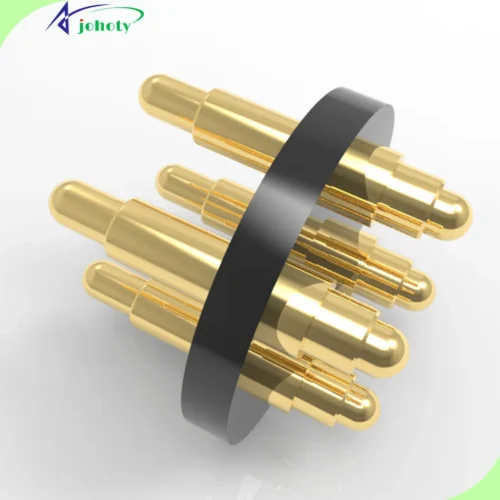

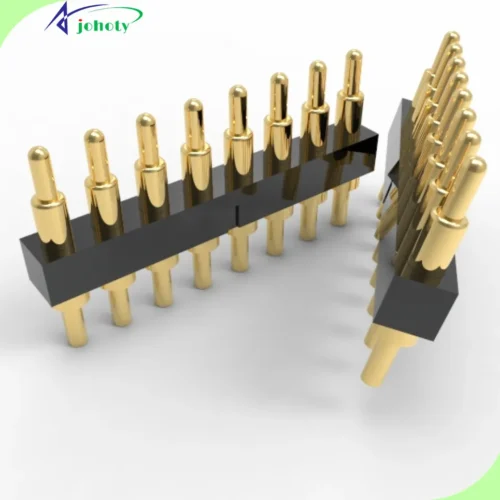

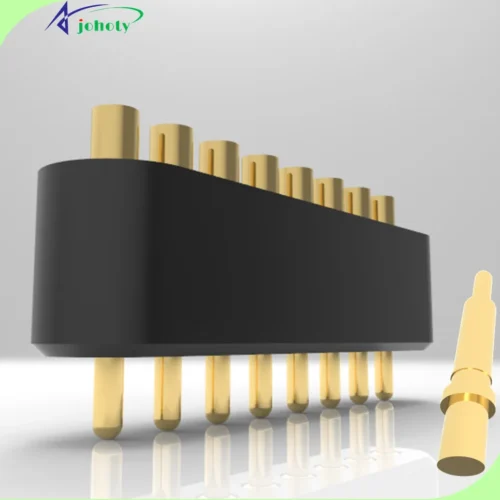

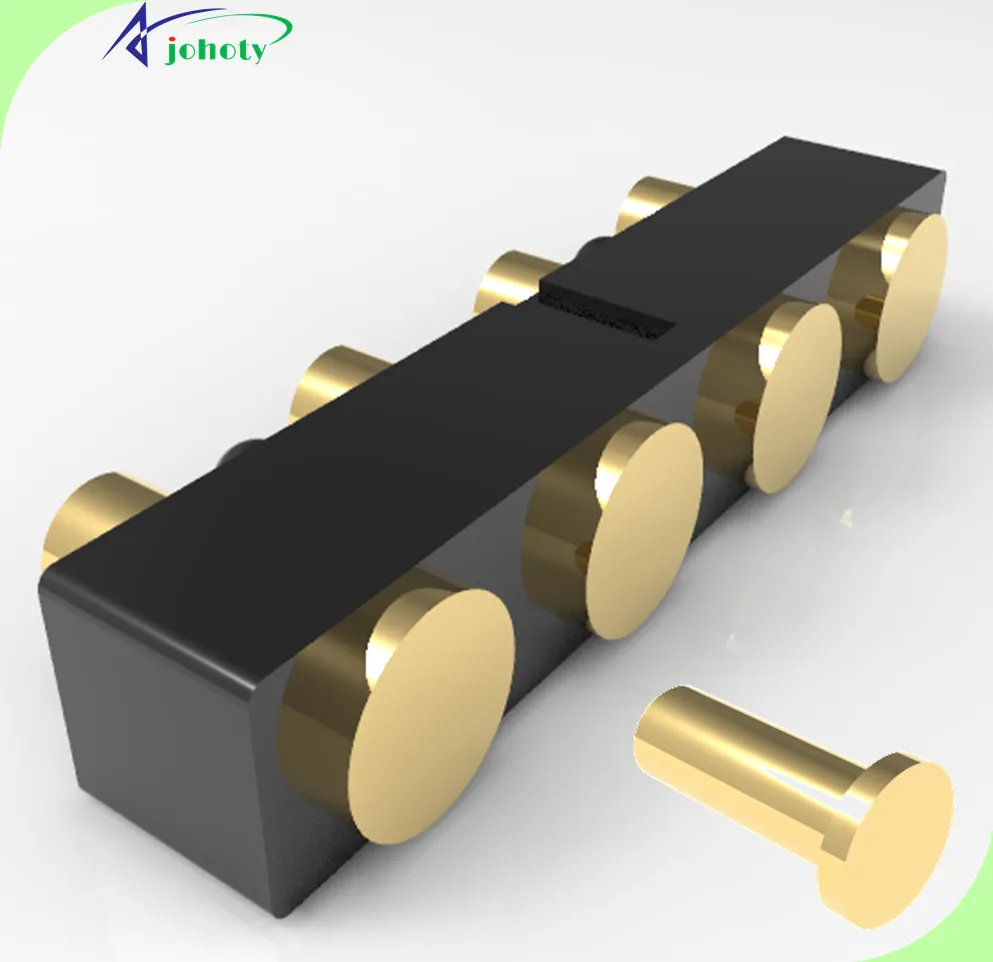

4 Pin Connector Description:

Catalogs of 4 Pin Connector:

4 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: ≥15mΩ, Custom. |

| Rated current: 0.1A~50A, Custom. | |

| Rated voltage: 3.3V ~230V, Cusotm. | |

| Insulation impedance: >100MΩ, Custom. | |

| EMI: Can be compatible. Custom. | |

| Working frequency: From MHz to GHz, Custom. | |

| Mechanical: | Contact force: ≥15gf, Custom. |

| Pitch: ≥1.27mm, Custom. | |

| Stroke: ≥0.40mm, Custom. | |

| Length: ≥2.80mm, Custom. | |

| Barrer diameter: ≥0.50mm, Custom. | |

| Shapes: Single-row, Dual-rows, SMT, DIP, Double-ended, Solder-cup, Right-Angle, Bending type, Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Plug and unplug: 10,000 ~ 200,000 times, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Plunger tip/barrer materials: Copper, copper alloys (phosphor copper), stainless steel, gold, etc. |

| Housing materials: Ctainless steel, aluminum alloy, plastic (nylon, PA, PPS, PBT), etc. | |

| Insulation materials: PI, PTFE, PBT, Nylon, etc. | |

| Spring materials: Gold-plated copper, phosphor copper, music steel, stainless steel, etc. | |

| Ball materials: Steel, zirconium, ceramic, Custom. | |

| Sealing materials: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating materials: Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering materials: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: Polyurethane, silicone, rubber, etc. | |

| Installation: | Surface mount: SMT, Automated production line. |

| Through-hole installation: Stable, high current, mechanical stress resistance. | |

| Right Angle installation: Limited space or a dynamic connection. | |

| Soldering installation: High current. | |

| Spring installation: Anti-vibration, anti-impact, high-vibration. | |

| Embedded installation: High waterproof and sealing requirements. | |

| Quick installation/disassembly: Testing equipment. | |

| Locking installation: Screws, nut, additional mechanical fixation force. | |

| Slot installation: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 4 Pin Connector?

4 pin connector has customized single or dual rows, male & female to transfer power and signals at best price, Johoty is trustworthy!

4 Pin Connector Benefits:

High-reliability Connection

Space Saving and Design Flexibility

Reduce Repair costs, Improve Assembly Efficiency

Support Diversified Function Integration

4 Pin Connector Applications:

Medical Equipment Connection

Industrial Automation

Communication Equipment

Automotive Electronics

Smart Home Devices

Consumer Electronics Products

Aerospace

Wearable Devices

4 Pin Connector Advantages:

high Reliability

Space Saving and Design Flexibility

Improve Assembly Efficiency

Diversified Functional Integration

FAQ

Selecting the right 4 pin connector requires consideration of the application’s electrical requirements, e.g. voltage, and current. environmental conditions, temperature, humidity, whether water and dustproofing are required? Mechanical characteristics, number of plugs and unplugs, locking mechanism. and dimensional constraints.

Yes, some connectors are designed to support data transfer for applications that require both power and data transfer.

Yes, we offer customization services, including customizing pin configurations, dimensions, materials, and special performance. Our goals are to adequately address the needs of various distinct applications.