Medical Gas Strut Description:

Medical Gas Strut Datasheet:

| Items | Details |

|---|---|

| Basic Info: | Name: Medical gas strut is a quality gas spring in surgical tables, hospital beds, etc. |

| Types: Standard, heavy-duty, compact, long stroke, temperature-controlled, corrosion-resistant, low-noise gas struts. | |

| Position: Flexibly and precisely adjusts smoothness, height, tilt, and angle. | |

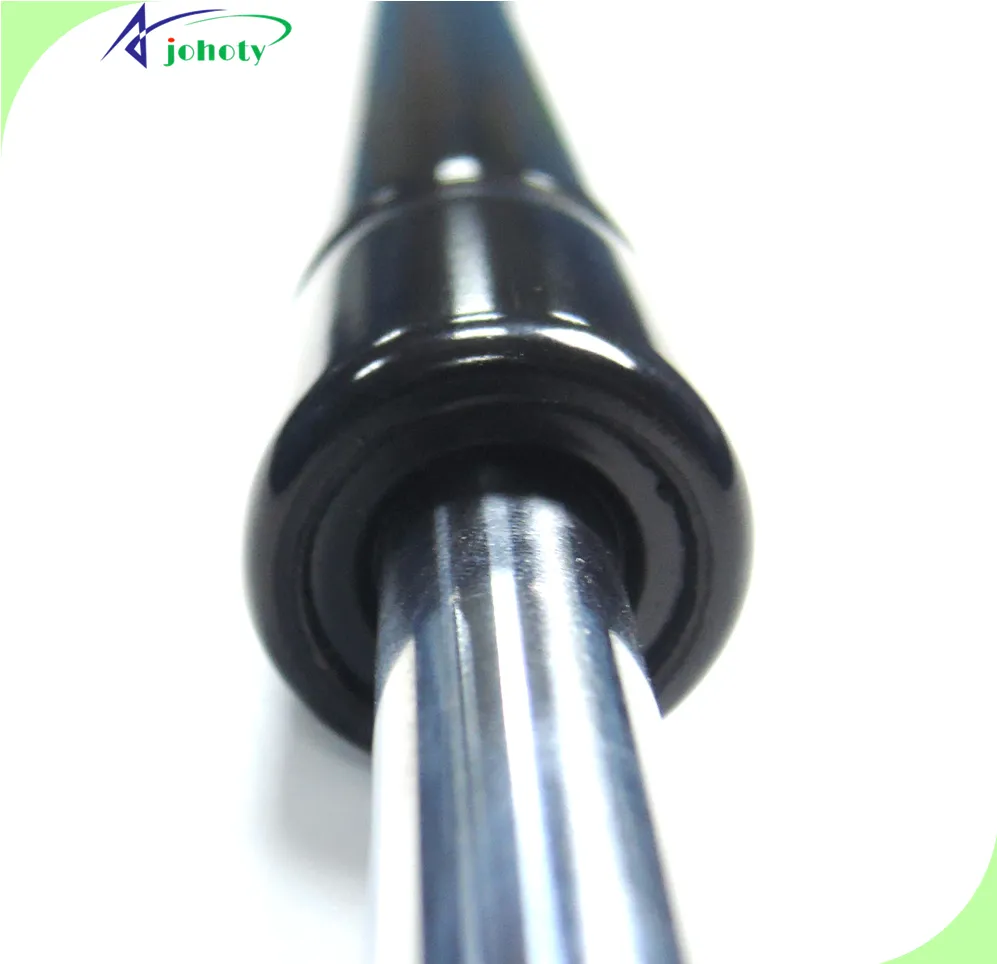

| Specifications: | Piston Rod Diameter: 6mm – 12mm. |

| Cylinder Diameter: 15mm – 28mm. | |

| Stroke Length: 50mm – 300mm. | |

| Extended/compressed Length: Stroke + 100mmc. | |

| Force: 50N – 1,000N. | |

| Thread Size: M6 / M8 / Custom. | |

| Angle: 0° – 120°. | |

| Spring Rate: 5N/mm – 20N/mm. | |

| Load: ≤ 1,200N. | |

| Adjustment speed: 5mm/s – 30mm/s. | |

| Performance: | Damping: Smooth and Silent. |

| Load consistency: ± 5%. | |

| Holding force precision: ± 2%. | |

| Vibration resistance: High resistance to shock. | |

| Leakage rate: < 0.1% per year. | |

| Response time: < 0.1s. | |

| Corrosion resistance: 500h salt spray test. | |

| Load Recovery: Full recovery after compression. | |

| Temperature: – 30°C to + 80°C. | |

| Cycle Life: > 50,000 cycles. | |

| Materials: | Cylinder: Carbon steel/stainless steel |

| Piston rod material: Chrome-plated steel. | |

| Seal material: Nitrile rubber / viton. | |

| Gas type: Nitrogen. | |

| Connector material: Steel / Nylon. | |

| Coating: Powder Coating, anti-rust oil. | |

| Paint ginish:Epoxy tesin voating. | |

| Packaging: Recyclable Carton / Foam. | |

| Connection Types: | Ball joint: Easy to rotate, suitable for angular movement. |

| Eyelet: Secure and robust for fixed mounting. | |

| Threaded connector: Customizable for precise fit. | |

| Fork end: Ideal for linear applications. | |

| Clevis mount: High stability for heavy loads. | |

| Swivel bracket: Allows multi-directional adjustment. | |

| Quick-release: Tool-free installation and removal. | |

| Angle bracket: Suitable or angled or corner mounting. | |

| Flat mount: Space-saving design for compact areas. | |

| Custom connector: Tailored for specific medical applications. | |

| Package: | Single unit packaging: Plastic bag, foam box, or cardboard box. |

| Box packaging: 5 to 50 pcs/box. | |

| Foam packaging: Protected with foam padding. | |

| Wooden crate packaging: Large volumes or special-sized gas springs. |

Why Choose Johoty’s Medical Gas Strut ?

Johoty’s medical gas strut is trusted by >500 hospitals with a >98% satisfaction rate, flexible custom. Johoty is trustworthy!

Medical Gas Strut Benefits:

Operation Smoothness and Comfort

Accurate Position Control

Save Manpower and Improve Efficiency

Improve Equipment Durability and Reliability

Medical Gas Strut Applications:

Adjustment of Medical Bed

Angle Adjustment of the Operating Table

Medical Equipment Bracket

Patient Transfer Equipment

X-ray Machines and Other Imaging Equipment

Adjustment of Dental Chair Lifting and Lowering

Medical Cart

Rehabilitation Equipment

Medical Gas Strut Advantages:

Precise Adjustment Ability

Medical gas strut can precisely adjust the height and angle of medical equipment. Why is hospital equipment so powerful? It’s gas struts! It can precisely adjust the height and angle of the operating table or hospital bed. When the doctor needs it, just press it to the desired position, no more or less than a millimeter. This makes it convenient for doctors to operate and makes patients more comfortable. Just like how we adjust the tables and chairs perfectly during exams, the adjustment is very easy!

Strong Stability

Medical gas strut provides stable support and will not easily slide or shake. When doctors use surgical lights, if the light shakes or the position is unstable, it must be troublesome, right? At this point, gas struts come in handy. It can fix the device’s position, and prevent it from sliding or shaking. Even if the doctor adjusts the position of the light, it will not suddenly lose control. It feels like the table legs are equipped with anti-slip pads making the table stable and making the mood more reassuring!

Easy to Operate

Just a gentle push or press is enough to control the position of the device. In fact, the medical gas strut is very intelligent. With just a gentle press or push, the device can be moved to the correct position without the need for brute force. The doctor needs to adjust the height of the operating table, just press it with one finger. Just like an automatic door, when you walk over, the door opens itself, this is convenient! And the design of these devices is user-friendly, doctors and nurses will find it effortless and easy to use.

Long Lifespan and High Durability

Medical gas strut can be used for a long time and is not easily broken. The durability of gas struts is impressive! They can be used continuously for a long time without breaking down due to excessive use. The hospital equipment is constantly adjusted every day, and if ordinary parts were used, they would have broken long ago. However, the gas spring is sturdy, and doctors can use it with confidence.

Silent Design

There is no noise and very quiet during operation. One of the most impressive is its quietness in a hospital, where you can’t even hear any noise when the equipment is in motion. This is because it uses Johoty’s medical gas strut, which has a silent design and operates without any sound. If there is a creaking sound when adjusting the surgical light, the doctor will feel annoyed. Gas springs are like a lubricated door, no matter how it is pushed or pulled, it won’t disturb others.

Enhance the Overall Aesthetics of the Equipment

The medical gas strut is compact and well-coordinated with the device. It also looks cool, is designed to be compact, and does not make medical equipment appear bulky or messy. It’s like a top-notch laptop, powerful but also looking simple and beautiful. Both doctors and patients feel that hospitals are high-end when they see such equipment. Just like how we like clean and tidy desks, this gas strut makes the equipment look professional!

FAQ

Maintenance of the gas strut is relatively minimal, but regular checks of their performance and integrity are still important. Especially in high-loa or frequently used medical environments.

A high-quality gas strut is for long-term use. Its expected lifespan can vary depending on usage frequency and maintenance, typically lasting several years or even longer.

Following our maintenance recommendations can maximize the lifespan and performance of the gas strut.

The replacements must meet the exact specifications and performance criteria of the original parts, including size, force, and stroke. Installation should follow our guidance and recommendations closely to achieve the correct installation.

Preventing equipment damage or safety risks caused by improper operation. It is important to maintain cleanliness during the replacement process to avoid contamination.

The customization options for the gas strut are extensive. Include the force of push and pull, stroke, speed, size and shape, installation method, and extreme temperature resistance.

We can provide fully customized solutions based on medical equipment requirements.