Gas valve Description:

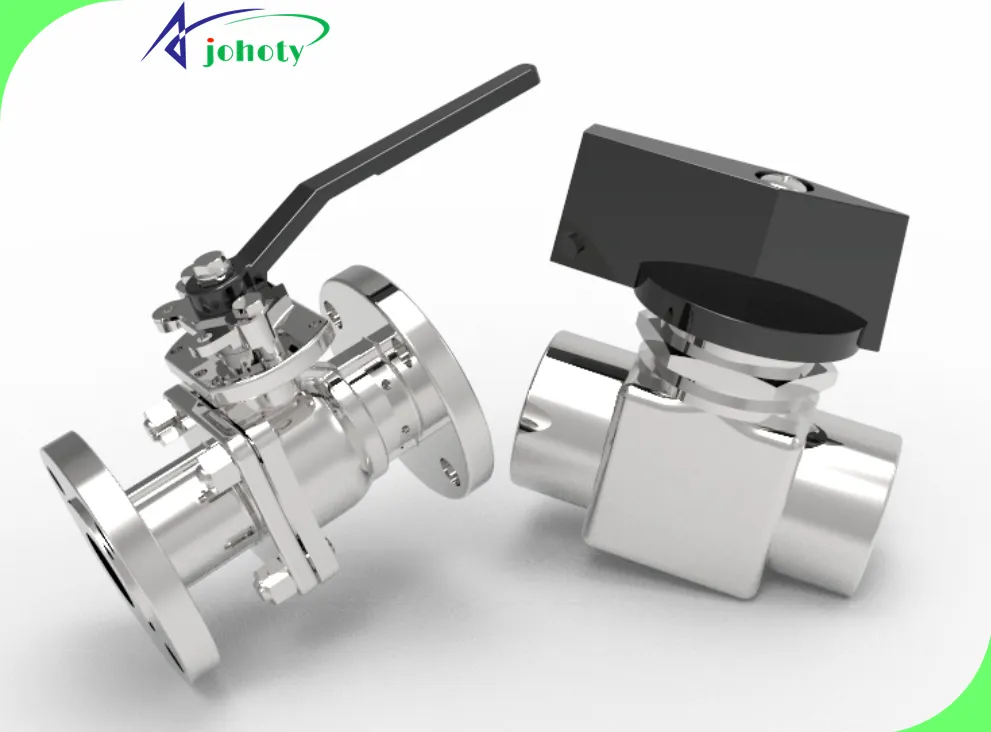

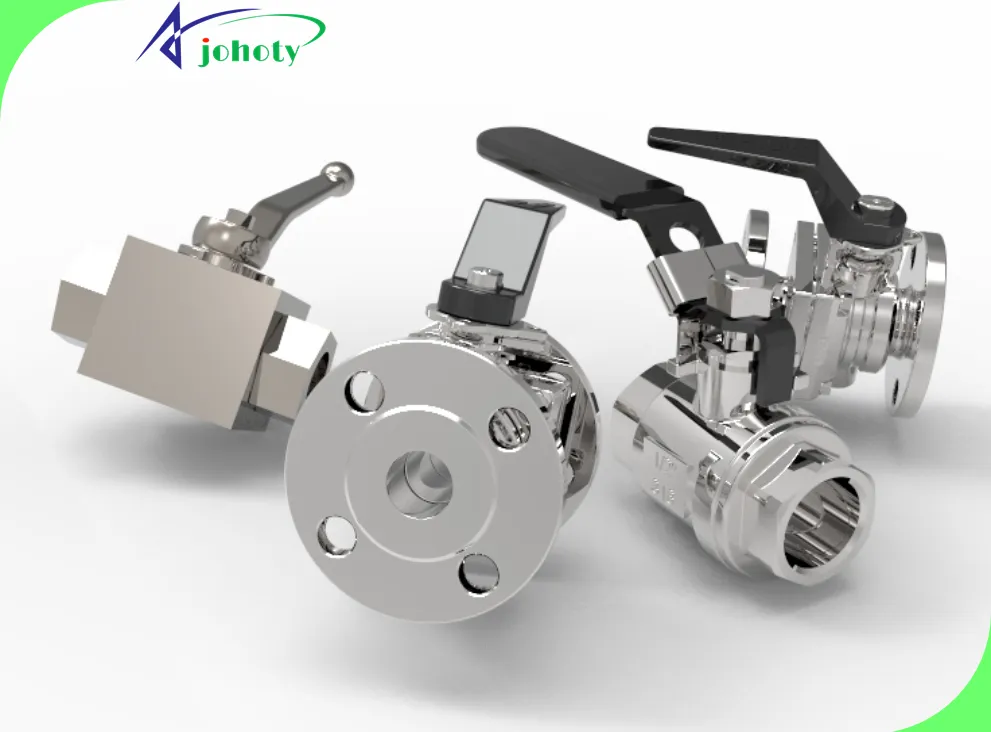

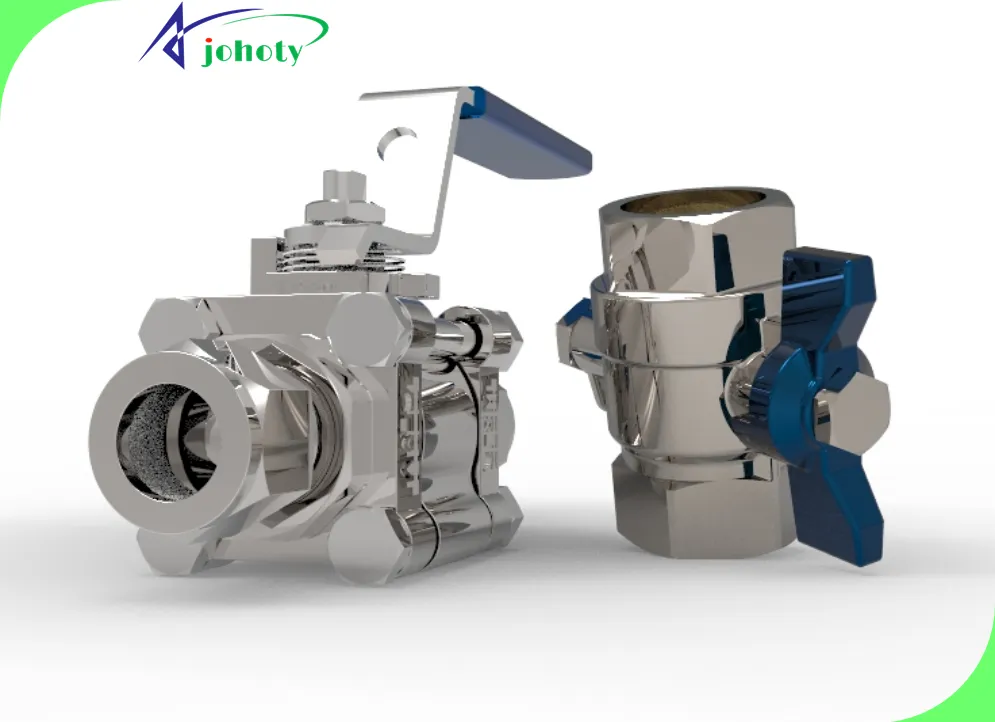

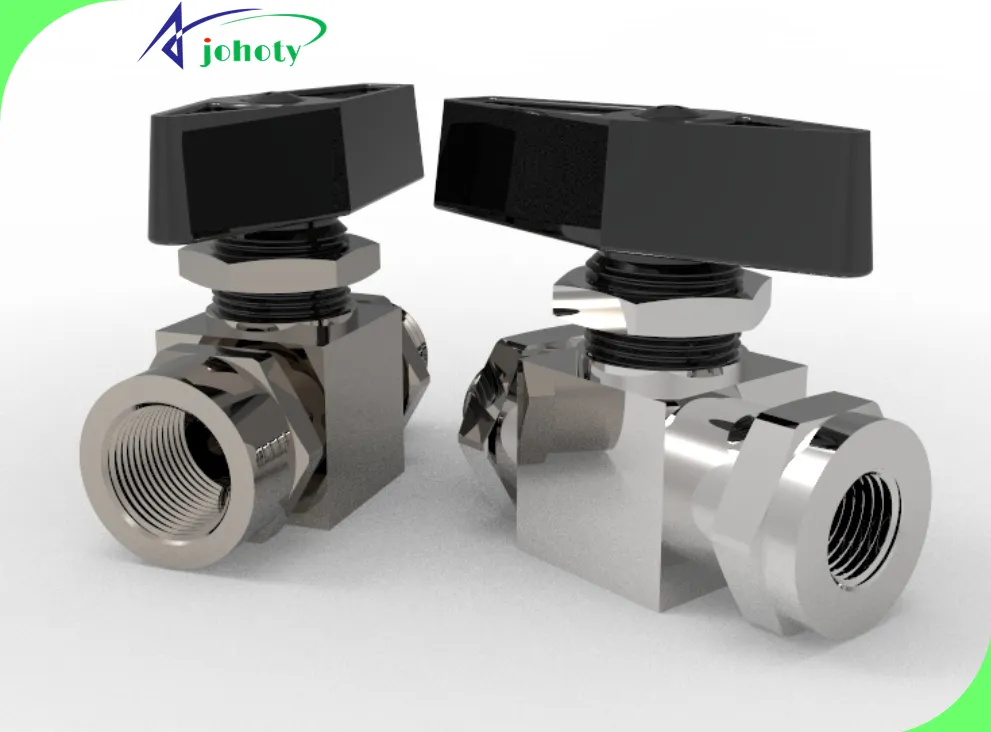

Catalogs of Gas Valve and ball Valve:

Gas valve Datasheet:

Items |

Details |

|---|---|

| Specifications | Valve Size: Available in 1/4 inch to 2 inches. |

| Pressure Rating: Rated up to 600 PSI. | |

| Temperature Range: Operates between -40°F and 350°F. | |

| Flow Capacity (Cv): Ranges from 5 to 120 depending on size. | |

| Connection Type: Threaded / Flanged. | |

| Thread Standard: NPT / BSPT. | |

| End Connection: Single or double. | |

| Material Grade: Brass, Stainless Steel (304, 316), PTFE. | |

| Performance | Leak Resistance: Zero-leakage rating at full pressure. |

| Cycle Life: Over 100,000 cycles. | |

| Corrosion Resistance: Tested for salt spray resistance for 96 hours. | |

| Flow Control: Smooth, unrestricted flow. | |

| Torque: Low operational torque. | |

| Function | Ball Port: Full port or reduced port. |

| Handle Type: Ergonomic and easy-grip. | |

| Anti-Blowout Stem: Built-in for safety. | |

| Seal Material: PTFE for durability. | |

| Body Construction: One-piece or two-piece design. | |

| Finishing | Electroplating: optional. |

| Spraying: optional. | |

| Anodizing: optional. | |

| Hot-Dip Galvanizing: optional. | |

| Chemical Plating: optional. | |

| Phosphating: optional. | |

| Polishing: optional. | |

| Sandblasting: optional. | |

| Coating: optional. | |

| Etching: optional. | |

| Certifications | ISO9001, ANSI, RoHS, L/F. |

| Packaging | Materials: Bag, Tray, Custom. |

| Methods: Blister, Foam, Custom. |

Why Choose Johoty’s Gas valve?

Johoty’s valve has a ±0.01 precision, save you >20% costs, ship in <2 weeks, perfect custom. Today Contact Johoty!

Gas valve Benefits:

Reliable Sealing Performance

High-pressure, Corrosion Resistance

Fluid Control Acuracy and Adjustability

Long Lifespan and Low Repair Cost

Gas valve Applications:

Natural Gas Transportation

Oil Drilling Platform

Food Processing Industry

Pharmaceutical Industry

Water Treatment

Air Compressor System

Automotive Engine Control

Electric Power Plant

Gas valve Advantages:

Reliable Sealing Performance

The gas valve sealing is very good and can keep gas from leaking out. By precisely controlling gas flow, it can reduce energy waste. Whether it is high-pressure gas or ordinary gas, the gas valve can ensure the safe flow of gas in the pipeline and prevent it from escaping outside. This can protect the system from problems, save energy, and prevent gas waste. Whether it’s natural gas, air, or other gases, Johoty’s gas valves can ensure that they flow smoothly and do not leak.

High-pressure and Corrosion Resistance

The gas valve can withstand high pressure and is not easily corroded. It is like an umbrella that can withstand strong storms, then, gas valves like this. It can work under high pressures, such as in oil and gas pipelines, to maintain smooth airflow. Even when encountering many acidic or highly corrosive gases, Johoty’s gas valves will not be damaged and can always maintain normal operation.

Fluid Control Accuracy and Adjustability

The gas valves can accurately control the gas flow, respond quickly to control signals, and adjust the flow rate in time. Engineers can adjust the gas flow rate through gas valves to make it larger or smaller, and can also cooperate with automation systems for intelligent regulation. In this way, the gas valves can help the system achieve the best working status. If you need faster flow, Johoty’s gas valves can help you adjust it. If you need slower traffic, it can also be easily controlled.

Long Lifespan, Low Repair Costs

The gas valves will not break after a long time and do not require much maintenance. Like a very durable bicycle, you ride it for a long time, and hardly need maintenance. The gas valve also has this characteristic, it uses stainless steel 316L and can still maintain stable operation in harsh environments. Due to the low maintenance requirements, Johoty’s gas valves can help many clients save a lot of repair costs and are also less likely to cause problems in long-term use.

FAQ

Gas valve is good for industrial gas and liquid. They include natural gas, hydrogen, oxygen, and nitrogen, as well as water, oil, steam, etc.

The gas valve opens and closes by controlling the movement of internal components, such as balls, discs, or valve stems. So, it can control the flow rate of air or gas.

The model and materials are key. Valves are for common industrial applications.