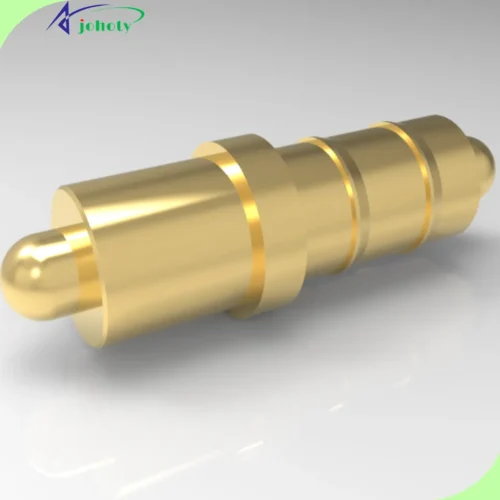

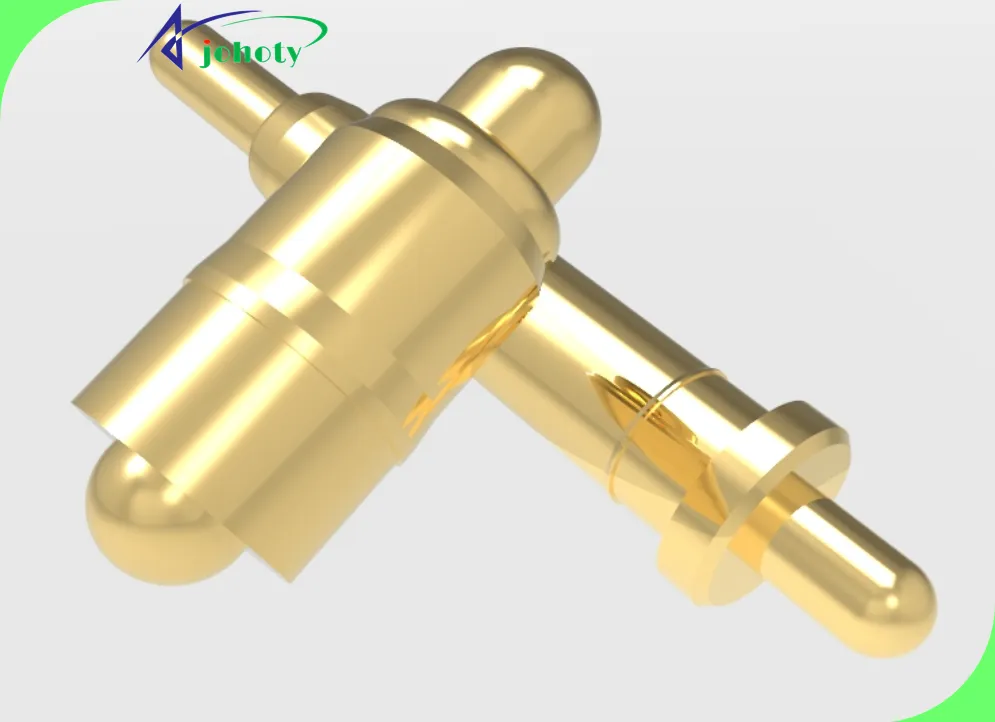

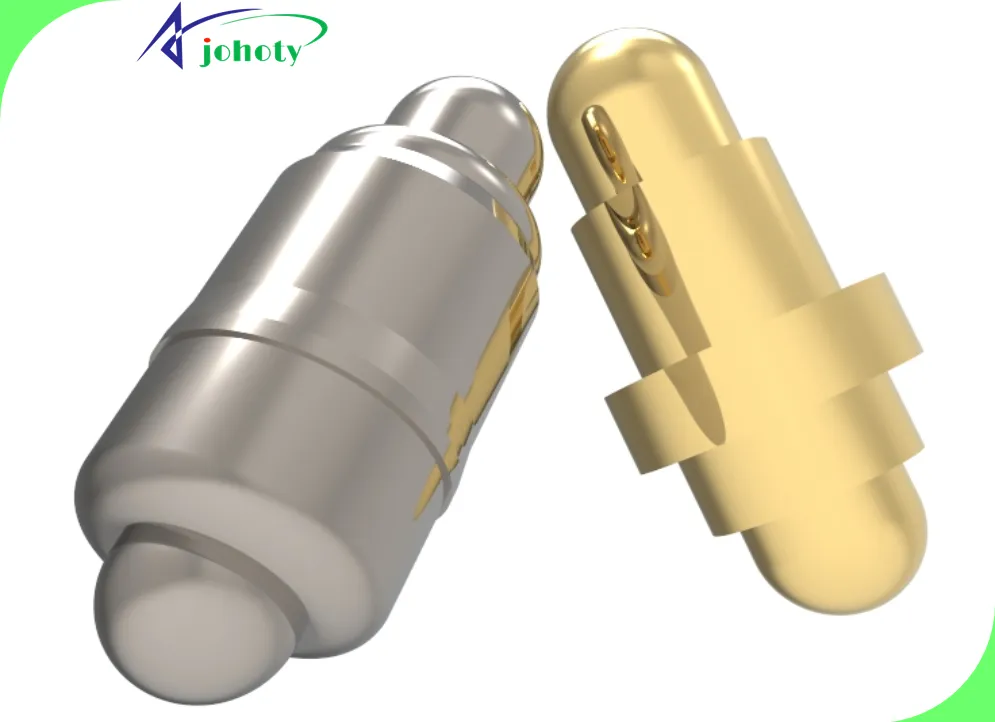

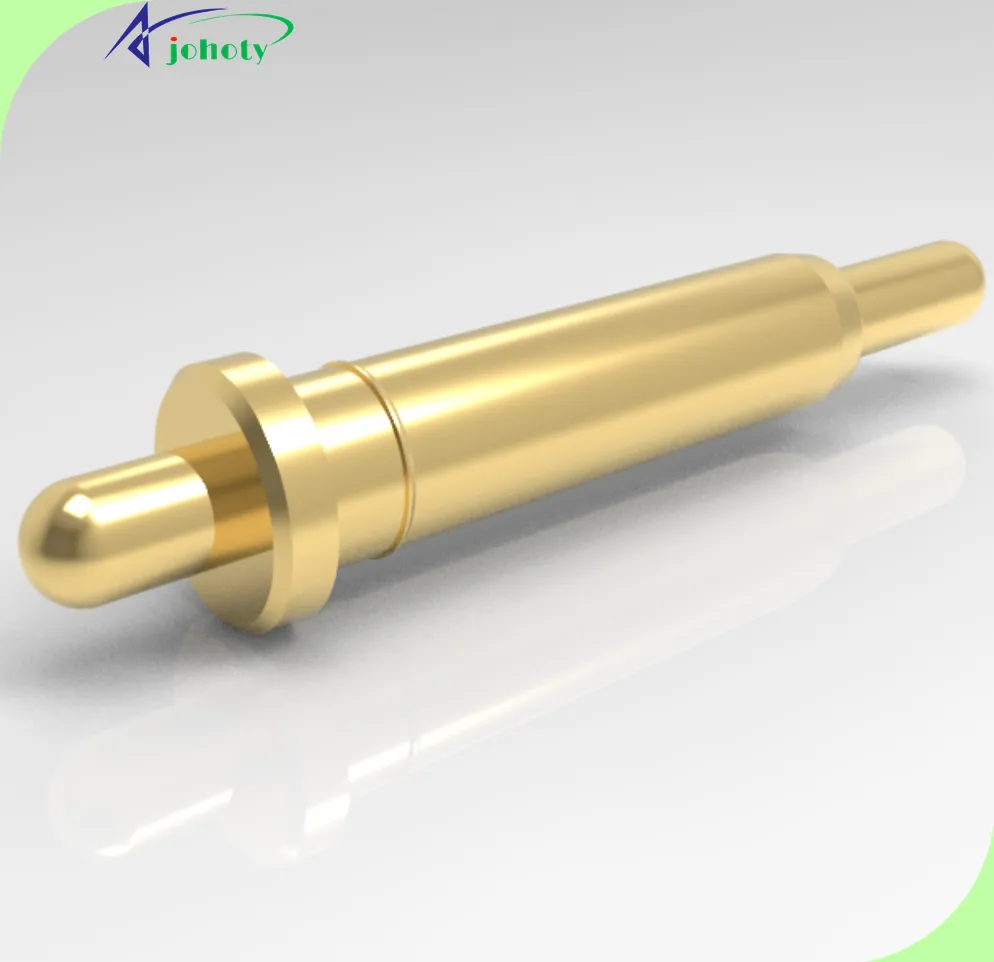

Double Ended Pogo Pin Description:

Catalogs of Double Ended Pogo Pin:

Double Ended Pogo Pin Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact Resistance: ≥15 mΩ, Custom. |

| Current Rating: 0.1A – 50A, Custom. | |

| Voltage Rating: 3.3V – 1000V, Custom. | |

| Mechanical: | Diameter: 0.50 mm to 50.00 mm, Custom. |

| Length: 5 mm to 200 mm, Custom. | |

| Spring Force: ≥ 15 gf at nominal working height | |

| Working stroke: 0.50 mm to 10.00 mm, Custom. | |

| Full stroke: 0.50 mm to 15.00 mm, Custom. | |

| Durability (Life Cycle): 10,000 ~ 500,000 cycles. | |

| Operating Temperature: -40°C to +85°C | |

| Materials: | Plunger: Gold-plated brass, tellurium Copper, or beryllium copper: ≥ 0.25um. |

| Barrel: Gold-plated brass, beryllium copper, tellurium Copper, Custom. | |

| Spring: Stainless steel, music wire, Custom. | |

| Installation: | Mounting Style: Buckle, plug-in, threaded fixation, elastic clamping, Custom. |

| Mounting Method: Solder-free | |

| Pad Size: 1.0mm x 1.2mm, Custom. | |

| Package: | Bulk Packaging: Optional. |

| Tape and Reel: Optional. | |

| Tray Packaging: Optional.. | |

| Tube Packaging: Optional.. | |

| Blister Packaging: Optional. | |

| Plastic Bag with Antistatic Film: Optional. | |

| Custom Packaging: Optional. | |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s Double Ended Pogo Pin?

Johoty’s Double ended pogo pin are flexible daul heads dual move, small sizes, soldering-free. Worthy of your trust!

Double Ended Pogo Pin Benefits:

Bidirectional Stable Connection

Improve Space Utilization Efficiency

Reduce Costs and Complexity

Flexibility and Versatility

Double Ended Pogo Pin Applications:

Smartphone Testing Connection

Electric vehicle battery testing

Wearable Device Assembly

Debugging of Drone Components

Automotive Electronic System Testing

Medical Equipment Signal Transmission

Connection of Robot Joint Module

Calibration of High-frequency Communication Equipment

Double Ended Pogo Pin Advantages:

High Conductivity, No Loss in Signal Transmission

No Welding Required, Easy and Fast Installation

Precision Manufacturing, Perfectly Connecting With Tiny Spaces

High Current Support to Meet the Needs of High-power Equipment

FAQ

In selection, factor in the specific demands of the application. Including the needed current carrying capacity, mechanical stability of the connection, required durability, and space constraints.

When installing the Pogo Pins, special attention should be paid to alignment and contact pressure. This can ensure a stable and reliable electrical connection. Additionally, choosing the appropriate base and packaging method is crucial for enhancing connection stability and performance.

Yes, we offer customization services. Including dimensions, shapes, stroke, current, spring force, materials, and electrical characteristics tailored to specific applications.