Best Ball Valve, China Manufacturer

Ball valve from Johoty has a high-precision design, is durable and non-corrosive; is made of stainless steel and brass materials, etc. Fit in the chemical and pharmaceutical. Johoty provides you with precise customization, quality assurance, and fast delivery.

Product Features:

- Accurate flow control without errors

- High-pressure resistance and leakage prevention.

- Life span of up to ten years.

- Lightweight and corrosion-resistant.

- Bidirectional closed seal.

- Easy installation and maintenance.

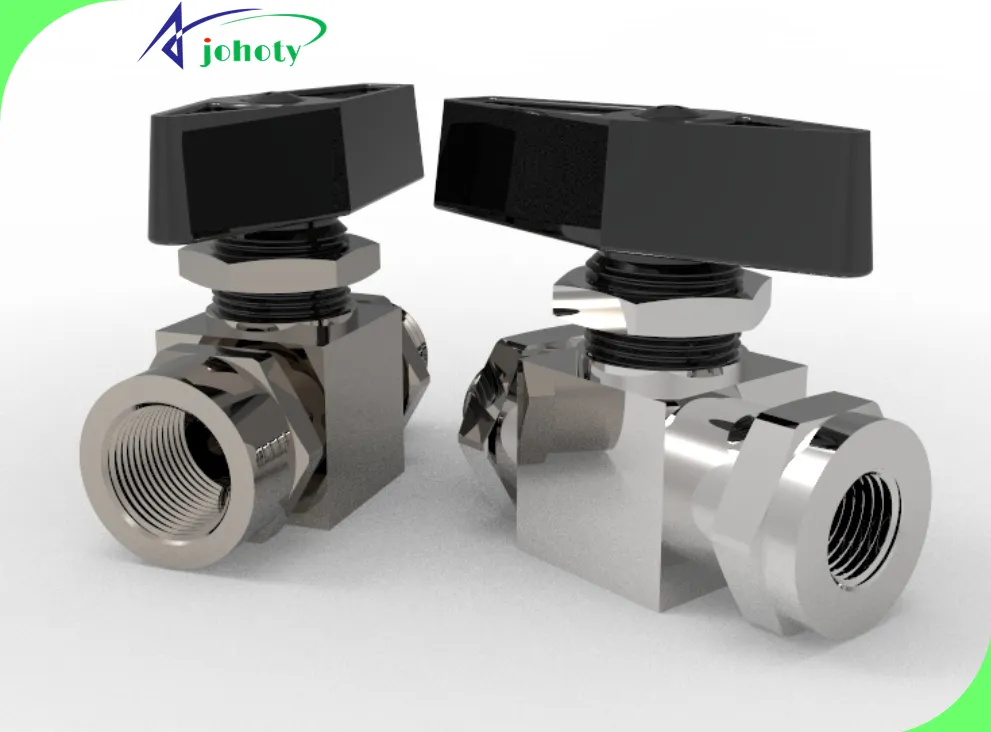

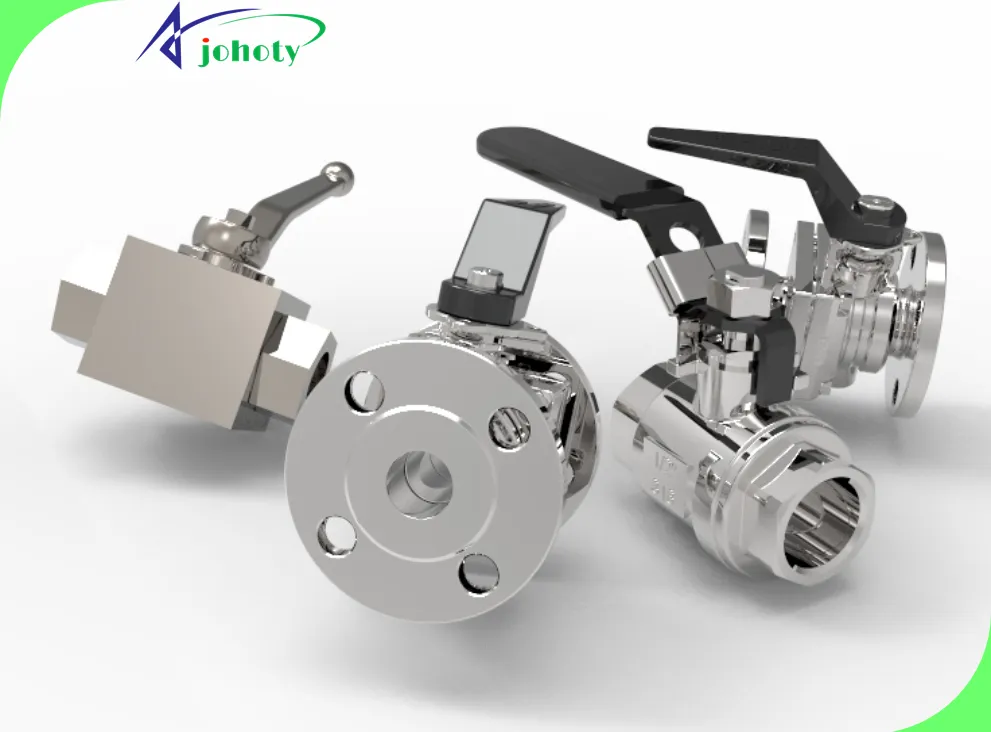

Ball Valve Series:

Ball Valve series: Stainless steel high-pressure ball valves (oil and gas, chemical industry), Anti-corrosion brass ball valves (water treatment and pharmaceutical industry), Micro precision ball valves ( instrumentation), Full bore high flow ball valves (high flow and efficient transmission), Food grade sanitary ball valves (food and beverage production), Bidirectional sealed ball valve (bidirectional switching in complex systems), etc. Johoty can support you!

Category |

Description |

|---|---|

| Product Types | ball valves, needle valves, gate valve, check valves, electric/pneumatic actuated valves, control valves, flow control valves, safety valves, gas valves, and diaphragm valves. |

| Target Customers | Engineers, procurement specialists, and decision-makers in oil & gas, chemical, and pharmaceutical. |

| Applications | Controlling flow and pressure from chemical reactors to pharmaceutical fluid systems in high-stakes environments. |

| Function & Spec | Corrosion-resistant, tight sealing, and high pressure. Specs range from 1/8” to 2” sizes, pressure ratings up to 10,000 psi, and temperature resilience between -40°F and 500°F. |

| Brand Info | Johoty has built trust and excellence for precision engineering over decades, continually pushing valve technology for high-stakes applications worldwide. |

| Price Range | Pricing varies from $1 to $800. |

| Quality Standards | Meet ASME, ISO 9001, ASTM, API, DIN, ANSI/FCI, NACE, RoHS, and REACH. |

| Where to buy | Johoty’s official website (https://johoty.com), Johoty CFT team ([email protected]). |

| Customer Services | Installation guidance, maintenance tips, troubleshooting, a warranty period of up to 5 years, and specialized advice. |

| User Feedback | Praise our valves for precision, durability, and ease of integration. |

| Competitive Edge | We provide unique, customizable options at a competitive price, focusing on quality materials and rapid response, though custom solutions may sometimes require longer lead times. |

Quality Stability

Johoty can help you reduce maintenance costs, ensure reliable operation, improve production efficiency, minimize downtime, prolong service life, and reduce the risk of fluid leakage

Cost-Effectiveness

We can help you choose the reliable ball valve within the budget, save long-term usage costs, reduce energy consumption & resource waste, minimize downtime losses, achieve high ROI, and reduce repeated purchasing costs.

Fast Delivery

Custom Services

Why Choose Johoty's Ball Valve?

Johoty's Ball Valve has a ±0.01 precision, it can save you >20% costs, ships in 2~3 weeks, as well as flexible custom. Contact Johoty for best ball valve!

Ball Valve Applications:

Pharmaceutical industry

In pharmaceutical production, a ball valve can control the flow of drugs, ensuring precise dosage for each bottle of medication. More than 100000 types of drugs are produced globally each year, and Johoty's ball valve ensures that the production process of these drugs is error-free.

Chemical Industry

Water treatment system

Oil and gas industry

In the oil and gas industry, pretty many Euro-American clients like to use our ball valve, which can switch and control the flow of liquids and gases in equipment very well. When transferring natural gas or oil, Johoty's ball Valve can withstand high pressure and provide long-term sealing. In recent years, the usage rate of Johoty's ball valve has continued to increase. Based on our clients' feedback, our ball valve is efficient and safe.

Ball Valve Advantages:

High Sealing

Low fluid resistance

Easy to operate, compact structure

Strong durability and adaptability

FAQ

A full ball valve and a reduced ball valve are different, they are two different sizes of water pipes. For the full pass ball valve, its pipeline size is the same as the valve body. and, its water flow is the biggest and highly efficient. but for the reduced flow ball valve, its pipeline is smaller than the valve body, and the water flow is a bit blocked a lower flow rate. Such a ball valve is suitable for wehre do not require a large flow rate. Most customers use Johoty's full ball valves for their industrial piping systems because they are more efficient and stable.

The ball valve is suitable for water, gas, steam, oil, acids, and alkalis. Special materials of the ball valve can also be used for corrosive or high-temperature media. When need, you can contact Johoty's CFT team for more details.