Pogo Pin Connectors Description:

Pogo Pin Connectors Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: 15 mΩ ~ 200 mΩ, Custom. |

| Rated current: 1.0 A to 150 A, Custom. | |

| Rated voltage: 12 V to 600 V, Custom. | |

| Insulation impedance: ≥500 MΩ, Custom. | |

| EMI: Support. Custom. | |

| Transfer speed: Up to 5Gbps | |

| Working frequency: From MHz to GHz, Custom. | |

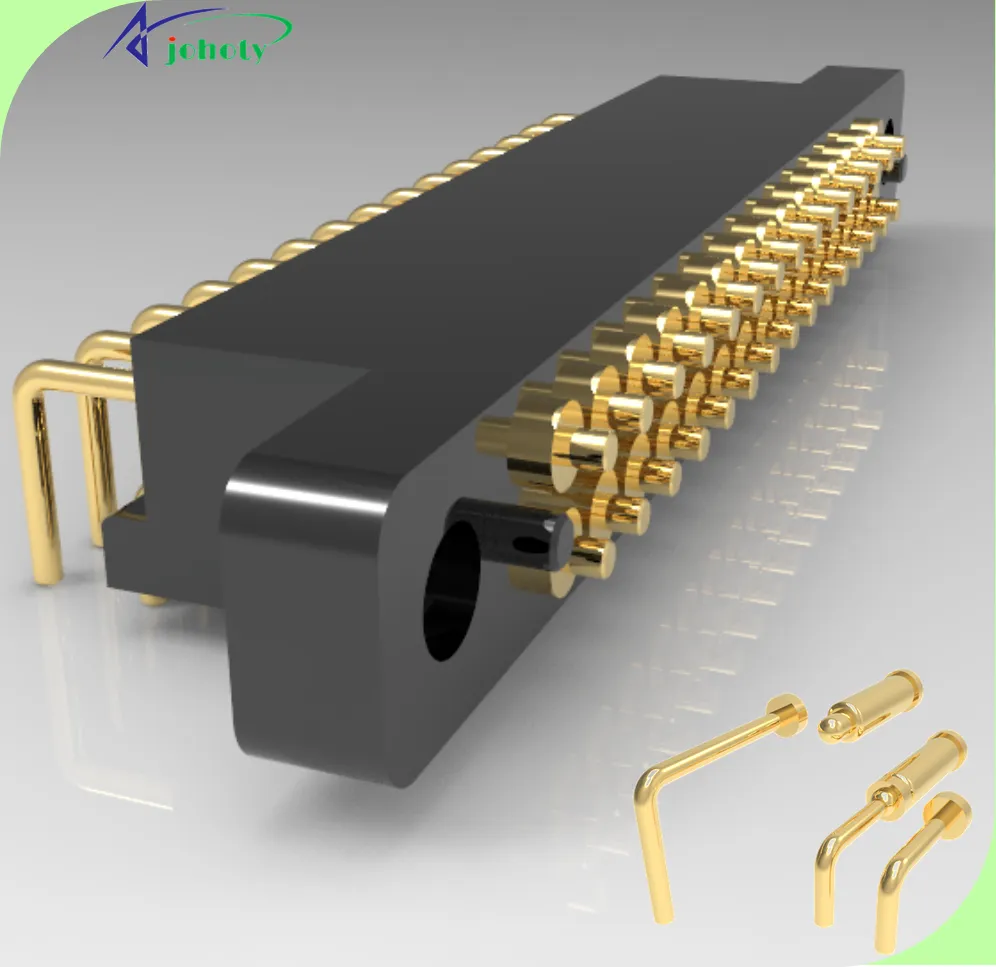

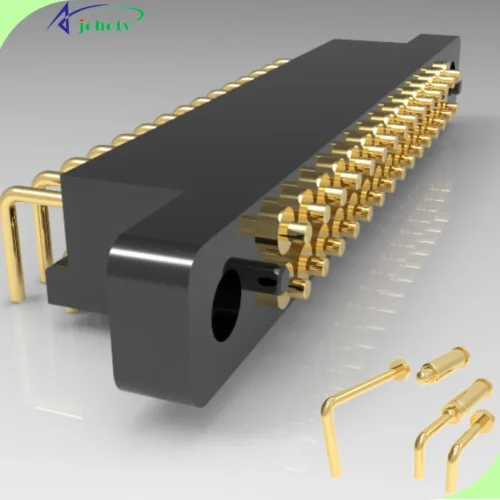

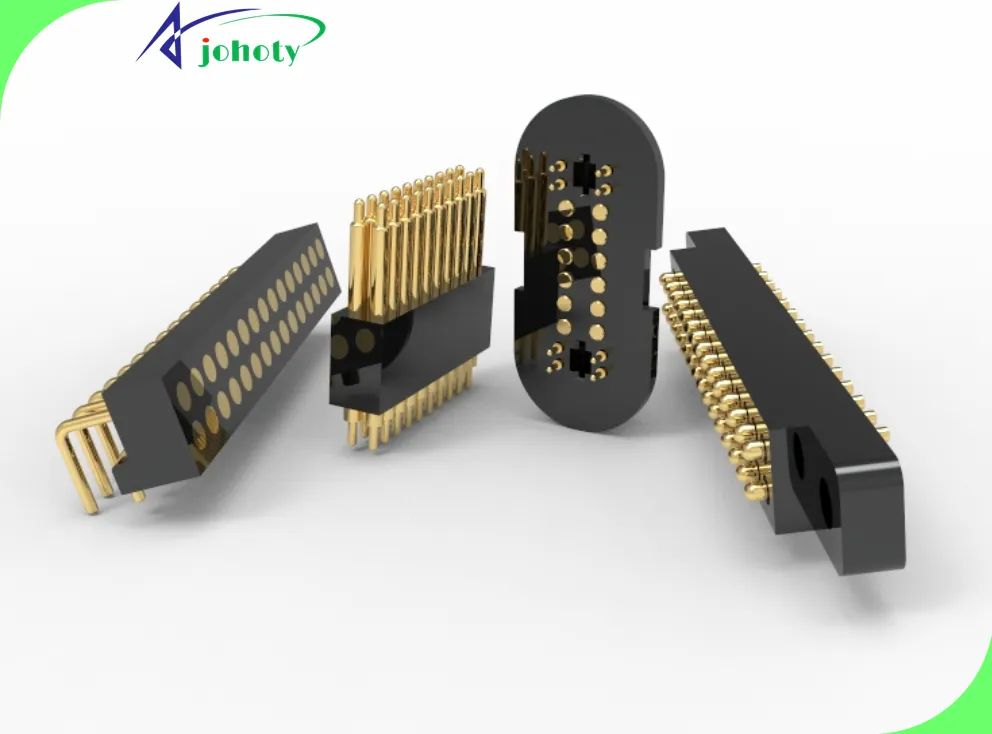

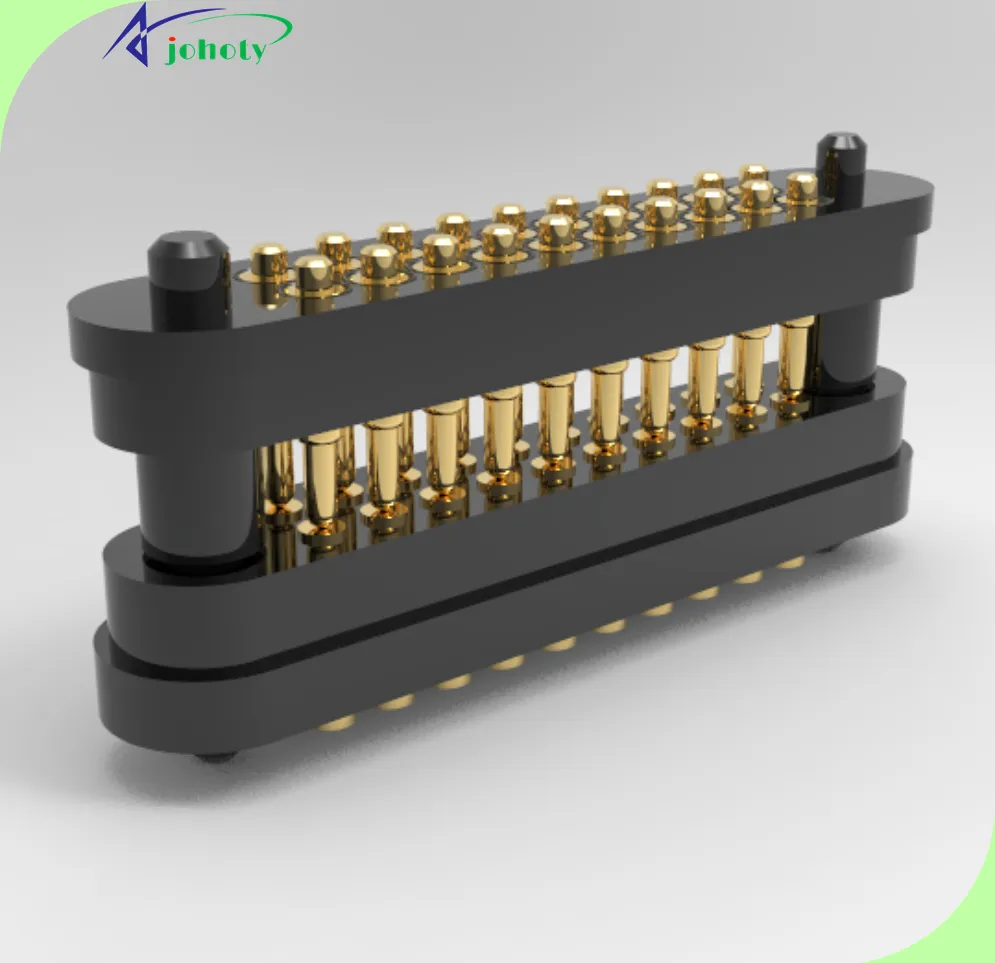

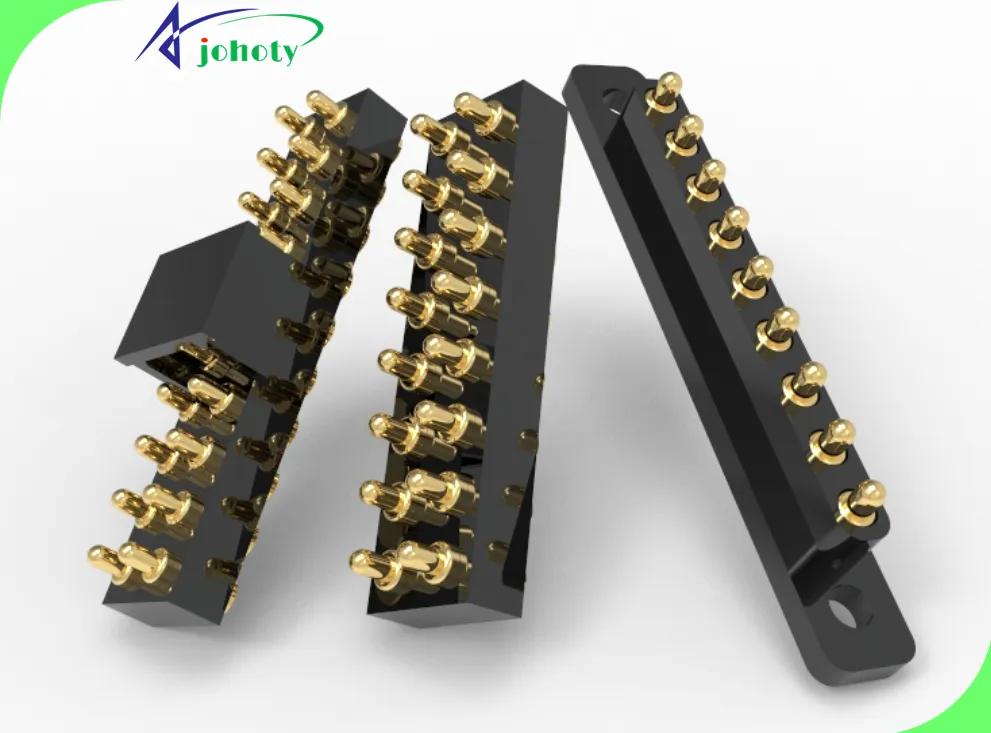

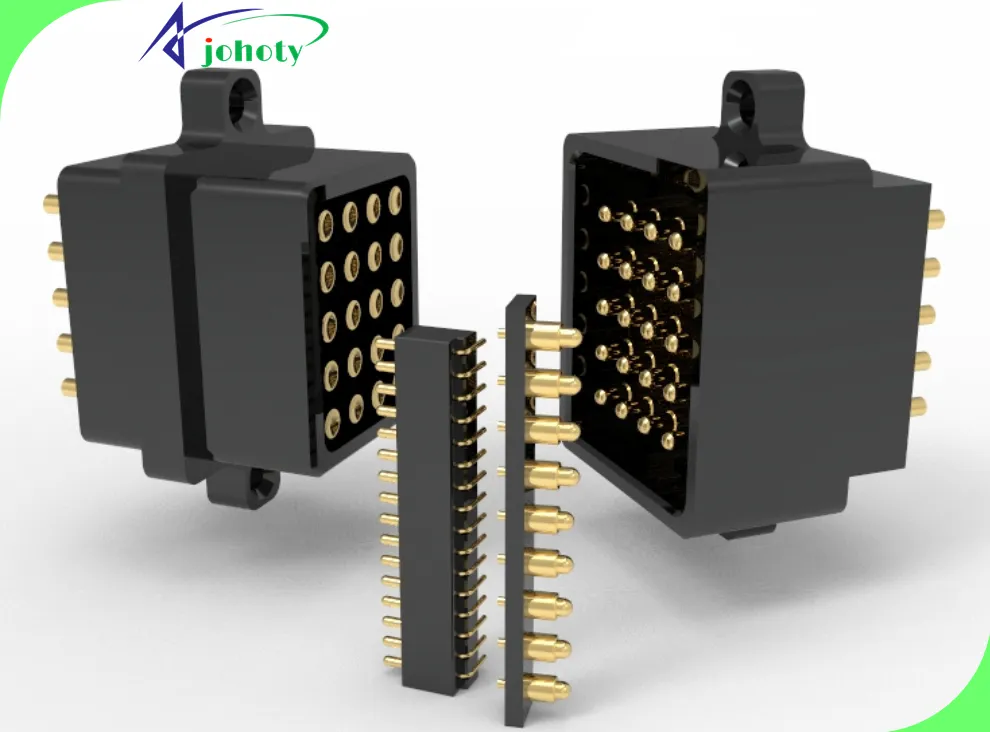

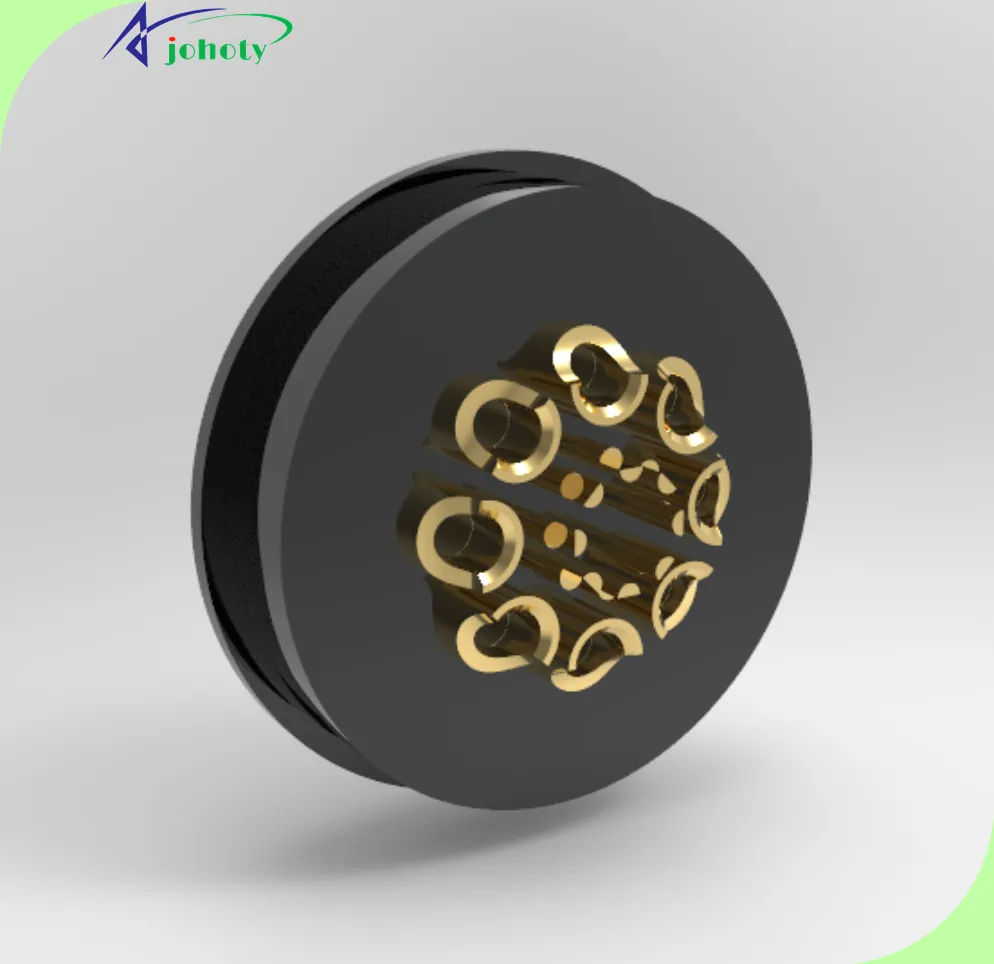

| Mechanical: | Shapes: 9, 14~598 pins, single/dual rows, SMT, DIP, Solder-cup, Right-Angle, Bending type, Rectangle, Round, Custom. |

| Spring force: ≥30gf, Custom. | |

| Pitch: 1.00mm~12.00mm, Custom. | |

| Stroke: ≥0.15mm, Custom. | |

| Length: ≥1.55mm, Custom. | |

| Barrer diameter: ≥0.84mm, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, female preferred, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: 10,000 ~ 200,000 cycles, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Plunger/Barrer: Brass, copper alloys (beryllium copper, tellurium copper), stainless steel, etc. |

| Housing: Plastics (nylon, PA66, PTE, PPS, PBT), stainless steel, aluminum alloy, etc. | |

| Spring: Gold-plated, music steel, stainless steel, etc. | |

| Ball: Steel, zirconium, ceramic, Custom. | |

| Sealing: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating: >1.5u”, Gold, silver, nickel, composite plating, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: PI, PTFE, PBT, Nylon, Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, ASTM B488, ASTM B733, etc. | |

| Flammability rating: UL94 V-0, etc. | |

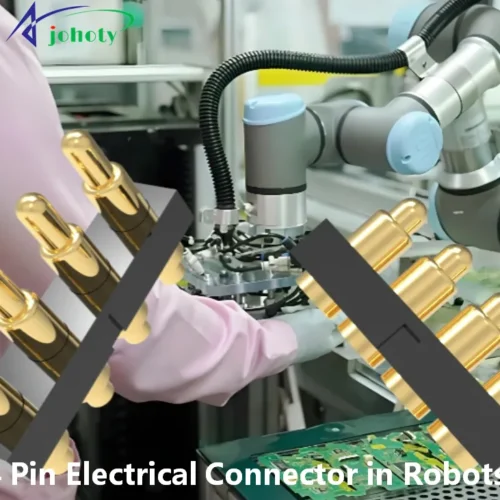

| Installation: | Surface mount: SMT, vertical, automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin, surface mounting, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact, high-vibration. | |

| Embedded: High waterproof and sealing requirements. | |

| Quick: Testing equipment. | |

| Locking: Screws, nut, additional mechanical fixation force. | |

| Slot: High requirements for connection stability. | |

| Package: | T&R(tape and reel), tray, bulk, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s Pogo Pin Connectors?

Pogo pin connectors has flexible customized shapes, sizes, durability, waterproof, and EMI performance. Johoty is trustworthy!

Pogo Pin Connectors Benefits:

Support More Feature Integration

Reduce Costs of Maintenance, Upgrade, Operation

Provide Long-term Stability

Improve Overall Equipment Efficiency

Pogo Pin Connectors Applications:

Surgical Robot

High-end Audio Equipment

High-precision 3D Printer

Offshore Wind Power Generation Equipment

Intelligent Wearable Medical Devices

Deep Sea Exploration Equipment

On-board Radar for Autonomous Vehicles

Military Electronic Equipment

Pogo Pin Connectors Advantages:

Independent Spring Structure Reduces Contact Failure Rate

The independent spring design is a major feature of pogo pin connectors. Each spring needle has its independent spring, and the damage to one pogo pin will not affect the overall connection effect. Engineers love this design because it greatly reduces the risk of poor contact during equipment operation, saves maintenance costs, and maintains long-term stable operation of the equipment.

Small Pitch Design, Suitable for High-density Requirements

Pogo pin connectors can accommodate more pogo pins in a small space, just like stuffing many people into a small meeting room without feeling crowded. This is great for engineers, especially in mobile phones, wearable devices, etc. Although the pogo pins are densely packed, each pogo pin still maintains excellent contact and ensures the reliability of signal and current.

Super Strong Seismic Resistance for Harsh Environments

This pogo pin connectors can withstand device vibrations or various bumps during transportation, just like running with a specially designed shock-absorbing insole, stable. For engineers, this advantage is suitable for aerospace and automotive that are prone to vibration. The device will not cause pogo pin connector damage or signal interruption due to vibration during transportation and use, which is really considerate.

Metal Plating Layer, Anti-oxidation and More Durable

The surface of pogo pin connectors has a high-performance metal coating, just like an iron door brushed with anti rust paint, which is not afraid of rusting over time. This design allows the spring loaded pin to maintain stable connection even in humid, high temperature, or chemical environments, extending the service life of the equipment. Engineers particularly love this because it saves the trouble of frequently replacing connectors.

Support Multiple Current Specifications, Strong Adaptability

This pogo pin connectors can support both high and low current transfer, just like a water pipe can simultaneously transport large and small water flows. Both high-power devices and small sensors can use this pogo pin connector to meet various needs. Engineers find it particularly convenient as they no longer have to search for different models every time, reducing the difficulty of procurement and design.

Modular Assembly, Fast Customization Capability

Pogo pin connectors can be quickly assembled and customized to different specifications and sizes according to requirements. Engineers’ projects often require highly customized equipment, and this modular design greatly shortens the production cycle while ensuring high precision and consistency, truly helping them achieve WYSIWYG.

FAQ

Absolutely, we offer comprehensive customization options, from pin diameter, length, stroke, shape, and spring force, to coating materials. This can ensure the precise fit of your specific applications and performance criteria.

Our pogo pin connectors are crafted from premium Tellurium copper, beryllium copper, stainless steel, and LEAN manufacturing. Including precision spring technology and high-conductivity gold plating. They can guarantee long-lasting electrical connections and stellar mechanical performance. Even under frequent plugging/unplugging and tough conditions.

Our Pogo Pin Connectors are designed with durability in mind. Using wear-resistant materials and an optimized structural design, for example, a 3-piece part, a 4-piece part, or a 5-piece part, They can support 10,000 times of connection cycles. this can reduce maintenance costs and boost efficiency.