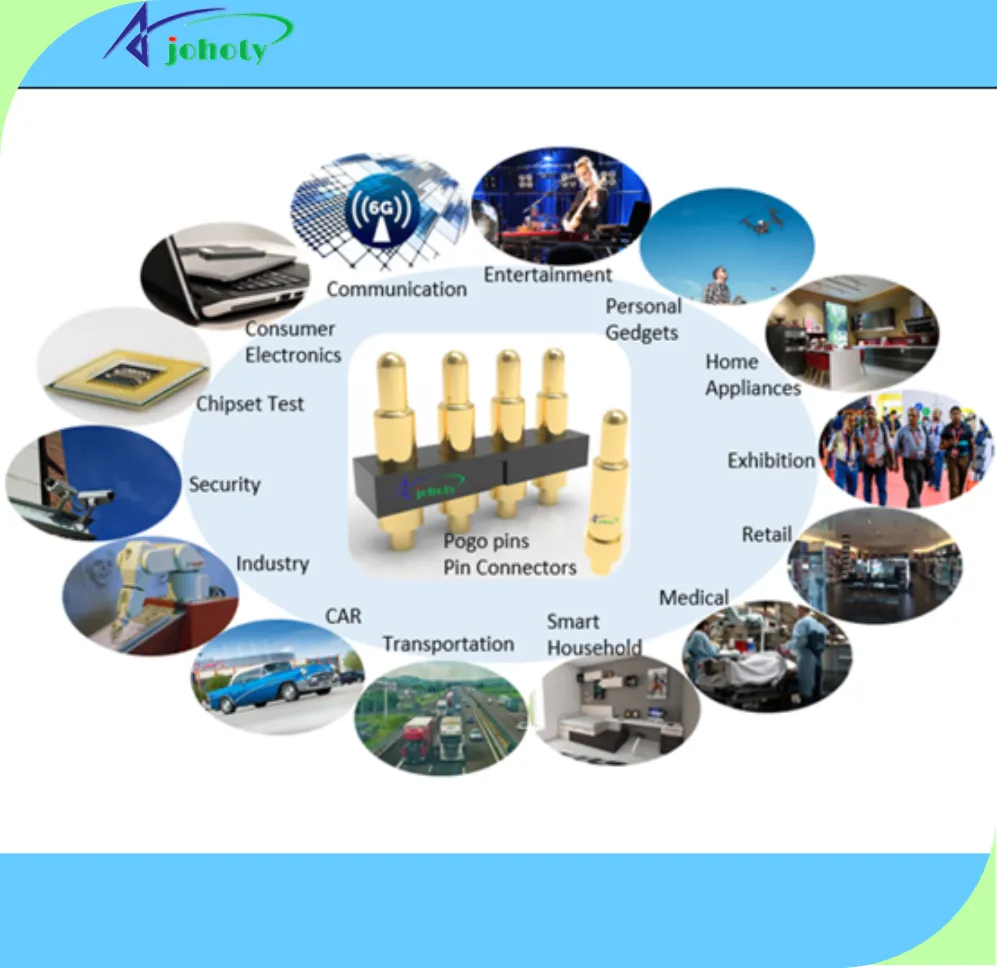

1. Pin Connectors Categories

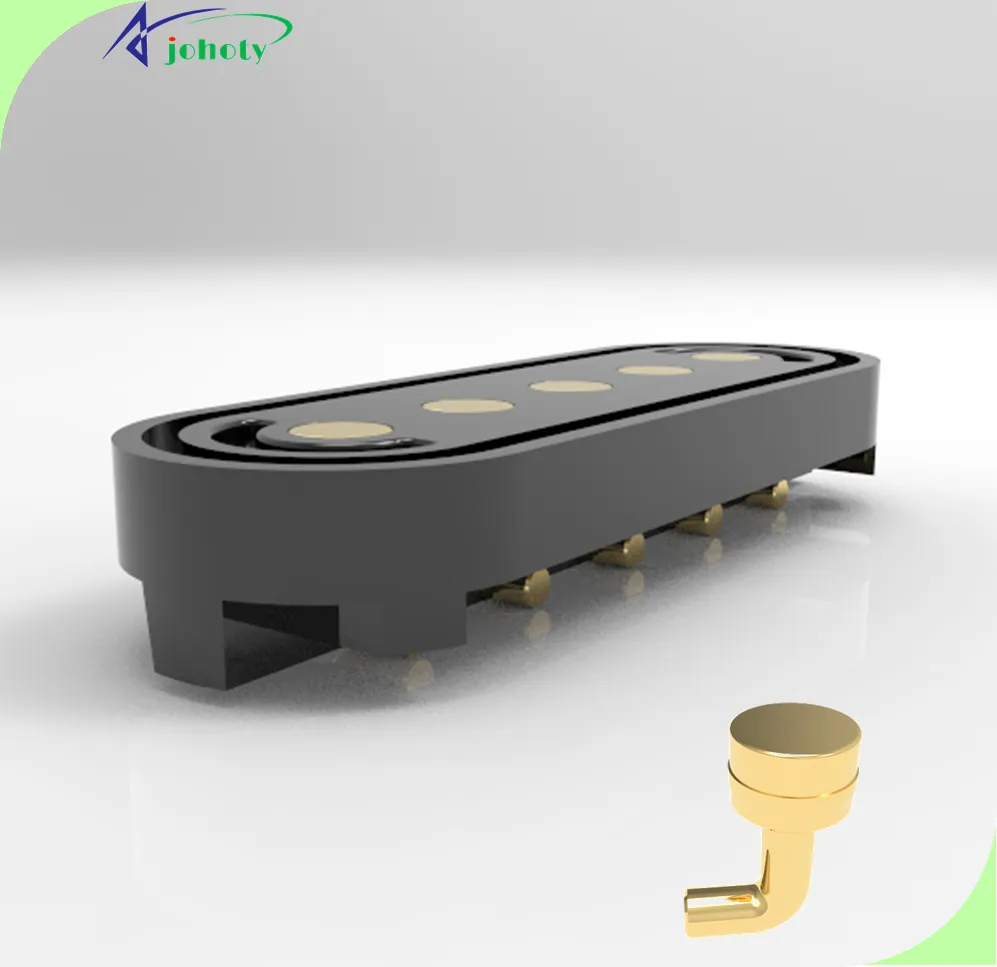

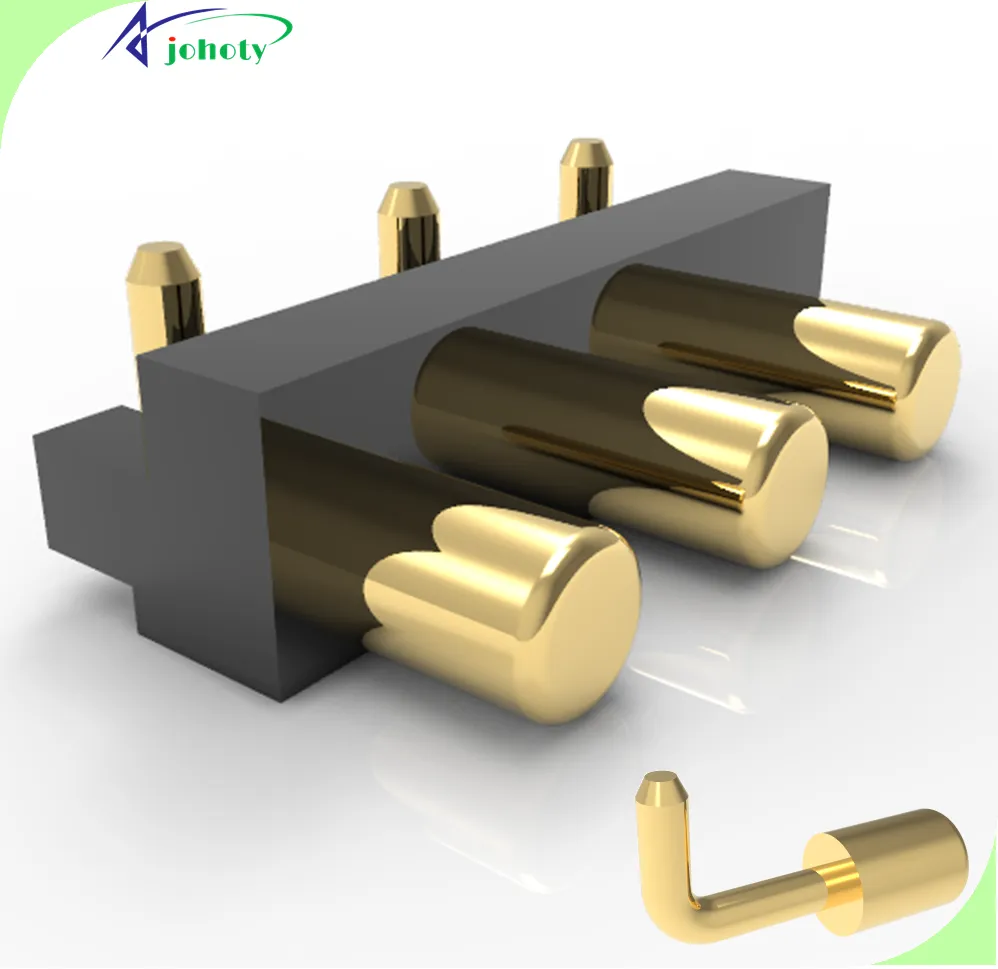

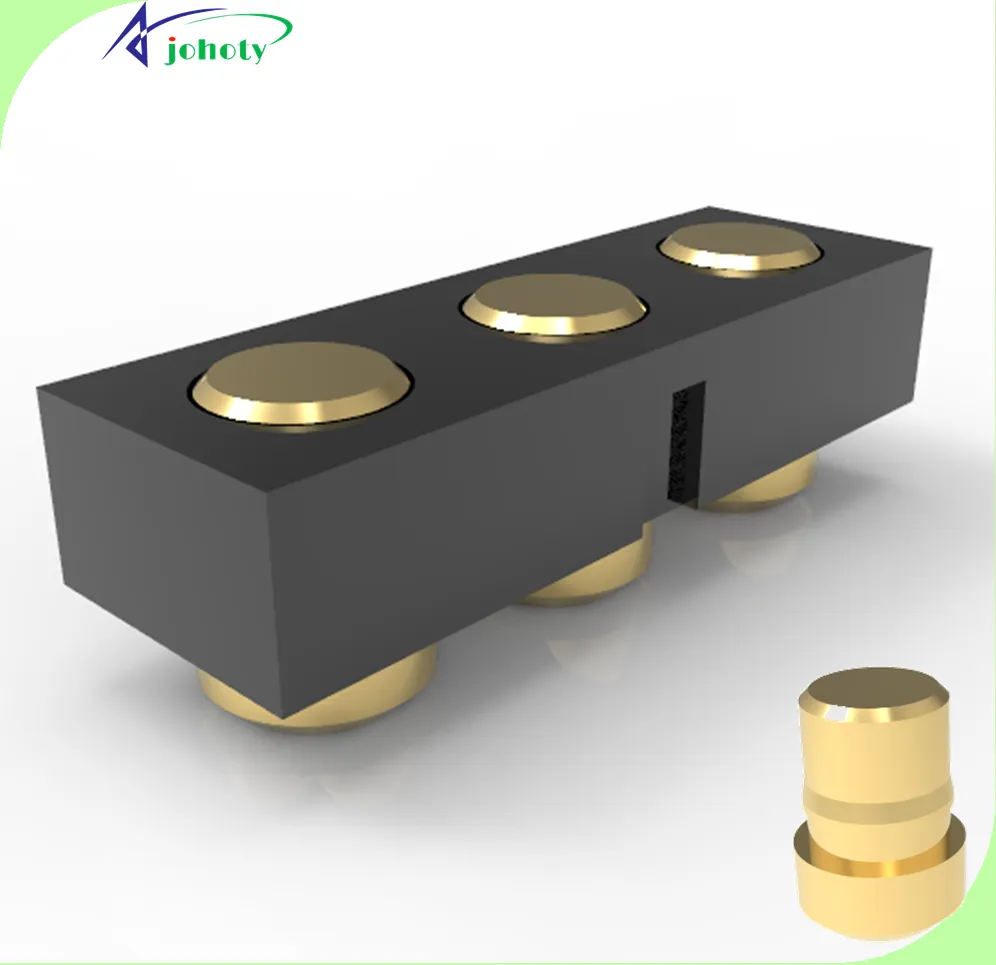

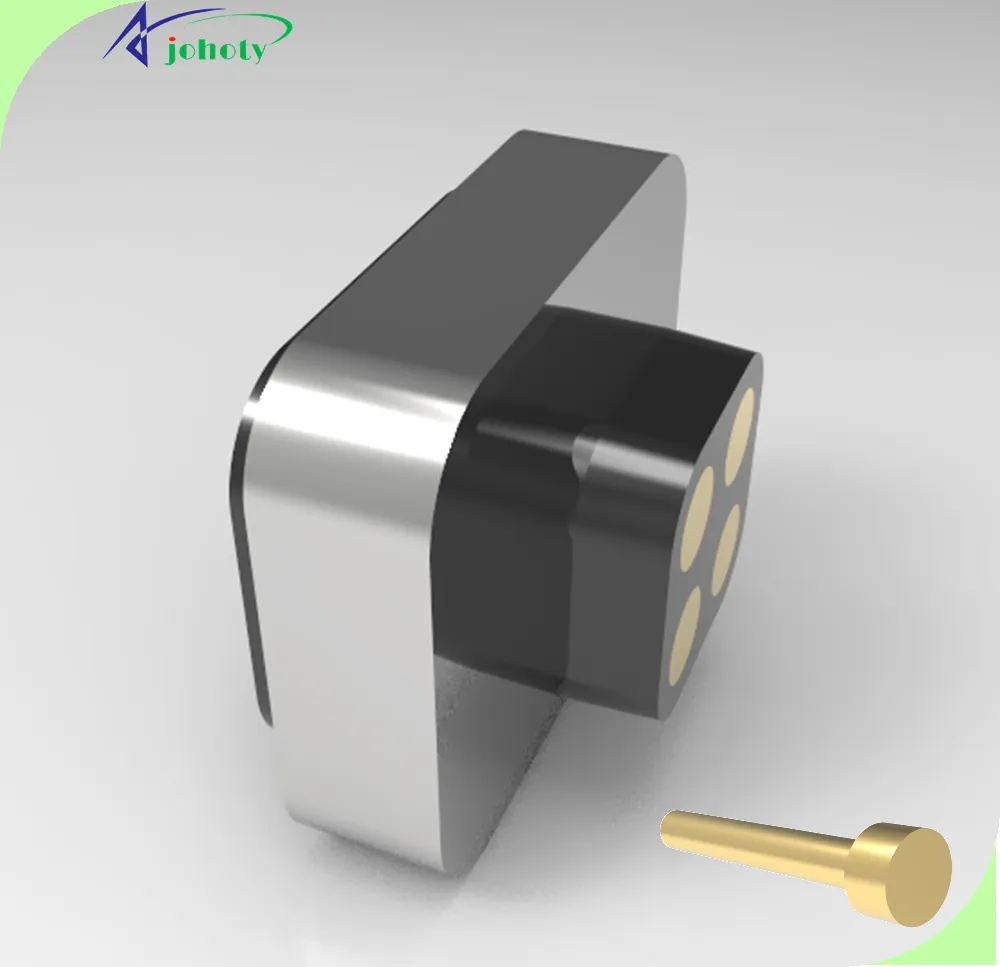

Categories:

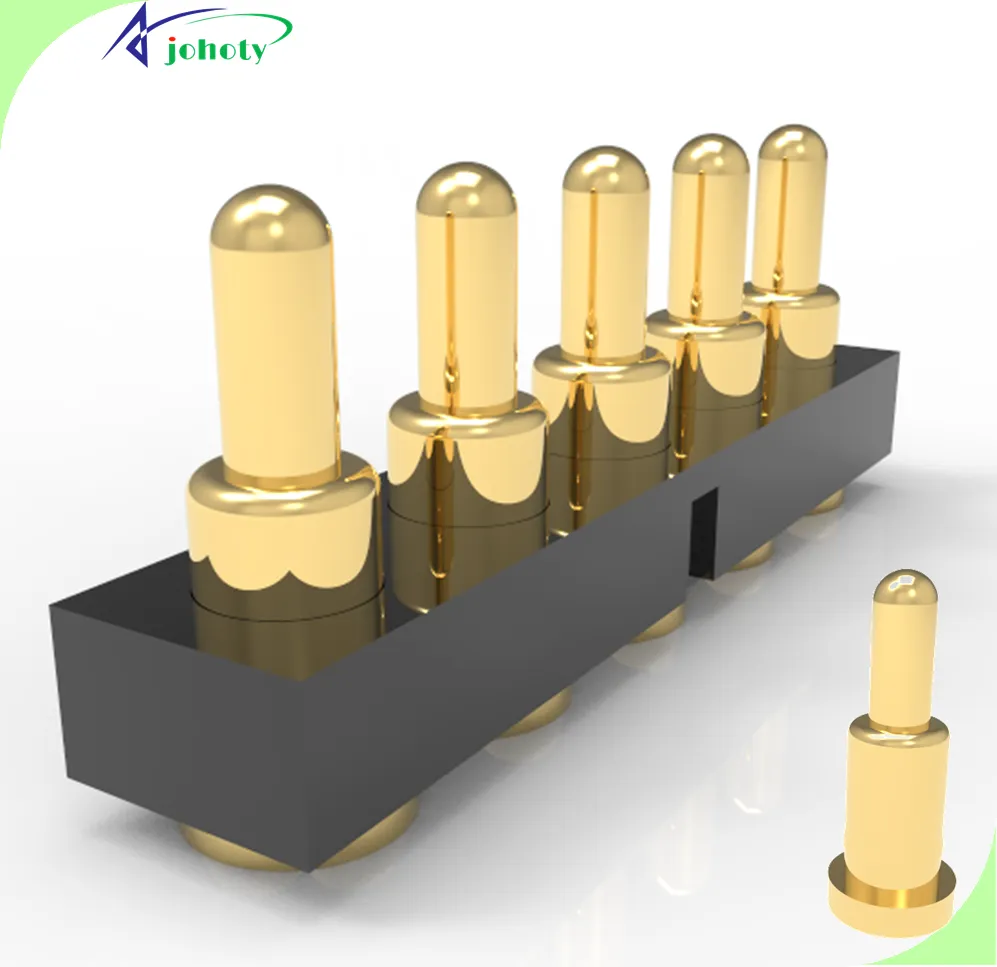

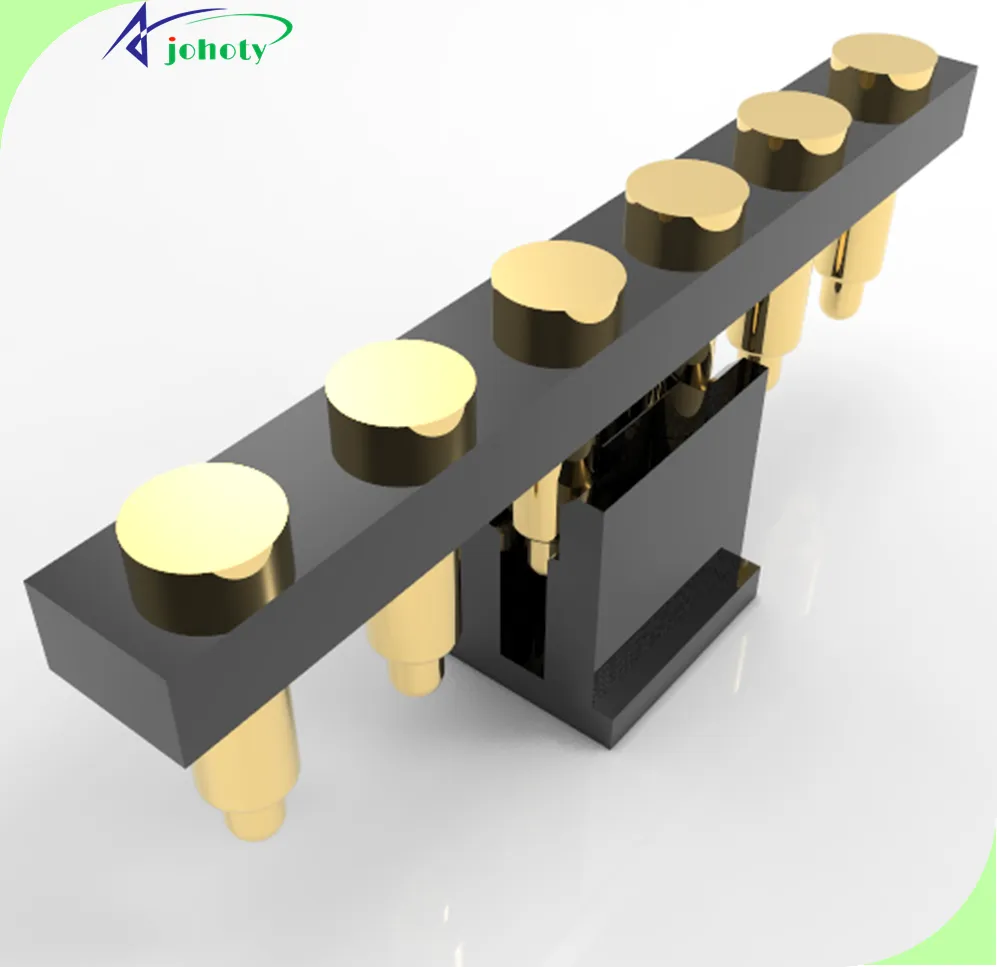

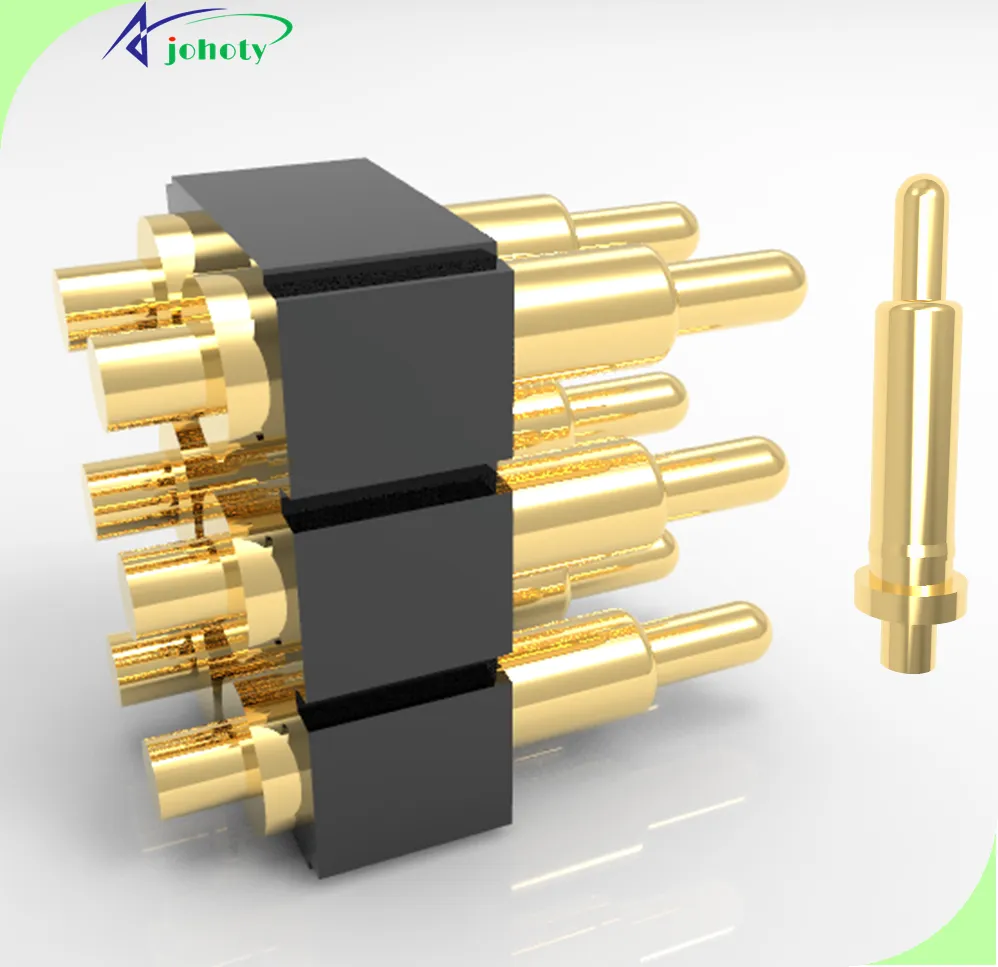

- 2 pin connector!

- 3 pin connector!

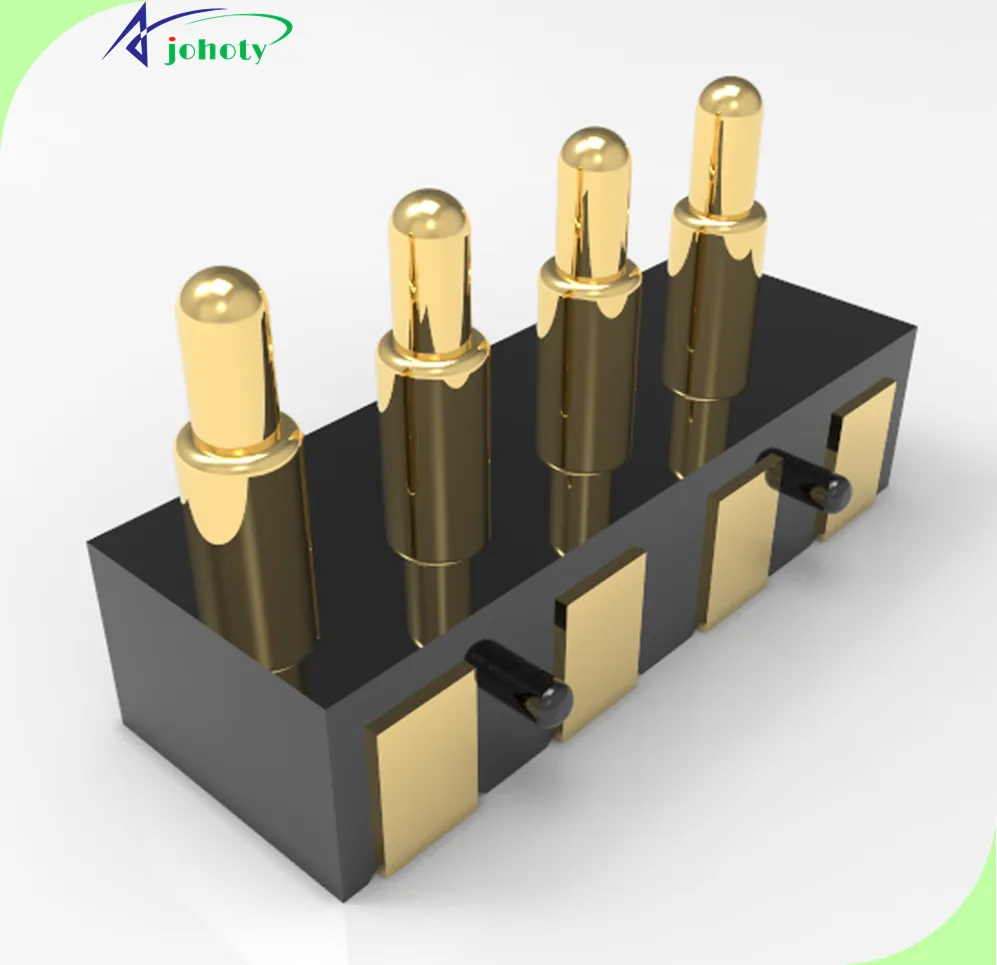

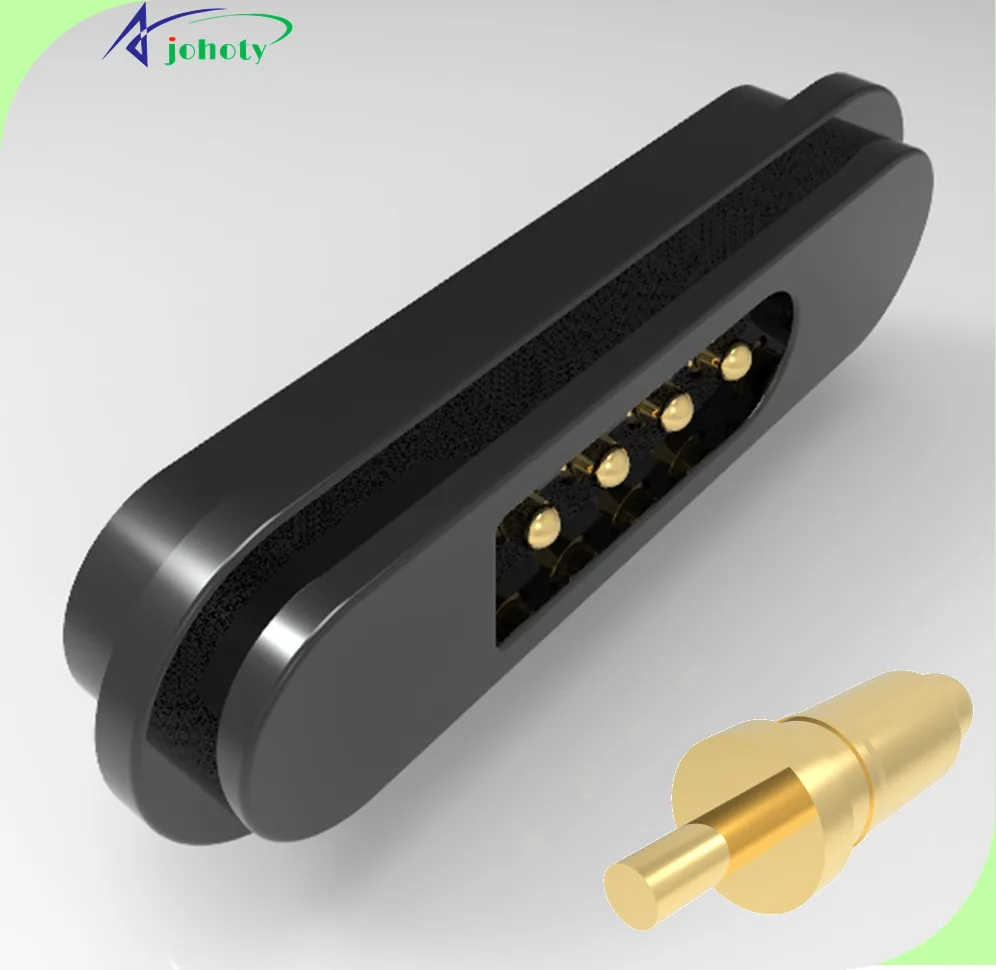

- 4 pin connector!

- 5 pin connector!

- 6 pin connector!

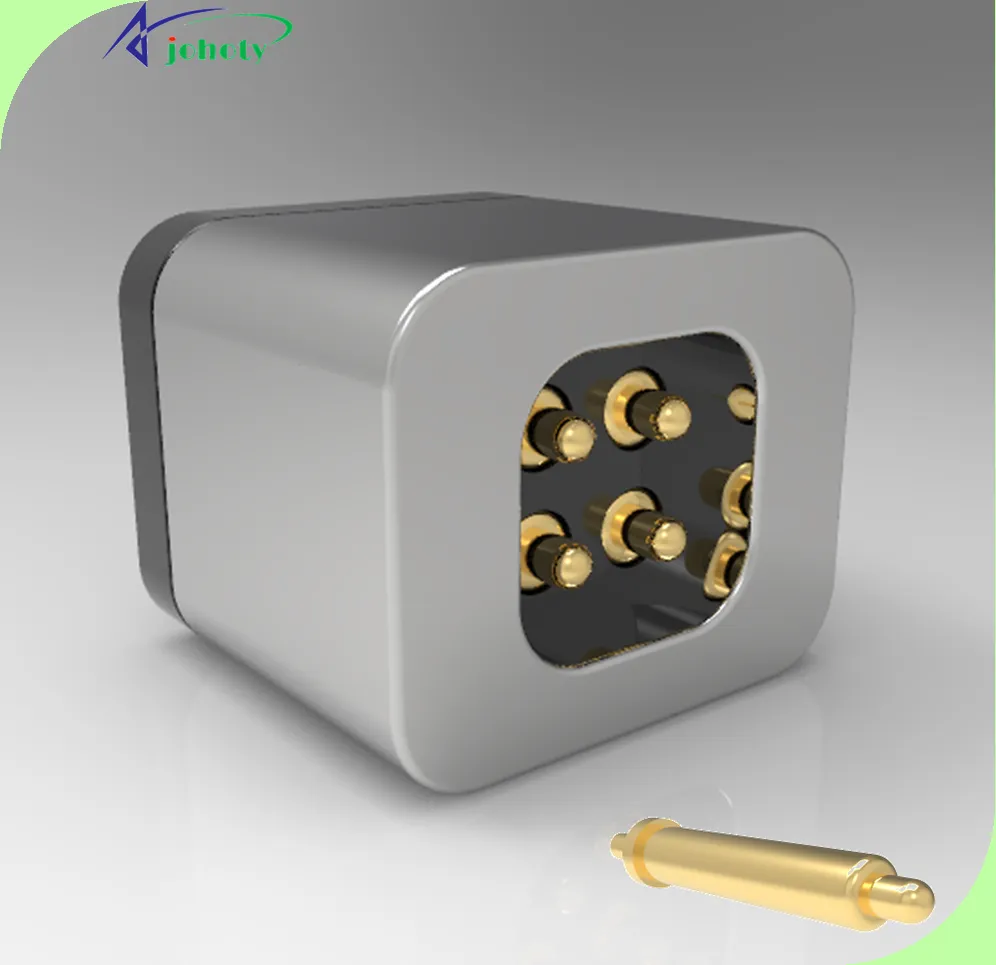

- 7 pin connector!

- 8 pin connector!

- 9 pin connector!

- 10 pin connector!

- 12 pin connector!

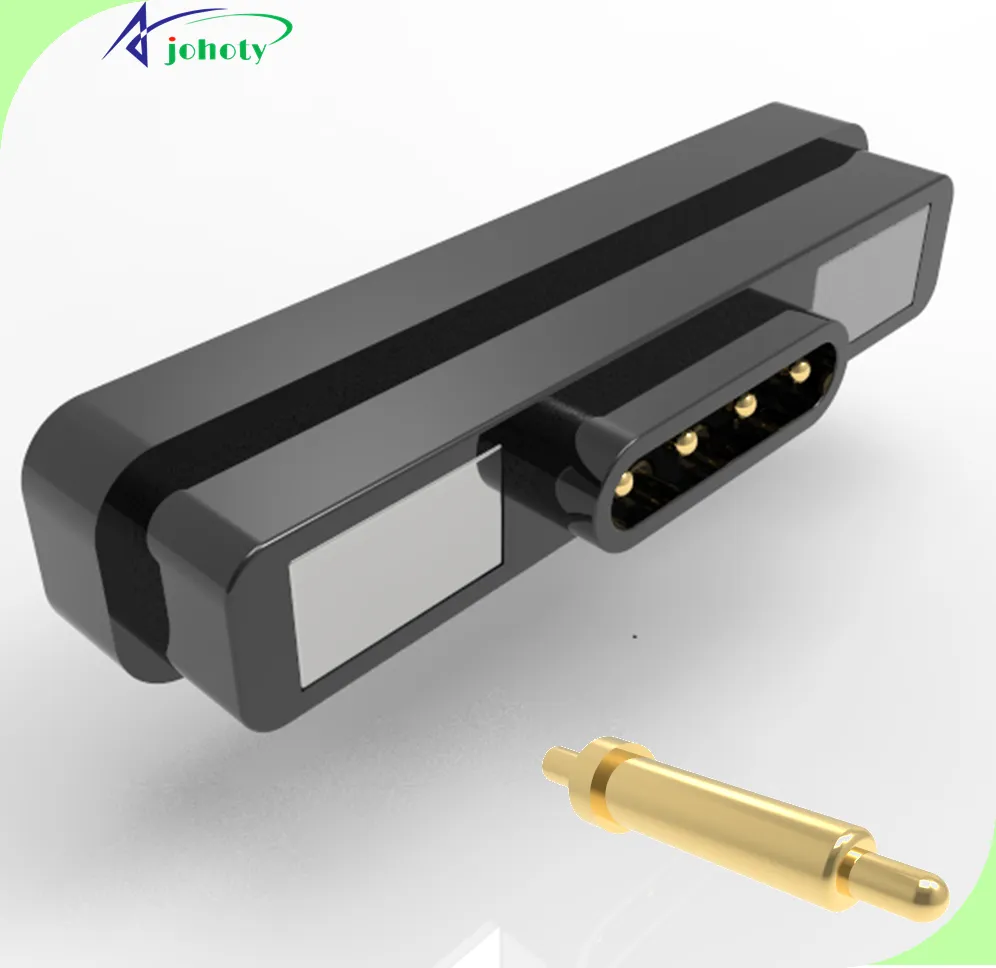

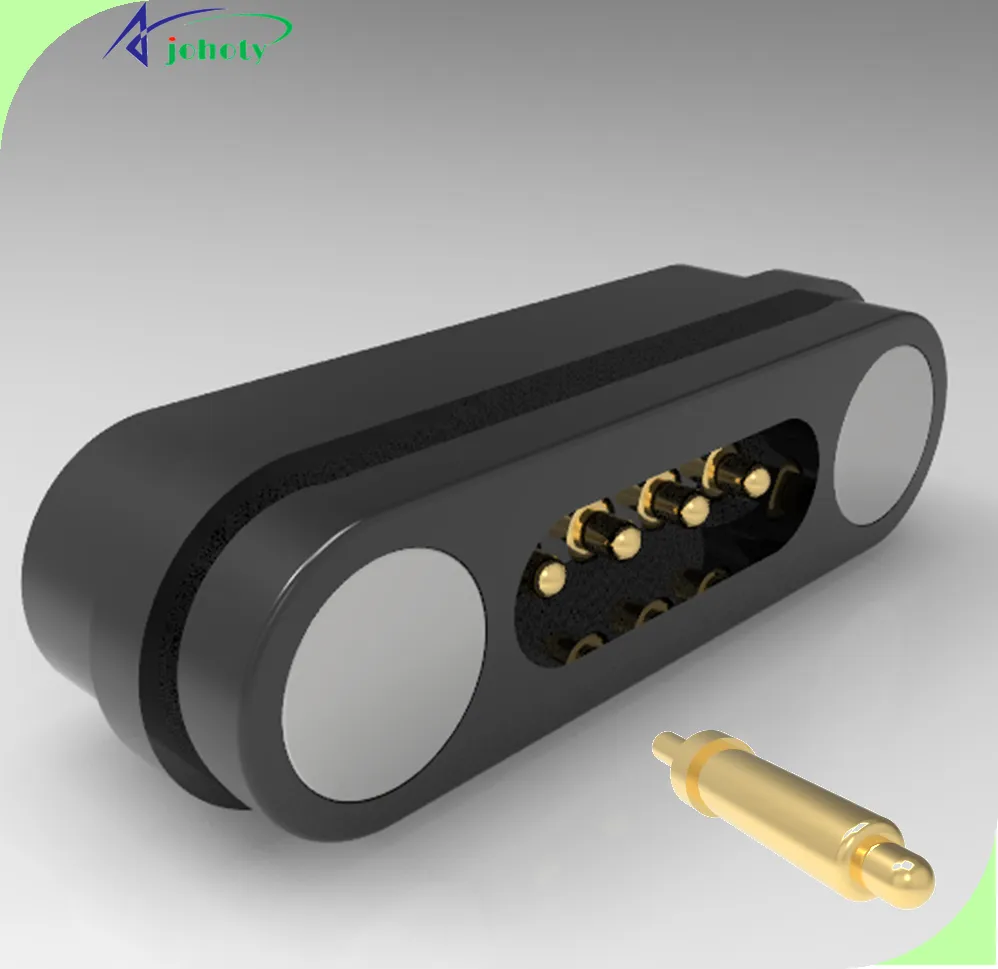

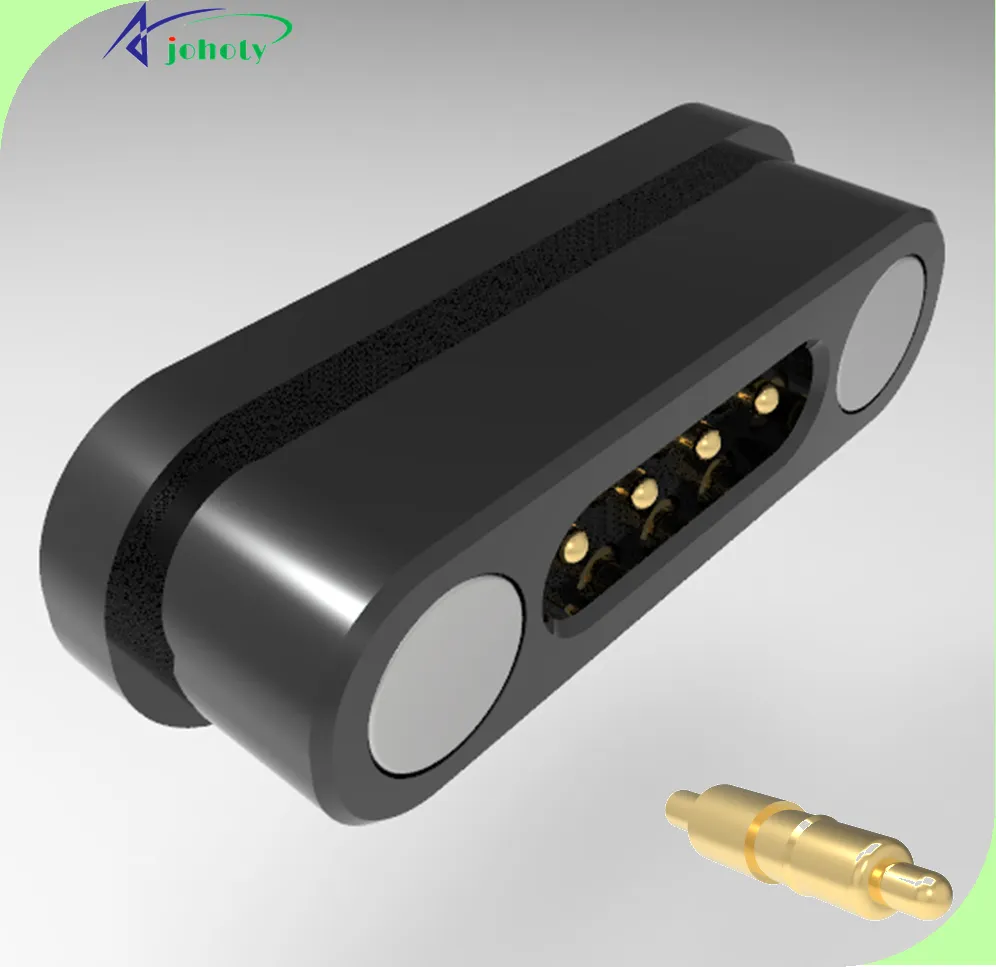

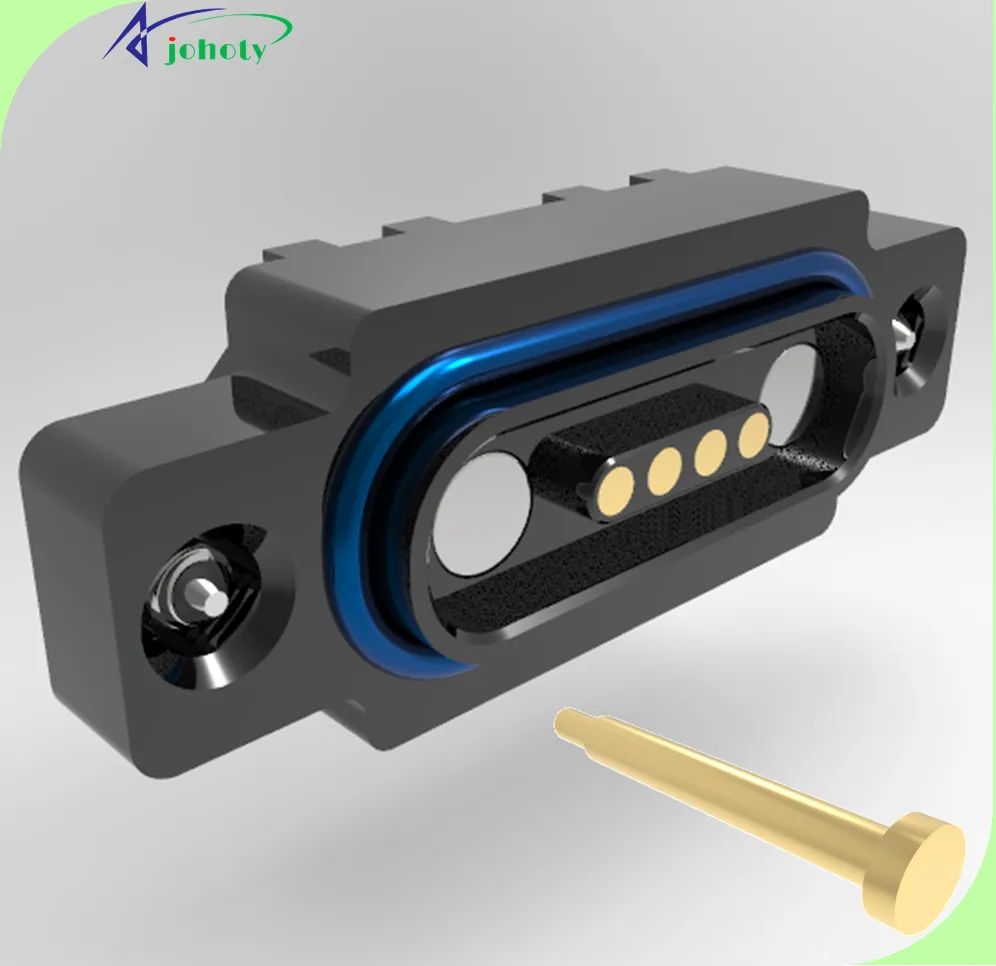

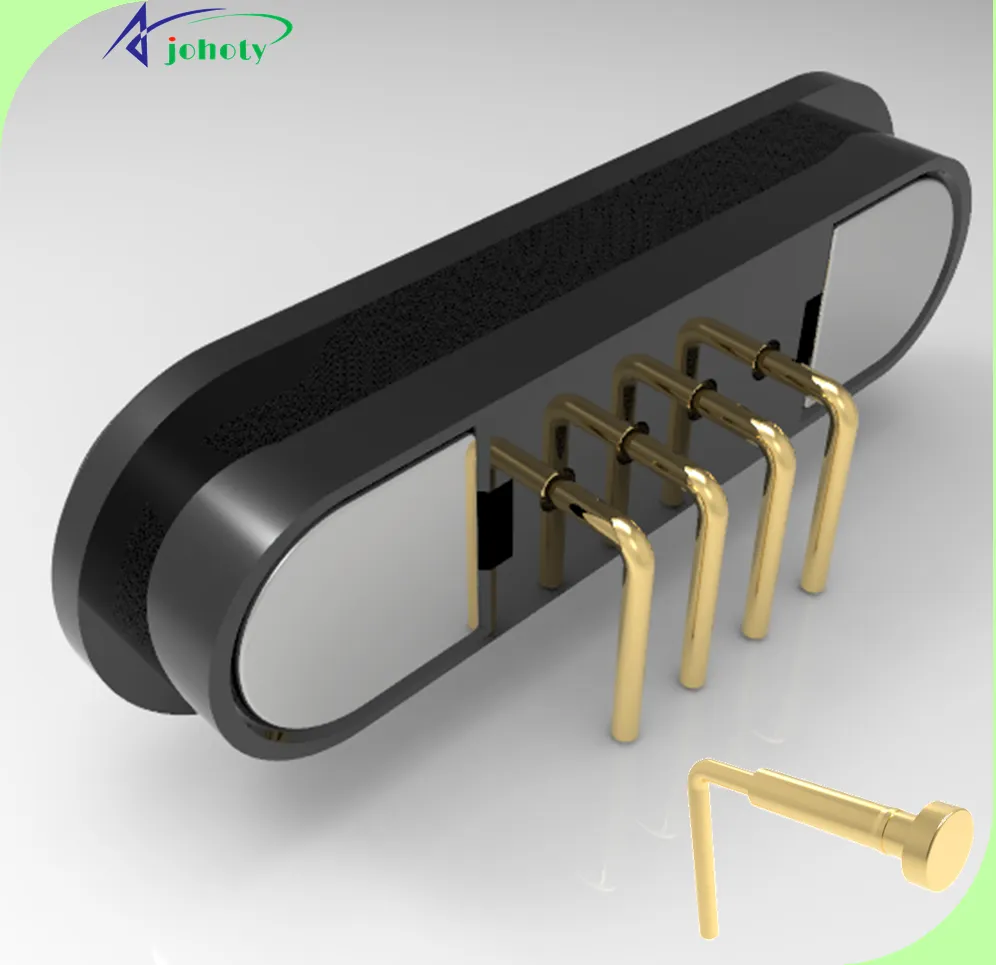

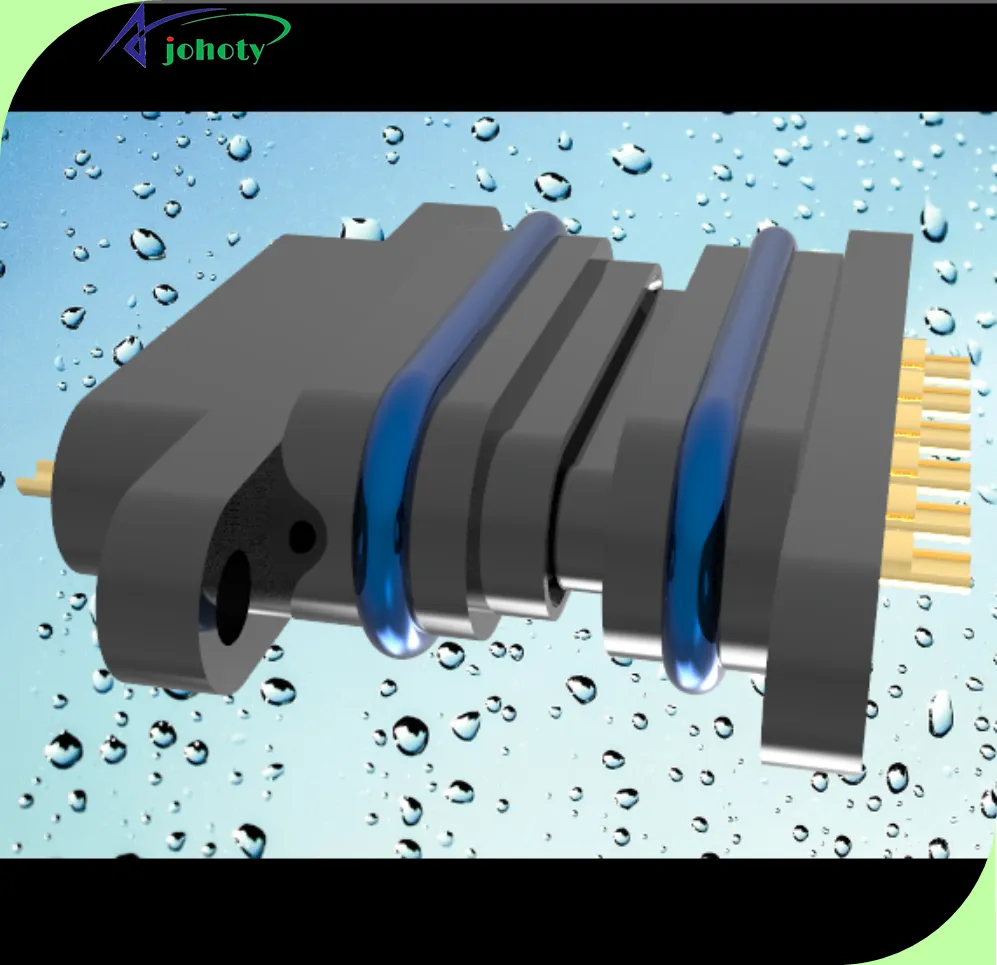

- Magnetic connector!

- 7 pin trailer connector!

- Other Pin connectors!

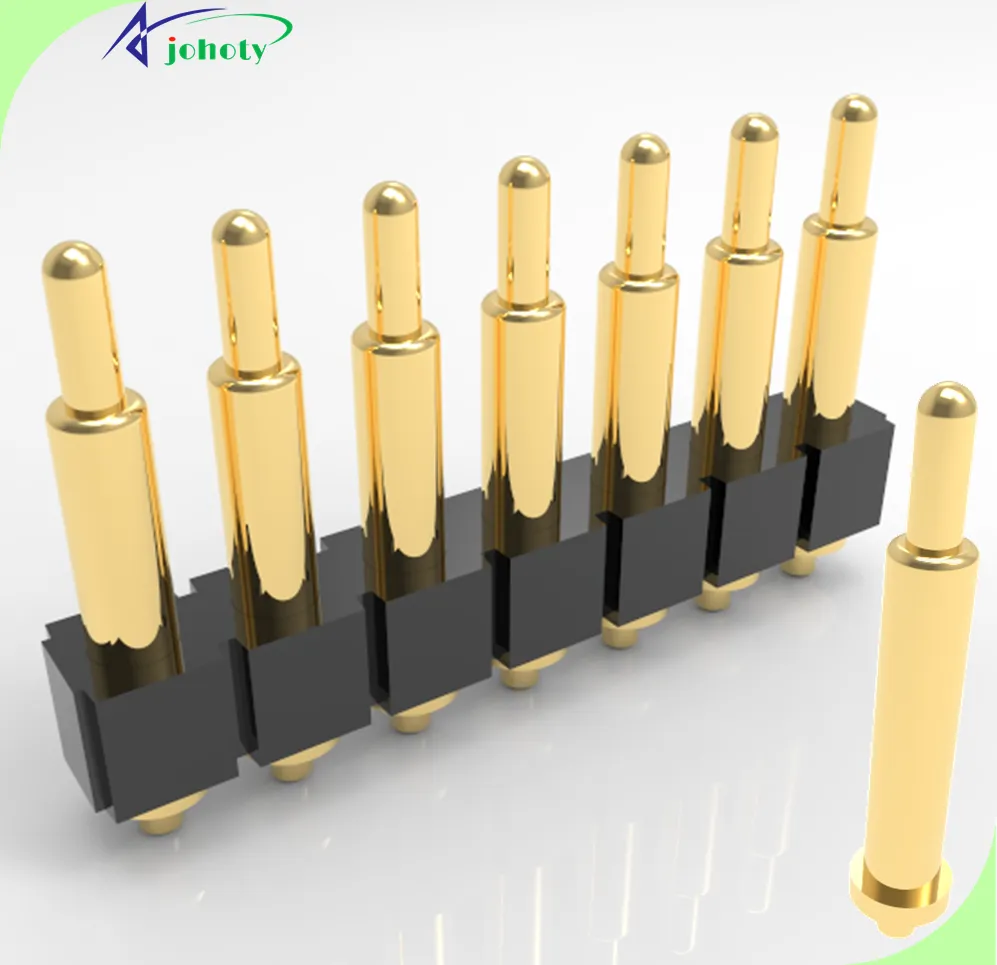

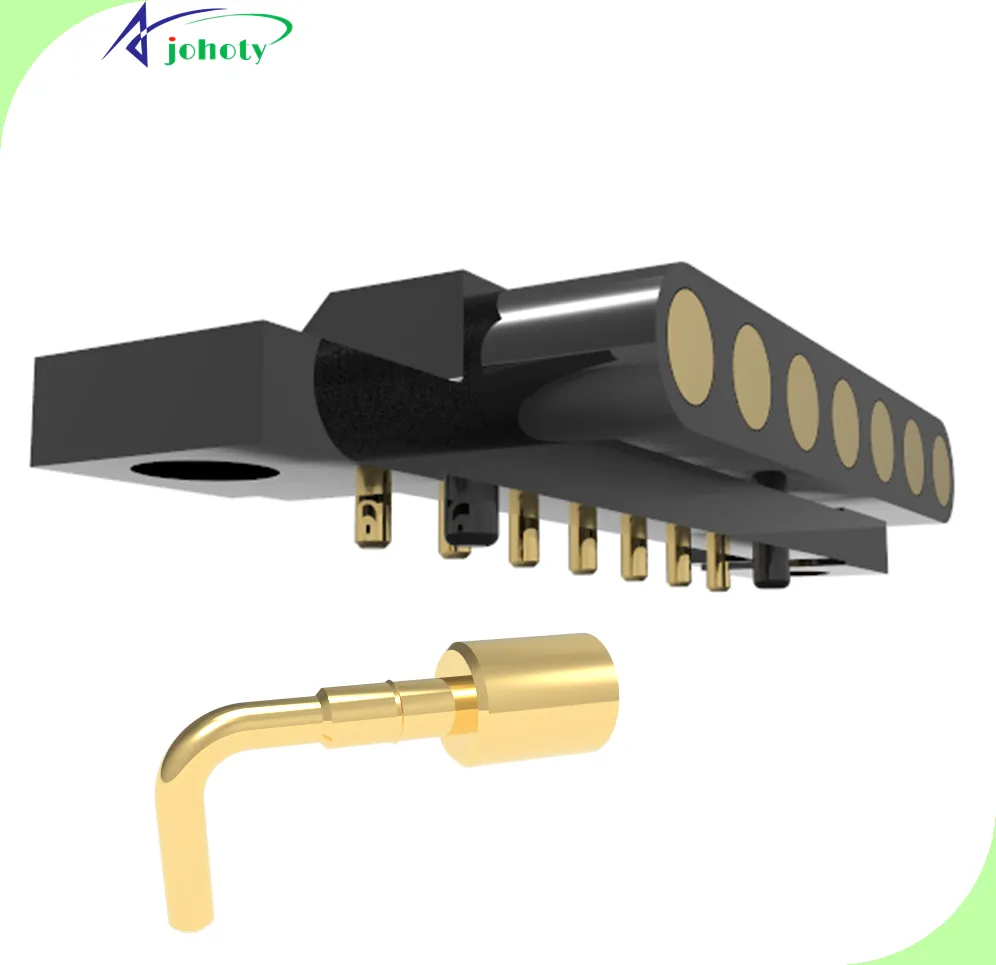

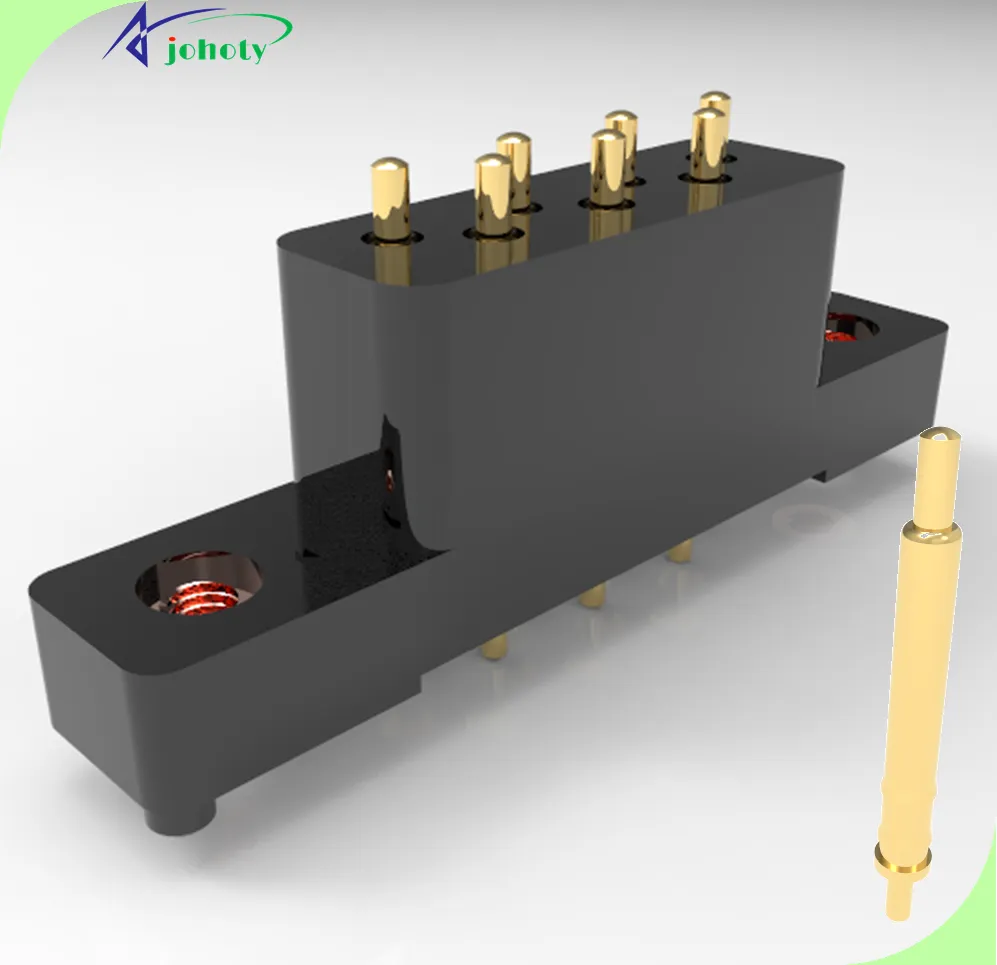

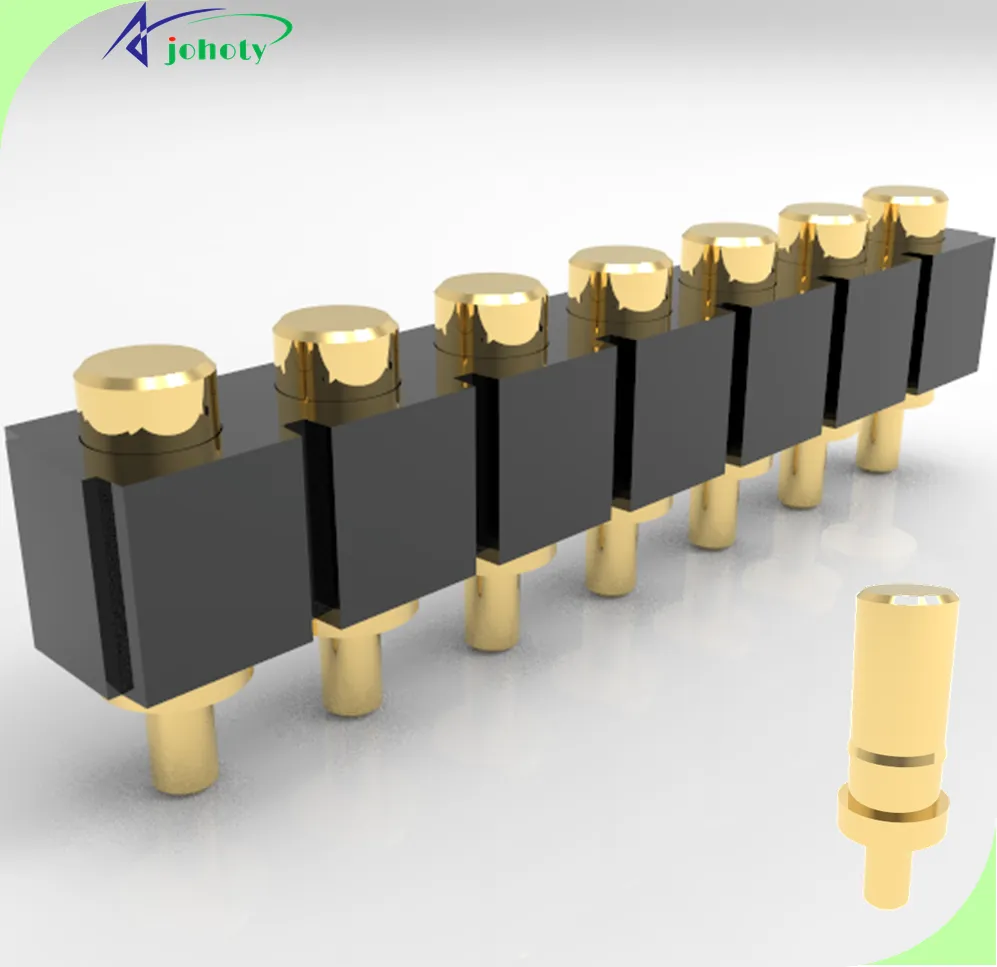

Male pin connectors and female pin connectors.