Electroplating innovations for Pogo Pins ensure electronics are more reliable and efficient. Learn how precision electroplating enhances contact reliability, extends device lifespan, meeting the stringent demands of modern high-tech products. Read now for the latest advancements in leading-edge technology.

Electroplating technology ensures a solid boost in performance for Pogo Pins, garnering attention for their widespread use in high-tech devices. Through precise electroplating, Pogo Pins achieve heightened contact reliability and durability, significantly enhancing overall device performance and longevity.

Whether it’s smartphones, wearables, or high-precision testing instruments, electroplating plays a crucial role, in delivering exceptional electronic product experiences. Dive into the vital application of electroplating in Pogo Pins and stay updated on the latest trends in cutting-edge technology.

Introduction: What is electroplating? What is Pogo Pins?

1. Introduction to Electroplating

- Electroplating is a process that uses electrochemical principles to deposit a layer of metal onto a conductor’s surface. This technique significantly enhances material corrosion resistance, conductivity, and aesthetics. It is by depositing metals like gold, silver, or nickel onto substrates.

- In electronics manufacturing, electroplating improves the performance of contact components and extends equipment lifespan, enhancing overall reliability and stability.

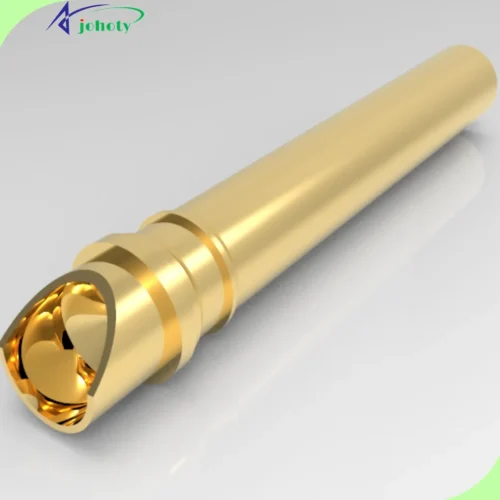

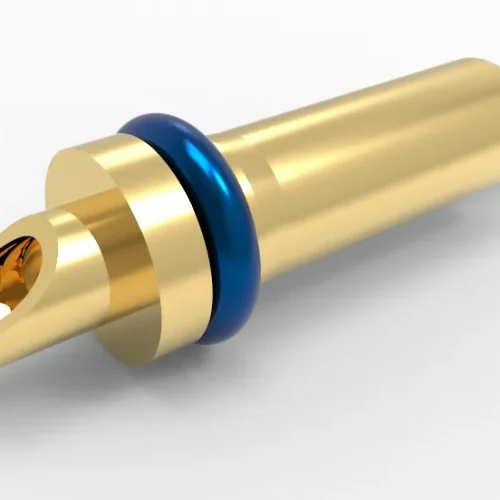

2. Introduction to Pogo Pins

- Pogo Pins are high-precision, high-reliability connectors widely used in electronic test equipment, mobile devices, and medical instruments. Comprising a cylindrical pin and an internal spring, they ensure a stable connection with contact points through spring pressure.

- Pogo Pins exhibit exceptional durability and conductivity, maintaining stable performance during high-frequency insertions and withdrawals. Ideal for taking on a variety of tough challenges.

- By leveraging the advantages of electroplating technology and Pogo Pins, electronic devices have achieved significant improvements in performance and durability. This meets the stringent requirements of modern high-tech products.

Learn more about the innovative applications of electroplating technology and Pogo Pins to stay ahead in technology and drive industry advancement.

Basic Principles of Electroplating: What is electroplating?

Electroplating is a process that deposits a layer of metal onto a conductor’s surface using electrolysis. The fundamental principle involves reducing metal ions from an electrolyte solution and depositing them onto the substrate using a current. The electroplating process generally includes several steps:

- Substrate preparation: Before applying the coating, we make sure to prep the substrate surface with a thorough cleaning and treatment.

- Electrolyte preparation: Preparing electrolyte solution containing metal ions for plating, common electrolytes include copper sulfate solution, nickel chloride solution, etc.

- Plating operation: The cathode in our setup is the substrate, while the metal designated for plating takes on the role of the anode. Metal ions are reduced on the substrate surface to form a uniform metal coating when an electric current is applied.

- Post-treatment: After the coating is formed, it undergoes cleaning, drying, and necessary heat treatment steps to improve its performance and stability.

Common Electroplating Materials and Their Uses

- Gold: Mainly used for high-conductivity and corrosion-resistant electronic devices such as connectors, switches, and contacts.

- Silver: With excellent conductivity and thermal conductivity, commonly used for electrical contact parts and conductive coatings.

- Nickel: Nickel coatings are corrosion-resistant and have high hardness, widely used for decorative coatings and protective coatings.

- Copper: Copper coatings have good conductivity and are often used as underlayers for other metal coatings to increase adhesion and conductivity.

- Zinc: Zinc coatings have good corrosion resistance and are commonly used as protective coatings for steel products.

Functions, Effects, and Benefits of Electroplating

- Enhancing corrosion resistance: Electroplating layers effectively prevent substrate corrosion from contact with corrosive media, prolonging substrate life.

- Improving conductivity and thermal conductivity: Depositing high-conductivity metals such as gold or silver on the substrate surface significantly enhances its conductivity and thermal conductivity.

- Enhancing appearance: Electroplating layers have good gloss and decorative effects, making the product appearance more attractive.

- Increasing hardness and wear resistance: Some metal coatings such as nickel coatings have high hardness and wear resistance, protecting the substrate from mechanical wear.

- Improving contact performance: In electronic devices, electroplating layers can improve the contact reliability and stability of contact components, reducing contact resistance.

Electroplating Process and Benefits for Manufacturing Pogo Pins

Manufacturing Process

1. Substrate Preparation:

- Material Selection: Pogo Pins are typically made from highly conductive and corrosion-resistant materials like copper alloys, stainless steel, etc.

- Surface Cleaning: Thoroughly remove surface grease, oxides, and other impurities using chemical cleaners and ultrasonic cleaning technology to ensure coating adhesion.

2. Electrolyte Selection

- Choose electrolytes according to the desired metal coating properties. For instance, gold plating commonly uses cyanide gold solution, while nickel plating utilizes nickel chloride solution.

3. Electroplating Operation

- Fixing: Secure Pogo Pins onto the cathode of the electroplating equipment.

- Electrolysis Reaction: In the plating tank, Pogo Pins serve as the cathode, while the plating metal acts as the anode. Upon applying current, metal ions on the surface of Pogo Pins are reduced, forming a uniform coating.

4. Post-treatment

- Cleaning: After electroplating, clean the Pogo Pins to remove electrolyte residues.

- Drying: Thoroughly dry the Pogo Pins using hot air or vacuum drying techniques.

- Heat Treatment: Perform heat treatment as needed to further enhance coating adhesion and stability.

Role and Advantages of Electroplating Coatings

1. Enhanced Conductivity

- Role: Electroplating coatings significantly improve the conductivity of Pogo Pins, ensuring stable and reliable signal transmission.

- Advantages: Excellent conductivity is crucial, especially in high-speed data transmission and precision measurement applications.

2. Increased Corrosion Resistance

- Role: Electroplating coatings protect Pogo Pins from corrosion caused by external corrosive substances.

- Advantages: Improves the stable durability of Pogo Pins, making them a superior choice for various rugged applications.

3. Enhanced Wear Resistance

- Role: Coatings like nickel plating provide high hardness and wear resistance, protecting Pogo Pins from mechanical wear during frequent use.

- Advantages: Ensure the long-term stable performance of Pogo Pins in applications requiring frequent insertion and removal.

4. Improved Contact Performance

- Role: Electroplating coatings make the surface of Pogo Pins smooth, reducing contact resistance and ensuring excellent contact performance during high-frequency use.

- Advantages: Applicable to various high-demand electronic connections and testing equipment, ensuring reliable and accurate signal transmission.

Applications and Importance of Pogo Pins in Electronic Devices

Applications

1. Smartphones and Tablets

- Charging Ports: Pogo Pins are used in charging ports of smartphones and tablets, ensuring excellent contact performance during frequent insertions and removals.

- Data Transfer Ports: In data transfer ports, Pogo Pins ensure high-speed and stable data transmission, enhancing user experience.

2. Wearable Devices

- Connectors: Pogo Pins serve as connectors in wearable devices like smartwatches and fitness trackers, ensuring reliable connections between devices and accessories.

- Charging Docks: In charging docks for wearable devices, Pogo Pins provide stable power transmission and efficient charging.

3. Medical Equipment

- Diagnostic Devices: Pogo Pins in medical diagnostic equipment ensure accurate signal transmission and high reliability of devices.

- Monitoring Equipment: In devices like ECG monitors, Pogo Pins’ high conductivity and reliability ensure real-time patient data monitoring.

4. High-Precision Testing Equipment

- Testing Probes: In circuit board and chip testing, Pogo Pins serve as testing probes, providing high-precision and reliable electrical connections.

- Signal Transmission: In testing equipment, Pogo Pins ensure the integrity of signal transmission, improving test result accuracy and consistency.

5. Automotive Electronics

- Sensor Connections: In automotive sensors, Pogo Pins ensure reliable connections between sensors and control systems.

- Control Modules: Pogo Pins in automotive control modules ensure the stable operation of complex electrical systems.

Importance

1. High Conductivity

- Performance Enhancement: Pogo Pins’ high conductivity ensures excellent performance in data transmission and power supply, reducing signal loss and resistance.

- Wide Application: This characteristic makes Pogo Pins widely applicable in high-speed data transmission and precision measurement equipment.

2. Durability and Reliability

- Frequent Use: Pogo Pins can withstand high-frequency insertions and use, suitable for devices requiring long-term stable operation like smartphones and medical devices.

- Extended Lifespan: Electroplating coatings protect Pogo Pins from corrosion and wear, extending the lifespan of devices.

3. High Precision and Stability

- Testing Equipment: In high-precision testing equipment, Pogo Pins provide stable electrical connections, ensuring test result accuracy.

- Data Integrity: Pogo Pins’ high precision manufacturing and stability ensure data transmission integrity, avoiding data loss and errors.

4. Flexibility and Versatility

- Wide Applicability: Pogo Pins are suitable for connectors of various shapes and sizes, meeting the needs of different devices.

- Multi-functionality: From consumer electronics to industrial equipment, Pogo Pins’ versatility makes them indispensable components in various application fields.

Case Study on the Enhancement of Electronic Device Performance through Plating Technology

1. Application of Electroplating Technology in Smartphone Charging Ports

Background:

- Smartphones, as indispensable electronic devices in daily life, directly impact user experience through the performance of their charging ports. These ports require high conductivity, wear resistance, and corrosion resistance to ensure prolonged stable device usage.

Application of Plating Technology:

In smartphone charging ports, electroplating enhances performance by depositing a layer of gold or nickel on the surface of Pogo Pins:

- Gold Plating: Gold, with excellent conductivity and corrosion resistance. It significantly enhances the conductivity of the charging port when deposited on the surface of the Pogo pins. This ensures efficient power transmission and prevents oxidation of contact points, thereby extending the port’s lifespan.

- Nickel Plating: Nickel is recognized for its impressive hardness and its ability to endure wear. It effectively protects the charging port from wear and maintains its stability during frequent insertions and removals.

Case Outcome:

The application of plating technology has resulted in significant improvements in smartphone charging ports:

- Enhanced Conductivity: The high conductivity of the plating layer ensures efficient and rapid charging.

- Increased Durability: The corrosion resistance and wear resistance of the plating layer significantly extend the port’s lifespan, reducing issues caused by wear and oxidation.

- Improved User Experience: Plating technology enhances the overall performance of the charging port, providing users with a more reliable charging experience.

2. Application of Electroplated Pogo Pins in Medical Equipment

Background:

Medical equipment demands high reliability and precision, especially in diagnostic and monitoring devices, where signal stability and equipment durability are crucial.

Application of Plating Technology:

In medical equipment, electroplating technology enhances performance. It is by depositing a layer of highly conductive and corrosion-resistant metal on the surface of spring pins:

- Gold Plating: Gold plating on the surface of Pogo Pins ensures high conductivity and low contact resistance. This improves the accuracy and stability of signal transmission.

- Silver Plating: Silver, known for its excellent conductivity and thermal conductivity, is used in some medical devices. This is to enhance overall conductivity and durability.

Case Outcome:

The application of plating technology in medical equipment Pogo Pins has resulted in significant improvements:

- Enhanced Signal Stability: The high conductivity and low contact resistance of the plating layer ensure accurate signal transmission, reducing signal loss and interference.

- Increased Durability and Reliability: The corrosion resistance and wear resistance of the plating layer extend the lifespan of the equipment. Ensuring stable performance during long-term use.

- Optimization of Equipment Performance: The application of plating technology enhances the overall performance of medical equipment. Providing more precise and reliable support for medical diagnosis and monitoring.

3. Electroplating Technology Enhances Measurement Accuracy and Equipment Reliability

Improving Measurement Accuracy

- Reduced Contact Resistance: The plating layer ensures low contact resistance between the Pogo Pin and the test point. Enhancing the accuracy of signal transmission and avoiding measurement errors caused by poor contact.

- Signal Integrity: The high conductivity of the plating layer ensures the integrity of signal transmission, reducing signal attenuation and interference. Thus improving the accuracy and consistency of test results.

Enhancing Equipment Reliability

- Wear Resistance: The high wear resistance of the plating layer enables the Pogo Pin to withstand frequent insertion and use. Maintaining its performance stability and prolonging the lifespan of testing equipment.

- Corrosion Resistance: The plating layer effectively prevents corrosion of the Pogo Pins from moisture and chemical substances in the environment. Ensuring reliable operation of the equipment in various harsh environments.

- Long-Term Stability: Electroplating technology enhances the overall quality of Pogo Pins, reducing equipment failures caused by poor contact and wear. And thereby improving the long-term stability and reliability of testing equipment.

4. Application of Pogo Pins in High-Precision Testing Instruments

Pogo Pins are critical components used for connection and signal transmission in high-precision testing instruments. They must maintain high conductivity and stable contact performance in various testing environments.

- Circuit board testing: Ensuring the integrity and performance of each solder joint and electrical connection.

- Chip testing: Conducting functional and performance tests on chips before encapsulation to ensure their quality and reliability.

- Module testing: Verifying the functionality of various electronic modules to ensure their stability and compatibility within systems.

5. Application of Electroplating Technology in Pogo Pins

Electroplating technology enhances the conductivity, wear resistance, and corrosion resistance of Pogo Pins. It is by depositing a layer of metal on their surface. Thereby improving the measurement accuracy and equipment reliability of testing instruments. Common plating metals include gold, silver, and nickel.

Gold Plating

- High conductivity: Gold possesses extremely high conductivity, ensuring efficient transmission of test signals and reducing signal loss.

- Corrosion resistance: Gold plating effectively prevents oxidation and corrosion, prolonging the lifespan of Pogo Pins.

Silver Plating

- Excellent conductivity: Silver has conductivity second only to gold, and it is cost-effective and suitable for large-scale applications.

- Antioxidant properties: Silver plating prevents oxidation in the air, maintaining long-term stable electrical performance.

Nickel Plating

- High hardness: Nickel plating has high hardness and wear resistance, suitable for frequent use and high mechanical stress environments.

- Protective: Nickel plating can serve as a base layer, enhancing the adhesion and protective properties of other metal plating layers.

Future Trends in Electroplating Technology

1. Nano Plating Technology

Overview:

- Nano electroplating technology controls the thickness and structure of coatings at the nanoscale. Providing coatings with ultra-high precision and performance.

Development Trends:

- Enhanced Coating Control: Nano electroplating technology enables precise control of coating thickness at the nanoscale, ensuring uniformity and consistency in performance.

- Improved Material Properties: Nano electroplating significantly enhances the hardness, conductivity, and corrosion resistance of coatings, meeting the demands of high-performance electronic devices.

Application Prospects:

- High-Precision Sensors: The application of nano electroplating technology in sensor manufacturing enhances sensitivity and reliability.

- Advanced Electronic Components: Nano electroplating technology will play a crucial role in high-end electronic components like chips and MEMS.

2. Green Plating Technology

Overview:

- Green plating technology aims to reduce environmental pollution and resource consumption during the electroplating process, promoting sustainable development.

Development Trends:

- Non-toxic Electrolytes: Developing non-toxic and biodegradable electrolytes to reduce environmental pollution.

- Energy-efficient Plating Processes: Through meticulous process optimization, we aim to lessen energy consumption and optimize resource utilization in plating.

- Wastewater Treatment and Recycling: Implementing advanced wastewater treatment and metal recovery technologies to reduce wastewater discharge and metal resource waste.

Application Prospects:

- Eco-friendly Electronic Products: Help electronics manufacturers reduce their environmental footprint to meet increasingly stringent global environmental regulations.

- Circular Economy: Promoting the transformation of the electronics manufacturing industry towards a circular economy through resource recycling and reuse.

3. Multi-functional Composite electroplating Technology

Overview:

- It deposits multiple layers of different functional metal coatings on the substrate, endowing products with various excellent properties.

Development Trends:

- Multi-layer Composite Coatings: Achieving multi-layer electroplating on the same substrate, with each layer serving different functions. Such as conductive, wear-resistant, and corrosion-resistant layers.

- Application of New Materials: Exploring the use of new alloys and composite materials to further enhance the comprehensive performance of coatings.

Application Prospects:

- High-End Electronic Devices: Composite plating technology will significantly improve the durability and performance of high-end electronic products like smartphones and wearable devices.

- Industrial Applications: In industries such as aerospace and automotive manufacturing, it will meet demanding requirements in complex environments.

4. Smart electroplating Technology

Overview:

- Smart plating technology integrates cutting-edge advancements like IoT, AI, and big data analytics. It is to achieve automation and intelligence in the plating process.

Development Trends:

- Real-time Monitoring and Optimization: Through sensors and data analysis, we achieve continuous monitoring and optimization of the plating process in real time. It is to ensure coating quality and process stability.

- Automated Production Lines: Developing fully automated plating production lines to improve production efficiency and reduce manual intervention and errors.

- Predictive Maintenance: Utilizing AI technology for equipment condition monitoring and fault prediction to reduce equipment downtime and maintenance costs.

Application Prospects:

- Smart Manufacturing: Smart plating technology will drive the electronics manufacturing industry towards intelligent and digital transformation, improving production efficiency and product quality.

- Customized Production: Through smart plating technology, achieving personalized and customized production to meet the special needs of different customers.

Conclusions: What is electroplating? What is Pogo Pins?

The application of electroplating technology in electronic device manufacturing has demonstrated its irreplaceable importance. Boosting the conductivity, wear resistance, and corrosion resistance of Pogo Pins. Improving the measurement accuracy and equipment reliability of high-precision testing instruments, the advantages of plating technology are evident. With the development of cutting-edge technologies, such as nano plating, green plating, multi-functional composite plating, and smart plating. Future electronic devices will be more efficient, reliable, and environmentally friendly.

Future:

Engineers should closely follow these trends and fully utilize the latest electroplating technology. This can drive innovation and performance enhancement in electronic products. In fields such as smartphones, wearable devices, medical devices, as well as high-precision testing instruments. Continuous advancements in electroplating technology will sustain the dynamism of the electronics manufacturing industry.

By mastering and applying these advanced technologies, engineers can achieve greater success. It is in designing and manufacturing high-performance electronic products, embracing a brighter future. Stay informed about the latest developments in electroplating technology, and explore its limitless potential in practical applications.

And empower yourself to excel in the electronic device assembly field. Let’s stride towards a new era of high-performance electronic devices led by electroplating technology!