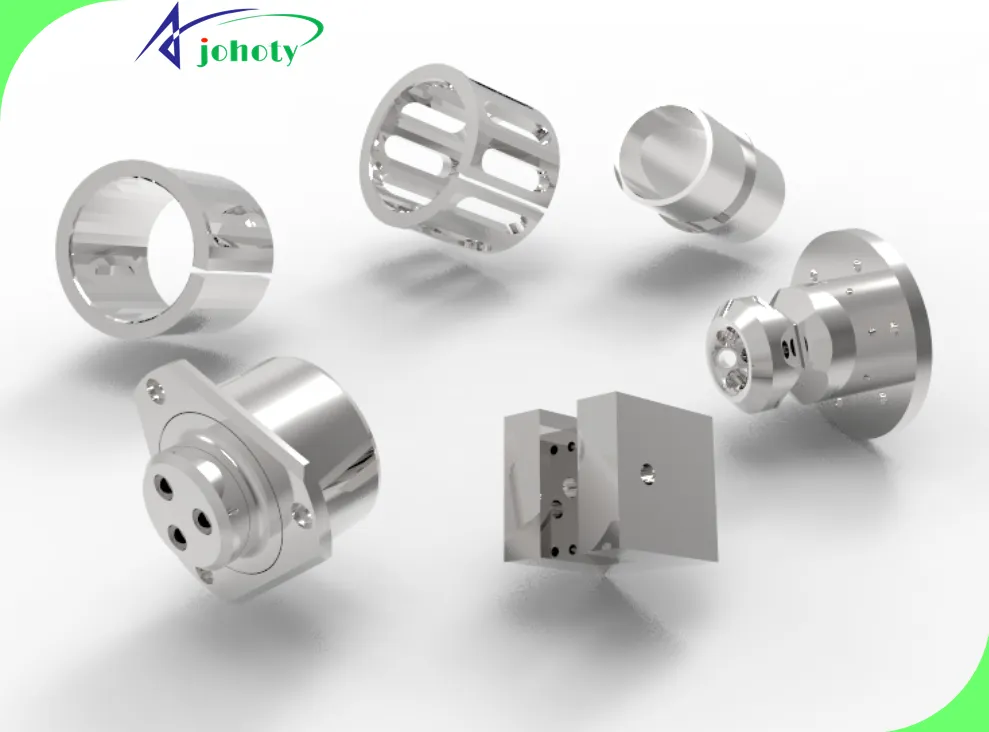

Precision Parts Description:

Precision Parts Datasheet:

Items |

Details |

|---|---|

| Specifications | Material is stainless steel, titanium, aluminum, or brass. |

| Dimension tolerance is ±0.01 mm. | |

| Weight is 10 grams, or real-time update | |

| Finish is anodized, electroplated, or polished. | |

| Precision | Standard precision is ±0.05 mm. |

| High precision is ±0.01 mm. | |

| Ultra precision is ±0.005 mm. | |

| Performance | Durability is rated for 1 million cycles. |

| Temperature: -40°C to 120°C, or wider. | |

| Corrosion resistance is high with premium coatings. | |

| Function | Interchangeability allows compatibility with existing systems. |

| Modularity enables easy assembly. | |

| Versatility suits multiple applications. | |

| Raw Materials | Primary materials include stainless steel, aluminum, and high-grade plastics. |

| Sustainability uses recyclable materials. | |

| Surface Treatment/Coating | Types of coatings include anodizing, powder coating, and plating. |

| Benefits increase wear resistance and improve aesthetics. | |

| Applications | Industries include aerospace, automotive, medical devices, and electronics. |

| Use cases are connectors, fasteners, and assemblies. | |

| Certifications | ISO 9001 ensures high quality |

| RoHS, REACH restricts hazardous substances. | |

| CE marking indicates compliance with European standards. | |

| Packaging | Packaging type is custom boxes or bulk packaging. |

| Labeling includes barcodes on each part. | |

| Weight per package is 5 kg per box. |

Who Choose Johoty’s Precision Parts?

Johoty’s Precision Parts have a ±0.005 precision, save >20% costs, safe ship in <15 days, flexible custom for you. Contact Johoty now!

Precision Parts Benefits:

Improve Product Quality and Performance

Johoty can help you improve the precision of component matching, enhance product durability, improve work efficiency and performance, reduce failures and maintenance needs, improve product consistency and repeatability, and enhance your customer trust and brand value. improve product consistency and repeatability, and enhance your customer trust and brand value.

Enhance Production Efficiency

Ensure Higher Security

We can help you improve system stability (strictly controlled dimensions and tolerances), enhance equipment durability, reduce failure rates, ensure high-precision operation, adapt to extreme environments (extreme temperatures, pressures, or vibrations), enhance the safety of end products (in aviation, medical, or automotive industries), and reduce the likelihood of accidents.

Long-term Cost-effectiveness

Precision Parts Applications:

Production of Phone Parts

Automotive Engine Parts

Medical Apparatus and Instruments

Aerospace Components

Robot Joints

High Precision Sensor

Semiconductor Manufacturing

Semiconductor chips are the brains of many modern technological devices, such as computers, mobile phones, etc. The semiconductor manufacturing requires extremely high precision, and any small defect can cause the chip to malfunction. Precision parts can ensure the stability and high efficiency of the chip.

Optical equipment

Precision Parts Advantages:

High Precision

Johoty’s parts are very precise! Their dimensions are very precise, with a tolerance of ± 0.005mm and almost no deviation. This ensures that the machine runs perfectly without any lag or shaking. Engineers do not need to worry about any impact on the machine when installing these parts, as precision parts have undergone strict inspection and measurement. Imagine that every piece of your high-end instrument fits perfectly! This is the effect of our precise parts.

High-quality Materials

Johoty’s precision parts are made with the best materials! For example, high-strength steel, corrosion-resistant alloys, etc. These materials can make the precise parts stronger, more durable, and minimal damage. Engineers don’t have to worry about parts being damaged when working in harsh environments. Just like you have a sturdy lock and key, Johoty’s precise parts will never easily wear out.

High Durability

Our precision parts are durable and will not easily wear. Johoty’s precise parts can work continually in various harsh environments. Engineers like this durability because they don’t have to frequently replace parts, saving time and costs. Like a fully charged watch, precise parts can run continuously.

Temperature Adaptability

Whether it’s hot or cold, our precision parts can maintain normal operation. Precise parts will not affect their performance due to temperature changes. Engineers can use them with confidence to work in extreme temperatures, making their equipment more reliable. Imagine a thermos that can keep hot and cold, and our precision mechanical parts are the same.

FAQ

- The manufacturing process includes design, material selection, machining, surface treatment, and quality control. it is a common process of precision parts.

- In the design phase, dimensions, materials, and processes are determined based on product requirements.

- This is followed by material selection and precision machining. The process is rounded off by surface treatment and quality inspection.

- The production cycle depends on the complexity, material selection, and manufacturing processes involved.

- Generally, we can complete the whole process from design to producing qualified precision parts in 2-3 weeks.

- Johoty’s quality control contains monitoring and testing, which goes through the entire process.

- It includes raw material inspection, IPQC in-process monitoring, and FQC final product testing.

- Common testing methods include dimensional measurements, material analysis, and non-destructive testing.

- Johoty always pays attention to the influence of the working environment, load conditions, wear resistance, corrosion resistance, and heat treatment properties.

- They often impact the material selection for precision parts. And, common materials include stainless steel, aluminum alloys, titanium alloys, and ceramics.