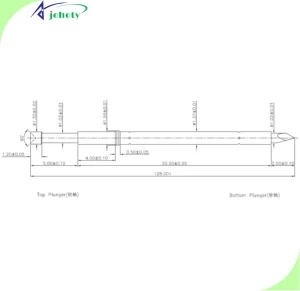

- Pogo pin total length: 1.39mm -70.00mm.

- Compression stroke: ≥ 0.10mm.

- Spring force range: ≥ 5gf.

- Contact head structure: spherical, conical, semi planar, crown, star, etc.

- Coating: Au, Ni-Au, Ag, Pd-Ni, composite coating.

- High temperature type supports reflow soldering environment at 260℃.

- Rated current: up to 50A per pin.

This type of fine customization ensures design parameters of mechanical engineers can be fully implemented. Avoid redundant selection, contact failure, and EMI exceeding standards.

Conclusions:

In today’s complex electronic system development, a small touchpoint may determine the stability and testing accuracy of the entire system.

Johoty always insists that connections are not attachments, but the infrastructure for system reliability. In IC verification or high-speed signal testing, a test probe with stable elasticity and low impedance contact retention force is important. The signal-to-noise ratio of the test data is improved, and the lifespan of the test board is extended.

It may also affect the pace of customer product releases. Johoty’s spring force 5gf pogo pins are designed for micrometer level docking control. In terms of contact reliability and long-term compression consistency, it provides a stable and highly reproducible solution. Suitable for applications such as high-density IC sockets, test sockets, and high-speed signal carriers.

Many times, there are strict constraints on contact accuracy, electrical stability, and micro load rebound force in the engineering verification process. We suggest that you contact Johoty for detailed technical specifications and parameters. Spring force 5gf pogo pins cover structural life prediction to solder packaging compatibility. The Johoty team can also provide detailed matching suggestions and structural simulation support.