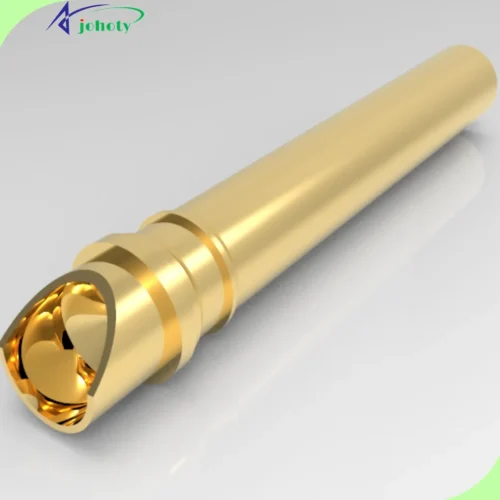

High Current Pogo Pins Description:

Catalogs of High Current Pogo Pins:

High Current Pogo Pins Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact Resistance: ≥ 15 mΩ, Custom. |

| Current Rating: 0.1A – 1,200A, Custom. | |

| Voltage Rating: 3.3V – 1000V, Custom. | |

| Mechanical: | Diameter: 1 mm to 50 mm, Custom. |

| Length: 5 mm to 200 mm, Custom. | |

| Spring Force: ≥ 15 gf at nominal working height | |

| Working stroke: 0.15 mm to 20 mm, Custom. | |

| Full stroke: 0.15 mm to 25 mm, Custom. | |

| Durability (Life Cycle): 10,000 ~ 500,000 cycles. | |

| Operating Temperature: -40°C to +125°C | |

| Mounting Style: DIP, SMT, Solder Cup, Thread, Right Angle, Custom. | |

| Materials: | Plunger: Gold-plated brass, tellurium Copper, or beryllium copper. ≥ 0.25um. |

| Barrel: Gold-plated brass, beryllium copper, tellurium Copper, Custom. | |

| Spring: Stainless steel, music wire, Custom. | |

| Installation: | Installation Type: PTH, SMT, Soldering, Custom. |

| Mounting Method: Solder cable, vertically mounted on the surface of the PCB in SMT. | |

| Pad Size: 1.0mm x 1.2mm, Custom, or no pad, Custom. | |

| Soldering Process: Place T&R pogo pins in SMT or reflow W/S, and solder onto PCB or cable with solder paste. | |

| Flux Type: No-clean flux, minimal residue. | |

| Package: | Bulk Packaging: Optional. |

| Tape and Reel: Optional. | |

| Tray Packaging: Optional.. | |

| Tube Packaging: Optional.. | |

| Blister Packaging: Optional. | |

| Plastic Bag with Antistatic Film: Optional. | |

| Custom Packaging: Optional. | |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s High Current Pogo Pins?

Johoty’s high current pogo pins are ≤1,200A for your reference, small sizes, large current. Worthy of your trust!

High Current Pogo Pins Benefits:

Reduce Total Procurement Costs

Flexibly Meet Complex Needs

Support Higher Electricity Demand

High Reliability and Stability

Johoty helps you extend the lifespan of your equipment by using gold-plated beryllium copper, stainless steel, and other materials. Reduces contact resistance, improves energy transmission efficiency, suitable for high-precision instruments, industrial automation equipment, and electric vehicle charging stations. Enhance environmental adaptability, ensure high current stability, and prevent overload failure. Reduce overall equipment failure rate, improve system electrical safety, and lower long-term operating costs.

High Current Pogo Pins Applications:

Contact Points of Solar Power Generation Equipment

Electric vehicle charging connector

High-performance Drone Power System

High Power Connection of Medical Equipment

Power Supply Module for Industrial Robots

Power Supply for Communication Equipment Base Stations

Connection of High-power Energy Storage Devices

Power Connection for Military Equipment

High Current Pogo Pins Advantages:

Super strong conductivity

High Durability

Multiple Shape Options

Extreme Temperature Adaptability

FAQ

Johoty can provide the maximum current based on raw materials and designs. 800 Amps or up to 1,200 Amps are available, for your specifics, please refer to our product specs or contact Johoty’s CFT team

Yes, we provide customization services. Including, sizes, dimensions, force, shapes, materials, and surface finishes. This can meet specific application needs.

Standard high current pogo pins usually have a quick delivery time of 2~3 working weeks. The delivery times of customized high current pogo pins vary with the complexity of the customization request. We’re committed to minimizing delivery times while ensuring high quality.