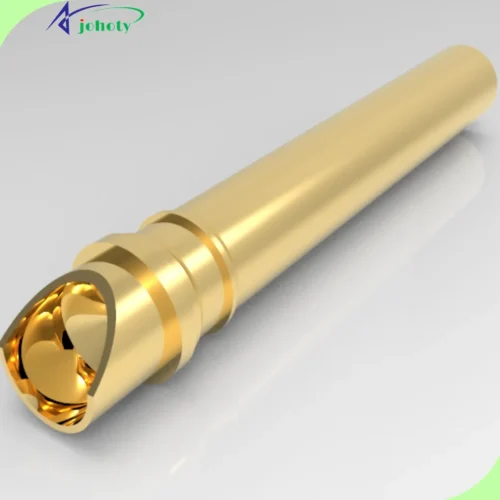

Through Hole Pogo Pins Description:

Catalogs of Through Hole Pogo Pins:

Through Hole Pogo Pins Datasheet:

Items |

Details |

|---|---|

| Electrical: | Contact Resistance: ≥ 15 mΩ, Custom. |

| Current Rating: 0.05A – 50A, Custom. (varies based on pin size and design) | |

| Voltage Rating: 3.3V – 1000V, Custom. | |

| Mechanical: | Diameter: 0.3 mm to 15 mm, Custom. |

| Length: 1.3 mm to 100 mm, Custom. | |

| Spring Force: ≥ 15 gf at nominal working height | |

| Working stroke: 0.1 mm to 10 mm, Custom. | |

| Full stroke: 0.15 mm to 10 mm, Custom. | |

| Durability (Life Cycle): Up to 100,000 cycles or more. | |

| Operating Temperature: -40°C to +125°C | |

| Mounting Style: Through-hole, with or without flanges | |

| Materials: | Plunger: Gold-plated brass or beryllium copper. |

| Barrel: Gold-plated brass or beryllium copper. | |

| Spring: Stainless steel or music wire | |

| Installation: | Standard Through-Hole: Optional. |

| Flush Mount: Optional. | |

| Extended Tai: Optional. | |

| Snap-in Mount: Optional. | |

| Press-Fit: Optional. | |

| Right-Angle Mount: Optional. | |

| Vertical Mount: Optional. | |

| Package: | Bulk Packaging: Optional. |

| Tape and Reel: Optional. | |

| Tray Packaging: Optional.. | |

| Tube Packaging: Optional.. | |

| Blister Packaging: Optional. | |

| Plastic Bag with Antistatic Film: Optional. | |

| Custom Packaging: Optional. | |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

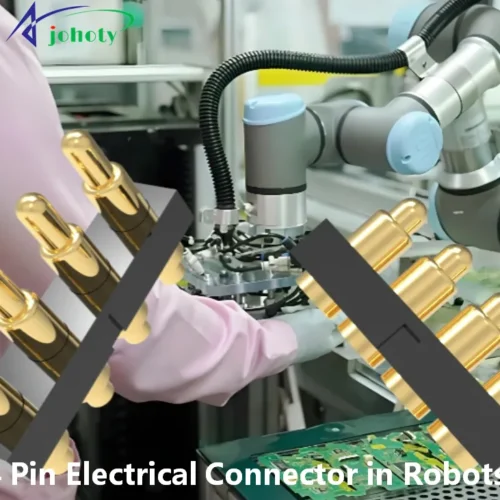

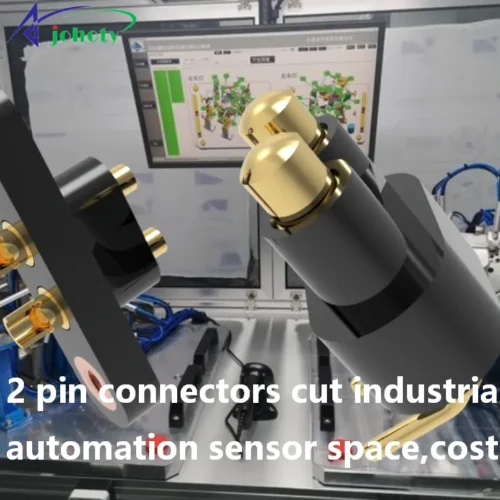

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s Through Hole Pogo Pins?

Johoty’s through hole pogo pins have >50k models, flexible custom of stroke, length, etc. Johoty is trustworthy!

Through Hole Pogo Pins Benefits:

Reliable Mechanical Connection

Excellent Electrical Performance

High Durability and Long Service Life

Easy and Efficient Installation

Through Hole Pogo Pins Applications:

PCBA Connections for Electronic Products

Automotive Electronic Control System

Signal Transmission of Industrial Automation Equipment

Electrical Connections of Medical Equipment

Internal Connections of Wireless Communication Devices

Connection of High-performance Computer Hardware

Circuit Installation of Aerospace Equipment

Assembly of Optoelectronic Communication Equipment

Through Hole Pogo Pins Advantages:

Reliable Mechanical Connection

Through hole pogo pins can be firmly fixed on the circuit board, avoiding any looseness or poor contact. Due to its passage through the circuit board, the connection is more robust and less susceptible to external vibrations or temperature changes, ensuring the long-term stability of the product.

This connection method is like nailing a nail into a wooden board, firmly fixed and not easy to loosen. Through this method, the pogo pins on the circuit board can be stably connected and not easily interfered with, ensuring that electrical equipment can be used for a long time without poor contact problems.

Stronger Current Carrying Capacity

The through-hole installation method of pogo pins provides a larger contact area and can carry larger currents. This makes it very suitable for applications that require high current transmission, such as battery charging and high-power systems.

Just like the thicker the wire, the greater the current it can transmit, through hole pogo pins are installed by through-holes, increasing the connection area and allowing more current to flow, making them suitable for battery charging or devices with high power demand.

Save space

Through hole pogo pins can be compactly placed on circuit boards, effectively saving space. For designs with limited space, they can provide higher integration. Just as we neatly arrange the books on the table without wasting an inch of space, the pogo pin can also make good use of space and help us put more functions on a small circuit board.

Support High-density Design

With through-hole installation, multiple pogo pins can be placed in a limited space, suitable for high-density and complex circuit designs. Just like how we put more toys in a box, through proper placement, the design of through hole pogo pins allows us to put more functions and components on a small circuit board without wasting any space.

FAQ

Our through hole pogo pins are made from top-notch materials using cutting-edge manufacturing techniques. Ensuring they last a heck of a long time. They stand up to frequent use and extreme conditions without breaking a sweat in terms of stability and reliability.

We’re all about customization. Whether you need different sizes, shapes, mechanical properties, or plating materials we’ve got you covered. We make sure you get the perfect fit for your specific application, with no compromises.

Yes, contact us! We’re committed to green production practices. Our designs of through hole pogo pins are focused on recyclability and reducing environmental impact. Aligning with sustainability goals and helping our customers fulfill their eco-friendly commitments.