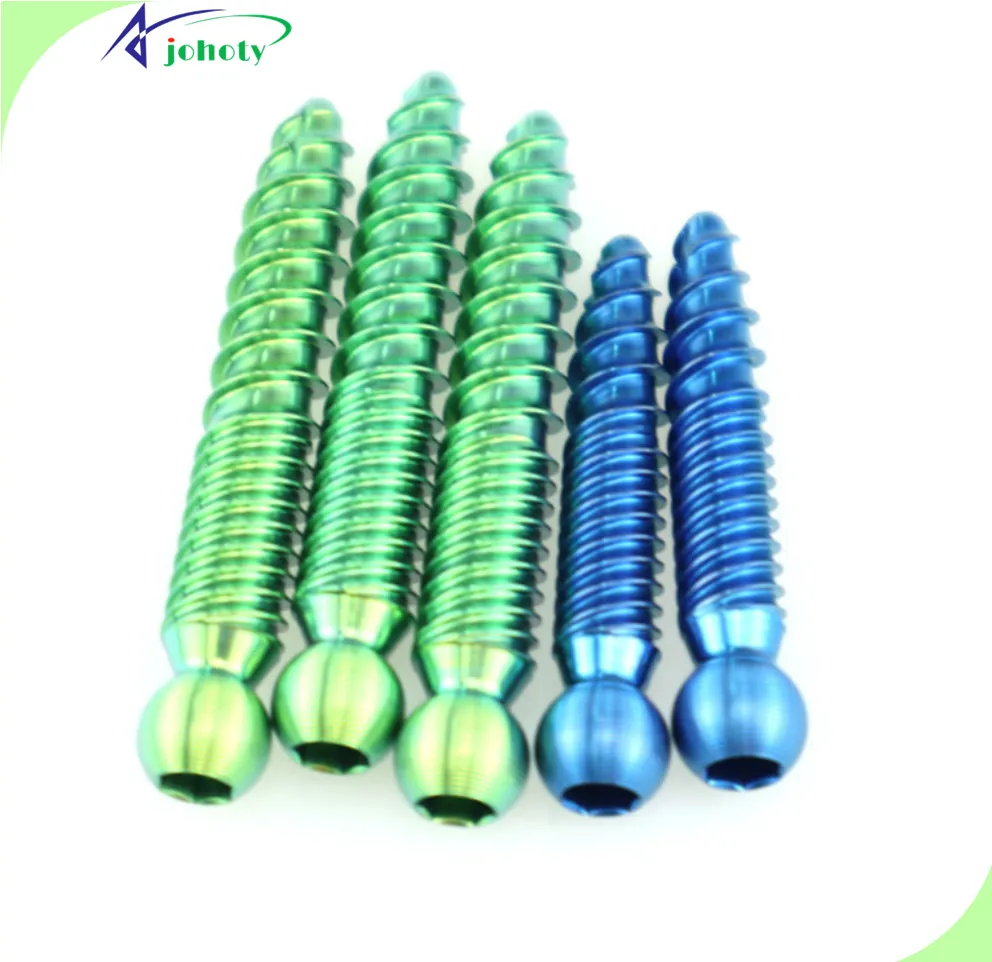

Bone Screws Description:

Catalogs of Bone Screws, Dental Implant Screws:

Bone Screws Datasheet:

| Items | Details |

|---|---|

| Specifications | Thread Size: M1.4, M2.0, M2.7, M3.5, custom. |

| Length Range: 4 mm to 20 mm, custom. | |

| Diameter: 1.0 mm to 3.5 mm, custom. | |

| Head Types: Flat, Phillips, Hex, Star, custom. | |

| Materials: Medical-grade stainless steel (316L), titanium (Ti-6Al-4V) | |

| Tolerance Level: ±0.01 mm, custom. | |

| Sterilization Compatibility: Autoclave, EO, Gamma. | |

| Thread Precision: Class 3A, 3B, Standardized 60° angle, Custom depth. | |

| Performance | Tensile Strength: 900 MPa to 1200 Mpa. |

| Yield Strength: 800 MPa to 1000 Mpa. | |

| Hardness HRC: 30 to 45. | |

| Fatigue Resistance: ≥10 million cycles. | |

| Function | Anti-Rotation: Prevents loosening in bone. |

| Self-Tapping: Allows insertion without pre-drilling. | |

| Corrosion Resistance: Maintains integrity in bodily fluids. | |

| Biocompatibility: Suitable for long-term implantation. | |

| Osteoconductive: Supports bone integration. | |

| Finishing | Anodized (for Titanium), |

| Passivated (for Stainless Steel). | |

| Certifications | ISO13485, ASTM F138 (Stainless Steel), ASTM F136 (Titanium), FDA 510(k). |

| Packaging | Materials: Bag, Box Tray, Custom. |

| Methods: Blister, Foam, Custom. |

Why Choose Johoty’s Bone Screws?

Johoty’s bone screws have a ±0.01 precision, save you >20% costs, ship in <2 weeks! Custom is perfect and flexible. Worthy of your trust!

Bone Screws Benefits:

High Strength and Durability

Johoty can help you achieve excellent fracture resistance by using high-strength materials ( titanium alloy or stainless steel). they have long-term corrosion resistance, precise fixation ability, stable load-bearing capacity, high fatigue resistance, optimized deformation resistance, and strict quality control to adapt to the strength adjustment of different bone types, with long-term reliability.

Easy to Implant and Operate

Biocompatibility

Optimized Thread Design and Fixing Effect

Bone Screws Applications:

Fracture Repair

Spinal Fixation:

If there are problems with the spine, such as deformation or compression, doctors will use bone screws to fix them. They include spinal stabilization surgery, spinal correction, spinal fusion, and minimal spinal surgery. Such medical screws help stabilize the spine, preventing it from continuing to bend or shift. This is like fixing a piece of furniture with screws, bone screws can ensure the spine can return to its normal position and help patients stand straighter and walk more steadily.

Joint Replacement Surgery

If the joint is injured or aged, doctors may use bone screws to fix the new joint. They include fixed prostheses, pelvic or femoral stabilization, auxiliary repair of bone defects, and enhancement of bone structure around joints. The medical screws help to tightly connect joints and bones, just like repairing a broken toy. This allows joints to move smoothly, reduces pain, and restores normal function.

Bone Tumor Repair:

Traumatic Fracture

Bone Deformity Correction

Hip Joint Repair

For patients with hip injuries, bone screws can help fix the bone and promote better bone healing. This includes hip fracture fixation, hip replacement surgery, joint loosening repair, and restoration of femoral head blood supply. By fixing the bone with screws, patients can recover walking faster and reduce hip pain. It’s like using a fixator to stabilize the parts and ensure they are reconnected healthily.

Ankle Joint Fixation

Bone Screws Advantages:

Enhanced Bone Stability

The threaded design of the bone screw allows it to firmly grip the bone, like a small nail fixing two things in place. In this way, the bones are less likely to move and can heal in the correct position. Doctors use it to ensure that the fractured part is not displaced, helping patients recover faster. Like putting a puzzle together, it needs to be securely fixed to remain intact.

Easy to Operate and Implant

The bone screw design is very convenient, and doctors can easily insert it into the bone. Just like how you tighten screws with a screwdriver, bone screws can quickly enter the bone and help doctors complete surgeries efficiently. This simple design makes surgery easier and reduces the patient’s recovery and anesthesia time.

Strong Anti-rotation Ability

Reduce Bone Damage

FAQ

1. What technical advantages do your bone screws and dental implant screws offer?

Our bone and dental implant screws use 5-axis CNC technology and materials of titanium alloys and 316L, They can ensure high strength and are safe.

Our design focuses on ease of surgery and quick patient recovery. Johoty has a special emphasis on thread design and surface treatment techniques. This can boost bone integration and minimize the risk of infection.

2. How do you make sure that your bone screws and dental implant screws are high quality and reliability?

We strictly follow international medical device standards for our bone screws and dental implant screws and testing them. Including ISO 13485 and FDA certifications.

From the CNC rough materials to the shipment of the finished bone screws. Each stage is rigorously inspected to ensure the performance and reliability of every screw.

3. Do you offer customization services?

Yes. Johoty always understands the diversity between surgical and patient. So we prefer to offer customization for you. It includes length, diameter, screw thread, thread type, head shape, material, coating, smoothness, screw sole, special shape, etc.

Our CFT team will engage closely with you to make sure our bone screws meet your exact requirements.

4. How competitive are your prices?

Our pricing strategy aims to deliver maximum value to our clients. We manage to offer you competitive prices without compromising on quality and performance. How to get it?

It is based on our material selection, SCM, manufacturing precision, finishing, production equipment, custom, and production volume. MOQ, mass production, shipping cost, customs duties and taxes, etc.

Johoty has flexible pricing proposals to meet you of various sizes and needs.

5. What are your support policies regarding ordering and logistics of your bone screws and dental implant screws?

Johoty always provides you with professional support and flexible logistics solutions. Our goal is to ensure timely, safe, and accurate delivery to you. No matter where you are, our CFT team and logistics team always promise to deliver our bone screws in a timely and safe manner.

In addition, our CFT team can solve your problems in logistics, technical confirmation, product quality, product selection, product pricing, and others. And, we can provide you with timely support and solutions. We can always ensure that your ordering experience is pleasant and trustworthy.

We strictly follow international medical device standards for our bone screws and dental implant screws and testing them. Including ISO 13485 and FDA certifications.

From the CNC rough materials to the shipment of the finished bone screws. Each stage is rigorously inspected to ensure the performance and reliability of every screw.

Yes. Johoty always understands the diversity between surgical and patient. So we prefer to offer customization for you. It includes length, diameter, screw thread, thread type, head shape, material, coating, smoothness, screw sole, special shape, etc.

Our CFT team will engage closely with you to make sure our bone screws meet your exact requirements.