Magnetic Connector Description:

Product info: Magnetic connector is a high-precision connector with strong magnetic force. It is simple and easy to use and quickly achieves electrical connections. It is waterproof and dustproof and has high flexibility for connecting different devices.

Product features: Magnetic connector has strong magnetic force, can automatically and accurately dock, and are easy to install for various electrical equipment. It has waterproof and dustproof IP67 or IP68, and can stably work in harsh environments. It has high flexibility to adapt to various usages.

Solving Problem: The magnetic connector solves the problems of poor contact and complex installation of traditional connectors. It can ensure the stability of the connection in harsh environments, waterproof and dustproof, avoid wear and tear, and improve equipment durability and work efficiency.

Specifications: Strong magnetic force range, rating voltage and current, material durability, spring force, stroke, waterproof level, etc. Its flexibility and ease of use for high connectivity.

Applications: Applied in industrial automation, smart homes, medical equipment, automotive electronics, etc. It can efficiently and conveniently achieve electrical connections and reduce equipment failures.

Target industries: Electronic device manufacturers, automation equipment companies, medical device manufacturers. It can meet the connection requirements for high precision and high reliability and ensure long-term stable operation.

Customer benefits: Save a lot of time and costs, no need for complex installations. Its waterproof and dustproof can improve equipment lifespan, and its high precision and flexibility ensure efficient and stable connections.

Magnetic Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: ≥15mΩ, Custom. |

| Rated current: 2A~100A, Custom. | |

| Rated voltage: 3.3V ~1,000V, Cusotm. | |

| Electrical insulation impedance: >100MΩ, Custom. | |

| Working frequency: From MHz to GHz, Custom. | |

| EMC: IEC 61000-4-2. | |

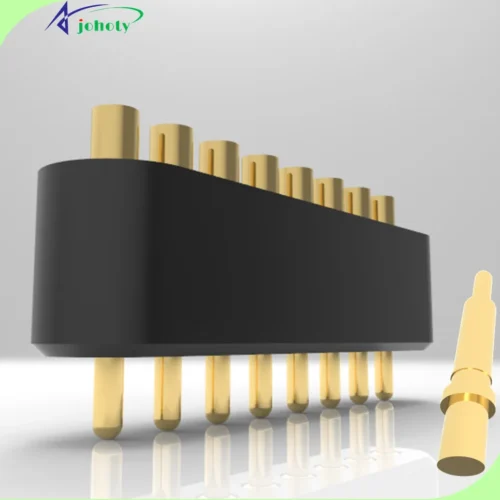

| Mechanical: | Pin number: 2 pins, 3 pins, 4 pins … 598 pins, Custom. |

| Magnetic/contact force: 10N ~ 200N, ≥15gf, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Plug and unplug: 10,000 ~ 50,000 times, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Magnetic materials: NdFeB, AlNiCo, Ferrite, etc. |

| Contact materials: Copper, copper alloys (phosphor copper), gold, etc. | |

| Housing materials: Stainless steel, aluminum alloy, plastic (PPS, PBT, nylon), etc. | |

| Insulation materials: PI, PA, PEEK, PTFE, PBT, Nylon, etc. | |

| Spring materials: Phosphor copper, music steel, stainless steel, gold-plated copper, titanium alloy, etc. | |

| Sealing materials: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating materials: Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Welding materials: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: Polyurethane, silicone, rubber, etc. | |

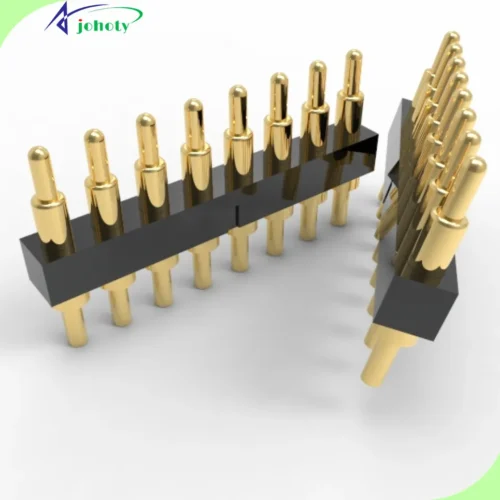

| Installation: | Surface mount: Automated production line, SMT. |

| Through-hole installation: High current, resistant to mechanical stress. | |

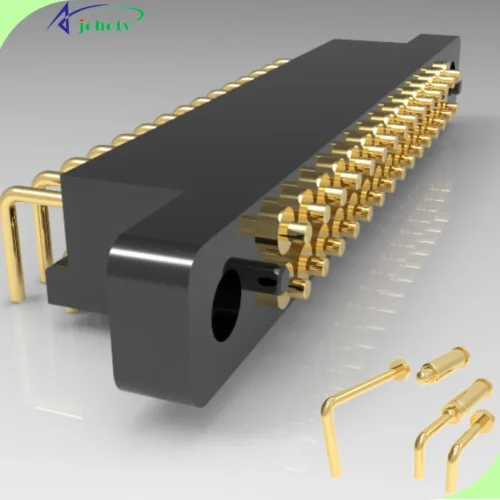

| Right Angle installation: Limited space or a dynamic connection. | |

| Soldering installation: High current. | |

| Spring installation: Anti-vibration, anti-impact, high-vibration. | |

| Embedded installation: High waterproof and sealing requirements. | |

| Quick installation/disassembly: Testing equipment. | |

| Locking installation: Additional mechanical fixation force. | |

| Slot installation: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s Magnetic Connector?

Johoty’s Magnetic connector have optional 8 shapes for 6 installations, flexible custom. Johoty is trustworthy!

Magnetic Connector Benefits:

Quick, Automatic, and Precise Docking

Reliable Waterproof and Dustproof Performance

High Flexibility and Versatility

Longer Service Life and Stable Performance

The Magnetic Connector Applications:

Medical Equipment Connection

Industrial Automation Equipment

Consumer Electronic Devices

Aerospace Equipment

Military Equipment

Marine Exploration Equipment

Charging Interface for New Energy Vehicles

Wearable Smart Devices

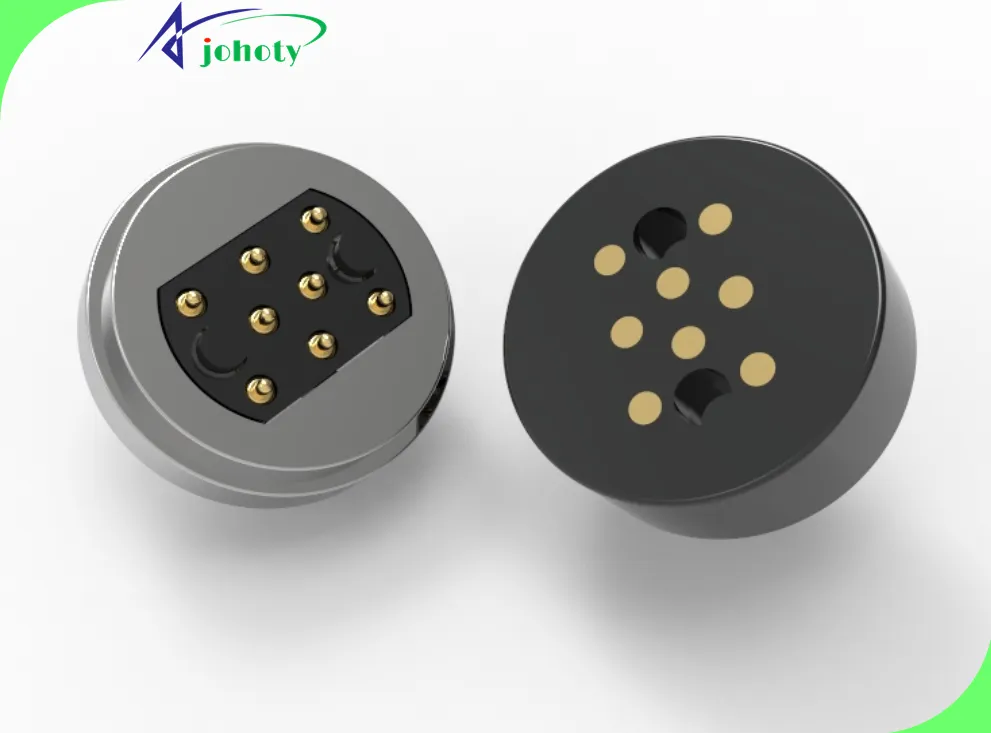

Magnetic connector is suitable for watches and headphones. It is compact and convenient with a magnetic suction that can charge as soon as you approach it. So, you don’t have to worry about the non-matching interface. The waterproof and dustproof are also very important, you don’t have to worry about the equipment breaking down when you sweat during exercise or accidentally wet it during washing. It has a stable connection and fast charging. This design makes smart devices more durable and user-friendly.

Magnetic Connector Advantages:

Strong Magnetic Force

High-Precision

Easy to Locate

Waterproof and Dustproof

FAQ

1. How does the magnetic connector work?

The working principle of the magnetic connectors is based on magnetic attraction and spring-loaded contact technology. The built-in magnets ensure that the connector parts are automatically and precisely aligned. While the spring-loaded Pogo Pins provide a stable and long-lasting electrical contact.

When the two connecting parts are close, the magnetic force attracts them together. And automatically aligns the male and female pogo pins. So that the spring-loaded pin ensures a reliable physical and electrical connection between the pogo pins.

This design can improve the ease and efficiency of the connection. Also enhances the performance and reliability of customers’ devices through stable electrical contact.

2. What key strengths does the magnetic connector offer?

The main advantage of the magnetic connector is that it provides a fast, reliable, and user-friendly connection solution. With magnetically self-aligning and spring-loaded pogo pins. It ensures a precise and stable electrical connection, dramatically improving connection efficiency and convenience.

In addition, its compact design and dust- and water-resistant capability make it suitable for wide environments. This meets the needs of portable and outdoor devices. High durability and low-maintenance features further reduce the total cost of ownership. This renders them a prime selection for connection across diverse applications.

3. What types of devices is magnetic connector suitable for?

The magnetic connector is suitable for a wide range of device types. Including smart wearables, such as smartwatches and health trackers. Portable consumer electronics, such as headsets and cell phones.

Medical monitoring devices, electric vehicle charging interfaces, military and aerospace equipment, and industrial automation components. Their fast and reliable connection characteristics, as well as excellent environmental suitability. This makes them ideal connection solutions.

The working principle of the magnetic connectors is based on magnetic attraction and spring-loaded contact technology. The built-in magnets ensure that the connector parts are automatically and precisely aligned. While the spring-loaded Pogo Pins provide a stable and long-lasting electrical contact.

When the two connecting parts are close, the magnetic force attracts them together. And automatically aligns the male and female pogo pins. So that the spring-loaded pin ensures a reliable physical and electrical connection between the pogo pins.

This design can improve the ease and efficiency of the connection. Also enhances the performance and reliability of customers’ devices through stable electrical contact.

The main advantage of the magnetic connector is that it provides a fast, reliable, and user-friendly connection solution. With magnetically self-aligning and spring-loaded pogo pins. It ensures a precise and stable electrical connection, dramatically improving connection efficiency and convenience.

In addition, its compact design and dust- and water-resistant capability make it suitable for wide environments. This meets the needs of portable and outdoor devices. High durability and low-maintenance features further reduce the total cost of ownership. This renders them a prime selection for connection across diverse applications.

The magnetic connector is suitable for a wide range of device types. Including smart wearables, such as smartwatches and health trackers. Portable consumer electronics, such as headsets and cell phones.

Medical monitoring devices, electric vehicle charging interfaces, military and aerospace equipment, and industrial automation components. Their fast and reliable connection characteristics, as well as excellent environmental suitability. This makes them ideal connection solutions.