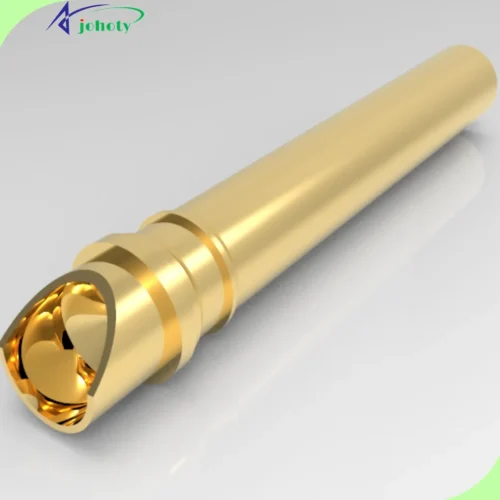

Spring Test Probe Description:

Spring Test Probe Datasheet:

| Items | Details |

|---|---|

| Specifications | Length: 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, custom. |

| Diameter: 0.5mm, 1mm, 1.5mm, 2mm, custom. | |

| Spring Force: 100g, 150g, 200g, 250g, 300g, custom. | |

| Stroke Range: 2mm, 3mm, 5mm, 7mm, custom. | |

| Electrical Resistance: < 1mΩ, custom. | |

| Insulation Resistance: > 1GΩ, custom. | |

| Contact Material: Gold, Nickel, Silver, custom. | |

| Current Capacity: 5A continuous, 10A peak, custom. | |

| Voltage Rating: 1000V DC, custom. | |

| Operating Temperature: -40°C to +150°C | |

| Storage Temperature: -55°C to +180°C | |

| Contact Resistance: < 1mΩ, custom. | |

| Vibration Resistance: Yes, absorbs vibrations for stable contact. | |

| Response Time: < 0.5ms. | |

| Durability: > 0.1 million cycles, custom. | |

| Materials | Plunger Tip: Stainless Steel, Beryllium Copper, custom. |

| Barrel: Stainless Steel, Beryllium Copper, custom. | |

| Spring: Stainless Steel, Music Wire, or Phosphor Bronze, custom. | |

| Finishing | Gold (Au): optional. |

| Silver (Ag): optional. | |

| Packaging | Packaging Type: Anti-static bag, foam insert, or custom. |

| Package Quantity: 100 pcs per box or custom. | |

| Package Size: 25x15x10 cm, or custom. | |

| Box Material: Acrylic (PMMA). | |

| Inner Packaging: Foam padding, or custom. | |

| Package Weight: ~0.5 kg per box. | |

| Labeling: Labels with P/N, spec, quantity, and custom. | |

| Sealing Method: Heat-sealed or tape-sealed, custom. |

Why Choose Johoty’s Spring Test Probe?

Johoty’s spring test probe hase >10 shapes of plunger tip, flexible custom of length, stroke, diameter, current, spring force, etc. Johoty is your trust partner!

Spring Test Probe Benefits:

Accurate Signal Transmission

Optimized Contact Design

High Reliability and Durability

Fast and Efficient Testing

Spring Test Probe Applications:

Test the PCBA Connectivity

Check If the Voltage and Current Are Stable

Measure Signal Quality

Detect Short and Open Circuits

Test the Quality of Welding Points

Measure the Power Supply Voltage

Test High-frequency Signal Transfer

Simulated Environmental Change Testing

The ICT spring test probe can be used to simulate different temperatures and humidities to test PCBA stability in various environments. A circuit board is like a plant, and changes may affect its health in the environment. ICT test probe is like a simulator for climate change, it can help engineers detect whether circuit boards can still function properly in cold, humid, or hot, ensuring good performance in any environment.

Spring Test Probe Advantages:

Improve Testing Efficiency

The ICT spring test probe can improve the testing speed, allowing test engineers to complete more testing work in a shorter time. It’s like when you’re working on a project, if the tools are complete and efficient, you can finish it faster.

Reduce Physical Damage

The ICT spring test probe designs can help reduce physical damage to circuit boards. It’s like carefully holding something and not letting it fall off. When using Johoty’s test probes, it will not cause significant scratches or damage to the circuit board, thereby improving the reliability of the product.

Reliable Contact Force

Johoty’s spring test probe can maintain stable contact force for a long time. This means you can ignore the usage times it is used, its contact effect will not deteriorate. You can imagine the test probe as a very powerful suction cup, always firmly holding onto the object without loosening.

Accurate Measurement of Voltage and Current

The ICT spring test probe can accurately measure voltage and current in circuits. It is like an electronic thermometer that can help TE engineers ensure that the circuit is working properly and there are no issues with high or low voltage.

FAQ

The spring test probe can provide constant contact force and ensure a stable connection with the tested board. The test probe tip aligns with the test point and establishes a physical connection through spring compression and release. They can enable the stable transfer and measurement of signals or currents.

When you select a spring test probe to use in ICT or FCT, you need to think about its size, stroke, and probe pitch first. and others, including contact resistance, rating current, required contact force, and your testing environment. We need to know the specific requirements and testing conditions of the tested board (UUT), this helps define test probe tips.

Lower contact impedance results in higher signal quality. A good test probe can minimize contact impedance, enhancing test accuracy and reliability.