Discover Why Spring Loaded Connector Is Essential in 2025 Electronics. Learn How Its Versatility Transforms Your Device Designs and Function

Introduction:

As electronics industry moves towards smaller, more efficient, and more reliable directions, The spring loaded connector is becoming a core component in the coming years. Why is spring loaded connector so important? From vibration resistance to high-density contact, spring loaded connector can solve many challenges that traditional connectors cannot cope with. 5G, IoT, and smart hardware have led to sharp increases in demand for connection stability and long-term reliability in electronic devices.

Johoty’s article shows you how spring loaded connector can meet these requirements and provide important support for electronic designs in 2025 and beyond.

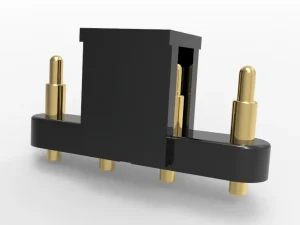

What is a spring loaded connector?

Spring loaded connector is a high-performance connector that uses built-in springs to ensure stable electrical contact. By spring pressure, it always maintains tight contact between contact terminal and connection point, ensures stable current conduction and signal integrity, even when the equipment is subjected to vibration, thermal expansion, or physical deformation. It is highly efficient and useful in modern electronics with high frequency, high speed, and high density, as well as in where space is limited and high reliability is required.

Why is spring loaded connector so important?

High reliability: The spring loaded connector’s spring can effectively eliminate poor contact caused by vibration, mechanical stress, temperature changes, etc., and is suitable for automation, automotive electronics, military, and aerospace.

Anti-vibration and anti-impact: In harsh automobiles and aviation, spring loaded electrical connectors can maintain good electrical contact continuously, avoid contact loss caused by external impact or vibration in traditional connectors.

High density connection: Due to spring presence, spring loaded electrical connectors can support more compact designs and higher density connections, meeting the dual requirements of volume and connection quantity in electronic products.

The demand for smart hardware and IoT: IoT devices and smart hardware often require efficient and reliable connections in small spaces. Spring loaded connector is an ideal choice due to its stable electrical connection.

Adapting to temperature differences and environmental changes: Automobiles and industrial automation require high environmental adaptability. Spring loaded electrical connectors can work continuously and stably under extreme temperature and humidity without affecting performance.

Working principle of spring loaded connector:

Working principle

Spring loaded connector maintains contact pressure through its built-in spring. When the connector is inserted or comes into contact with the mating socket, the spring provides sufficient force to ensure stable pressure at contact point. Thereby, it can avoid poor contact or signal interruption.

Spring action:

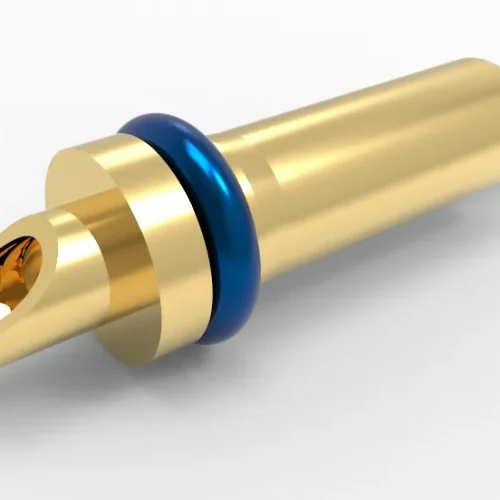

Spring is the most critical component and is usually made of stainless steel, music steel, or other highly elastic metal materials. The spring provides constant pressure on the contact surface, ensures stable contact when there is slight displacement or external vibration between connector and mating socket.

Contact surface design:

The contact points inside such pogo pin connector are often designed as small metal contacts. When in contact with conductive surface of mating socket, the spring will stretch or compress, forming a stable contact pressure. This design allows connector to maintain stable electrical contact under small vibrations or offsets.

Adaptive pressure:

The adaptive pressure of spring loaded connector ensures good electrical connection. It is on different sizes and types by adjusting spring preload force. This flexibility can be effectively utilized in various applications.

Seismic and anti-detachment design:

In high vibration or impact, spring loaded electrical connectors maintain connection stability through spring pressure. This can avoid loosening or detachment caused by external forces. Spring loaded connector is used in military and aerospace due to its excellent seismic.

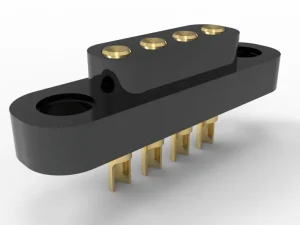

Structural characteristics of spring loaded connector

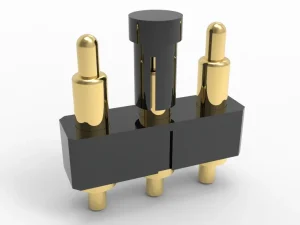

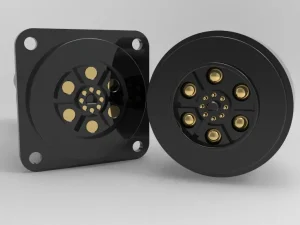

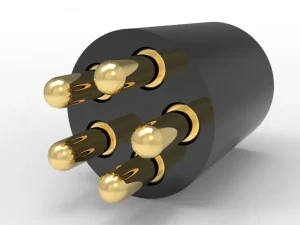

Compact and high-density design:

Spring loaded connector is compact in size and design for space constrained situations. High density design allows for multiple electrical connections, and it is achieved within a limited space.

High reliability:

Due to spring action, spring loaded connector has high reliability and can provide long-term and stable service in harsh. So, it is suitable for frequent connection.

Strong corrosion resistance:

The contact points of spring loaded electrical connectors is made of corrosion-resistant gold, silver, or gold-plated contacts. This can ensure contact surface is not oxidized or corroded during use, further enhance its durability and stability.

Considerations for spring loaded connector

Environment requirements:

It is necessary to consider connector working environment, including corrosion, temperature, humidity, vibration, etc. The designs require selecting appropriate materials and spring stiffness based on environments.

Number of insertions and durability:

Different applications have different life cycles. Choosing appropriate spring pressure and contact design can ensure stable electrical connection within specified lifespan.

Electrical performance:

For high-frequency signal transfer, it is better for low resistance and voltage.

Space and size limitations:

When designing limited space, choose spring loaded electrical connectors with small volume and high density. Select suitable connectors based on specific size and requirements.

Manufacturing process and costs:

When selecting a spring loaded connector, you’d consider feasibility and cost-effectiveness. High quality materials and precise manufacturing processes often mean higher costs, but they will have a longer lifespan and stronger reliability.

Anti-vibration, high-reliability performance, advantages of spring loaded connector.

High reliability: long life cycles, low maintenance costs.

- Fatigue resistance: Spring-loaded connector utilizes continuous spring pressure to achieve electrical contact and has excellent fatigue resistance. Connectors can maintain stable electrical performance and greatly extend customer products’ lifespan after use or repeated connection.

- Reduce contact resistance: The spring-loaded design automatically adjusts spring pressure to ensure contact surface is always in close contact. It can also avoid an increase in contact resistance. It is very important in high-precision, high-frequency circuits and high-vibration automotive, aviation, and industrial automation.

- Low maintenance cost: Due to its high reliability, spring loaded connector can significantly reduce frequency and cost of equipment maintenance. Engineers can reduce downtime caused by poor contact or connector failures.

Anti vibration: Ensure stability in dynamic.

- High seismic resistance: Spring loaded connector can withstand high-frequency and high-intensity vibration impacts without losing their connection. Compared to traditional rigid connectors, the spring-loaded design provides a certain flexibility degree, which can maintain stable electrical connections in dynamic and avoid loosening or disconnection caused by vibration.

- Adapt to harsh environments: In aerospace, automotive, and military equipment, devices are often exposed to extreme vibration and shock conditions. The design of spring loaded connector can precisely cope with these harsh conditions and ensure equipment long-term reliable.

Enhance design flexibility: smaller packaging size.

- Compact design: Spring loaded electrical connectors are suitable for space constraints based on their high-performance. Engineers can achieve efficient connections within smaller packaging sizes. It adapts to design requirements of future electronic products for compact and lightweight.

- Multi functionality: In addition to traditional electrical connections, spring loaded electrical connectors can also support signals and ground wires to meet the needs of different electrical systems. Engineers can utilize their flexible design to simplify the overall product connection scheme.

Advantages of high temperature, humidity resistance.

- Resistance to extreme temperatures: The spring loaded connector adopts high-performance materials and design, which can maintain stable electrical performance from -55℃ to+125℃. In autonomous driving, electric vehicles, and industrial automation, it can work stably in environments with large temperature fluctuations.

- Corrosion resistance: Due to corrosion-resistant metal and advanced gold-plated coatings, spring loaded electrical connectors can effectively cope with moisture and salt spray. And it can avoid connector corrosion.

Meet demands of electronic device market in 2025.

- Electrical connection challenge of smart devices: In 2025, electronic devices will develop towards intelligence, wireless, and high-frequency transfer, gradually exposing the limitations of traditional connectors. Spring loaded electrical connectors can address complex high frequency, high current, and high reliability. This makes them suitable for wireless communication, automation, intelligent sensors, and more.

- Automated manufacturing and industrial applications: In future intelligent manufacturing, spring loaded electrical connectors can provide higher levels of automation. It can reduce the manual operation of traditional plug-in connectors, and ensure stable connections under high-speed and high-precision conditions.

Simplify assembly and integration: reduce system complexity.

- Modular design: The design of spring loaded connector supports modular assembly, which can be easily integrated with other modules or devices. And it can reduce overall system design complexity. For electronic engineers, the time for design and testing can be significantly reduced, thereby improving development efficiency.

- Reduce risk: The stability and high fault tolerance of spring loaded electrical connectors can effectively reduce system risks. This is caused by poor contact, vibration, or temperature changes in engineering design.

Save space and reduce weight, advantages of spring loaded connector

Space saving: Spring loaded connector provides greater flexibility in compact design

Spring loaded electrical connectors can enable efficient connection of electronic devices in limited space. Traditional connectors typically require more space to handle cable connections and plugging. But spring loaded electrical connectors utilize compressible springs that significantly reduce required physical space without sacrificing connection reliability. This is important for mobile devices, wearable devices, medical electronics, and aerospace.

- Maximizing Space Utilization: Spring loaded electrical connectors can be flexibly arranged in a compact layout, reduce the size of circuit boards and increase the integration of more functional modules.

- Adjustable: Compared to traditional connectors, spring loaded electrical connectors allow for more mechanical tolerance, ensure connection stability. In board-to-board connections, it can adapt to small changes in board to board spacing.

Weight reduction: Spring loaded connector reduce electronic device weight without sacrificing performance

Lightweight design is a key requirement in many high-end aerospace, automotive electronics, and portable consumer electronics products. The lightweight design of spring loaded electrical connectors has become an important component in these fields. Spring loaded connector is made of small and lightweight brass, titanium alloy, or nickel alloy, which can significantly reduce product total weight without affecting connection quality.

- Material selection and design optimization: Utilizing advanced materials and optimized design, spring loaded connector is lighter and more durable than traditional connectors.

- Non threaded connection design: The non-threaded connection design of spring loaded connector reduces the use of traditional screws and metal components, further reduces the overall weight of components, improves electronic device portability.

Reliability and Durability: Performance of spring loaded connector under extreme conditions

Spring loaded connector has high reliability and durability, withstands frequent connections, vibrations, and temperature changes. It is very suitable for aerospace, automotive, high-end intelligent devices, industrial automation, etc. These fields have very high performance requirements. The built-in spring can help the connector maintain stable contact when there are significant changes in temperature, humidity, and pressure.

- Anti vibration performance: Spring loaded electrical connectors can maintain stable electrical connections in high vibration, avoid poor contact or disconnection caused by vibration.

- Adapt to extreme temperatures: The spring loaded connector’s spring can maintain good electrical performance under large temperature changes, greatly improve equipment overall durability.

High temperature, corrosion resistance, advantages of spring loaded connector

High temperature resistance:

- Reliability at high temperatures: Automobiles, aerospace, industrial automation, and high-performance consumer electronics all require operation in extreme temperatures. The unique design of the spring loaded connector ensures stable contact pressure amidst temperature fluctuations. It effectively avoids poor contact or electrical faults caused by temperature changes.

- Thermal expansion compensation: Spring loaded electrical connectors can automatically adjust contact force within temperature fluctuation. Offset differences impact in thermal expansion coefficients of different materials. To ensure stable connection and avoid poor contact or interruption of current transfer because of inconsistent thermal expansion.

Corrosion resistance:

- Long term exposure corrosion resistance: Spring loaded connector is designed with gold plating, titanium alloy, or stainless steel, and are corrosion-resistant in marine environments, chemical plants, and automotive engine compartments. It can resist oxidation effects, acid-base erosion, and other corrosive substances, significantly extending equipment lifespan.

- Surface finishing: Spring loaded connector utilizes advanced metal electroplating, coating treatment, and anodizing to enhance their corrosion resistance. By improving connector surface performance, it can effectively prevent moisture, salt spray, and chemical substances from damaging contact surface.

Long lifespan:

- Stability under combined action of high temperature and corrosion: Some electronic systems often operate simultaneously in high temperature and corrosion. Spring loaded connector can provide stable contact force and exhibit longer lifespan. It can avoid frequent replacement & maintenance, reduce maintenance cost of the entire system.

- Test data and application cases: Based on IP rating and UL certification and standards, spring loaded electrical connectors can demonstrate performance in high temp and corrosion. In automotive engine compartments, industrial equipment, or spacecraft, there are high requirements for connector temperature and corrosion resistance.

Technological progress and innovation trends:

- Application of new materials: New alloys and surface coating materials can further enhance high-temp & corrosion resistance of spring loaded electrical connectors. Titanium alloy or high-temp alloy can improve temperature resistance, enhance corrosion resistance, and adapt to demanding environments.

- Intelligent detection and automatic repair: The combination of emerging intelligent sensors and connectors can monitor temperature changes and corrosion levels. They provide dynamic feedback to engineers, and further improve connector reliability.

Design challenges and optimization directions:

- Design challenges in high-temp & corrosion: Engineers often face technical challenges in designing spring loaded electrical connectors, including material selection, structural design, durability testing, etc. Johoty often solves these problems through innovative design, improves long-term connector reliability.

- Optimization direction: In response to increasing connector demand in future electronic products, Johoty always improves spring loaded connector performance. It is through material innovation, design optimization, and advanced manufacturing processes to meet more intelligent devices in the future.

Application areas of spring loaded connectors

Consumer Electronics:

Smartphones, wearable devices, and smart home devices are increasingly demanding high performance, reliability, and compact design. The superior stability and adaptability of Johoty’s spring loaded electrical connectors make it a part of these products. The headphone jack, charging port, etc. in smartphones require spring loaded connector to ensure long-term reliability.

Automotive Electronics:

EV, Autonomous driving and automotive electronics are getting more complex. Spring loaded electrical connectors can provide stable electrical connections in high vibration & temperatures. It is widely used in vehicle BMS, electric drive systems, sensors, and communication systems.

Medical equipment:

Today, more and more medical equipment needs high stability, reliability and accuracy. Spring loaded connector can provide reliable electrical contact at connection end of medical devices. It ensures continuous and stable performance in high-precision medical devices and wearable health devices.

Aerospace and Industrial Applications:

In industrial equipment and aerospace often face extreme temperatures, radiation, and high vibrations. Spring loaded electrical connectors can ensure stable and reliable connections for devices. It is used in satellite communication systems, robots, flight control systems, and automated production lines.

Future trends of spring loaded connector in 2025

Miniaturization and high integration

Electronic products are trending towards miniaturization and high integration, and spring loaded connector needs to be further miniaturized. In this way, it will adapt to smaller devices and denser circuit board layouts. At the same time, these connectors will combine more intelligent functions to enhance overall performance and reliability.

Intelligence and automation

Future spring loaded connector may combine intelligent sensing technology to monitor connection status. It will be able to automatically detect connection status, temperature changes, current fluctuations, etc. Advance warning and self- repair or adjustment to further improve connection reliability.

Environmental Protection and Sustainability

Today and future, environmental protection is always important directions for future design. In 2025, spring loaded electrical connectors will increasingly use eco-friendly and recyclable materials. This will meet environmental requirements of global electronics industry.

Higher current transfer capability

With increasing demand for higher power, the current transfer capability of spring loaded connector will continue to improve in the future. This will develop high-power electric vehicles and battery systems.

Conclusions:

Nowadays, electronic products are becoming increasingly miniaturized, functional, and intelligent, and the requirements for connectors are also constantly increasing. In improving product performance as well as optimizing production processes, it will be a key component that every engineer cannot ignore.

- Ultra miniaturization design: With development of 5G, IoT, device sizes are becoming smaller and smaller. Spring loaded connector, due to its compact design, can effectively solve space limitations and are suitable for miniaturized electronic devices.

- Improve connection stability: Spring loaded connector provides continuous pressure during connection, transmit high-density signals. It greatly reduces connection problems caused by vibration or temperature changes, and enhances device reliability.

- Quick assembly and maintenance: Compared to traditional welded connectors, spring loaded connector has convenient insertion and removal functions. This can accelerate assembly and maintenance cycle and greatly improve production efficiency.

- Environmental Protection, Energy Efficiency: Johoty designs spring loaded electrical connectors with focus on environmental protection, materials and production processes. They can meet RoHS, REACH, ASTM, etc, help the industry move towards green manufacturing.

If you are looking for high-quality spring loaded connector, Johoty can provide you with effective top-notch solutions. Contact Johoty for more professional information and order customization, Johoty can help you easily tackle electronic technology challenges in 2025!