Injection molding, In the field of medical device pogo pin connectors, successfully manufacturing these tiny connectors. With our guidance and insights, you’ll unlock endless possibilities in medical engineering!

Injection molding provides you with a detailed exploration of technology applications in the production of miniature connectors for medical devices.

Firstly, it will delve into the principles and processes of injection molding. Covering aspects such as material selection, mold design, and machine operation.

Then, addressing the specific requirements of medical device connectors, such as high precision and material safety. It will extensively discuss the techniques and methods of injection molding to meet these demands.

Additionally, the blog will showcase the specific applications and advantages of injection molding technology in producing miniature medical device connectors. This is through case studies or descriptions of actual production processes.

Finally, it will examine injection molding technology’s development and application prospects in these fields. Such as wearable medical devices and smart healthcare. In conjunction with current hot topics or industry trends, aiming to attract the attention and learning of engineers.

Introduction: Injection molding crafts tiny connectors for medical devices

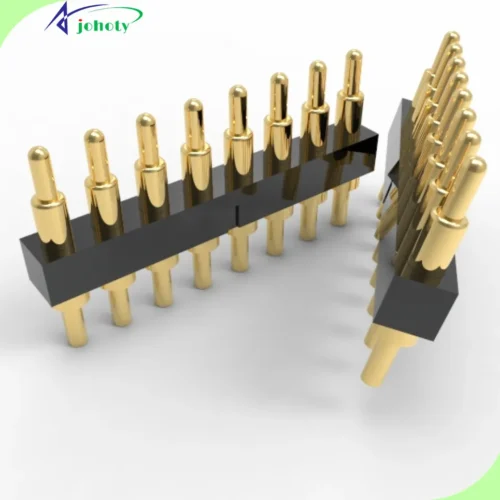

In medical device manufacturing, the precision and reliability of miniature Pogo Pin connectors are paramount. The application of injection molding in this field is increasingly gaining attention. This blog delves into how to utilize injection molding technology to produce miniature medical device Pogo Pin connectors. And discusses their widespread application and future development trends in the medical industry.

Through this article, you will understand how injection molding plays a crucial role in medical device manufacturing As well as its advantages in improving product quality, reducing costs, and shortening production cycles. Additionally, we will explore the technical innovations and challenges of injection mold. It is in meeting the stringent requirements of the medical industry for Pogo Pin connector precision and safety. Right now, injection molding is poised to become a significant driving force in medical device manufacturing. Providing valuable learning and application resources for engineers.

What is injection molding?

Injection molding is a standard process in plastic manufacturing for manufacturing miniature medical device connectors. The basic idea is to heat solid plastic pellets until they’re molten, then forcefully inject them into specialized molds. Inside the mold, the molten plastic fills the cavity and cools and solidifies, ultimately forming the required Pogo Pin connectors.

Key steps of the injection molding process:

1. Material Preparation:

- Selecting medical-grade plastic materials suitable for use in medical devices and preparing them in pellet or powder form.

2. Heating and Melting:

- Placing plastic pellets into the injection molding machine’s heating barrel. Melting them into a molten state through heating and mixing.

3. Injection and Molding:

- The high-pressure machine shoots molten plastic into the mold. The connector’s ultimate shape and size hinge on the mold’s design. We design the mold based on our client’s requirements.

4. Cooling and Solidification:

- During cooling in the mold, the molten plastic gradually solidifies into a solid. Molding the shape and structure of the Pogo Pin connector.

5. Mold Release and Post-Processing:

After cooling and solidifying, the mold unlocks, and the finished connector is expelled. If necessary, Pogo Pin connectors may undergo additional processing, such as removing mold marks or surface treatment. The advantages of injection molding lie in its ability to achieve high precision and high-efficiency production. And suitability for manufacturing Pogo Pin connectors of various shapes and sizes. For medical device manufacturing, injection molding meets stringent product quality and safety standards. It allows quick reaction to client needs, boosts production efficiency, and cuts manufacturing expenses.

Demand and Challenges of Tiny Pogo Pin Connectors in Medical Devices

Primary requirements for tiny Pogo Pin connectors:

Precision:

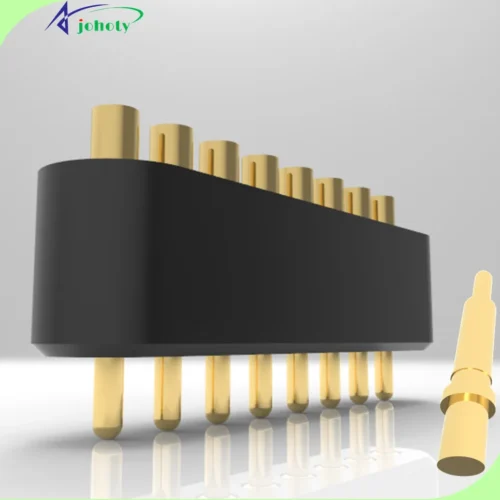

- Medical devices typically demand extremely high precision from Pogo Pin connectors. Especially in miniature equipment where the dimensions and shapes of the connectors must precisely match to ensure proper device functionality.

Reliability:

- As crucial components in medical devices, Pogo Pin connectors must exhibit high reliability and stability. The medical industry strictly requires Pogo Pin connectors to operate consistently over extended periods without failure.

Safety:

- Pogo Pin connectors need to adhere to strict safety standards in the medical industry. Ensuring material safety, non-toxicity, non-irritation, and resistance to environmental factors such as disinfectants and cleaning agents.

Technical and market challenges:

Manufacturing Precision:

- Producing miniature Pogo Pin connectors requires high-precision machining technology and equipment, including mold manufacturing and injection molding process control. This requires top-notch manufacturing techniques and equipment.

Material Selection:

- Medical device Pogo Pin connectors demand the utilization of medical-grade materials. They are often costly and must meet stringent safety standards, posing challenges in material selection.

Market Demand:

- The medical device industry evolves rapidly, with market demand constantly changing. Pogo Pin connector manufacturers need to swiftly respond to market demands, flexibly adjusting production lines and supply chains.

Application of Injection Molding in Manufacturing Tiny Pogo Pin Connectors for Medical Devices

Precision Molding:

- Injection molding enables the high-precision manufacturing of miniature Pogo Pin connectors. Through our precise mold design and advanced injection molding equipment. The dimensions and shapes of Pogo Pin connectors can meet stringent medical device specifications.

Complex Structures:

- Tiny Pogo Pin connectors in medical devices often feature complex structures and intricate features. Injection molding can flexibly manufacture Pogo Pin connectors with complex shapes and structures. Meeting the requirements of medical device designs.

Material Selection:

- Injection molding can utilize various medical-grade plastic materials, such as polycarbonate (PC), polyamide (PA), polystyrene (PS), etc. These materials possess excellent physical properties and biocompatibility, meeting the requirements of medical devices for material safety and durability.

Production Efficiency:

- Injection molding boasts high efficiency and high yield. Through automated injection mold production lines, miniature Pogo Pin connectors can be rapidly and mass-produced. Enhancing production efficiency and reducing costs.

Quality Control:

- Injection molding features a stringent quality control system, ensuring that each Pogo Pin connector meets quality standards. Real-time monitoring and inspection equipment enable the timely detection and correction of quality issues during the production process. Ensuring Pogo Pin connectors are stable and reliable.

How does injection molding achieve dust and water resistance while enhancing the retention force in the manufacturing of Pogo Pin connectors for medical devices?

Material Selection:

- Choose medical-grade plastic materials with excellent sealing and durability, such as silicone or fluoroelastomer. These materials offer outstanding waterproof and dustproof properties, effectively isolating external influences on Pogo Pin connectors.

Design Optimization:

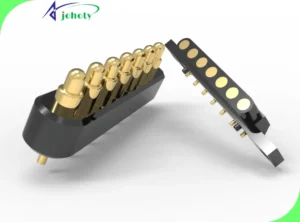

- Consider dust and water resistance requirements in the design of Pogo Pin connectors, employing sealing structures and waterproof designs. By adding sealing rings, sealants, and other devices.

- Ensure that all parts of the Pogo Pin connector effectively prevent the intrusion of dust, moisture, and other external substances.

Injection Molding Process Control:

- We monitor temperature, pressure, and injection speed throughout the injection mold. Ensure thorough filling of the mold with the plastic material, forming a compact structure for the Pogo Pin connector.

- Proper injection molding parameters ensure that the Pogo Pin connector has good sealing performance and strength.

Surface Treatment:

- Apply special treatments to the surface of Pogo Pin connectors, such as spraying waterproof coatings or surface treatment processes. This is to enhance the dust and water resistance of the Pogo Pin connector surface.

Enhancing the Retention Force of Pogo Pin Connectors:

- In design, use appropriate Pogo Pin structures, such as increasing the length of Pogo Pins or using spring structures. To enhance the connection force between Pogo Pins and sockets.

- Additionally, optimize the injection molding process to ensure sufficient contact area between Pogo Pins and connectors. Utilize suitable materials to boost the wear and corrosion resistance of Pogo Pins.

Material Selection and Process Optimization in Injection Molding for Manufacturing Tiny Connectors in Medical Devices

Material Selection:

a. Medical-Grade Plastic Materials:

- Such plastic materials meet industry standards, such as polycarbonate (PC), polyamide (PA), and polypropylene (PP). These materials have excellent biocompatibility, chemical resistance, and mechanical properties, suitable for manufacturing medical device connectors.

b. Silicone Materials:

- For Pogo Pin connectors requiring excellent waterproof performance, silicone materials can be chosen for sealing components. Silicone exhibits good elasticity and high-temperature resistance, effectively preventing moisture and dust infiltration.

c. Conductive Materials:

- For connectors requiring conductivity, conductive plastic materials like carbon fiber-filled polymers can be selected to ensure electrical performance.

Process Optimization:

a. Mold Design Optimization:

- When designing molds, consider the complex structure and precision requirements of connectors. Use advanced CAD/CAM technology to design molds with proper runner design and cooling systems for efficient injection molding production.

b. Injection Molding Process Control:

- Control parameters like temperature, pressure, and injection speed throughout the injection molding process. This ensures thorough mold filling and avoids quality issues like bubbles and defects.

c. Post-Processing Techniques:

- After connector molding, perform necessary post-processing techniques. Such as removing mold marks, surface polishing, and applying waterproof coatings to enhance the appearance and functionality of connectors.

d. Quality Control:

- Implement stringent quality assurance procedures, conducting comprehensive testing and inspection of connectors. To ensure each meets product standards and customer specifications.

Quality Control and Inspection in the Manufacturing of Tiny Connectors for Medical Devices Using Injection Molding

Process Parameter Monitoring:

- Real-time monitoring of parameters, such as temperature, pressure, injection speed, etc., during the injection molding process. Advanced injection molding machines and control systems are employed.

- It is to ensure that the production process of each connector operates within appropriate process parameter ranges. Ensuring the long-term stability of product high-quality.

Raw Material Quality Control:

- Ensure stringent quality standards for raw materials. This ensures that the plastic pellets or powders used comply with relevant standards and regulations in the medical industry.

- Perform essential inspections and tests on raw materials to ensure they meet requirements for physical properties, chemical composition, biocompatibility, etc.

Mold Inspection:

Comprehensive inspection and testing of injection molds before production. Ensure the integrity of mold structure, accurate dimensions, and compliance with product design requirements. Special attention is paid to mold runner design and cooling systems. It ensures proper filling of the mold with plastic material, avoiding defects such as air bubbles, short shots, etc.

Finished Product Inspection:

Comprehensive quality inspection of injection-molded products, including visual inspection, dimensional measurement, functional testing, etc. Advanced equipment, such as visual inspection systems, coordinate measuring machines, etc. They’re used to ensure each connector meets product specs and customer needs.

Functional Testing:

Rigorous testing of connector functionality, including insertion and withdrawal cycles testing, contact resistance testing, waterproof performance testing, etc. By simulating actual usage environments and conditions, the stability and reliability of connectors are verified.

Quality Records and Traceability:

Recording production data and inspection results for each connector to establish a complete quality management system. Ensuring product quality traceability so that, in case of quality issues. Identifying the problem source enables swift action for effective solutions.

Why can the quality and functionality of Tiny Pogo pin connectors for medical devices only be ensured through injection molding?

Precision and complexity:

- Micro Pogo pin connectors for medical devices typically have very small dimensions and complex structures. They require highly precise machining and molding capabilities.

- The injection molding process can accurately shape the tiny connector components and meet the demands of complex structural requirements. They are through precise mold design and high-pressure injection of plastic

Integral molding:

- Injection molding allows for the integral molding of connectors, avoiding the process of assembling multiple parts. This integral molding design reduces the number of parts and enhances the stability and reliability of the connectors. Lowers the risk of problems and damage during assembly.

Material selection and characteristics:

- The plastic materials used in injection molding can be selected according to the requirements of medical devices. For instance, high-temperature resistance, biocompatibility, and corrosion resistance are key.

- Material selection ensures the connectors meet the environmental and operational requirements of medical devices while maintaining stability and reliability.

Quality control:

- Injection molding employs strict quality control systems to monitor and control the production process of each connector. Ensuring quality stability and consistency.

- Through real-time detection and testing, problems in the production process can be promptly identified and corrected. Thus, guaranteeing the quality and functionality of the connectors.

Conclusion: Injection molding crafts tiny connectors for medical devices

We delve into the significant application of injection molding technology in the manufacturing of tiny connectors for medical devices. With its advantages of high precision, efficient production, and wide material selection. Injection molding has become a crucial technological support in the medical device industry. For engineers, understanding and mastering the latest developments in injection molding technology. This will contribute to their professional and efficient work in the design and manufacturing process of medical devices.

As the medical device field keeps evolving and innovating. We believe that the application of injection molding technology will become increasingly widespread and profound. This is in the field of miniature connector manufacturing. Looking forward.

We’ll keep sharing the latest technologies and trends in medical device manufacturing. Engineers are exploring the myriad potentials of medical technology.