Industrial Gas Springs Description:

Catalogs of Industrial Gas Springs:

Industrial Gas Springs Datasheet:

| Items | Details |

|---|---|

| Basic Info: | Name: Industrial gas springs are quality gas struts in machinery, automotive, aerospace, furniture, electronics, medical equipment. They provide power support and motion control. |

| Types: Standard, locking, double-acting, constant force, adjustable, miniature, stainless steel, gas-liquid hybrid gas springs. | |

| Position: Machine covers, control panels, presses and lifts, aircraft doors, TV Stands, hospital beds, surgical tables, medical cabinets | |

| Specifications: | Force: 100-5,000N. Custom. |

| Length: 50-700mm. Custom. | |

| Stroke: Compression 30-400mm. Extension 20-400mm. Custom. | |

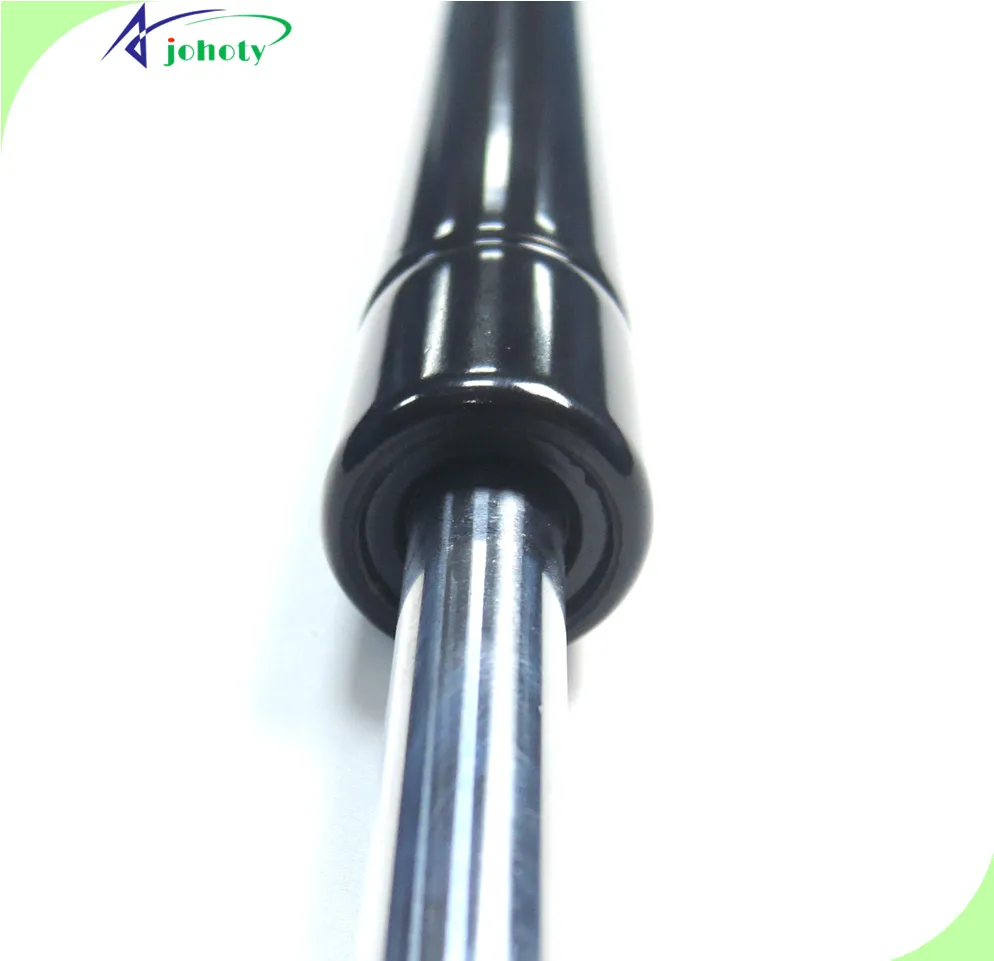

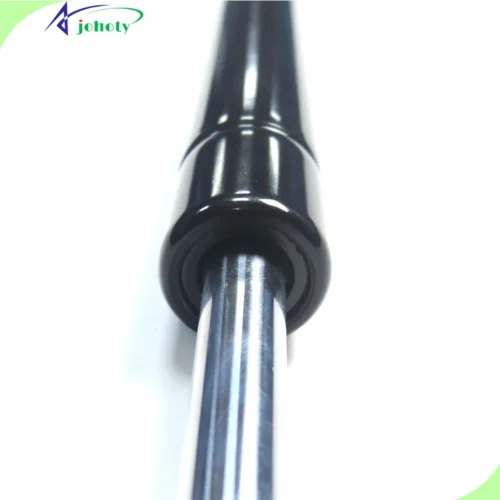

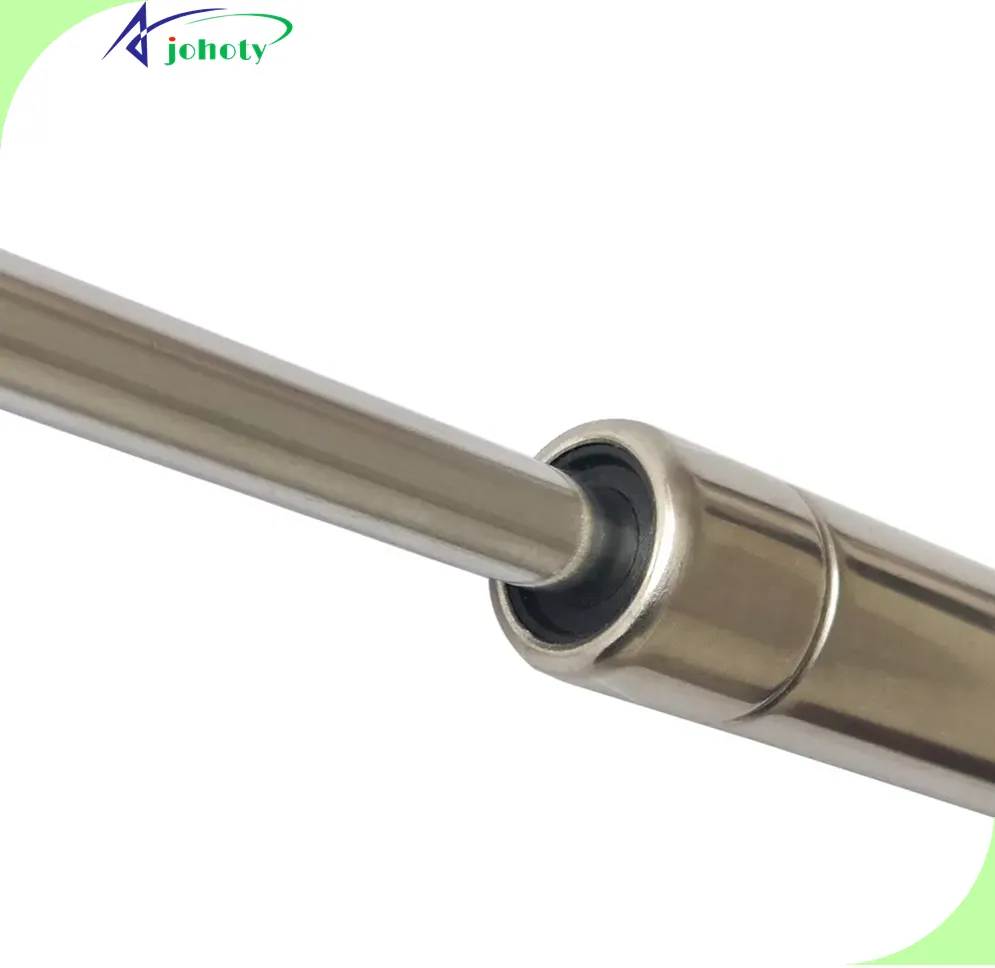

| Diameter (Tube): 20-40 mm. Custom. | |

| Diameter (Rod): 6-16 mm. Custom. | |

| Operating pressure: 20 bar to 100 bar. | |

| Sealing: Piston, ring, fluid seals. | |

| Temperature: -30°C~80°C. | |

| Mounting: Eyelet, Clevis, Pin Mount. | |

| Cycle Life: 100,000-500,000 cycles. | |

| Performance: | Initial Force: 10 N to 3000 N |

| Load: Linear load, non-linear load, dual load. | |

| Corrosion Resistance: Excellent, Custom. | |

| Leakage Rate: ≤ 1.5% per year. | |

| Gas Seal Performance: High gas tightness. | |

| Cylinder Hardness: 50 HRC to 60 HRC. | |

| Impact Resistance: High strength. | |

| Materials: | Cylinder: Carbon steel, SUS or AISI, aluminum alloy, etc. |

| Rod: Carbon steel, stainless steel, high-strength alloy steel. | |

| Seal Material: NBR, FKM, PU. | |

| Piston: Aluminum alloy, steel, composite materials. | |

| Gas Type: Air, Nitrogen, Helium, etc. | |

| Finishing: Phosphating, chromium, Zinc. | |

| Fitting: Plastic, zinc alloy, steel. | |

| Connection Types: | Fitting Type: Threaded, Eyelet, Pin, Right Angle, etc. |

| Hole Diameter: 4 mm ~ 30 mm | |

| Method: Fixed, adjustable, rotating, internal/external thread Mount | |

| Rod connection type: Straight, bent, double rod, threaded, clamp, quick, welded. | |

| Mounting position: Horizontal, vertical, inclined. | |

| Mounting angle: 0°, 30°, 45°, 90°. | |

| Package: | Single unit packaging: Plastic bag, foam box, or cardboard box. |

| Box packaging: 5 to 50 pcs/box | |

| Foam Packaging: Protected with foam padding. | |

| Wooden crate packaging: Large volumes or special-sized gas struts. |

Why Choose Johoty’s Industrial Gas Springs?

Johotys industrial gas springs have a 99.9% pass rate and 99% customer satisfaction with flexible custom. Johoty is trustworthy!

Industrial Gas Springs Benefits:

Effortless Operation and Improved Efficiency

Precise Control to Enhance Security

Save Space and Enhance Design Flexibility

Long Service Life, Reducing Maintenance Costs

Industrial Gas Springs Applications:

Automotive Industry

Home Appliance Industry

Furniture Industry

Medical Equipment

Aircraft Industry

Mechanical Equipment

Elevators and Escalators

Self Driving RV Equipment

Industrial Gas Springs Advantages:

Stable Operability

Long-lasting and Durable

Automatic Adjustment Function

Save Space

Easy to Install

Improve Security

FAQ

High-quality industrial gas springs typically exhibit excellent safety performance. Capable of stable operation under normal working conditions and possessing characteristics such as explosion resistance and corrosion resistance.

When choosing industrial gas springs, it’s crucial to take into account the precise demands. Including load range, working environment, adjustability, and consult with our CFT team for selection.

Yes, Johoty can customize industrial gas springs according to your specific requirements. including pressure range, dimensions, shapes, and connection methods.

The size and specifications of industrial gas springs are contingent upon the individual requirements of our customers. Typically, includes parameters such as diameter, length, stroke, and pressure range.