Precision Hardware, Best China Supplier, Manufacturer

Precision Hardware has excellent precision and durability, aluminum alloy or stainless steel. It is used in electronic devices, medical equipment, etc. Johoty can provide you with custom, safe and fast delivery, and technical support, bringing you quality assurance, cost-effectiveness, and satisfaction to help you succeed.

Product Features:

-

High precision,

-

Durable materials,

-

Unique design,

-

Easy to install,

-

Strong compatibility,

-

Reliable performance.

Precision Hardware Series:

Precision hardware is precision parts with ultra-high precision. Its material is sturdy and durable, with fine workmanship, easy operation, adaptability to various environments, precise control, and stable performance. It can help you rapidly complete your work more easily and accurately.

| Category | Description |

|---|---|

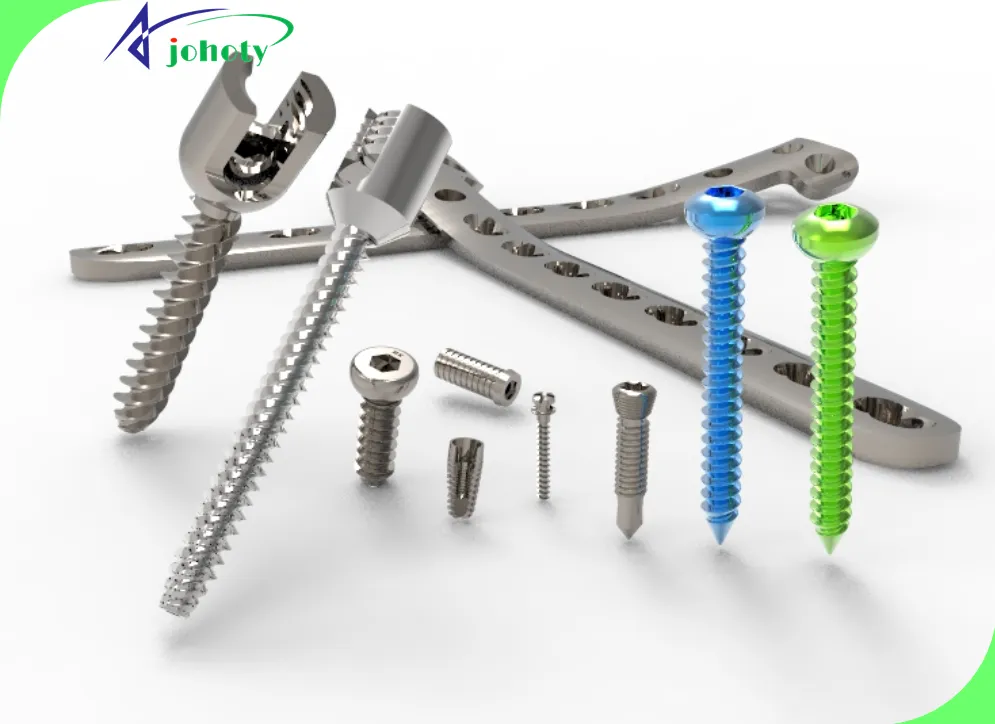

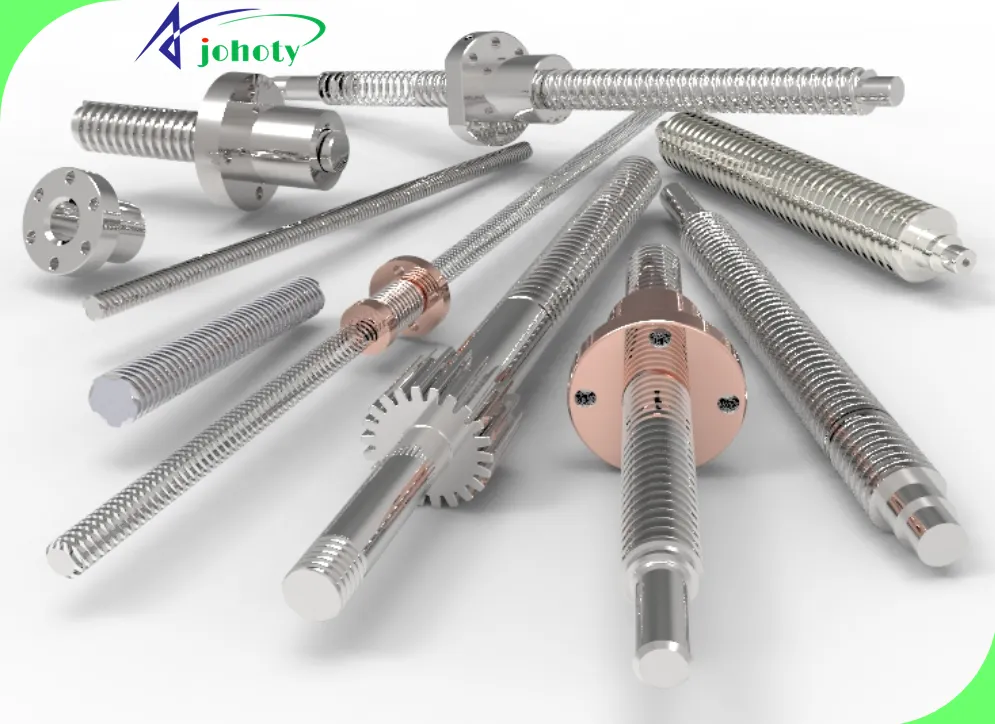

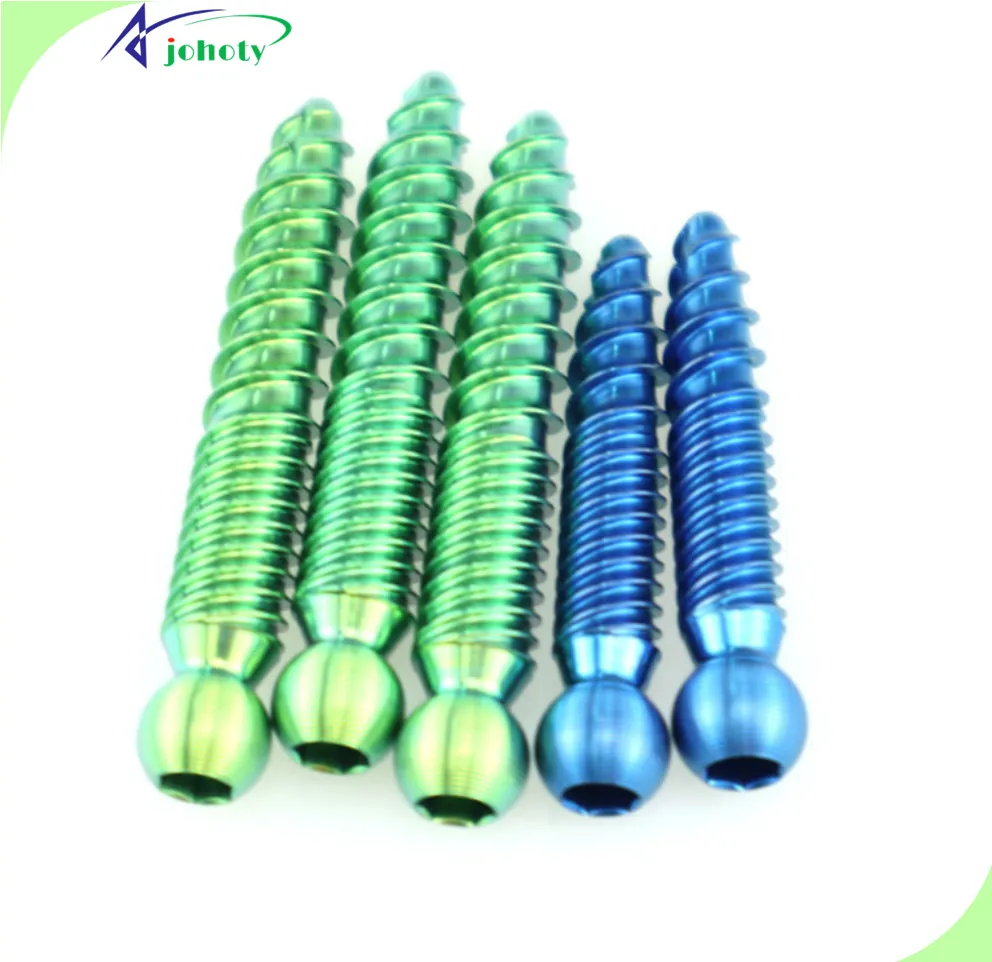

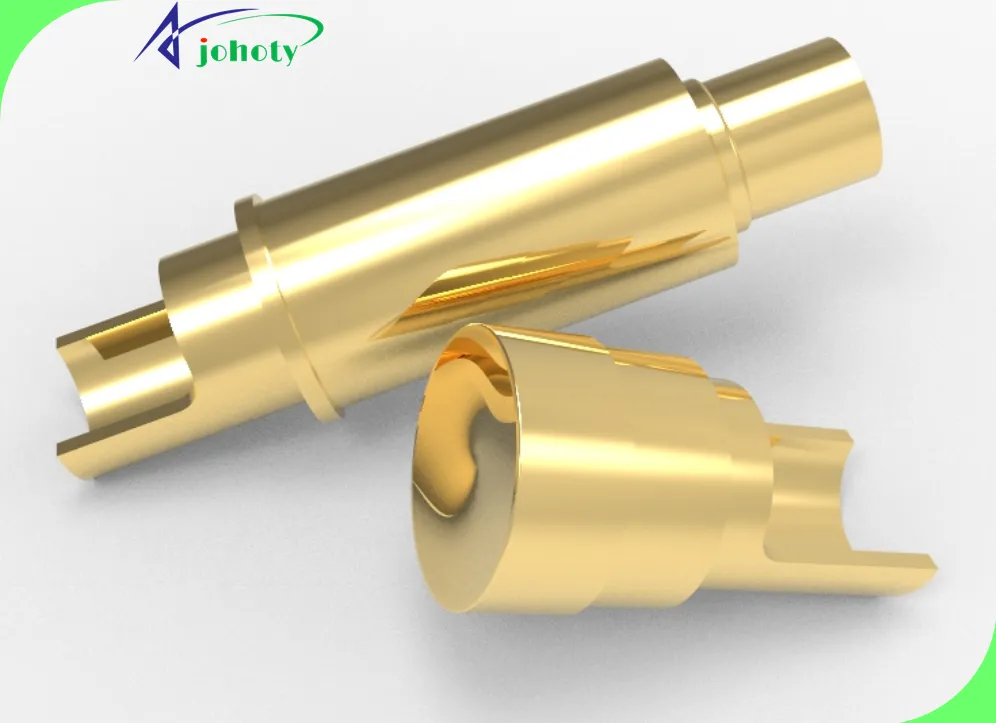

| Product Categories | Precision Hardware: CNC Part, Lead Screws, Medical Screws, Pogo Pins, Pogo Pin Connector, Valve, Gas Spring, etc. |

| Target Customer | Industrial manufacturers, OEM/ODM companies, Engineers, Sourcing Experts, Founders, etc. |

| Applications | Automotive, electronics, aerospace, medical R&D/manufacturering, construction, general engineering, etc. |

| Raw materials | Stainless steel, brass, aluminum alloy, titanium alloy, tungsten, gold, silver, platinum, palladium, rhodium, etc. |

| Function | High precision, stability, safety, durability, anti-vibration, corrosion resistance, and eco-friendly. |

| Brand Info | Johoty focuses on innovation, quality, and reliability, supported by years of engineering expertise. |

| Price Range | From affordable $1 for basic items to $500 for specialized and complex precision parts. |

| Quality | Comply with ISO9001, ASTM, DIN, JIS, RoHS, REACH, MIL, IPC, AISI, ISO45001. |

| Where to buy | Available through Johoty website (https://johoty.com), directly contact Johoty CFT team ([email protected]). |

| Customer Support | Johoty provides dedicated support via phone, email, and live chat (+86 18007608187) to assist you |

| User Feedback | High satisfaction due to high reliability, high precision, and ease of use in their projects. |

| Advantages | High precision manufacturing, customer-focused service, and extensive product range. |

| Disadvantages | Challenges involve rising raw material costs and competition from lower-cost international brands. |