What Is Precision Machining? Explore its Key Role in Producing Accurate CNC Parts to Meet High Industry Standards and Achieve Flawless Performance

Introduction: What is Precision Machining?

Precision machining is a high-tech process that uses advanced technology and equipment—like cutting, grinding, and turning—to shape raw materials into parts with extremely tight tolerances. This method is crucial in modern manufacturing, especially in industries with strict requirements for dimensions and tolerances, such as aerospace, medical devices, and electronics.

Johoty specializes in precision machining to create high-accuracy CNC parts that meet demanding standards for quality, performance, and efficiency, ensuring each component performs flawlessly in complex applications.

Origins and Development of Precision Machining: What is Precision Machining?

Precision machining began during the Industrial Revolution, as industries sought higher quality and more complex machine parts. Traditional methods were limited by manual precision and efficiency, but the advent of precision machining transformed the landscape. The introduction of CNC technology in the mid-20th century propelled precision machining to new heights by allowing computers to automate complex tasks, surpassing the constraints of manual operations and vastly improving consistency and accuracy.

With ongoing advancements in CNC technology, precision machining now includes various materials and integrated processes, far beyond simple metalworking. Today, Johoty leverages cutting-edge CNC equipment and innovative techniques to achieve higher precision, more intricate designs, and faster production cycles, meeting the stringent demands of industries like aerospace, medical devices, and electronics. Through these technological advancements, Johoty sets new industry standards for producing high-precision CNC parts, ensuring optimal performance in every piece.

Technical Principles of Precision Machining: What is Precision Machining?

Precision machining is a critical technique in manufacturing high-precision, complex components. But how is it achieved, and what unique technical principles underpin Johoty’s CNC parts production?

The Core Principle of CNC Systems

- At the heart of precision machining lies CNC (Computer Numerical Control) systems, which precisely control tools based on pre-programmed code. Johoty’s CNC equipment uses G-code to translate design blueprints into specific machining paths, ensuring every step meets exacting standards. This automated programming approach allows Johoty to machine with micron-level accuracy.

Multi-Axis Synchronized Machining

- Utilizing advanced multi-axis machining, particularly with five-axis centers, Johoty can cut from various angles simultaneously. This technique not only allows for machining complex surfaces and angles but also reduces repositioning errors during multiple setups, enhancing overall accuracy. Multi-axis machining reduces steps, lowers error rates, and ensures consistent machining across all angles.

Micron-Level Tool Displacement Control

- Tool displacement control is essential in precision machining. Johoty’s CNC machines utilize linear encoders and laser interferometers for real-time position monitoring and adjustments. This micron-level control ensures smooth surfaces and consistent quality on every part, delivering the highest standards in the final product.

Thermal Stability Management

- Temperature shifts can affect how accurately machines work, especially in precision tasks. Johoty uses a temperature control system to manage the heat of both machines and tools in real-time, preventing material and tool size changes due to temperature shifts during high-precision cuts. Additionally, they use specialized coolant to maintain constant temperatures for both tools and workpieces, enhancing accuracy and tool longevity.

High-Precision Fixtures and Positioning System

- To ensure stability and exact positioning of workpieces during machining, Johoty employs custom high-precision fixtures and an automated positioning system. These systems automatically calibrate positions with each setup, minimizing human error and securing precise positioning for every part, providing a solid foundation for subsequent processes.

High-Frequency Vibration Cutting Technology

- Johoty uses high-frequency vibration cutting technology to reduce heat and friction during machining. This technology prevents chips from sticking to the tool, keeping it sharper and extending its lifespan. High-frequency cutting also improves surface smoothness, making it ideal for producing various high-precision parts.

Automated Inspection and Feedback System

- To ensure each step in precision machining meets exact standards, Johoty integrates automated inspection and feedback systems into their CNC equipment. These systems detect dimensions, shapes, and surface finishes in real-time, making adjustments immediately if any deviations arise, ensuring every product meets the client’s high standards.

Johoty elevates CNC precision machining to new levels. In precision manufacturing, Johoty not only delivers unparalleled technical prowess but also provides top-quality CNC parts and machining services for high-end industries. If your project demands exceptional accuracy and complexity, choosing Johoty means choosing reliability and perfection.

Johoty’s Precision Machining Capabilities: What is Precision Machining?

Precision machining is a core element of modern manufacturing, involving detailed processing of materials with advanced equipment to produce parts that meet strict standards for accuracy and complexity. So, what unique skills and technologies define precision machining? With its top-tier CNC precision machining abilities, Johoty stands out in the industry.

Ultra-High Precision

- Using advanced CNC (Computer Numerical Control) technology, Johoty achieves accuracy as high as ±0.001mm on every small detail, ensuring perfect part fit and greatly improving product durability.

Multi-Axis Machining and Complex Geometries

- Johoty’s five-axis machining centers handle complex geometries and challenging materials, allowing them to manufacture parts with unique designs and intricate features to meet the needs of high-demand industries.

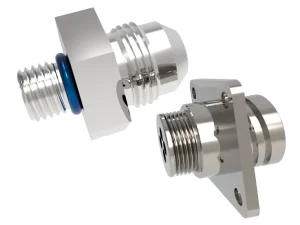

Diverse Materials and High-Strength Material Processing

- Johoty has extensive experience and expertise in machining various high-strength materials, including stainless steel, aluminum alloys, and titanium alloys. Whether it’s high-hardness titanium or corrosion-resistant high-nickel alloys, Johoty’s precision machining transforms them into ideal precision parts.

Stringent Quality Control

- Every CNC part produced by Johoty undergoes rigorous quality checks, including dimensional inspection, surface roughness measurement, and geometric accuracy testing. These steps ensure that all parts meet clients’ high standards and strict requirements.

Efficiency and Repeatability

- Johoty achieves high-efficiency production while ensuring repeatability in every batch. Whether making small prototypes or mass-producing, their precision machining ensures parts are consistent and dependable.

Eco-Friendly and Low Waste

- By optimizing material use and employing efficient machining methods, Johoty minimizes waste during precision machining. This saves money and lowers environmental harm, showing their dedication to sustainability.

With unmatched precision, extensive machining experience, and powerful CNC capabilities, Johoty meets the high standards of various industries. From aerospace and medical devices to automotive manufacturing, Johoty’s precision machining delivers unparalleled quality and performance. Explore Johoty’s precision machining services to experience industry-leading CNC technology that brings unbeatable accuracy and quality to your products!

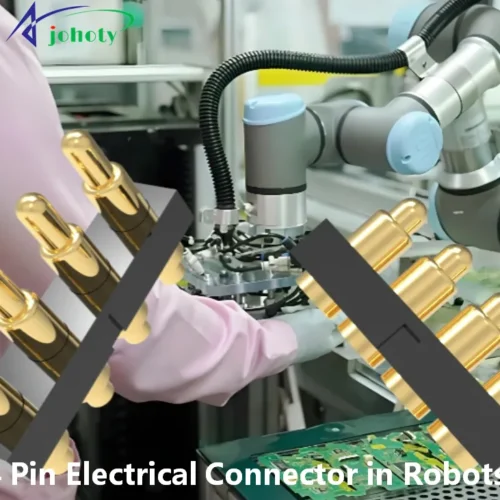

Application of Precision Machining in CNC Parts Production: What is Precision Machining?

Precision machining is indispensable in modern manufacturing and plays a crucial role in high-end industries like aerospace, medical, and automotive. So how is precision machining applied in CNC parts production? Through unique methods and leading technologies, Johoty provides customers with high-precision parts that meet strict standards:

Ultra-High Precision Dimensional Control

- In CNC machining, dimensional accuracy is key to part quality. Johoty uses high-precision encoders and sensors to control tool position within ±0.001mm. This accuracy ensures parts fit perfectly into assemblies, meeting complex assembly requirements.

Machining of Complex Geometries

- Johoty specializes in producing CNC parts with complex shapes like curves, holes, grooves, and bosses. Using five-axis machining, Johoty completes these intricate structures in a single setup, reducing repositioning errors and ensuring geometric precision and surface quality.

High-Precision Multi-Material Machining

- Johoty excels in machining high-strength materials such as stainless steel, titanium alloys, and aluminum alloys, commonly used in aerospace and medical device fields. By using precise tools and various cooling methods, Johoty controls material temperature and thermal deformation, allowing high-strength materials to maintain optimal surface finish and accuracy during precision machining.

Surface Treatment and Post-Processing

- After CNC machining, Johoty offers surface treatment and post-processing to enhance part functionality and appearance. Precision grinding, polishing, and coating techniques increase corrosion resistance and surface durability, ensuring that parts are not only accurate but also smooth and visually appealing, meeting all client requirements.

Efficient Custom Machining Solutions

- For clients with special needs, Johoty provides customized machining solutions. Whether for small-batch prototypes or large-scale part production, Johoty can adjust machining parameters based on client designs, delivering high-precision parts in the shortest possible production cycles. This flexibility gives Johoty a unique advantage in meeting high industry standards.

Non-Destructive Testing and Real-Time Quality Monitoring

- To ensure every part meets strict quality standards, Johoty incorporates non-destructive testing and real-time monitoring in its production. Automated inspection tools measure dimensions, shapes, and finishes, adjusting right away if they find any issues. This smooth inspection process makes sure every batch meets our clients’ high standards.

Precision Assembly and Clamping Techniques

- The stability of part clamping directly impacts machining accuracy and results. Johoty uses advanced vacuum and magnetic clamping systems to secure precise positioning for each part, eliminating errors due to instability. This approach ensures each surface and hole meets ultra-high precision standards.

Eco-Friendly and Material Optimization

- In precision machining, minimizing waste and optimizing material usage are essential. Johoty achieves this through precise programming and optimized machining paths, reducing material waste and production costs while contributing to environmental sustainability. Johoty’s commitment to sustainability extends beyond efficiency to the protection of natural resources.

With exceptional CNC precision machining technology, Johoty meets the highest industry standards for CNC parts production. Whether your project requires complex geometries, high-strength materials, or ultra-high precision, Johoty offers reliable solutions to help your product achieve peak performance.

Advantages of Precision Machining

Johoty brings significant advantages in precision machining, delivering exceptional performance in CNC part production and providing clients with multiple benefits:

Ultra-High Machining Precision

- Leveraging advanced CNC technology, Johoty achieves micron-level precision on each part. With high-accuracy sensors and encoders, they maintain machining tolerances within ±0.001mm, ensuring every part meets strict dimensional and geometric standards. This precision enables Johoty’s parts to support complex assemblies and significantly enhance equipment longevity.

Comprehensive Multi-Axis Machining Capability

- Johoty’s five-axis and multi-axis machining centers allow for complete cutting in a single setup. This five-axis technology handles complex curves and shapes without multiple setups, reducing positioning errors and increasing efficiency. The flexibility of multi-axis machining enables Johoty to produce parts with intricate features, meeting various unique client requirements.

Broad Material Compatibility

- Whether working with stainless steel, aluminum, titanium alloys, engineering plastics, or carbon fiber, Johoty expertly shapes a wide range of materials. Using customized tools and machining strategies for each material, Johoty maximizes precision while minimizing waste and thermal deformation. This multi-material machining capability allows Johoty to serve multiple industry sectors.

Comprehensive Quality Control System

- At Johoty, quality control is integral to every step of the machining process. Equipped with advanced CMM (Coordinate Measuring Machines), laser scanners, and surface finish testing devices, Johoty ensures each part meets the client’s high standards. Real-time detection and feedback systems quickly identify and correct any deviations, reducing rework rates and guaranteeing superior product quality.

Efficient Custom Machining Solutions

- Johoty excels at providing customized machining services based on specific client needs. From small-batch prototyping to large-scale production, Johoty’s flexible production system efficiently allocates resources to quickly meet client demands. This efficient, adaptable approach not only reduces production costs but also significantly shortens product launch timelines.

Superior Surface Finishing Techniques

- Johoty’s precision machining extends to superior post-processing capabilities. With techniques like precise polishing, sandblasting, and electroplating, Johoty adds protective layers to parts, enhancing durability and wear resistance. Johoty’s surface treatments focus on looks too, providing parts that are both useful and attractive.

Smart and Automated Production

- By integrating automated inspection and feedback systems with advanced CNC programming, Johoty achieves streamlined, unmanned production management. This intelligent production method boosts machining precision and efficiency, allowing Johoty to consistently deliver high quality on even the most complex parts. It also enhances competitiveness and enables rapid market responsiveness.

Eco-Friendly and Sustainable Development

- Throughout the precision machining process, Johoty is committed to reducing waste and energy consumption. By optimizing material usage and minimizing energy use, Johoty maintains high-precision machining while minimizing environmental impact, reflecting its commitment to sustainability.

Johoty’s precision machining technologies and services deliver unmatched value to clients, ensuring product reliability and premium performance. Whether your project requires high-precision parts, customized machining solutions, or sustainable production practices, Johoty offers comprehensive solutions that help your products stand out in a competitive market.

How to Choose a Precision Machining Provider?

Technical Expertise and Equipment Quality

- A top-tier precision machining provider should have advanced CNC equipment and a skilled technical team. Multi-axis machining, micron-level precision, and intelligent automation are key indicators of equipment quality. Johoty boasts cutting-edge CNC capabilities, including five-axis machining centers and precision measurement tools, efficiently meeting complex machining needs.

Extensive Material Machining Experience

- Precision machining requires both high accuracy and a deep understanding of various materials. Different materials like stainless steel, aluminum, and titanium alloys have unique traits that can cause mistakes or waste if not handled properly. Johoty has extensive experience with a wide range of materials, expertly handling high-strength metals and engineering plastics to ensure perfect material compatibility.

Quality Control and Certification Standards

- Tight quality control is crucial in precision machining. Choosing a supplier with a robust quality management system, such as one that meets ISO certifications and industry standards, better ensures product quality. Johoty has established a comprehensive quality management system with advanced inspection equipment, including CMM (Coordinate Measuring Machines) and laser inspection tools, ensuring each part meets clients’ exacting standards.

Customer Service and Customization Capabilities

- A great precision machining provider should have strong customization abilities, adapting machining solutions to meet specific client needs. Johoty shines here, providing quick responses and efficient production for prototypes and big orders. Additionally, Johoty’s technical team offers one-on-one consulting to help clients optimize designs for maximum cost-effectiveness.

Reasonable Pricing and Delivery Speed

- Pricing and lead time are also key considerations when selecting a precision machining service. A reliable provider should not only be competitively priced but also capable of fast delivery to help clients reduce time to market. Johoty maintains cost control advantages and ensures quick delivery through efficient production processes, all while upholding quality standards.

Commitment to Sustainability

- As a modern precision machining service provider, a commitment to environmental sustainability is another valuable measure of quality. Johoty is dedicated to minimizing waste, optimizing energy use, and adhering to eco-friendly production principles. This focus on sustainability allows Johoty to provide green manufacturing solutions.

Selecting a precision machining partner is vital for ensuring your products’ quality and effectiveness. By considering factors such as technical expertise, material handling experience, quality control, customer service, pricing, and environmental commitment, you can find a partner who best meets your needs. With advanced technology, a professional team, and superior customer service, Johoty has become a top choice for many industries. If your project requires exceptional precision machining, Johoty is a reliable partner.

Conclusion: The Endless Possibilities of Precision Machining

Precision machining combines advanced technology, meticulous craftsmanship, and rigorous quality control to meet high standards for dimensional accuracy, surface quality, and production efficiency. As a leader in this field, Johoty showcases unparalleled strengths in CNC parts production. Through multi-axis machining, tailored solutions, efficient quality control, and a focus on sustainability, Johoty not only meets client demands for high-precision parts but also drives industry standards forward.

Johoty’s precision machining capabilities effectively meet the needs of high-end industries, from aerospace to medical devices. In these demanding fields, Johoty is committed to delivering top-quality parts and services to ensure clients’ products perform flawlessly. This dedication to quality and pursuit of technological excellence has earned Johoty a trusted reputation in the global precision machining market.

For a reliable CNC parts manufacturer that upholds high standards, choose Johoty. Whether your project demands ultra-high precision, multi-material adaptability, or flexible custom solutions, Johoty’s advanced technology and extensive experience will help your products stand out and achieve superior performance.