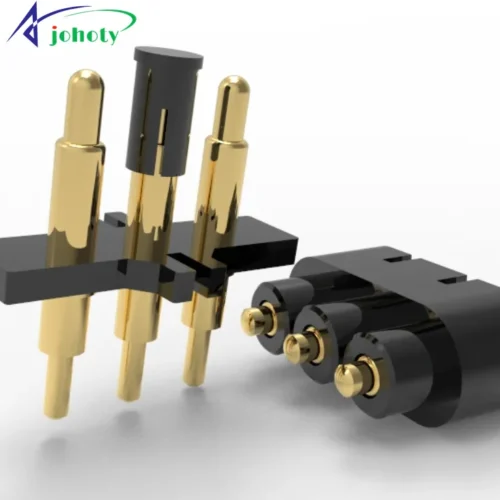

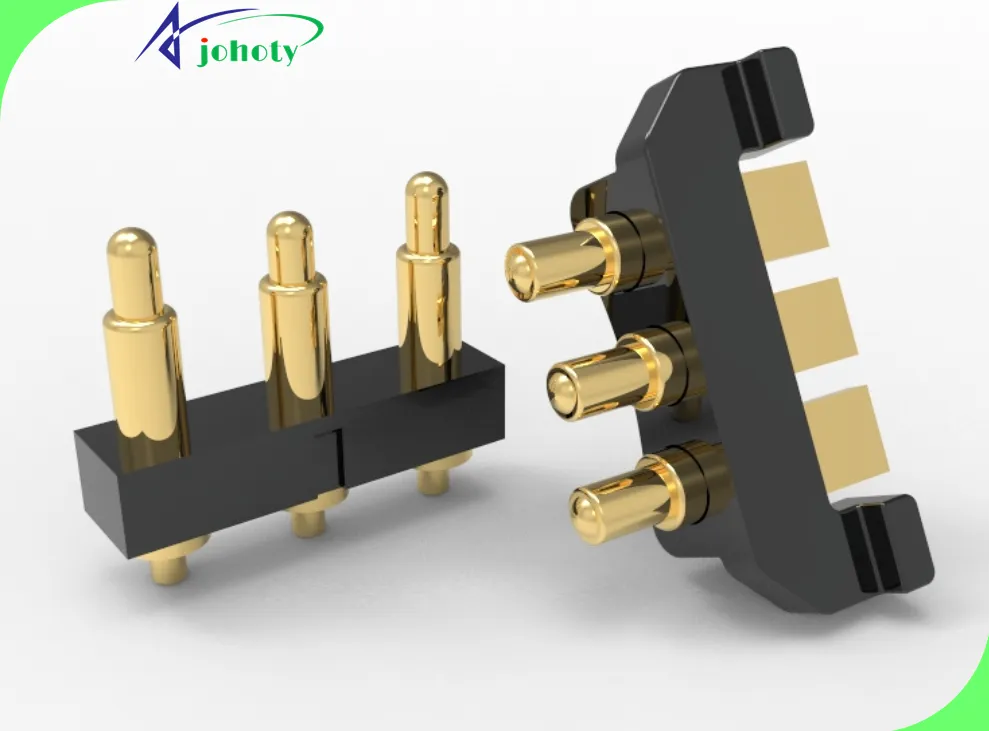

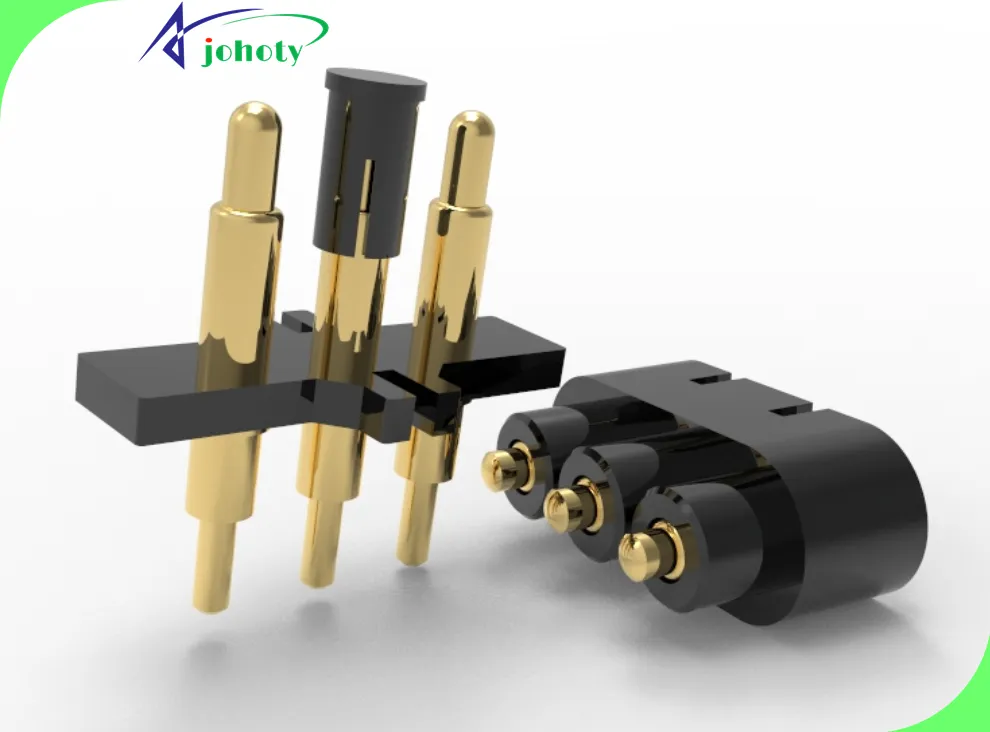

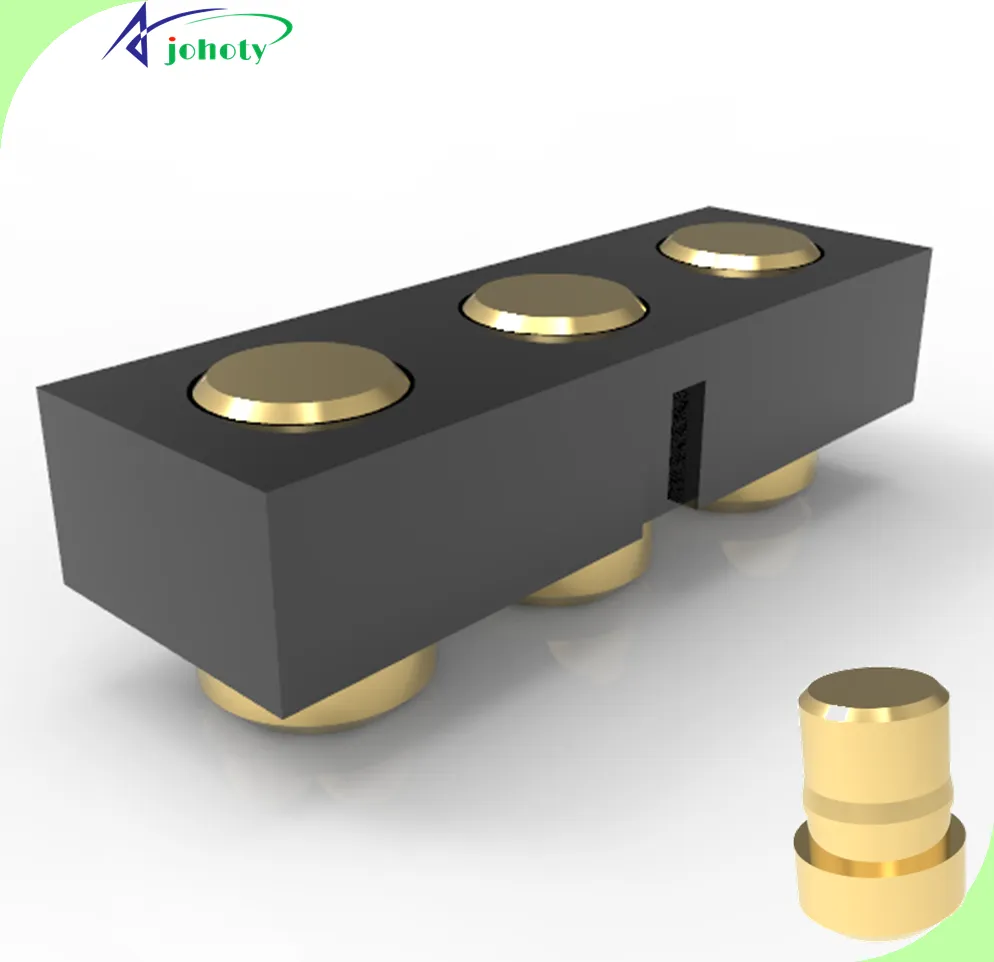

3 Pin Connector Description:

3 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: ≥15mΩ, Custom. |

| Rated current: 0.1A~100A, Custom. | |

| Rated voltage: 3.3V ~1,000V, Cusotm. | |

| Electrical insulation impedance: >100MΩ, Custom. | |

| EMI: Can be compatible. Custom. | |

| Working frequency: From MHz to GHz, Custom. | |

| Mechanical: | Contact force: ≥15gf, Custom. |

| Pitch: ≥1.50mm Custom. | |

| Stroke: ≥0.60mm, Custom. | |

| Barrer diameter: ≥0.50mm, Custom. | |

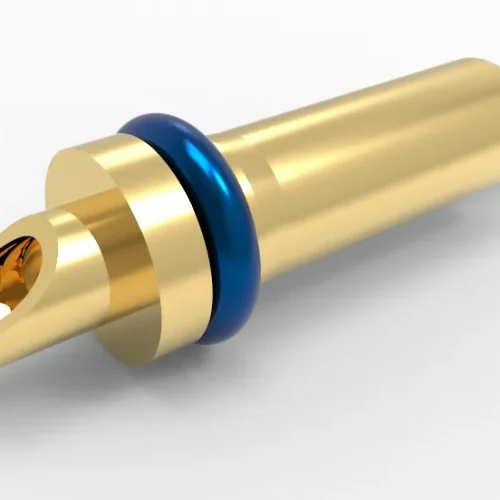

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Plug and unplug: 10,000 ~ 200,000 times, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Contact materials: Copper, copper alloys (phosphor copper), gold, etc. |

| Housing materials: Ctainless steel, aluminum alloy, plastic (PA, PPS, PBT, nylon), etc. | |

| Insulation materials: PI, PTFE, PBT, Nylon, etc. | |

| Spring materials: Gold-plated copper, phosphor copper, music steel, and, stainless steel, etc. | |

| Ball materials: Steel, zirconium, ceramic, Custom. | |

| Sealing materials: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating materials: Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering materials: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: Polyurethane, silicone, rubber, etc. | |

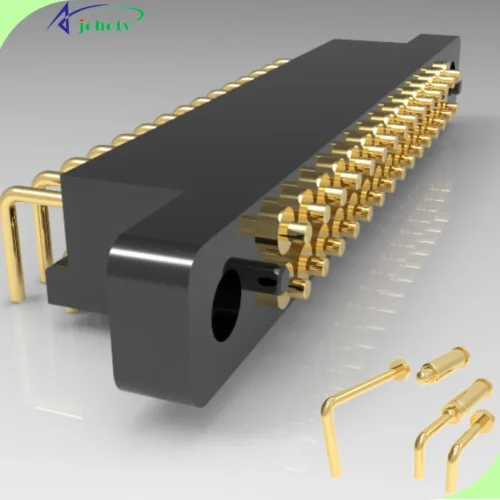

| Installation: | Surface mount: SMT, Automated production line. |

| Through-hole installation: Stable, high current, mechanical stress resistance. | |

| Right Angle installation: Limited space or a dynamic connection. | |

| Soldering installation: High current. | |

| Spring installation: Anti-vibration, anti-impact, high-vibration. | |

| Embedded installation: High waterproof and sealing requirements. | |

| Quick installation/disassembly: Testing equipment. | |

| Locking installation: Screws, nut, additional mechanical fixation force. | |

| Slot installation: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 3 Pin Connector?

3 pin connector has male & female to transfer power and signals, best price, flexible custom, Johoty is trustworthy!

3 Pin Connector Benefits:

Improve Equipment Performance and Reliability

Supports Multiple Functions and Adapts to Diverse Needs

Save Maintenance Costs and Reduce Downtime

Dual Advantages of Environmental Protection and Economy

3 Pin Connector Applications:

Consumer Electronics

Automotive Industry

Medical Equipment

Industrial Automation

Aerospace

New energy industry

Testing and Measuring Equipment

Military Equipment

3 Pin Connector Advantages:

High reliability

Easy to Install

Strong Adaptability

Save space

FAQ

Our approach involves rigorous quality management and oversight across all process stages. It is from raw material to production. Our 3 pin waterproof connector complies with relevant international and industry standards. This can completely ensure the high-quality and strong safety of our 3 pin connector.

We offer a wide range of sizes and shapes to meet the design needs of different customer devices. Our 3 pin connector has through-hole mounting, SMT mounting. Right-angle mounting, solder cup mounting, double-ended type, and so on. They form for customers to choose flexibly.

Our 3 pin connector has excellent electrical performance. Including low contact resistance, high conductivity, stable rated voltage and high current, and other characteristics. Our 3 pin connectors are rigorously tested and verified. This ensures consistent signal transfer and reliable power supply in different operating conditions.