3 Pin connectors boost aerospace lighting stability and safety. Uncover their design, applications, and real-world impact to enhance system performance and advance engineering designs.

3 pin connectors are essential, ensuring stable and reliable performance with high-conductivity materials and advanced anti-vibration designs. Reliable aerospace lighting is critical for flight safety.

3 pin connectors maintain stable connections in extreme temperatures and high vibration. And their waterproof, dustproof, and corrosion-resistant features ensure durability in harsh conditions. As technology evolves towards smarter, modular, and eco-friendly solutions, the future is bright for 3 pin connectors in aerospace lighting. Engineers stay updated to select the best connectors and improve system performance and safety.

Introduction: 3 Pin Connectors Secure Aerospace Lighting for Peak Stability

In aerospace, reliable lighting systems are crucial for ensuring flight safety. At the heart of achieving this goal lies the 3 Pin connector. This compact yet powerful component stands out for its exceptional features. Features like anti-vibration, heat resistance, and corrosion protection, make it the optimal choice for aerospace lighting systems.

This blog delves into how 3 Pin connectors ensure top-tier stability in extreme environments. They offer engineers valuable technical insights and practical guidance.

Whether in design phases or real-world applications, the advantages of 3 Pin connectors are irreplaceable. They serve as essential tools for every engineer aiming to enhance system performance and safety.

Basic Overview of 3 Pin Connectors

Structure:

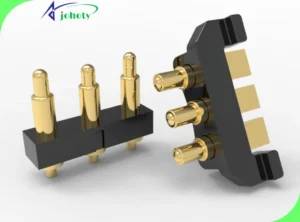

- 3 Pin connectors consist of three pins, typically positive power, negative power, and a signal line. Designed for stable and reliable electrical connections, they are used across various industrial and aerospace applications.

Materials and Manufacturing:

- Material selection is crucial for 3 Pin connector. Pins are usually made from highly conductive copper or gold-plated materials to minimize resistance and power loss.

- The housing is crafted from high-temperature resistant and corrosion-resistant engineering plastics or metals. Ensuring long-term stability in harsh environments.

Connection Methods:

- 3 Pin connector offers various connection methods including plug-in, threaded lock, and snap-in types. Each method suits different application scenarios. plug-in connectors allow for quick connect and disconnect, while threaded lock and snap-in types provide stronger connection stability.

Applications:

- Widely used in aerospace, automotive electronics, industrial automation, etc. The 3 Pin connector is crucial in aerospace lighting systems for their excellent performance and reliability in ensuring continuous stable operation.

Electrical Performance:

- Electrical performance of 3 Pin connectors includes current carrying capacity, voltage ratings, and contact resistance. High-quality connectors boast high current carrying capacity and low contact resistance, ensuring stable transmission of power and signals.

Installation and Maintenance:

- Installation of 3 Pin connectors is typically straightforward, designed for convenience and practicality. Maintenance involves periodic inspection and cleaning of contact points to extend connector lifespan and ensure long-term reliable system operation.

Physical Locking of 3 Pin Connectors

Importance of Locking Design:

- In high-vibration and extreme environments like aerospace, a physical locking mechanism for connectors is crucial.

- This mechanism ensures connectors remain securely fastened at all times, preventing loosening or disconnection due to vibration or impact. Thereby ensuring system stability and safety.

Common Types of Locking:

1. Threaded Locking:

- This mechanism secures connectors by rotating threads. Threaded locking connectors often feature anti-loosening designs to prevent unintentional disconnection in high-vibration environments.

- Threaded locking provides robust mechanical stability and is commonly chosen for aerospace applications.

2. Latch Locking:

- Latch locking utilizes springs or latch structures for quick connection and disconnect. While convenient for installation, these connectors must be designed with sufficient strength and durability to prevent loosening under vibration.

3. Push-Pull Locking:

- Push-pull locking mechanisms use push-in and pull-out forces for connection and disconnection. They typically include locking rings or other auxiliary structures to enhance connection strength.

- Push-pull connectors are user-friendly and suitable for applications requiring frequent insertion and removal.

Material Selection for Locking Mechanisms:

- Choosing materials for locking mechanisms is equally critical. High-strength alloys or engineering plastics are common choices, offering long-term reliability in high-stress and high-vibration environments.

- Corrosion resistance and wear resistance are also crucial design considerations to ensure durability in harsh conditions.

Maintenance of Locking Mechanisms:

- Despite robust design, regular maintenance of physical locking mechanisms is essential. This includes checking for wear, cleaning locking components, and lubricating necessary mechanical parts.

- These maintenance tasks extend the connector’s lifespan and ensure reliability in critical applications.

Applications:

- Threaded and latch-locking 3 Pin connectors are widely used in aerospace lighting systems. These locking mechanisms withstand high vibrations and temperature fluctuations during flight, ensuring continuous stable operation of lighting systems under harsh conditions.

- For instance, lighting equipment on aircraft wings uses threaded locking 3 Pin connectors to maintain secure connections in high wind speeds and low temperatures.

Vibration Resistance Design of 3 Pin Connectors

Importance of Vibration Resistance Design:

- In aerospace, vibration is an inevitable issue. Aircraft experience various vibrations and impacts during flight, which can loosen or disconnect connectors, affecting system operation.

- Therefore, vibration resistance design in 3 Pin connectors is critical for maintaining stability and reliability amidst significant vibrations.

Elastic Contact Design:

- Elastic contact design is a key technology for vibration resistance. 3 Pin connectors use high-elasticity materials for contact points, absorbing and cushioning vibration through elastic deformation.

- This design enhances connection stability and reduces contact wear, extending the connector’s lifespan.

Reinforced Housing:

- 3 Pin connectors typically feature a reinforced housing design using high-strength materials, such as alloys or engineering plastics. The housing structure is designed for vibration resistance,

- with increased wall thickness, and optimized structural shapes. And the use of shock-absorbing pads to enhance overall vibration resistance capability.

Multi-Point Contact Mechanism:

- Another common vibration resistance design is the multi-point contact mechanism. By increasing the number of contact points, vibration energy is evenly distributed across multiple contact points.

- This reduces stress on individual contact points. This design improves vibration resistance performance and enhances electrical connection stability.

Locking and Fixing Devices:

- To further improve vibration resistance, 3 Pin connectors are often equipped with locking and fixing devices. Mechanisms such as threaded locking, latch locking, and push-pull locking ensure connectors maintain a secure connection in high-vibration environments.

- These devices simplify installation processes and provide additional mechanical stability.

Testing and Experimentation:

- During design and production, 3 Pin connectors undergo rigorous vibration testing and experimentation. They are subjected to durability tests and performance verification under simulated vibration conditions similar to actual operating environments.

- This ensures connectors maintain stable connections in high-vibration environments and meet stringent aerospace application requirements.

Real-World Applications:

- The vibration resistance design of 3 Pin connectors has been extensively validated in practical applications. For instance, in aircraft fuselage and wing lighting systems, these connectors withstand various vibrations and impacts.

- During takeoff, landing, and flight, ensure stable operation and safety of the lighting systems.

Material Selection for 3 Pin Connectors

Importance of Material Selection:

- In aerospace, choosing the right materials for 3 Pin connectors is critical. Quality materials ensure reliable performance in extreme environments and extend operational lifespan.

- Material selection directly impacts key performance factors such as conductivity, corrosion resistance, high-temperature tolerance, and mechanical strength.

Conductive Materials:

- Pogo pins in 3 Pin connectors typically use highly conductive materials like copper, gold-plated copper, or silver-plated copper. These materials ensure consistent conductivity, maintaining reliable current and signal transmission.

- Gold or silver plating enhances conductivity and provides oxidation and corrosion resistance.

Housing Materials:

- Connector housings require high strength and durability. Common materials include high-performance engineering plastics such as PBT and PA. Praised for their heat and impact resistance, these materials are lightweight and simple to process.

- Metal alloys like aluminum and stainless steel offer higher mechanical strength and corrosion resistance, suitable for harsh environments.

Insulation Materials:

- High-quality insulation materials like PTFE, PI, and ceramics are used inside 3 Pin connectors to prevent short circuits and electrical shocks.

- These materials excel in electrical insulation and withstand high temperatures, ensuring reliability and safety in demanding high-temperature and high-voltage settings.

Corrosion-resistant Materials:

- Aerospace environments commonly deal with corrosive elements like humidity and salt spray. Therefore, 3 Pin connector materials must have good corrosion resistance.

- Gold, nickel-plated, or silver-plated pins and housing materials with corrosion-resistant coatings effectively prevent corrosion and oxidation. They ensure the long-term stability of connectors.

Thermal Management Materials:

- Efficient heat dissipation is crucial for connectors in high-temperature environments. Some high-performance connectors utilize thermal management materials like thermal conductive silicones and thermoplastic composite materials.

- Which effectively dissipates heat and prevents overheating. Additionally, metal housings contribute to improved heat dissipation.

Comprehensive Performance Assessment:

- When selecting materials for 3 Pin connectors, it’s essential to comprehensively evaluate various performance aspects. Including mechanical strength, conductivity, corrosion resistance, insulation, and thermal management capabilities.

- Through laboratory testing and real-world applications, ensure selected materials meet the stringent requirements of aerospace applications.

Real-world Application:

- In aircraft cabin lighting systems, 3 Pin connector with gold-plated copper pogo pins and aluminum alloy housings. They provide excellent conductivity and mechanical strength and ensure long-term stability in high-humidity and high-salt environments. Guaranteeing reliable operation of the lighting system.

- Understanding the material selection for the 3 Pin connector enables engineers to better design and apply these connectors. Ensuring stability and reliability in various extreme environments and providing robust support for aerospace lighting systems.

Environmental Protection for 3 Pin Connectors

Importance of Environmental Protection:

- 3 Pin connectors often face extreme conditions, such as extreme temperatures, high humidity, corrosive gases, and strong vibrations.

- To ensure the stability and reliability of aerospace lighting systems, the 3 Pin connector must possess exceptional environmental protection capabilities.

Waterproof and Dustproof Design:

- 3 Pin connectors typically feature waterproof and dustproof designs to operate reliably in humid and dusty environments. Common protection ratings include IP65, IP67, and even IP68, indicating varying levels of waterproof and dustproof capabilities.

- Take IP67-rated connectors, for instance; they stop dust from getting in and handle short dips in water.

Corrosion-resistant Materials:

- To resist corrosive gases and salt spray, materials for the housing and contact points of the 3 Pin connector need excellent corrosion resistance. Common corrosion-resistant materials include stainless steel, gold-plated copper, and nickel-plated alloys.

- These materials ensure long-term stability in harsh environments, preventing corrosion and oxidation that could affect connector performance.

Extreme Temperature Resistance:

- Aircraft may experience extreme temperature changes during flight, from high heat to freezing conditions. Material selection and design of the 3 Pin connector must withstand these temperature challenges.

- High-temperature materials like PBT, as well as low-temperature materials like specialized rubbers and high-performance plastics. Ensure connectors operate normally in extreme temperatures.

Vibration and Impact Resistance:

- Vibrations and impacts are common stresses in aviation environments, requiring 3 Pin connectors to have strong vibration and impact resistance. Through optimized designs such as using elastic contact points, multipoint contact mechanisms, and reinforced housings.

- Connectors effectively absorb and mitigate vibration and impact, ensuring stable connections.

EMI Protection:

- Aerospace equipment operates in complex electromagnetic environments that may cause EMI, affecting the normal operation of electronic systems.

- 3 Pin connectors need good electromagnetic shielding performance, achieved through shielding covers or materials. This is to prevent EMI from impacting signal transmission and ensure the electrical stability of the system.

Comprehensive Protection Testing:

- During design and production, 3 Pin connectors undergo rigorous environmental protection testing. Including tests for waterproofing, dust-proofing, corrosion resistance, extreme temperature resistance, vibration resistance, and impact resistance.

- These tests ensure connectors maintain stable and reliable performance in various extreme environments. Meeting the high standards required for aerospace applications.

Real-world Application:

- In aircraft exterior lighting systems, 3 Pin connectors are designed with an IP67 protection rating and gold-plated copper contacts.

- They can operate reliably in high humidity and corrosive gas environments, ensuring the long-term stability of external lighting equipment.

- By understanding and implementing these environmental protection measures, engineers can effectively design and select 3 Pin connectors.

- This can ensure their stability and reliability in various demanding environments, providing comprehensive assurance for aerospace lighting systems.

Successful Applications of 3 Pin Connectors in Aerospace Lighting

1. Aircraft Wing Navigation Light Systems

Background:

- Aircraft wing navigation lights are crucial for flight safety, indicating direction and position during nighttime or adverse weather conditions. These lights need to function reliably amidst severe vibrations, strong winds, and extreme temperatures.

Application:

- 3 Pin connectors play a vital role in aircraft wing navigation light systems. Featuring high-strength alloy housings and gold-plated copper contacts, these connectors ensure long-term stability in extreme environments.

- Their waterproof and dustproof design (up to IP67) prevents moisture and dust ingress, thereby avoiding short circuits and malfunctions.

Key Success Factors:

- Vibration Resistance: Designed with multipoint contacts and elastic contact points to absorb and mitigate vibrations effectively. Ensuring stable connections in high-vibration environments.

- Temperature Resistance: Using materials resistant to high and low temperatures ensures connectors function normally from high-altitude cold to ground-level heat.

- Corrosion Resistance: Employing gold-plated copper materials effectively prevents corrosion from salt spray and corrosive gases. Extending operational lifespan.

2. Aircraft Cabin Interior Lighting Systems

Background:

- Aircraft cabin interior lighting systems provide comfortable lighting environments and require continuous stable operation during flights. Connectors in this system must offer high reliability and ease of maintenance.

Application:

- In aircraft cabin interior lighting systems, 3 Pin connectors have simple installation and maintenance designs, they are widely used.

- These connectors feature lightweight high-strength plastic housings and highly conductive copper pins. Ensuring electrical performance and mechanical stability of the system.

Key Success Factors:

- Ease of Installation: Snap-lock mechanisms simplify installation and maintenance, reducing time and costs associated with upkeep.

- Durability: High-strength plastic housings and gold-plated copper pins ensure long-term mechanical and electrical stability.

- EMI Shielding: Built-in electromagnetic shielding effectively prevents electromagnetic interference from affecting lighting system quality and stability in the cabin.

3. Helicopter External Searchlight Systems

Background:

- Helicopter external searchlights are used for nighttime search and rescue missions. Requiring robust lighting support under harsh environmental and high-vibration conditions.

- The connector system must exhibit high reliability and resistance to environmental impacts.

Application:

- 3 Pin connectors are critical components due to their excellent vibration resistance and waterproof/dustproof performance.

- These connectors utilize push-pull locking and high-wear-resistant materials. Ensuring stability under high stress and frequent operations.

Key Success Factors:

- High Vibration Resistance: Optimized elastic contact points and reinforced housing designs effectively handle high-frequency vibrations from helicopters, ensuring stable connections.

- Waterproof and Dustproof: Achieving IP68 protection rating, these connectors can operate normally in high humidity and adverse weather conditions. Preventing water and dust ingress.

- Quick Connect and Disconnect: Push-pull locking facilitates quick and easy operations, suitable for frequent use scenarios, enhancing system responsiveness and reliability.

Development Trends of 3 Pin Connectors in Future Aerospace Lighting

1. Smart and Digital Integration of 3 Pin Connectors

Background:

- As aerospace technology advances, lighting systems are moving towards smart and digital integration. Automated lighting systems adjust automatically to suit environmental conditions and specific mission needs. Providing more efficient and energy-saving solutions.

Development Trends:

- Future 3 Pin connectors will integrate more smart functionalities. Such as data transmission and communication capabilities to support interconnectivity with sensors and control systems.

- Embedded smart chips in these connectors will transmit power monitor and provide real-time feedback on system status. Enhancing overall reliability and maintenance efficiency.

2. Enhanced Environmental Adaptability of 3 Pin Connectors

Background:

- Future aerospace missions will face complex and harsh environments such as extreme temperatures, high radiation, and deep space exploration. Connectors need enhanced environmental adaptability to maintain stable system operation over the long term.

Development Trends:

- 3 Pin connectors will adopt advanced materials and manufacturing processes to enhance their resistance to high/low temperatures, radiation, and corrosion.

- For instance, using new high-temperature ceramics and composite materials improves connector stability in extreme environments.

- Additionally, nano-coating technologies will enhance corrosion resistance, prolonging connector lifespan.

3. Modular and Reconfigurable Design of 3 Pin Connectors

Background:

- Modular and reconfigurable designs are critical directions for future aerospace systems. Aiming to improve system flexibility, maintainability, and reduce costs and complexity.

Development Trends:

- Future 3 Pin connectors will emphasize modular design, enabling quick integration into various lighting systems.

- Standardized modular interfaces will allow connectors to adapt to different mission requirements flexibly, simplifying design and maintenance processes.

- Moreover, reconfigurable designs will enable engineers to replace or upgrade connector components based on actual needs rapidly. Enhancing system maintainability and scalability.

4. Enhanced Electrical Performance of 3 Pin Connectors

Background:

- With the continuous upgrade of aerospace electronic equipment, demands for electrical connector performance are increasing. High current, high frequency, and low latency are basic requirements for future lighting systems.

Development Trends:

- 3 Pin connectors will optimize their conductive materials and contact point designs to support higher current and frequency transmission.

- Using new high-conductivity alloys and advanced contact technologies like multipoint contacts and elastic contact designs. This will significantly enhance the connector’s electrical performance.

- Additionally, low latency and high-precision signal transmission capabilities will enable them to adapt to more complex aerospace electronic applications.

5. Green Environmental Protection of 3 Pin Connectors

Background:

- Environmental protection has become a global priority, including in the aerospace industry. Connector manufacturing and usage processes need to meet green environmental requirements to reduce environmental impact.

Development Trends:

- Future 3 Pin connectors will use green environmental materials and processes to minimize harmful emissions and resource consumption during manufacturing.

- For example, using renewable materials and eco-friendly coating technologies will reduce environmental pollution.

- Furthermore, connector design and manufacturing will consider recyclability and reusability, promoting sustainable development in the aerospace industry.

Conclusion:

In aerospace lighting systems, 3 pin connectors are crucial components ensuring stability. Due to their excellent vibration resistance, high/low-temperature durability, waterproof/dustproof design, and superior electrical/mechanical performance. By integrating smart features, enhancing environmental adaptability, adopting modular designs, and optimizing electrical capabilities. These 3 pin connectors will continue advancing aerospace lighting technology. Engineers should closely follow these trends, selecting and applying the most suitable Johoty 3 pin connectors. This approach guarantees dependable operation across diverse extreme conditions. Thereby providing robust assurance for aerospace safety and advancement.