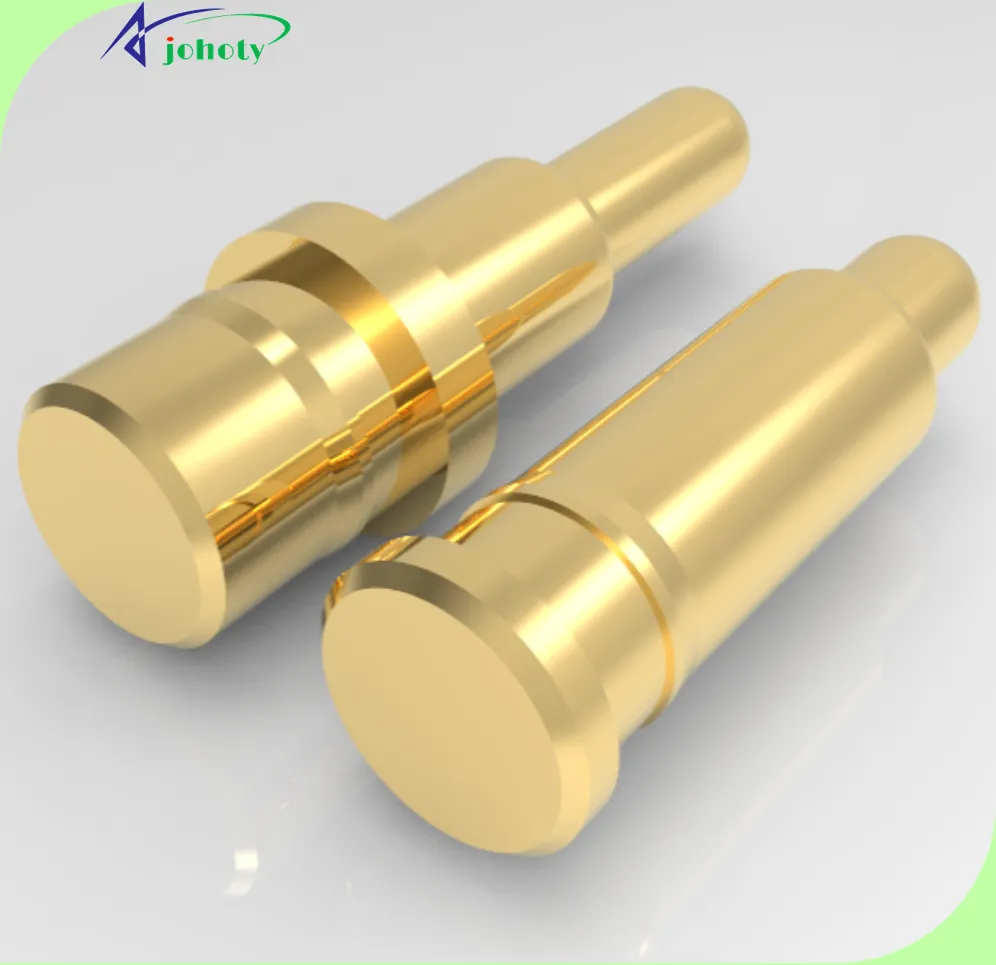

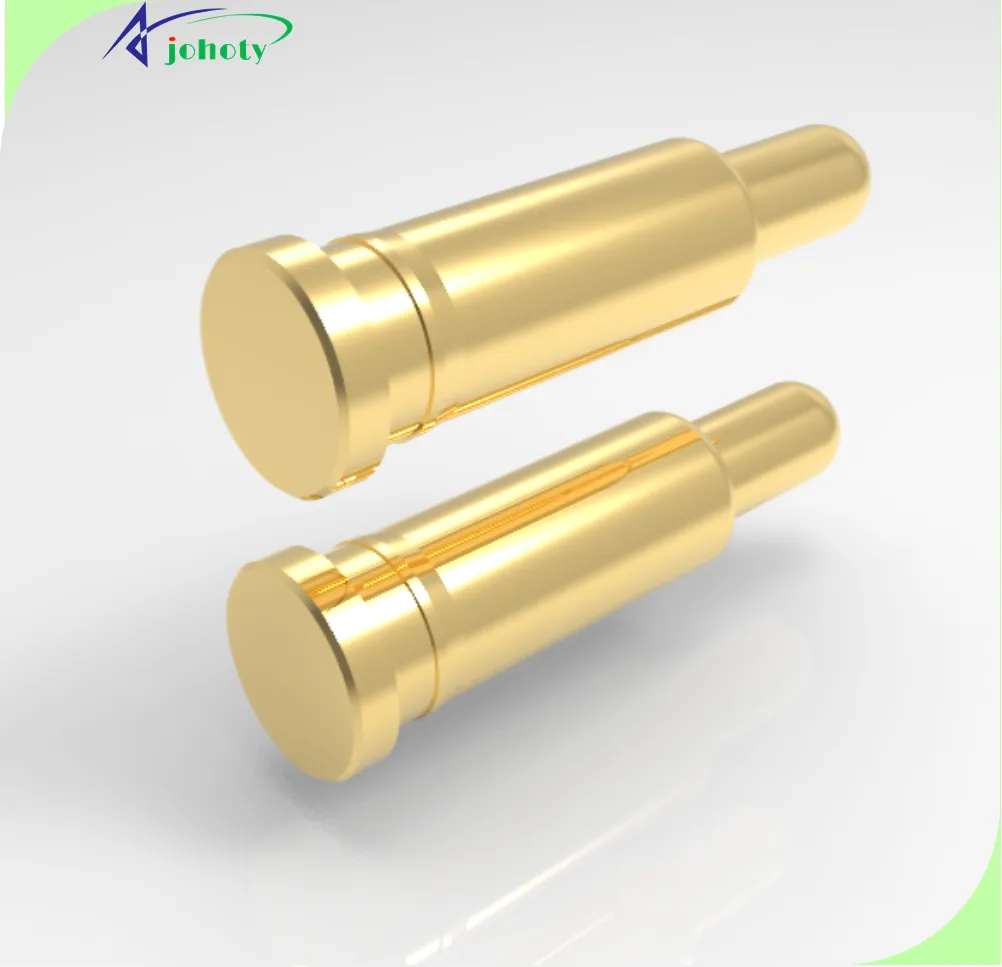

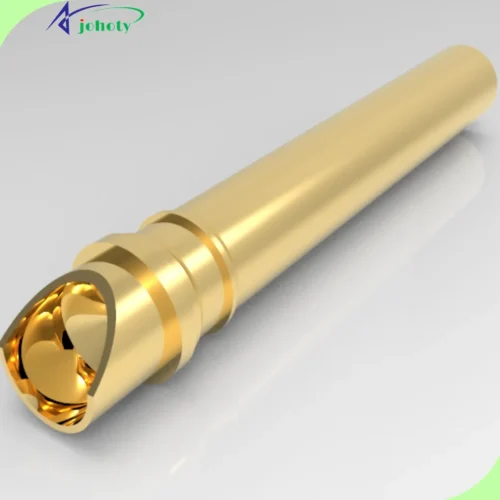

SMT Pogo Pins Description:

Catalogs of SMT Pogo Pins:

SMT Pogo Pins Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact Resistance: ≥ 15 mΩ, Custom. |

| Current Rating: 0.1A – 50A, Custom. | |

| Voltage Rating: 3.3V – 1000V, Custom. | |

| Mechanical: | Diameter: 0.3 mm to 20 mm, Custom. |

| Length: 1.3 mm to 100 mm, Custom. | |

| Spring Force: ≥ 15 gf at nominal working height | |

| Working stroke: 0.15 mm to 20 mm, Custom. | |

| Full stroke: 0.15 mm to 25 mm, Custom. | |

| Durability (Life Cycle): > 10,000 cycles. | |

| Operating Temperature: -40°C to +125°C | |

| Mounting Style: MT surface mounting | |

| Materials: | Plunger: Gold-plated brass or beryllium copper. ≥ 0.25um |

| Barrel: Gold-plated brass or beryllium copper. | |

| Spring: Stainless steel, music wire, Custom. | |

| Installation: | Installation Type: Surface Mount Technology (SMT) |

| Mounting Method: Solder vertically onto the surface of the PCB in SMT. | |

| Pad Size: 1.0mm x 1.2mm, Custom. | |

| Soldering Process: Place T&R pogo pins in SMT and vertically solder onto PCB with solder paste. | |

| Flux Type: No-clean flux, minimal residue. | |

| Package: | Bulk Packaging: Optional. |

| Tape and Reel: Optional. | |

| Tray Packaging: Optional.. | |

| Tube Packaging: Optional.. | |

| Blister Packaging: Optional. | |

| Plastic Bag with Antistatic Film: Optional. | |

| Custom Packaging: Optional. | |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s SMT Pogo Pins?

Johoty’s SMT pogo pins have >50k models for your reference, flexible custom of sizes, current, etc. Johoty is trustworthy!

SMT Pogo Pins Benefits:

High Density Design

Accurate and Reliable Contact Force

Simplified Assembly Process

Strong Durability and Adaptability

SMT Pogo Pins Applications:

Charging Interface for Wearable Devices

Battery Connection for Smartphones

Automotive Electrical Connections

Sensor Connection of Medical Equipment

Charging Port for Portable Game Consoles

Connection of Drone Battery and Circuit Board

Robot Control System

Wearable Health Monitoring Devices

SMT Pogo Pins Advantages:

Space saving

SMT pogo pins are vertically mounted onto PCBs, which can save a lot of space and make the circuit board design more compact. This installation method is like standing upright with small feet, allowing more space on the circuit board to accommodate more electronic components. The pogo pin not only makes the circuit board look neater, but also allows more components to be placed in a small box, reducing unnecessary space occupation.

It’s like employees organizing the production line by putting the parts boxes neatly in order to accommodate more materials. For many devices that require compact design, such as mobile phones, aviation equipment, and smart wristbands, using this method is very helpful!

Better Contact Quality

Easy to Automate Production

Simplify Design

SMT pogo pins reduce layout complexity through vertical surface installation, making the design simpler and easier to optimize. Just like how your child arranges all the books and stationery neatly when doing homework, his desk won’t be messy. Similarly, SMT pogo pins can make your design very simple.

Suh spring loaded pins only need to stand on the circuit board, unlike other components that require lying down or rotating. In this way, designers can free up more space on the circuit board to place other important components, making the entire circuit board look clean, neat, and very professional.

FAQ:

The primary benefits of pogo pins lie in their provision of high-precision electrical connections. Coupled with outstanding durability and reliability. They maintain low contact resistance and high versatility. Making them highly suitable for high-density electronic assembly applications.

By employing advanced manufacturing processes, high-performance materials, and automated production lines. We maximize production efficiency, minimize wastage, and consequently reduce costs while ensuring uncompromised quality standards.

Performance evaluation is based on a series of standard tests, including electrical performance testing, durability testing, and environmental adaptability testing. This is to ensure that each SMT pogo pin can meet various high standards.