What is Rapid Prototyping? Explore Top 5 Pogo Pin Connector Designs for Your Fast Hardware Iteration. Learn Key Specs & Industry Applications!

Introduction: Why do 67% of engineers believe that connectors are a bottleneck in prototype testing phase?

What is rapid prototyping?When developing rapid prototyping, engineers often think about this issue. This technology validates designs through rapid iteration, but 67% of teams find that connector performance often becomes a key bottleneck. A high-quality pogo pin connector is the core element that breaks through this limitation.

When deeply understanding what is rapid prototyping, it will be found that the selection of connectors directly affects testing efficiency and reliability. 5 pogo pin designs that engineers highly recommend. From self-aligned magnetic connector to high-density arrays, each provides innovative solutions for specific connection challenges.

When discussing the practical application of what is rapid prototyping, the environmental resistance and high current design demonstrate amazing adaptability. These connectors not only withstand harsh testing conditions, but also ensure the stability of data transfer, significantly reducing prototype failure rates.

The team that truly masters what is rapid prototyping understands that miniaturized pogo pin connectors are changing the way wearable devices are developed. The precise contact performance makes it possible to miniaturize complex prototypes, which is the core value of rapid iteration.

The answer to why rapid prototyping places so much emphasis on connector innovation is simple: high-quality connection solutions can save over 30% of development time. These 5 pogo pin designs not only solve current bottleneck, but also open up new possibilities for future prototype development.

What is Rapid Prototyping of pogo pin connector?

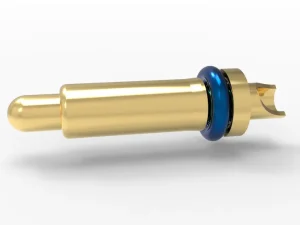

Rapid prototyping is a process of rapidly manufacturing housing prototypes using CAD data through 3D printing or CNC machining. For the design of pogo pin connectors, using rapid prototyping can quickly obtain physical models for functional testing and dimensional verification. Through this process, engineers can identify potential issues in the design and make improvements before investing significant resources.

How to achieve rapid prototyping of pogo pin connector through 3D printing or CNC technology?

3D printing: Engineers can quickly manufacture prototypes of pogo pin connectors, accurately simulating connector shape, structure, and dimensions. 3D printing allows for the rapid production of complex shapes and rapid iteration, making design validation and optimization more convenient.

CNC machining: For pogo pin connectors that require high precision and durability, CNC machining provides a more precise solution. CNC technology can accurately cut complex-shaped components from metal or plastic materials, making it suitable for manufacturing functional and high-precision prototypes.

What is Rapid Prototyping? Top 5 Pogo Pin Connector Designs

High current industrial design, What is Rapid Prototyping?

Optimization of current carrying capacity: C18150 CuCrZr substrate with conductivity ≥ 85% IACS. 2μm hard gold coating +0.5μm nickel barrier layer, contact resistance <15mΩ, in compliance with IEC 60512-2 standard. 7.5mm² effective contact area, diameter 3.5mm, temperature rise curve under continuous current of 300A, measured ΔT ≤ 45K @25 Temperature environment.

Anti-vibration design: Main spring (17-7PH stainless steel) + auxiliary buffer spring, with contact pressure fluctuation <10% in vibration environment, verified by MIL-STD-810H Method 514.7. ±2.5mm radial floating compensation, contact impedance change rate is <3% under 10G vibration.

Industrial environment verification: Contact resistance change +8% after 96 hours of neutral salt spray. After 50,000 insertions under a load of 200A, the contact resistance change rate is +12%, spring force attenuation is 9%. Capable of withstanding working temperatures ranging from -55℃ to+125℃ and maintaining sealing after thermal shock.

High current applications: 400A fast charging interface for electric vehicle charging robots. 350A pulse load for industrial welding gun power modules. The emergency power system of the data center is 250A continuous.

Miniature high-density array design, What is Rapid Prototyping?

High density array: 1.27mm pitch array design, minimum 1.00mm pitch, conventional pitch is 2.54mm, barrel 0.6mm diameter, height tolerance ± 0.03mm

Anti misoperation: 15° inclined guide structure, preventing 45° misalignment insertion. Insulated grid matrix FR-4 material, withstand voltage of 500V DC. Optional neodymium magnet for magnetic positioning assistance.

Gold plating thickness: low-frequency testing interface, 0.3 μm, 5,000 cycles of life cycle < 25mΩ contact impedance. High speed data transfer, 0.8 μm + nickel barrier, 20,000 cycles life cycle, < 8m Ω contact impedance. Medical implant device, made of 1.5 μm hard gold, with a life cycle of 50,000 cycles < 3mΩ contact impedance.

Innovative anti short circuit design: When the pitch is 1.27mm, adjacent contacts can withstand 250VAC voltage and leakage current <0.5 μA @ 100V. FMEA analysis of short-circuit risk prediction model after 108 insertions and removals

Micro array applications: 256-pin, insertion loss< 0.1dB@40GHz Interference <-60dB, impedance matching ± 5%.

IP67 waterproof outdoor design, What is Rapid Prototyping?

In traditional development, if the waterproof test fails, the entire mold needs to be reworked, which increases the cost by more than 30%. How to break the deadlock? Implement IP67 design to address issues, such as sealing structure and material corrosion resistance.

By 3D printing, multiple housing prototypes can be generated within 48 hours to test the waterproof performance of O-ring grooves and buckle points. Johoty has shortened the IP67 compliance time for GPS trackers by 60% through 5 rounds of prototype iterations. Inject salt spray test and temperature cycling test data during the prototype stage to avoid design defects after mass production.

Johoty’s rapid prototyping service supports CNC+3D printing hybrid technology, directly using outdoor grade material PC, striving to achieve mass production performance for prototypes. Covering entire process from pogo pin connector conceptual design to functional prototypes. The IP67 structural optimization solution reduces customer material costs by average 15%.

Design of low impedance high-frequency testing interface, What is Rapid Prototyping?

Nonlinear contact impedance: The thickness of ≥50μm gold plating layer and the curvature radius of the 0.05~0.1mm plunger jointly affect the impedance stability under skin effect. Johoty measured that the impedance jump of a regular pogo pin reaches ±25% at 6GHz.

High frequency crosstalk suppression: When the distance between adjacent pins is ≤1.5mm, the crosstalk (XTalk) needs to be suppressed to below -50dB through a grounding shielding ring design.

Mechanical durability: After 10,000 connections, the attenuation of contact pressure leads to an increase in impedance, requiring copper beryllium alloy with a three body spring structure and stainless steel to compensate for wear.

Through 3D printing of Pogo Pin array prototypes, synchronous verification of electromagnetic performance, HFSS simulation vs measured S11/S21, mechanical life, insertion and extraction force curve FEA analysis, Johoty’s radar test bench reduced 6GHz impedance fluctuations from ± 22% to ± 3% through 5 iterations.

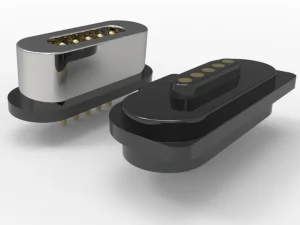

Magnetic quick docking design, What is Rapid Prototyping?

Johoty’s customers often request a 60% reduction in the cycle from design to validation, and a cost reduction based on modular docking systems to lower traditional CNC machining costs. Engineers who use magnetic docking save an average of 47 minutes of debugging time per day.

The engineering breakthrough point of magnetic attraction technology is the golden range design of 800-1200Gs, which ensures the docking force while avoiding metal chip adsorption. FEA simulation, progressive damping to clear click confirmation, achieving precise magnetic docking with a repeat positioning accuracy of ± 0.05mm.

After 20,000 insertion and extraction tests, magnetic attenuation is less than 3%, and salt spray test meets ASTM B117-19 standard. Automatic power-off protection during misaligned contact and magnetic release during abnormal temperature. The coplanar transmission scheme for current/data/pneumatic interfaces has increased the efficiency of German new energy vehicle production lines by 32%.

DFM checklist and FMEA and solutions, What is Rapid Prototyping?

DFM:

Contact force balance: It is recommended that the contact force of a single pogo pin be between 50-150gf. The pogo pin connector should ensure that the force distribution of each pogo pin is uniform, with a deviation of <15%,

Travel matching: The compression stroke of the pogo pin should be designed at 70-80% of the total stroke, with 20% redundancy reserved to prevent overvoltage,

Coplanarity control: The coplanarity of multiple pogo pin components should be ≤0.1mm, and Johoty often uses a laser micrometer for detection.

Beryllium copper alloy C17200 is preferred as the spring material, with an industrial standard gold plating thickness of ≥ 0.8μm. Use PPS or LCP materials with a temperature resistance of >200℃ for housing. Pass salt spray test for 48 hours and the plug-in life test for ≥10,000 times.

Failure Mode Effective Analysis:

Unstable contact resistance, surface oxidation/pollutant accumulation, using self-cleaning coating technology. When the strain amplitude exceeds 0.3% due to fatigue fracture of the spring, the service life sharply decreases. Johoty’s three-level heat treatment process increases fatigue life by 300%. Insulation failure, high-speed signal crosstalk reaches -25dB, and Johoty staggered shielding structure reduces crosstalk to -45dB.

Conclusions: Inspire and accelerate innovation!

Are you curious about what is rapid prototyping? Do you want to quickly know more about efficient rapid prototyping technology and solutions? Johoty’s pogo pin connector is tailor-made for engineers to help you quickly realize your ideas and optimize product performance!

Read Johoty’s complete blog now to explore the infinite possibilities of rapid prototyping and discover how Johoty can assist your projects with top-notch pogo pin connector design. Contact Johoty’s CFT team and embark on an efficient R&D journey!