Is Brass Magnetic? Discover How Brass Impacts Pogo Pin Performance. Learn Why Its Non-magnetic Features Are Essential In Advanced Engineering.

Introduction

Is brass magnetic? Have you ever been curious? In fact, brass is very common in our daily lives, such as keys, musical instruments, and some electrical accessories, but it is very important in high-tech applications. Especially pogo pin, which is widely used in high-precision connections, brass plays key roles.

Brass is non-magnetic and very popular in electronic devices. It doesn’t interfere with current based on excellent corrosion resistance. In pogo pins, brass is commonly used as the core material to ensure good electrical performance and withstand frequent contact pressure. This makes brass the preferred material for engineers to design reliable connections.

Brass is a part of pogo pin materials and affects the overall performance of the equipment. Do you want to really know brass more as a specific role in Pogo Pin? This article will show you the mysteries behind it!

Magnetic properties of brass to Answer: Is Brass Magnetic?

What is brass? is brass magnetic?

Brass is alloy of zinc and copper. According to different composition ratios, brass can be adjusted to different hardness and color. It is used musical instruments, gears, and pogo pins due to its good conductivity, corrosion resistance, and mechanical performance.

Magnetic properties of brass: Is brass magnetic?

Brass isn’t magnetic. It is non magnetic and isn’t attracted by magnets like iron. But in some brass with high impurity content, it may exhibit slight magnetism due to the presence of small amounts of iron or nickel.

Why do engineers care about brass magnetism?

In some electronic devices, magnetism may interfere with signal transfer or affect other components. Pogo pins are often used in high-precision electrical connectors that require low magnetic interference. Brass is highly suitable for these applications due to its low or even non-magnetic properties.

The role of brass in pogo pin

Excellent conductivity: ensure efficient conduction of current.

Mechanical durability: able to withstand multiple compressions and releases.

Corrosion resistance: prolongs the service life. Brass fully meets these requirements, while its non-magnetic nature ensures signal stability.

How to do if magnetic are needed?

If certain application requires magnetism, engineers often choose iron nickel alloy or magnetic coating on brass surface. But brass itself is generally used in low magnetic or non-magnetic applications.

Actual testing: How to confirm whether brass has magnetism?

A simple way is to test brass with a magnet. If brass is attracted by a magnet, it may be because it contains a small amount of magnetic impurities. Pure brass will not be attracted by magnets.

Why is brass the ideal for pogo pins?

Non magnetic: Avoid interfering with electronic devices.

Strong durability: can withstand 10,000 cycles of connections.

Competitive cost: more cost-effective compared to pure copper.

Good processing: suitable for mass production of complex shapes.

Composition and properties of brass to Answer: Is Brass Magnetic

Brass is suitable for pogo pins as its non-magnetic, good conductivity, and durability.

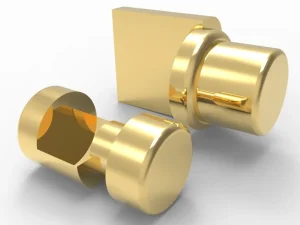

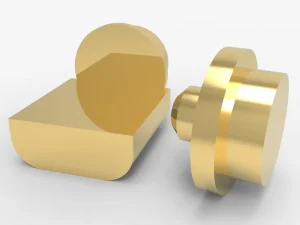

What are brass components?

Copper content of brass is 60%~70%, others are zinc. To enhance special properties, aluminum, tin, or nickel are added too.

Color and appearance.

Brass looks like gold, presents a bright yellow. This color makes brass very popular, used as mechanical parts in industry, commonly make brass vessels and musical instruments.

Hardness and toughness.

It is harder than pure copper, but brass still retains good toughness. It isn’t easy to break and is easy to cut, bend, or stamp for making pogo pins.

Conductivity.

Conductivity isn’t as good as pure copper, but brass is still good enough to meet electronic needs. Its conductivity is about 50% of pure copper, which can effectively conduct current and has good wear resistance.

Corrosion resistance.

Has strong corrosion resistance. When brass is exposed to air, a layer of oxide film forms on the surface to protect internal metal from further corrosion. Pogo pins made of brass are not easily rusted in electronic devices.

Magnetic:

Brass is non-magnetic. Ordinary magnets cannot attract brass. Because copper and zinc in brass are non-magnetic, this makes brass an ideal choice for pogo pins to avoid magnetic interference.

Thermal conductivity:

Quickly conduct heat with good thermal conductivity. This is important for electronic components as it can help dissipate heat from the device and ensure its stable operation.

Eco-friendliness and recyclability:

Brass is eco-friendly to recycle multiple times with almost no change in performance. Brass is very useful for industrial production.

Antibacterial performance:

Copper in brass can naturally resist and kill bacteria. This is important for medical equipment on high hygiene standards.

Application of brass in Pogo pins to Answer: Is Brass Magnetic

Brass has excellent conductivity, mechanical strength, corrosion resistance, and processability, enables pogo pins to provide reliable electrical connections under various harsh conditions. With surface coating, brass provides engineers with a cost-effective solution and is also an eco-friendly choice.

Conductivity:

Brass has excellent conductivity containing copper and zinc. For pogo pins, conductivity is crucial as they are primarily used for electrical connections, and brass ensures fast and stable signal transfer. Compared to other materials, brass has lower resistance and minimum energy loss.

Mechanical strength:

Pogo pins require frequent compression and elastic recovery during use, and brass mechanical strength is very suitable for this application. It has moderate hardness and good ductility, is not easily deformed or broken, maintain long-term performance.

Corrosion resistance:

Brass has strong resistance to oxidation and corrosion, adapts to humid or acidic for pogo pins in various environments for a long time. In automobiles, industrial equipment, or electronic devices, pogo pins need to face harsh environments, and brass can ensure their long-term stability.

Plateability:

The pogo pin surface usually requires gold, silver, or nickel plating to enhance conductivity and wear resistance, while brass has good platability. It is easy to coat the brass surface with metal, and the coating can firmly adhere. This can enhance pogo pin performance and durability.

Machinability:

Brass is very easy to process into pogo pin subparts through turning, stamping, and other methods. This processability reduces production costs and can produce very complex structures to meet different needs.

Non magnetism:

The brass non magnetism is very important for certain special applications. In electronic devices that require avoidance of electromagnetic interference, non-magnetic brass can prevent magnetic influence on signal transfer, ensuring equipment’s stable operation.

Cost effectiveness:

Compared to pure copper, brass has a lower cost but still provides higher performance. This high cost-effectiveness is an ideal choice for pogo pin mass production.

Wide adaptability:

Brass can adjust its composition ratio according to different applications, thereby changing its properties. This flexibility allows pogo pins to adapt to high-end consumer electronics and industrial control equipment.

Environmental friendliness:

As a recyclable material, brass is eco-friendly. In today’s environment, pogo pins made of brass have excellent performance and follow environmental trends.

Corrosion resistance of brass to Answer: Is Brass Magnetic?

Brass is resistant to oxidation in air and is also very stable in water and chemical environments

Why can brass resist corrosion?

Brass is a copper-zinc alloy, and copper itself has strong corrosion resistance. The addition of zinc allows brass to work well in more environments. Copper forms an oxide film in the air, and this thin protective layer can prevent further corrosion.

Brass performance in humid:

Brass is stable in humid because it can resist moisture erosion. Even in acidic rainwater, a corrosion-resistant passivation layer can form on the surface to prevent damage to internal materials.

Corrosion resistance is related to brass composition:

Brass corrosion resistance is directly related to the copper content inside it. Generally speaking, the higher the copper content, the better the corrosion resistance. Some advanced brass alloys also add a small amount of aluminum or tin to further enhance brass’ oxidation and corrosion resistance.

Resistance to electrolytic corrosion:

Iron often rusts due to electrolytic corrosion in humid or marine environments. Brass has stable electrochemical properties and is not prone to electrochemical reactions with other metals, making it suitable for scenarios exposure to water or salt spray.

Corrosion resistance of brass in industries:

Brass can resist corrosion from many mineral oils, organic acids, and even sulfides. It is often used in industry, and pogo pin surface layer is reliable in places requiring conductivity and corrosion resistance.

Corrosion resistance under high temperature:

Brass can keep good corrosion resistance. Compared to iron or ordinary steel, brass is not easily oxidized in high temp and is used as a contact point in electronic devices at higher temperatures.

Significance of brass corrosion resistance in Pogo pins:

Pogo pins need to maintain good conductivity and mechanicals for a long time, and brass corrosion resistance can make them stable in humid car systems or high acid and alkali industrials. Engineers choose brass because it can extend the service life of pogo pins and reduce costs.

Brass Mechanical Features to Answer: Is Brass Magnetic?

The easy processing and conductivity of brass perfectly meet the mechanical requirements of pogo pins. Engineers are interested in brass because it can stably function in applications and has high cost-effectiveness!

High strength but flexible.

Brass is copper-zinc alloy with higher strength than pure copper, but it maintains flexibility.

It is not easy to break and can withstand significant pressure or external impact.

When producing pogo pins, brass strength ensures long-term stability.

Even after repeated use, brass will not easily deform and use in mechanical components.

Meanwhile, its flexibility can also reduce damage to the device interface.

Excellent wear resistance.

Brass has high wear resistance and can maintain a smooth surface through multiple contact frictions.

Ideal material for spring loaded pins, reducing contact resistance and ensuring stable current transmission.

Engineers like brass because it can maintain durability in harsh.

This wear resistance provides less maintenance needs and reduces equipment usage costs.

In high-frequency testing, brass can work continuously and won’t easily fail.

Good processing performance.

Easily machined into complex shapes by turning, milling, drilling.

The small and precise parts of pogo pins are usually made of brass to ensure high precision during processing.

Engineers appreciate its ease of processing, shorten production time, improved efficiency.

After processing, brass can still maintain good surface smoothness, making the parts more beautiful and durable.

Due to its excellent processing, brass is cost-effective.

Strong corrosion resistance.

Brass can resist moisture, salt spray, and many chemicals.

Corrosion resistance is crucial in electronic components to ensure long-term stability.

Engineers choose brass because it can protect circuits from being affected in harsh.

Gold-plated brass, resist corrosion, improve conductivity.

This anti-corrosion makes brass ideal for outdoor and industrial environments.

Excellent conductivity.

Although its conductivity is slightly lower than pure copper, brass is sufficient for electronic devices.

In pogo pins, brass can provide stable current transfer, reduce energy loss.

Adding old plating will improve brass conductivity and transfer high-quality signals.

Its conductivity makes it crucial in electronic applications and various electronics testing.

The combination of conductivity and mechanical properties makes brass one of the most favored materials by engineers.

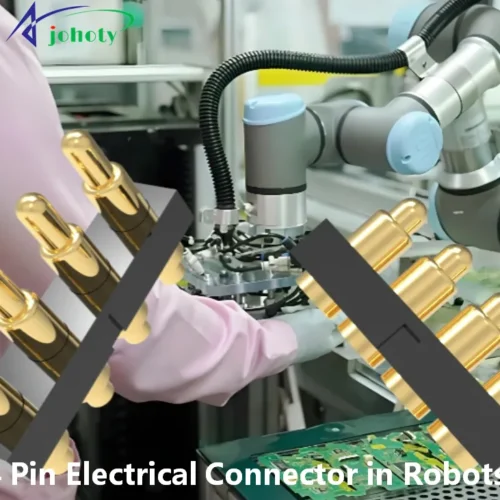

Brass Connectivity in Pogo Pins to Answer: Is Brass Magnetic?

The brass connectivity in pogo pins is reflected in its conductivity, vibration & corrosion resistance, flexibility, and processing flexibility. It helps pogo pins become efficient, stable, and durable precision connectors, loved by engineers!

Stable conductivity and strong signal transfer.

Brass is one of the most important materials in pogo pins, conduct electricity well, stably transfer current and signals.

Brass can ensure that high-frequency electronic signals do not generate too much resistance.

Engineers like brass because it can reduce signal loss, ensure data accuracy.

In testing, pogo pins are made of brass and can quickly and stably connect electronic components.

Gold plating process, brass can also enhance oxidation resistance and make signal transfer smoother.

Strong resistance to vibration and impact

Pogo pins made of brass can maintain stable connection in vibration or impact.

In automotive electronic testing, brass spring loaded pins can withstand road bumps and maintain good contact at all times.

Its combination of toughness and strength makes pogo pins less prone to breakage or poor contact.

Engineers will choose brass because it ensures equipment reliability in complex environments.

Brass pogo pins are also popular in industrial equipment and military testing.

Enhanced corrosion resistance and lifespan

Pogo pins’ brass can resist corrosion of salt spray, moisture, and chemicals in the environment.

Brass can maintain excellent connection without ease oxidization after long-term use.

Corrosion resistance is the key to ensuring lifespan in mobile phones or laptops.

After nickel or gold plating, brass corrosion resistance is further enhanced.

Engineers believe that brass long lifespan can greatly reduce maintenance costs.

Flexibility ensures good contact

Pogo pins require repeated compression and release, and brass flexibility can perfectly meet this requirement.

Brass maintains its elasticity during high-frequency use and will not break or lose its elasticity due to repeated use.

Flexibility ensures that the contact area between pogo pins and electronic components is always sufficient, reducing contact resistance.

In low and high pressure, brass pogo pins can always provide stable connection.

Engineers choose it because brass can make equipment run more smoothly.

Flexible processing, adaptable to different designs

Brass is very easy for complex shapes, it can meet different testing and connection requirements

Some pogo pins require longer stroke and special tips, star tip, brass can meet all requirements.

Easy to achieve high-precision machining, making the contact points of pogo pins more precise.

Engineers are interested in brass because of its powerful performance, flexibly adapt to various innovative designs.

In automated testing, brass pogo pins can quickly complete complex connections.

Brass Impact on Electronic Devices to Answer: Is Brass Magnetic?

Brass has an impact on electronic devices in terms of non-magnetic, excellent conductivity, corrosion resistance, wear resistance, and thermal stability. Can help electronic devices run more stably and sustainably, suitable for high-precision testing and long-term stable operation

Non magnetic ensures stability of electronic devices

Non magnetic brass is not affected by magnetic fields and doesn’t affect sensitive components of electronic devices.

In electronic testing, using pogo pins made of brass can avoid signal deviation caused by magnetism.

Engineers choose brass because it can provide reliable and interference free connections in precision circuits.

Non magnetism is very important in medical equipment or high-precision sensors.

Using brass pogo pins can make the signal purer and the data more accurate.

Excellent conductivity enhances equipment performance

Brass has good conductivity and can efficiently transmit current and signals in electronic devices.

In pogo pins, brass material can reduce resistance, minimize energy loss, and improve equipment efficiency.

Gold plated brass enhances conductivity and fit high-frequency signal transfer.

Engineers have found that brass pogo pins can significantly improve connection stability and accuracy.

Support faster and smoother operation of electronic devices.

Corrosion resistance prolongs equipment lifespan

Brass corrosion resistance is crucial for electronic devices, as it can protect circuit contacts from oxidation or environmental erosion.

In humid and salty environments, brass durability can extend equipment lifespan.

In outdoor or industrials, brass pogo pins can continuously maintain efficient operation.

Engineers choose brass because it is corrosion-resistant and can reduce equipment PM costs.

Electronic devices made of brass are more reliable and can keep good performance.

Reduce mechanical wear and maintain stable performance

Brass wear resistance reduces mechanical contact wear in electronic devices.

In repeated connection interfaces or testing equipment, brass pogo pins can withstand a large amount of use without compromising performance.

Engineers believe brass wear resistance is important for equipment used at high frequencies.

It can reduce equipment shutdown frequency and ensure a continuous and efficient working state.

Brass has become an important connecting component in high-performance electronics.

Thermal stability protection sensitive components

Brass has a high thermal conductivity, which can quickly conduct and disperse heat, preventing equipment from overheating.

In some high-power electronic devices, brass pogo pins can help control local temperature.

Its thermal stability ensures that sensitive electronic components can operate normally in high temps.

Engineers are interested in bras thermal performance because it can effectively prevent equipment from overheating damage.

In continuous testing or high loads, brass can protect equipment from temp fluctuations.

How to choose the appropriate Pogo pin material to Answer: Is Brass Magnetic?

Choosing the appropriate pogo pins material requires comprehensive consideration of conductivity, mechanical strength, corrosion resistance, processability, and non-magnetic. Brass performs well in these aspects and is an ideal material for electronic devices and testing tools. Many engineers like it because of its excellent performance and balancing cost and practicality!

Material conductivity is very important

Pogo pins transfer current and signals, so material conductivity is a critical factor when selecting.

Brass is highly conductive and can reduce signal loss and ensure electronic devices stability.

In high-frequency electronic testing, brass can provide low resistance and improve equipment efficiency.

If the device requires higher conductivity, brass surface can be gold-plated or silver plated to further optimize the effect.

Engineers like brass because it has good electrical conductivity and can balance cost and practicality.

Consider mechanical adaptability.

Pogo pins need to withstand repeated pressure and friction, so material strength and flexibility must meet standards.

Brass has excellent mechanical properties, is not easily broken, and can maintain moderate elasticity.

Materials with good flexibility can maintain good contact effects after multiple uses without affecting test results.

If equipment needs to withstand higher pressure or frequent use, special treated brass or other high-strength alloys can be selected.

Engineers choose brass because it can maintain stable performance in high-intensity work.

Corrosion resistance ensures long-term use

Pogo pins are often used in humid or complex environments, and materials with strong corrosion resistance are more suitable.

Brass itself has strong oxidation and corrosion resistance, after nickel or gold plating on the surface, it works even better.

Corrosion resistant pogo pins can reduce damage to contact points and extend equipment lifespan.

Engineers choose brass because it can maintain stability in harsh.

In industrial, medical, and outdoor, corrosion-resistant materials are essential.

Processing performance affects cost and efficiency

The pogo pin designs requires high-precision machining, so material machinability directly affects production efficiency.

Brass is easy to process and can quickly produce complex shapes.

Materials with good processing can shorten production cycles, minimize costs for highest quality.

If customized special designs, brass is also a good choice as it ensures precision and strength.

Engineers like brass because it enables efficient processing while reducing production difficulty.

Non magnetic ensures signal purity

If electronic devices are sensitive to magnetic fields, you need to use non-magnetic materials.

Brass is non-magnetic and doesn’t interfere with equipment electromagnetic signals, making it very suitable for high-precision tests.

Non-magnetic pogo pins can avoid signal bias and improve test result accuracy.

Non magnetic materials are an essential choice in pure signals.

Engineers choose brass to ensure that equipment working environment not affected by magnetic interference.

Conclusions

Through this article, we learned about non-magnetic brass, which does not interfere with electrical signal transfer and provides durability and reliability. Because of these characteristics, brass has become an important raw material in pogo pins and guarantees efficient operation of various electronic devices.

For engineers or technician experts, choosing the right pogo pin materials is crucial, and high-performance brass is satisfactory. If you are looking for a solution that can improve electronic product connectivity, you can pay more attention to the application of Johoty’s brass in pogo pins. I believe its extraordinary features will bring unexpected surprises to your design! If you have more needs and questions about pogo pin or brass non-magnetic, please continue to follow Johoty’s blog and explore more interesting technical details together!