IP67 devices are paramount in reliability in harsh environments. Discover how Pogo Pins ensure their stable connections, explore real-world examples and drive your engineering innovation. Click here to explore further and dive into the specifics of the IP67 rating.

IP67 devices operating in harsh conditions rely on Pogo Pins for reliability and performance. Pogo Pins offer stable and efficient electrical connections, ensuring devices operate smoothly even amidst challenges like vibration, dust, and water.

The unique design of Pogo Pins enables durability during frequent insertions and withdrawals, delivering exceptional contact performance. Hence, for IP67 devices requiring high reliability and durability, Pogo Pins are indispensable components.

Why do engineers often focus on IP67 devices?

The IP67 standard is an international protection rating, indicating devices can withstand brief immersion in water while completely protected against dust. This makes IP67 devices highly suitable for use in harsh environmental conditions such as high dust, humidity, or significant rainfall. For engineers in fields like construction, manufacturing, field operations, or any profession requiring equipment to withstand harsh natural environments. The importance of IP67-rated devices is evident. The high durability of these devices ensures efficient and safe operation even in extreme conditions. Reducing maintenance costs and downtime while increasing overall operational reliability and sustainability.

Therefore, it is very important to understand and apply the IP67 standard in device design and selection. This can help engineers ensure their systems continue to operate even in the harshest environments, maintaining project efficiency and cost-effectiveness.

What is the IP67 protection rating?

1. Meaning of the Protection Rating:

- IP: Abbreviation for Ingress Protection.

- 6: The first digit represents the dust protection level. 6 signifies the highest dust protection, meaning the device is completely dustproof. Preventing any fine particles from entering and affecting its normal operation.

- 7: This figure tells us about the waterproofing level. It means the device can endure being submerged in water. This is at depths of up to 1 meter for half an hour without harm.

2. Importance of IP67 Application:

- Suitable Environments: IP67 devices are particularly suitable for harsh external conditions. This includes construction sites, field survey sites, and any areas where water and dust exposure are common.

- Device Protection: By preventing water and dust ingress, IP67 devices can reduce the risk of damage, extend device lifespan, and maintain efficient performance.

- Reduced Maintenance Costs: With less dust and water penetration, maintenance requirements and frequency are reduced, saving on maintenance costs and minimizing equipment downtime.

What are the advantages of IP67 protection?

1. Dust proofing:

- No Fine Dust Ingress: The “6” in IP67 signifies the device’s complete dust protection, preventing any fine particles from entering. This is crucial for devices operating in dusty environments like construction sites or manufacturing workshops.

- Component Protection: Dust resistance shields internal mechanical and electronic components, reducing failures or wear caused by dust accumulation and extending the lifespan.

2. Waterproofing:

- Temporary Immersion Protection: The “7” in IP67 indicates the device can withstand continuous immersion in water. It is up to 1 meter deep for 30 minutes without damage. This ensures device reliability in environments prone to short-term immersion, such as during heavy rain or floods.

- Outdoor Suitability: This waterproof capability makes devices particularly suitable for outdoor or humid environments. Such as in agriculture, marine research, or outdoor exploration.

3. Enhanced Reliability and Safety:

- Reduced Maintenance Needs: Dust and water resistance minimize environmental damage, reducing maintenance requirements and associated costs.

- Improved Operational Continuity: IP67 devices can continue operating in harsh conditions, enhancing operational reliability and continuity. This is critical for businesses relying on uninterrupted device performance.

4. Building Customer Trust:

- Market Advantage: IP67 devices meet stringent application requirements, providing a competitive edge in the market and attracting customers with specific performance demands.

- Brand Reputation: Our clients can reinforce their reputation as high-quality manufacturers by offering IP67 devices that reliably operate in extreme environments.

The Role and Importance of Pogo Pins in IP67 Devices

1. High Reliability Connection:

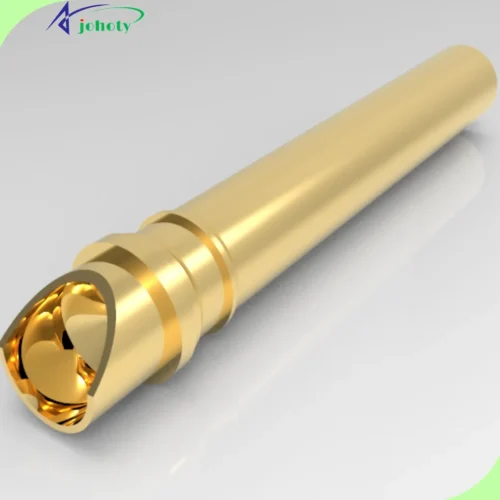

- Pogo Pins are highly reliable connectors for electronic devices, providing stable electrical connections due to their built-in spring structure. This design allows Pogo Pins to maintain good contact even in harsh environments with vibration, shock, or temperature variations.

2. Waterproof and Dustproof Characteristics:

- Waterproof and dustproof features are essential requirements for devices meeting the IP67 standard. The design of Pogo Pins allows them to seamlessly integrate with the device’s waterproof and dustproof characteristics. Often integrated into the sealed parts of the device using specialized sealing materials to protect electrical connections from environmental factors.

3. Increased Design Flexibility:

- The compact design and excellent electrical performance of Pogo Pins make them ideal. It is for use in electronic devices featuring limited space or intricate configurations. This aspect holds particular significance for IP67 devices with stringent design requirements. As they often need to combine high protection levels with compact designs.

4. Corrosion Resistance:

- In harsh environments, device connectors must withstand corrosion. Pogo Pins are typically made from corrosion-resistant materials, such as stainless steel or gold-plated surfaces. Effectively resisting corrosion from moisture, chemicals, and salt spray, thereby extending the device’s lifespan.

5. Easy Maintenance and Replacement:

- In industrial applications, both maintenance and quick replacement are crucial considerations. The structural design of Pogo Pins ensures reliable connections and facilitates quick replacement. This can be done by maintenance staff without requiring specialized tools or extended downtime. Thus improving equipment maintainability and reducing production interruptions.

6. Enhanced Product Reliability and Performance:

- Pogo Pins provide stable connections in extreme conditions, they help improve the overall performance and reliability of the entire device. This is crucial for industrial and outdoor applications relying on continuous stable operation.

Pogo Pins play an indispensable role in ensuring the high performance and reliability of IP67 devices in harsh environments. These small yet powerful connectors are an innovative highlight in modern electronic device design, especially in applications requiring strict protection levels.

Challenges in Designing and Maintaining IP67 Devices

Design Challenges

1. Material Selection:

- Challenge: Choosing materials that can withstand prolonged exposure to harsh environments while meeting dust and waterproof requirements.

- Solution: Use high-quality sealing materials like silicone or rubber, along with corrosion-resistant metals such as stainless steel or gold plating. This enhances overall durability and protection.

2. Structural Integrity:

- Challenge: Designing a structure that is both compact and capable of withstanding extreme physical pressures.

- Solution: Employing advanced CAE software for structural simulation, optimizing designs to ensure seamless sealing and resistance to external pressure.

3. Thermal Management:

- Challenge: Managing internal heat buildup while ensuring complete sealing.

- Solution: Designing effective internal thermal circulation channels, using heat pipes or phase-change materials to enhance heat dissipation efficiency.

Maintenance Challenges

1. Detection and Diagnosis:

- Challenge: Performing fault diagnosis and maintenance without compromising device sealing.

- Solution: Utilizing non-destructive testing methods including infrared thermography or ultrasonic testing. To monitor device status without affecting its protection rating.

2. Sealing Restoration:

- Challenge: Restoring the IP67 protection rating after device opening or maintenance.

- Solution: Using reusable sealing designs and ensuring maintenance teams are familiar with correct assembly techniques to maintain sealing integrity.

3. Cost Control:

- Challenge: Controlling costs of high-protection devices without sacrificing performance and reliability.

- Solution: Optimizing designs to reduce the need for expensive materials and procuring bulk production parts to lower costs.

Common Applications of IP67 Devices

1. Industrial Automation

Applications:

- Robot operations in harsh environments: Industrial automation equipment, such as robots on production lines, often need to operate in conditions. Including high dust, moisture, or other factors that may damage electronic components. IP67 devices prevent dust and water ingress, maintaining uninterrupted operation while reducing downtime.

- Remote monitoring and control systems: In industries like mining and oil drilling, monitoring equipment needs to operate stably in extreme environments. The waterproof and dustproof characteristics of IP67 devices guarantee the precise transmission of data and the reliability of the system.

Advantages:

- The protection provided by IP67 greatly reduces maintenance costs and enhances production efficiency and safety. This makes it an indispensable technology in the field of industrial automation.

2. Medical Devices

Applications:

- Operating room and laboratory equipment: Medical environments require high cleanliness and disinfection standards. IP67 devices prevent liquid and bacterial penetration, ensuring equipment hygiene and operational safety.

- Portable diagnostic instruments: Often used in variable environments such as ambulances and outdoor emergencies. IP67 devices can resist water and other liquid intrusion, ensuring uninterrupted device functionality.

Advantages:

- By using IP67 devices, the medical industry can ensure equipment reliability and hygiene safety, crucial for improving patient care quality.

3. Military Equipment

Applications:

- Communication devices: Communication equipment in military operations must operate in extreme climate conditions, including sandstorms and heavy rain. The dust and waterproof capabilities of IP67 devices are crucial to maintain continued high-quality communication.

- Field reconnaissance equipment: In field combat or reconnaissance missions, equipment needs to withstand humidity, mud, and other natural elements. The durability of IP67 devices is particularly important in these situations.

Advantages:

- The reliability of IP67 devices is related to the success of missions, enhancing the adaptability and survivability of military units.

How do IP67 Devices Play a Key Role in Extreme Environments?

IP67 Application in Mining Equipment

Background:

- In a large-scale mining operation, excavation equipment is often exposed to high dust, moisture, and particle-rich environments. These conditions can quickly lead to electronic equipment aging and failure.

Implementation of IP67 Devices:

- Dust and Water Resistance: Introducing a range of sensors and control units conforming to IP67 standards, designed to prevent dust and water ingress. Protecting internal electronic components from damage.

- Equipment Monitoring and Maintenance: These devices provide critical performance data and real-time monitoring. Assisting mine managers in adjusting operational strategies promptly and preventing potential equipment failures.

Demonstrated Effectiveness:

- Following the introduction of IP67 devices, the failure rate of mining equipment significantly decreased. With maintenance costs reduced by approximately 30%, contributing to overall operational efficiency enhancements.

IP67 Application in Oceanographic Instruments

Background:

- Oceanographic research institutes require data collection and analysis in deep-sea environments. However, the high pressure and humidity conditions pose significant challenges to equipment.

Implementation of IP67 Devices:

- Waterproof Requirements for Deep-Sea Operations: Utilizing IP67-rated underwater cameras and sensors capable of withstanding deep-water pressure and saltwater corrosion. Ensuring stable operation underwater for extended periods.

- Data Transmission Protection: All connections and data transmission lines utilize IP67-standard waterproof connection technology, ensuring data accuracy and integrity.

Demonstrated Effectiveness:

- These IP67 devices enable researchers to obtain previously inaccessible seabed data. Greatly advancing marine ecology and geological research, enhancing data reliability, and expanding research scope.

Conclusion:

Selecting appropriate technical solutions is crucial for upholding equipment reliability and performance. IP67 devices and the use of Pogo Pins are excellent answers to this need.

IP67 devices, with outstanding waterproof and dustproof, provide engineers with a reliable tool for stable operation in various extreme environments. These devices reduce maintenance costs and extend equipment lifespan, ensuring production efficiency and safety. Especially in critical fields like automation, healthcare, and the military.

At the same time,

Pogo Pins, with excellent electrical performance and mechanical stability, increase design flexibility while maintaining equipment performance. This connection technology guarantees effective electrical contact even with frequent insertion and removal. Greatly enhancing the reliability and durability of IP67 devices.

We understand that every engineer strives for technical excellence, aiming to apply the best technical solutions to their projects. If you are interested in applying these high-protection level devices and advanced connection technology. It is for your engineering projects or exploring more solutions, we eagerly await further discussion.

Contact us to leverage these technologies to elevate your projects to new heights. We’re committed to the belief that collaboration enables us to extend the limits of technology and achieve more together.