10 Pin Connector Description:

Catalogs of 10 Pin Connector:

10 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: 15 mΩ ~ 200 mΩ, Custom. |

| Rated current: 1.0 A to 50 A, Custom. | |

| Rated voltage: 3.3 V to 230 V, Custom. | |

| Insulation impedance: ≥100 MΩ, Custom. | |

| EMI: Support. Custom. | |

| Transfer speed: Up to 5Gbps | |

| Working frequency: From MHz to GHz, Custom. | |

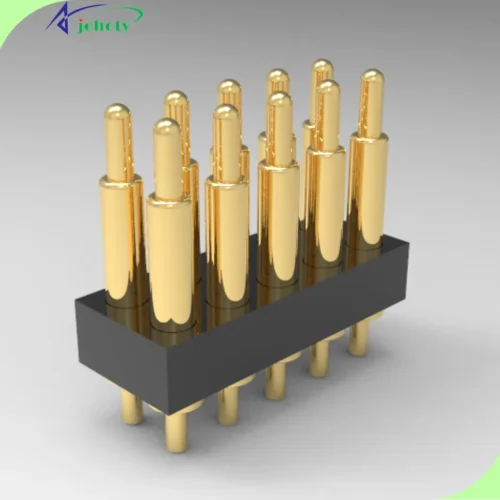

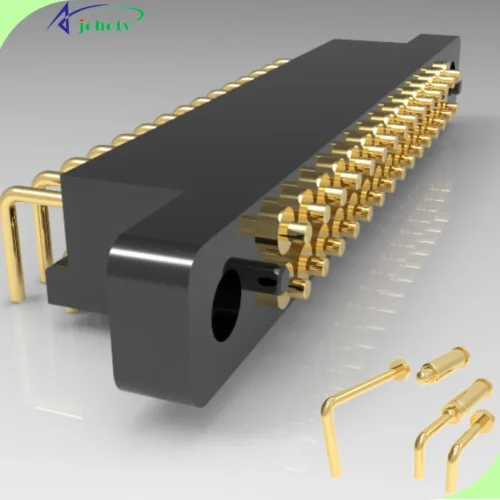

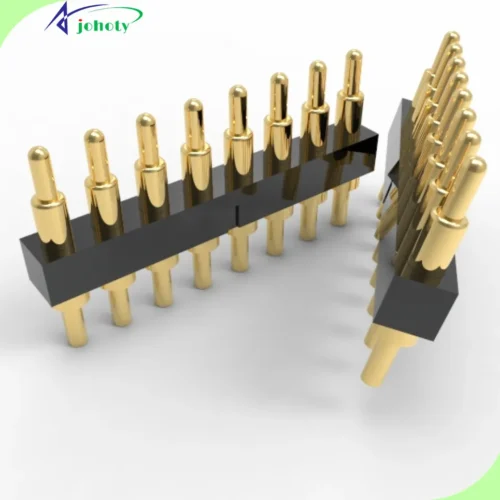

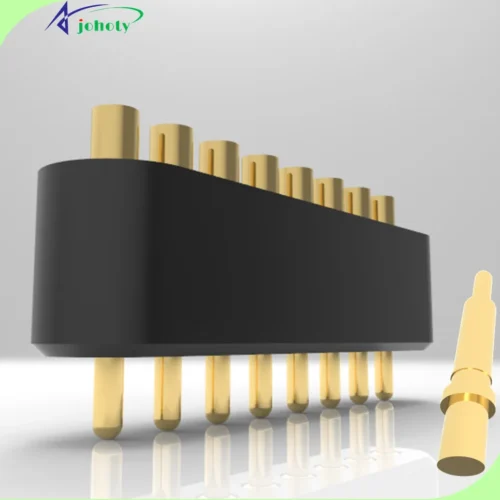

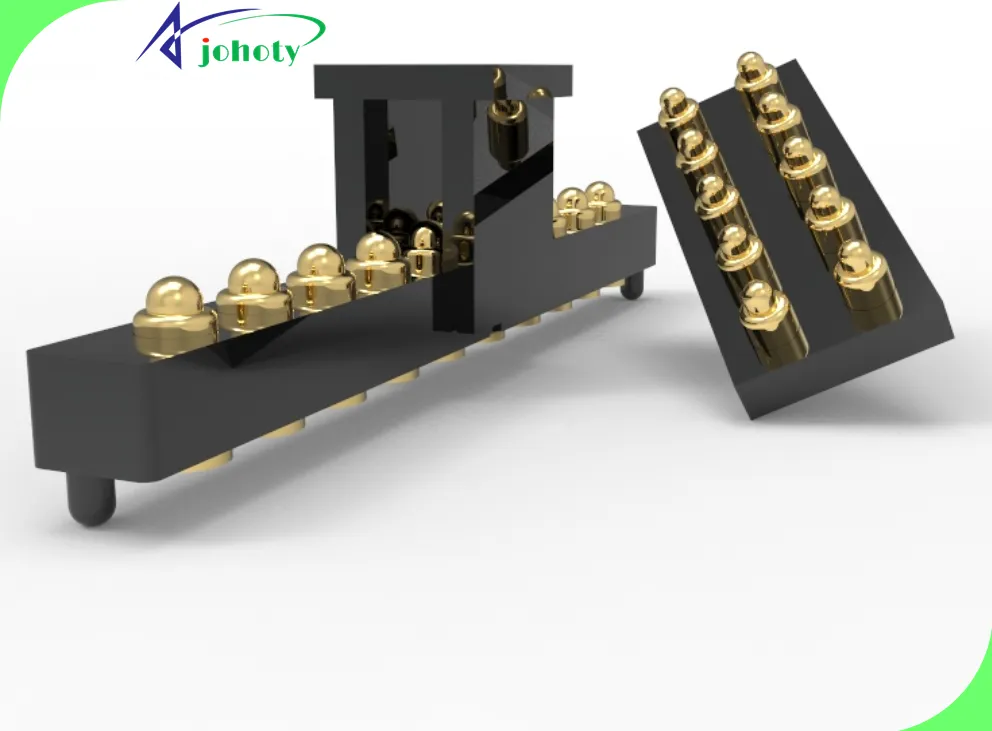

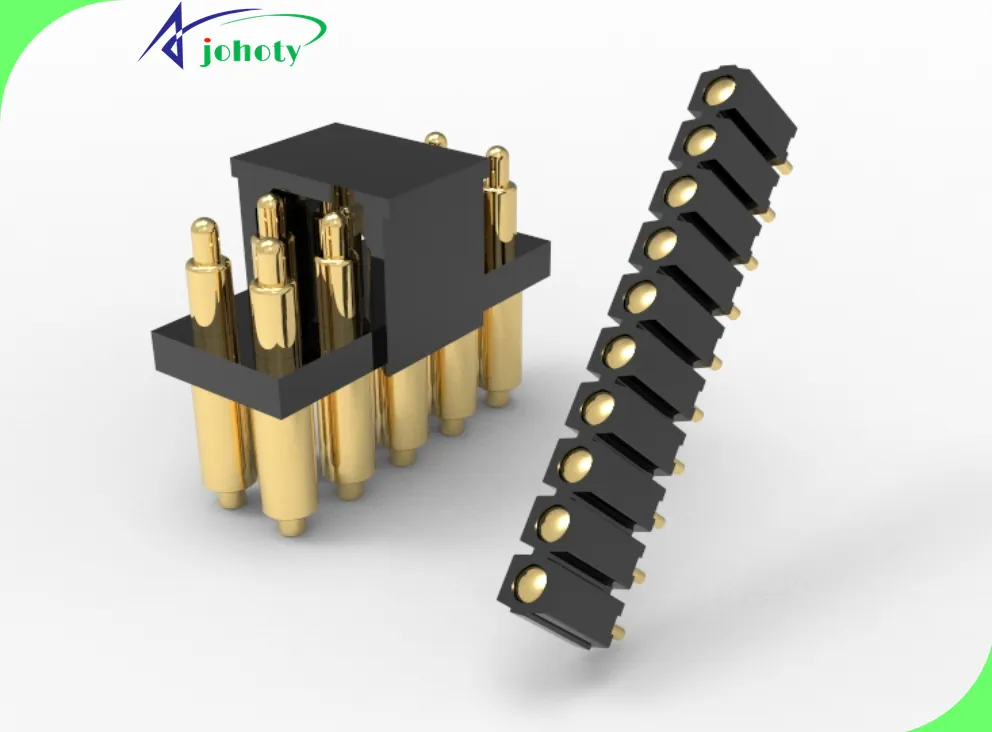

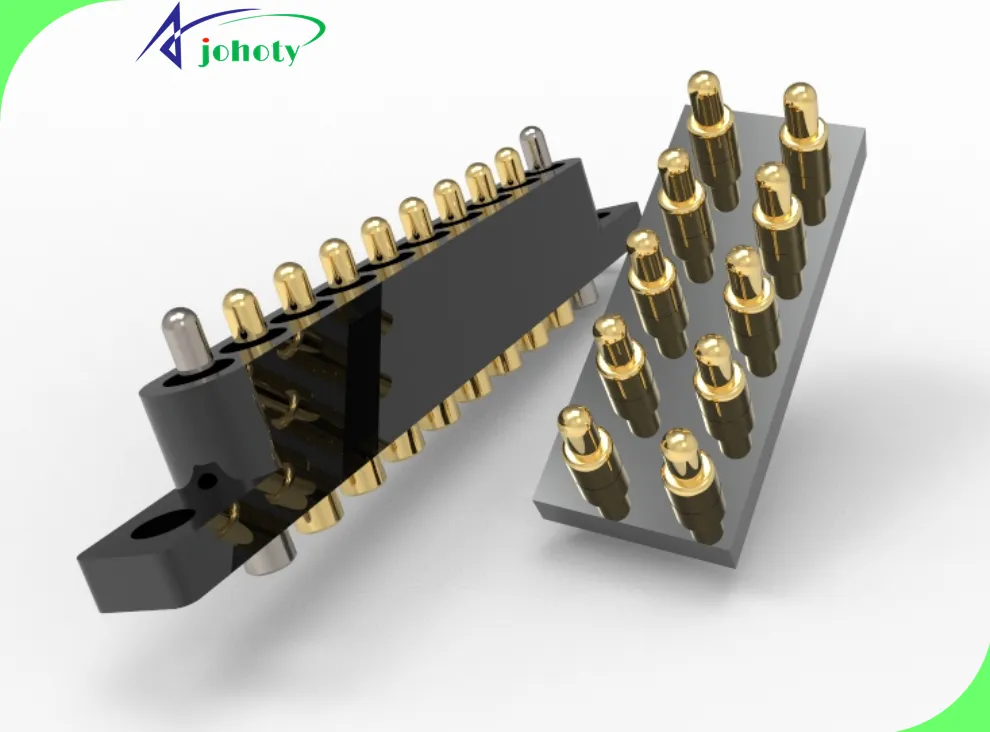

| Mechanical: | Shapes: 10-pins, single/dual rows, Rectangle, Round, SMT, DIP, Solder-cup, Dual-end, Right-Angle, Bending type, Custom. |

| Spring force: ≥30gf, Custom. | |

| Pitch: ≥2.30mm, 2.54mm is popular, Custom. | |

| Stroke: ≥0.50mm, Custom. | |

| Length: ≥3.40mm, Custom. | |

| Barrer diameter: ≥1.30mm, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: 10,000 ~ 200,000 times, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

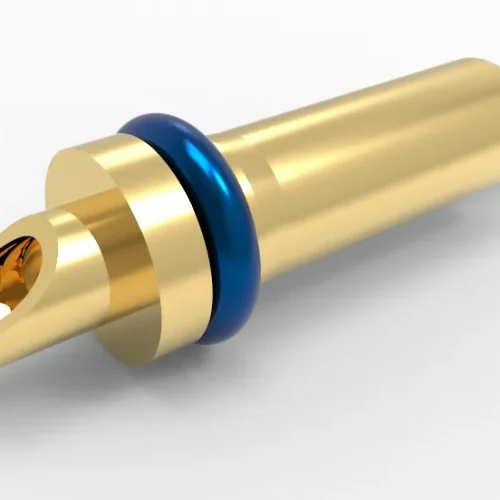

| Materials: | Plunger/Barrer: Brass, copper alloys (beryllium copper, tellurium copper), stainless steel, etc. |

| Housing: Plastics (nylon, PA66, PTE, PPS, PBT), stainless steel, aluminum alloy, etc. | |

| Spring: Gold-plated, music steel, stainless steel, etc. | |

| Ball: Steel, zirconium, ceramic, Custom. | |

| Sealing: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating: >1.5u”, Gold, silver, nickel, composite plating, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: PI, PTFE, PBT, Nylon, Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, L/F, H/F, etc. | |

| Flammability rating: UL94 V-0, etc. | |

| Installation: | Surface mount: SMT, vertical mounting, automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin, surface mounting, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact, high-vibration. | |

| Embedded: High waterproof and sealing requirements. | |

| Quick: Testing equipment. | |

| Locking: Screws, nut, additional mechanical fixation force. | |

| Slot: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 10 Pin Connector?

Johoty’s 10 Pin Connector has flexible custom, fast and safe delivery at competitive prices. Johoty is trustworthy!!

10 Pin Connector Benefits:

Enhance Connection Stability, Reduce Poor Contact

Simplified Installation with Almost No Maintenance Required

High Adaptability and Wide Compatibility

Enhance the Product Reliability and Safety

10 Pin Connector Applications:

PCB Circuit Board Connection

High-frequency Signal Transmission

Automated Equipment Connection

Medical Equipment Connection

Automotive Electronic Connectivity

Application of Smart Home System

Industrial Robot Applications

Application of Consumer Electronics Products

10 Pin Connector Advantages:

High-density CConnection

Strong Stability

High Durability

High Transfer Efficiency

Flexible Applications

Easy to Install and Repair

FAQ

No, the price varies based on the connector’s sizes, performance specs, material, etc. We’re all about giving our customers unbeatable prices, no exceptions.

To ensure you’re getting the sweetest deal, go for bulk purchases, and compare quotes from various suppliers. Take advantage of promotional offers, and consider high-value compatible brands are your best bets.

The price can be swayed by several elements, including the material, manufacturing process, brand, sales channels, and market demand.

The cost-effectiveness of the 10 Pin Connector shines through its low production costs. The economic benefits of mass production, and its wide market application. All these factors mean we’re talking lower costs for Johoty’s 10 pin connector.