IoT devices are crucial. With high-performance Pogo pins, Johoty offers engineers efficient and reliable solutions. Ensures long-term stability in your device’s performance. Learn more, you can stay ahead in the industry.

IoT devices and their stable electrical connections are key to ensuring reliable operation. Pogo Pins emerge as the ideal choice to achieve this goal, boasting exceptional elasticity and conductivity. Precision-engineered, the pogo pin maintains stable electrical contacts amidst repeated insertions, withdrawals, and vibrational environments. Their goal is to achieve data transmission efficiency and accuracy.

Their outstanding durability and corrosion resistance enable prolonged connection stability even in harsh environments. By adopting Pogo Pins, IoT devices significantly enhance performance and reliability, offering engineers an advanced and dependable solution.

Introduction: IoT Devices Achieve Stable Electrical Contacts with Pogo Pins

- In the design and application of IoT devices, the stability and reliability of electrical contacts are paramount. As spring-loaded pins, Pogo Pins are gradually becoming the preferred choice for electrical connections in IoT devices. Because of their ability to offer flexible design options, reduce contact resistance, and withstand wear and tear.

- Compared to traditional connectors, Pogo Pins can provide stable electrical contacts in complex and dynamic environments. This assures that IoT devices operate efficiently and endure over time.

- This blog will briefly delve into the working principles, key design elements, and typical applications of Pogo Pins in IoT devices. Aiming to provide engineers with practical technical insights and application guidance. It is to optimize device design and enhance product performance, and reliability.

Basic Principle of Pogo Pins: IoT Devices Achieve Stable Electrical Contacts with Pogo Pins

Spring loading:

- The internal spring provides continuous pressure between the barrel and the plunger. Ensuring a firm physical contact between the plunger and the contact surface. Thereby achieving stable electrical connections.

Low contact resistance:

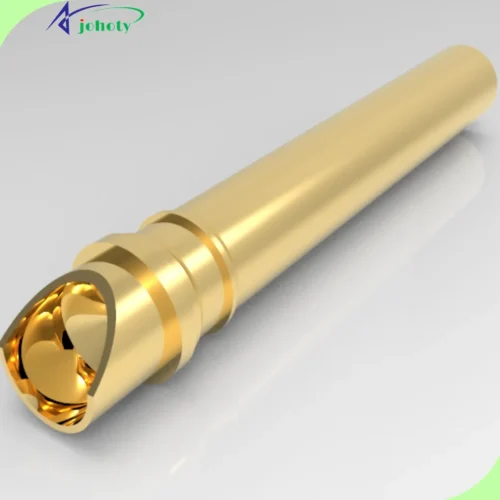

- The pogo pin is typically made of highly conductive materials, such as gold plating, palladium plating, or platinum plating. This feature guarantees a low level of contact resistance, reducing energy dissipation and enhancing the efficiency of signal transmission.

Adaptability:

- Pogo Pins can automatically adjust the position of the plunger within a certain range. This can adapt to the unevenness or slight displacement of the contact surface. Ensuring continuity and stability of the contact.

Durability:

- With high-strength materials and precision manufacturing processes, Pogo Pins have high wear resistance and long service life. Suitable for applications requiring frequent insertions and withdrawals and in vibrating environments.

- This design allows Pogo Pins to provide reliable electrical contacts in various complex and demanding working environments. Widely used in fields, such as IoT devices, communication equipment, and medical devices.

Application of Pogo Pins in IoT Devices

1. Smart Home Devices

- Smart door locks, smart speakers, and smart lighting systems often require frequent insertions and stable electrical connections. Pogo Pins can provide reliable electrical contacts, ensuring the stable operation and longevity of devices.

- For example, the battery connection in smart door locks can achieve efficient power transmission and low loss through Pogo Pins. Thereby extending battery life.

2. Wearable Devices

- Wearable devices, such as smartwatches and fitness trackers require connectors that are compact and durable. Pogo Pins are not only compact but also withstand daily wear and vibration, ensuring device reliability and user experience.

- The charging interface of smartwatches often utilizes Pogo Pins to ensure stable charging and accurate data transmission.

3. Industrial IoT Devices

- Industrial IoT devices need to operate in harsh environments, such as vibration, high-temperature high humidity. Pogo Pins exhibit excellent environmental resistance and are suitable for electrical connections in industrial sensors, automation equipment, and robotic systems.

- The sensor interfaces and data transmission modules of these devices often use Pogo Pins. This is to ensure stable connections and data accuracy under harsh conditions.

4. Medical IoT Devices

- Medical IoT devices have high requirements for the reliability and hygiene of electrical connections. The high conductivity and corrosion resistance of Pogo pins makes them an ideal choice for medical devices. Such as portable medical monitoring devices and smart medical instruments.

- The data interfaces and power connections in these devices are implemented through Pogo Pins. Ensuring efficient and reliable electrical contacts throughout device usage.

5. Smart Agriculture Equipment

- In smart agriculture, Pogo Pins are used in various sensors and automation equipment. Such as soil moisture sensors, environmental monitoring systems, and automatic irrigation systems.

- Pogo pins excel in delivering unwavering electrical connections in outdoor environments, resisting dust, moisture, and temperature changes. Ensuring long-term stable operation of equipment.

- Through practical applications in these diverse scenarios, Pogo Pins demonstrate their indispensable role in IoT devices. Helping engineers tackle various challenges in electrical connections and strengthening the overall effectiveness and consistency of devices.

Design Considerations of Pogo Pins in IoT Devices

Spring Pressure and Contact Force

- Optimize spring pressure to ensure sufficient contact force for stable electrical connections. At the same time, avoid excessive pressure to reduce wear and mechanical fatigue, thereby extending the lifespan of Pogo Pins.

Material Selection

- Choose materials with high conductivity and corrosion resistance, such as palladium plating, platinum, or gold. To reduce contact resistance and improve durability. Material selection directly affects the electrical performance and environmental adaptability of Pogo Pins.

Surface Treatment

- Utilize high-quality surface finish, such as gold plating, to enhance conductivity, wear resistance, and oxidation resistance. High-quality surface treatment can significantly improve the reliability and lifespan of Pogo Pins.

Size and Shape

- Tailor the size and design of Pogo Pins to meet the specific criteria of the application. This can meet the demands for miniaturization and multifunctionality of IoT devices.

- Precise size and shape design can ensure good compatibility between Pogo Pins and contact surfaces, ensuring the stability of electrical connections.

Environmental Resistance

- Consider the environmental resistance of Pogo Pins during design, including dustproof, waterproof (such as IP67), and high-temperature resistance capabilities.

- Ensuring that Pogo Pins can maintain reliable performance under various harsh environments. It is critical for their application in industrial, outdoor, and medical devices.

Installation Method

- Design simple and sturdy installation methods, such as soldering or press-fitting, to improve assembly efficiency and connection stability. Good installation design enhances production efficiency and lowers the chances of potential damage during the installation phase.

- By comprehensively considering these design factors, engineers can ensure that IoT devices have efficient, stable, and reliable electrical connections.

High-End Precision Manufacturing of Pogo Pins in IoT Devices

Precision Machining Technology

- Utilizing high-precision CNC machining and lathe machining to ensure the precise dimensions and consistency of Pogo Pins. Precision machining ensures tight fits between the spring, plunger, and barrel of Pogo Pins. Thereby achieving reliable electrical contacts.

Automated Assembly and Testing

- Utilizing automated assembly lines for the assembly of Pogo Pins to ensure consistent quality and performance of each Pogo Pin. Automated assembly systems help to alleviate errors that can arise from manual procedures, ultimately bolstering production efficiency.

- Additionally, equipped with CCD during assembly to conduct real-time testing on each Pogo Pin. This ensures compliance with design specifications and quality standards.

High-Quality Surface Treatment

- Gold plating or nickel plating is applied to the surfaces of the Pogo Pin plunger and barrels. This is to enhance conductivity and wear resistance. The surface treatment process requires strict control of plating thickness and uniformity.

- It can ensure that each Pogo Pin presents excellent electrical properties alongside a high degree of resistance to corrosion.

Spring Manufacturing and Heat Treatment

- Utilizing high-strength spring steel materials and precise coiling processes to manufacture Pogo Pin springs. After manufacturing, strict heat treatment processes are employed to enhance the hardness and elasticity of the springs.

- Ensuring stable pressure and contact force during long-term usage.

Quality Control and Testing

- Implementing comprehensive quality control, including raw material inspection, manufacturing process monitoring, and finished product testing. Utilizing high-precision testing equipment, such as coordinate measuring machines and microhardness testers.

- This conducts measurements on dimensions, hardness, plating thickness, and contact resistance of Pogo Pins. Ensuring that each Pogo Pin meets design requirements.

Environmental Adaptability Testing

- Conducting environmental adaptability tests on Pogo Pins. Including dustproof, waterproof, such as IP67, high-temperature resistance, and corrosion resistance tests. It is to simulate working conditions in actual usage environments.

- Through these tests, ensure that Pogo Pins maintain stable performance and reliable electrical contacts in various demanding environments.

Continuous Improvement and Innovation

- Continuously monitoring the latest manufacturing and materials science to optimize the design and manufacturing processes of Pogo Pins. Through research and innovation, contributing to the increased performance and trustworthiness of Pogo Pins. This can meet the evolving demands of IoT devices for electrical connectors.

- These high-end precision manufacturing techniques ensure the outstanding performance and long-term reliability of Pogo Pins in IoT devices. Providing engineers with high-quality electrical connection solutions.

Successful Cases of Pogo Pins in IoT Devices

1. Charging Interface of Smartwatches

Due to their compact design, smartwatches demand high standards for charging interfaces. A well-known smartwatch brand utilizes Pogo Pins as its charging interface, achieving the following advantages:

Efficient charging: Pogo Pins provide stable current transmission, significantly improving charging efficiency.

Durability: The high wear resistance of Pogo Pins ensures a long interface lifespan during frequent charging insertions.

Waterproof performance: The design of Pogo Pins grants smartwatches excellent waterproof capabilities, meeting IP67 standards for everyday usage environments.

2. Battery Connector of Smart Door Locks

Smart door locks require battery connectors with high reliability and safety. Many smart door lock manufacturers select Johoty’s Pogo Pins as the battery connector, achieving the following objectives:

- Stable electrical connection: Even under frequent usage and vibration, Pogo Pins maintain stable electrical contacts.

- Ease of replacement: Modular design enables users to easily replace batteries, enhancing user experience.

- Oxidation resistance: Gold-plated Pogo Pins exhibit excellent oxidation resistance, ensuring electrical stability during long-term usage.

3. Interface Connections of Industrial Sensors

In industrial IoT applications, sensors need to maintain reliable electrical connections in harsh environments. Some industrial sensor manufacturers adopt our Pogo Pins, achieving the following effects:

- Environmental resistance: Pogo Pins possess dustproof, waterproof, and high-temperature resistance capabilities, allowing stable operation in demanding industrial environments.

- High-precision data transmission: The low contact resistance of Pogo Pins ensures high-precision transmission of sensor data, meeting the high demands of industrial automation.

- Longevity: The high wear resistance and corrosion resistance of Pogo Pins significantly extend the lifespan of sensors, reducing maintenance costs.

4. Data Transmission Interface of Medical Devices

In portable medical devices, data transmission interfaces require high reliability and hygiene. A portable electrocardiograph device utilizes Pogo Pins as the data transmission interface:

- Stability: Pogo Pins maintain stable electrical connections even during movement, ensuring continuity and accuracy of data transmission.

- Durability: High-strength materials and precision manufacturing processes enable Pogo Pins to maintain excellent performance during frequent use.

- Hygiene safety: The design facilitates easy cleaning and disinfection, meeting medical device hygiene standards and ensuring safe usage.

5. Sensor Connections of Smart Agriculture Equipment

Smart agriculture equipment needs to reliably operate in outdoor environments. A soil moisture sensor manufacturer selects Johoty’s Pogo Pins as its connectors, achieving the following effects:

- Waterproof and dustproof: Pogo Pins designed according to IP67 can operate stably in damp and dusty environments.

- Corrosion resistance: Pogo Pins made of corrosion-resistant materials maintain excellent performance even when buried in soil for extended periods.

- Stable connection: Even amidst drastic environmental changes, Pogo Pins provide stable electrical contacts, ensuring data transmission reliability.

These successful cases demonstrate the wide applicability and superior performance of Pogo Pins in various types of IoT devices. Fully proving their critical role in achieving stable electrical connections.

Installation and Maintenance of Pogo Pins in IoT Devices

Installation Guide

1. Design Phase

- Selection and Matching: Choose Pogo Pins with suitable specifications and types based on the specific requirements of IoT devices. Ensuring their dimensions, spring force, and electrical performance match the device design requirements.

- PCB Layout: In PCB design, reserve appropriate mounting holes and soldering positions for Pogo Pins. This can ensure they can be securely installed and make good contact with the circuit board.

2. Installation Steps

- Soldering Process: Use precise soldering techniques to solder Pogo Pins onto the circuit board. You can use reflow soldering or wave soldering to ensure strong and conductive solder joints.

- Press-fit Process: For applications requiring removable installation, use press-fit to install Pogo Pins into the device, ensuring stability and preventing loosening. Use specialized tools for press-fitting to guarantee the precision and dependability of the installation procedure.

- Testing and Calibration: After installation, perform electrical performance testing and mechanical calibration. This ensures the contact resistance of each Pogo Pin meets the design specifications and the spring pressure is appropriate.

Maintenance Guide

1. Regular Inspection

- Contact Surface Inspection: Regularly inspect the condition of the needle head and contact surface of Pogo Pins. To ensure there is no oxidation, wear, or contamination. Any identified issues should be promptly resolved through cleaning or replacement measures.

- Spring Performance Inspection: Check whether the spring force of Pogo Pins is normal to ensure stable contact force. If there is spring fatigue or failure, replace them promptly.

2. Cleaning and Maintenance

- Surface Cleaning: Regularly clean the plunger head and barrel of Pogo Pins, removing surface dust and contaminants to ensure good electrical contact.

- Protective Measures: Pogo Pins used in harsh environments should be protected, such as installing dust covers or waterproof sealing rings to extend their lifespan.

3. Troubleshooting

- Electrical Faults: If there are issues, such as poor contact or high resistance. First, check whether the plunger of Pogo Pins and the contact surface are clean and if the contact force is sufficient. And make corresponding adjustments or replacements.

- Mechanical Faults: If Pogo Pins experience mechanical damage or spring failure during use, replace the damaged parts promptly. This is to ensure the continuous stable operation of the device.

4. Replacement Cycle

- Regular Replacement: Determine the replacement cycle of Pogo Pins based on the frequency of device usage and environments. For applications with high-frequency usage or in harsh environments, it is recommended to replace every 6 months to 1 year.

- Preventive Maintenance: During annual equipment maintenance, conduct a unified inspection and replacement of Pogo Pins. It is to prevent potential failures and maintain the device’s reliability and performance integrity over an extended time.

Market Prospects and Development Trends of Pogo Pins in IoT Devices

Market Prospects

1. Growth in IoT Device Demand

- With the rapid development of fields, such as smart homes, industrial IoT, wearable devices, and smart cities. The market demand for IoT devices continues to grow. Pogo Pins, as crucial connecting components, also witness an increasing market demand.

2. Demand for High-Reliability Connections

- IoT devices increasingly demand high reliability from connectors, and Pogo Pins, with their excellent electrical performance and mechanical stability. They become the preferred connection solution for various IoT devices. The market demand for high-reliability Pogo Pins will continue to rise.

3. The trend toward miniaturization and Multifunctionality

- Modern IoT devices pursue designs that are both miniaturized and multifunctional. The compact size and diverse application characteristics of Pogo Pins can meet this trend’s requirements. The market demand for small, efficient Pogo Pins will continue to increase.

Development Trends

1. Advancements in Material Technology

- The application of new materials with high conductivity and corrosion resistance will further enhance the performance of Pogo Pins. As material science advances continuously, it is getting better.

- In the future, more Pogo Pins using new materials will enter the market, improving device reliability and lifespan.

2. Advancement in Automated Production

- Improvements in automated production technology will further enhance the production efficiency and consistency of Pogo Pins. Through automated assembly and testing, Johoty can provide high-quality, low-cost Pogo Pins to meet large-scale market demands.

3. Enhanced Environmental Adaptability

- For applications in harsh environments, Pogo Pin designs will pay more attention to characteristics. Features like withstanding high temperatures, repelling water, and blocking out dust.

- Through improved designs and manufacturing processes, future Pogo Pins will be able to maintain stable performance in various environments.

4. Smart Applications

- As the degree of intelligence in IoT devices increases, the application of Pogo Pins will also evolve towards smart connections. For example, by integrating sensors and data interfaces, future Pogo Pins will be electrical connectors and perform more functions.

5. Customized Solutions

- The design and manufacturing of Pogo Pins will become more customized to meet the specific different applications. Providing tailored connection solutions will empower customers to flourish in the face of intense market competition.

Conclusion: IoT Devices Achieve Stable Electrical Contacts with Pogo Pins

- Johoty’s Pogo Pin, with its high reliability, durability, and flexibility, has become an indispensable key component in IoT devices. Engineers always fully consider the advantages of our Pogo Pins during the design process. Choosing the appropriate specifications and types to enhance device performance and reliability.

- Through continuous innovation and improvement, Johoty’s Pogo Pin will provide stronger support for the future development of IoT devices. Driving technological advancement in the industry. Meanwhile, our CFT team will spare no effort in supporting you!