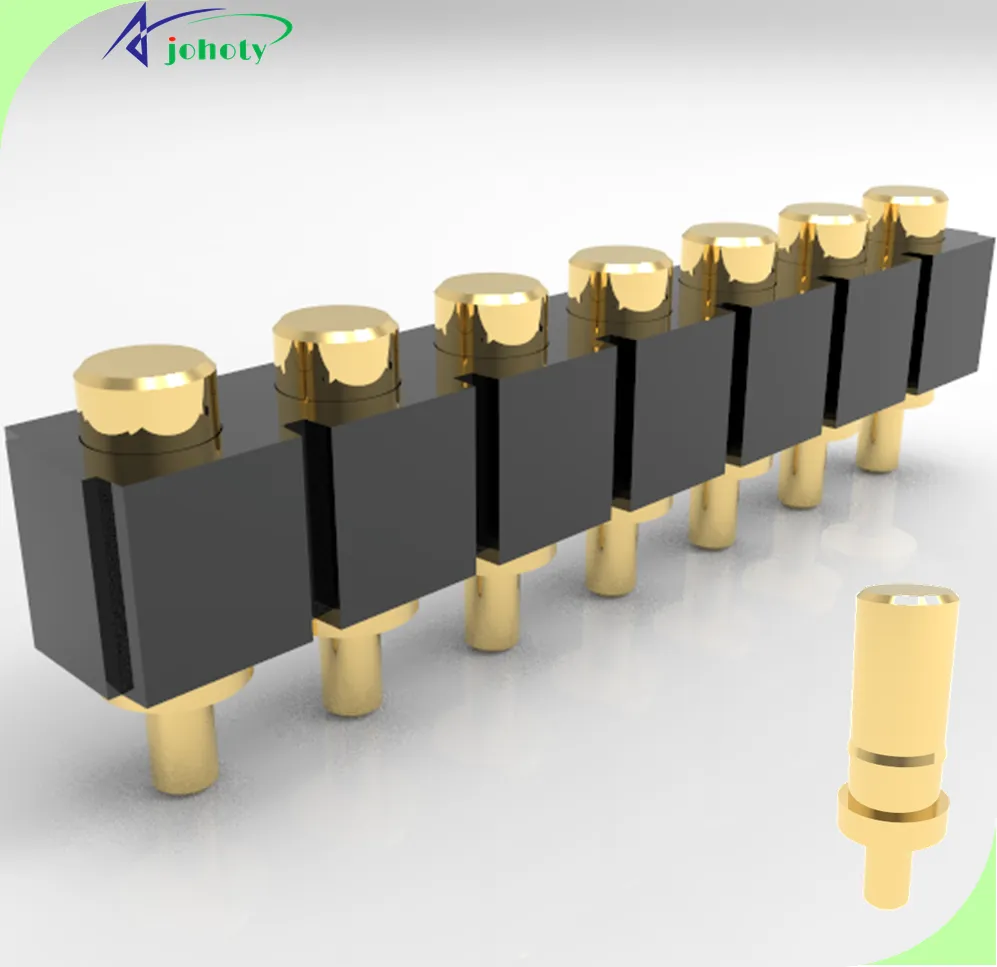

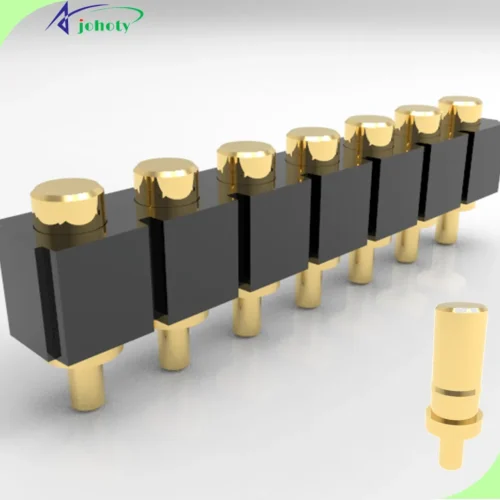

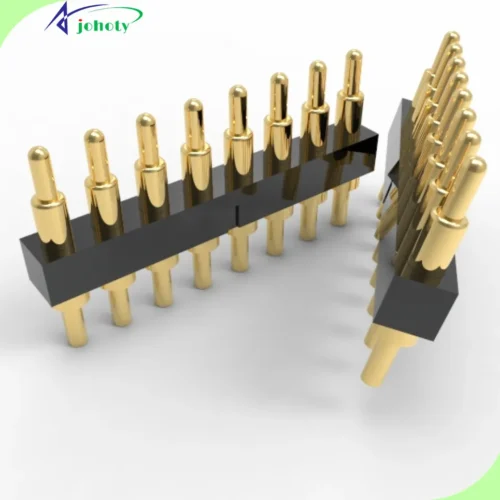

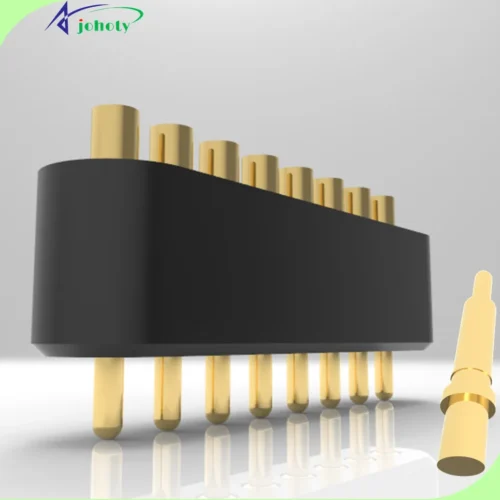

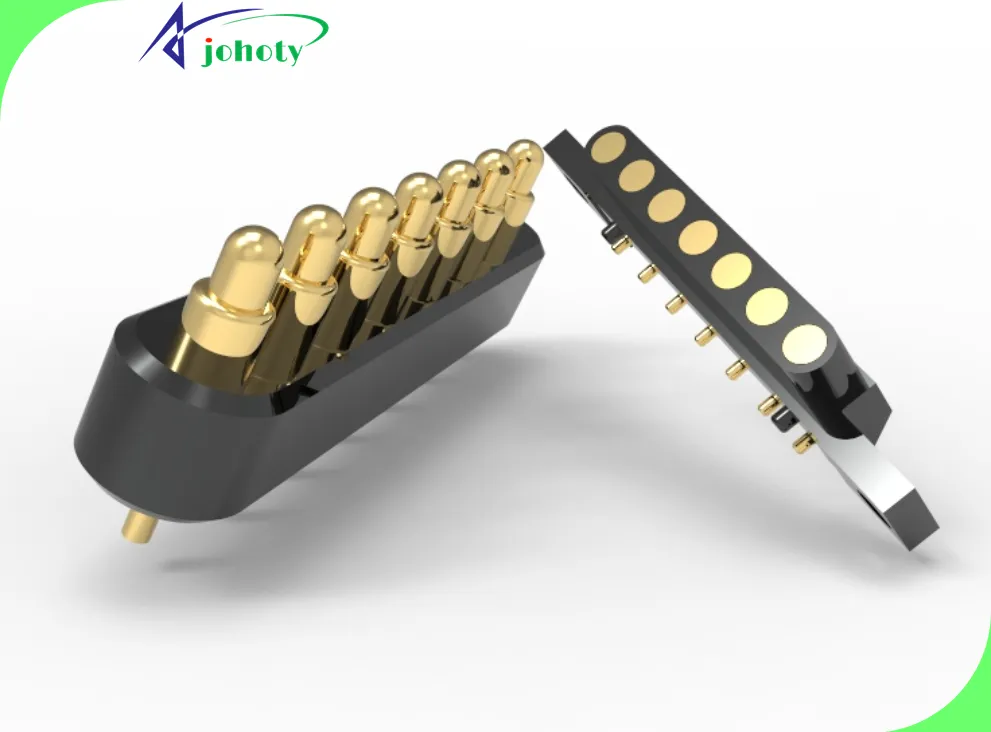

7 Pin Connector Description:

7 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: 15 mΩ ~ 200 mΩ, Custom. |

| Rated current: 1.0 A to 20 A, Custom. | |

| Rated voltage: 3.3 V to 230 V, Custom. | |

| Insulation impedance: ≥100 MΩ, Custom. | |

| EMI: Support. Custom. | |

| Transfer speed: Up to 5Gbps | |

| Working frequency: From MHz to GHz, Custom. | |

| Mechanical: | Shapes: Single/dual rows, Rectangle, Round, SMT, DIP, Dual-end, Right-Angle, Bending type, Solder-cup, Custom. |

| Spring force: ≥15gf, without upper limit, Custom. | |

| Pitch: ≥1.00mm, 2.54mm is popular, Custom. | |

| Stroke: ≥0.60mm, Custom. | |

| Length: ≥5,00mm, Custom. | |

| Barrer diameter: ≥0.85mm, >1.00mm popular, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: 10,000 ~ 200,000 times, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Plunger/Barrer: Brass, copper alloys (beryllium copper, phosphor copper), stainless steel, etc. |

| Housing: Plastics (nylon, PA66, PTE, PPS, PBT), stainless steel, aluminum alloy, etc. | |

| Spring: Gold-plated, music steel, stainless steel, etc. | |

| Ball: Steel, zirconium, ceramic, Custom. | |

| Sealing: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating: >1.5u”, Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: PI, PTFE, PBT, Nylon, Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, L/F, H/F, etc. | |

| Flammability rating: UL94 V-0, etc. | |

| Installation: | Surface mount: SMT, Automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin is available, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact, high-vibration. | |

| Embedded: High waterproof and sealing requirements. | |

| Quick: Testing equipment. | |

| Locking: Screws, nut, additional mechanical fixation force. | |

| Slot: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 7 Pin Connector?

7 Pin Connector has rectangle, round, IP67, compact, EMI, magnetic signle/dual rows costomization. Johoty is trustworthy!

7 Pin Connector Benefits:

Stable and Reliable 7-core Connection

Efficient Data/Power Transmission

Flexible Adaptation to Multiple Environments

Reduce Repair and Consumables Costs

Pogo Pin Connector Applications:

Electronic Device Data Transmission

Automotive Electronic Systems

Mobile Device Charging

Charging a phone with a 7 pin connector is simply a fast charging tool. Its seven core design can transmit more current and charge much faster than a regular interface. The key is that the pogo pins of the pogo pin connector can automatically adjust pressure, reduce interface wear, and extend device lifespan. You don’t need to worry about the charging port breaking easily, it’s user-friendly.

Medical Equipment Connection

In medical devices, the 7 pin connector is popular, such as instruments that monitor patients’ physical signs. Its connection is very stable, even if the device is in motion, it will not affect signal transmission. For doctors, this stability is like a life-saving straw, ensuring that patient data can be accurately transmitted to the screen.

Industrial Robot Connection

Smart Home System

Aerospace Equipment

Test Equipment Connection

Pogo Pin Connector Advantages:

High Reliability

High-pressure Resistance

Strong Anti-interference Ability

Compact Design

Strong Durability

Easy to Install and Maintain

FAQ

The main innovations include precision spring-loading mechanisms, the use of high-conductivity materials, and magnetic self-aligning properties. Taken together, these factors contribute to improving the reliability of connections and the efficiency of data transmission.

Design optimization ensures minimal signal attenuation and minimal EMI. Making it perform excellently in high-speed data transmission applications.