Medical Connectors Designed for Precision and Reliability, 6 Top Pogo Pin Connector Solutions Engineers Trust. Contact Johoty Now for Details!

Introduction: Why can’t medical connectors make mistakes?

Medical connectors, why can’t it make mistakes? Because every connection is related to life safety and precise device operation. For medical equipment engineers, the performance, durability, and reliability of connectors directly affect the stability of end products and user trust. This blog will comprehensively analyze 6 most reliable pogo pin medical connectors for you. It covers design essentials, applications, and selection recommendations. Immediately learn how these solutions can help you optimize your design, reduce risks, and contact Johoty for customized support.

Difficulties in Selecting Medical Connectors:

The contradiction between biocompatibility and sterilization resistance

Traditional epoxy resin is prone to brittleness after gamma ray sterilization, and the cost of new PEEK remains high. The connector for surgical robots must meet both the ISO 10993-5 cytotoxicity standard and 800 cycles of high-temperature steam sterilization. The Da Vinci surgical arm connector adopts a ceramic filled PTFE solution. This increases the cost by 35% but increases the lifespan by 4 times.

Coexistence of microampere level signal and kilovolt voltage

The defibrillation device connector needs to be isolated between 5 μV ECG signal acquisition and 2,000V defibrillation pulses. The multi-layer shielding design resulted in diameter exceeding the standard: the outer diameter of the defibrillator connector increased from 6mm to 9.2mm, causing clinical operational controversy. Using carbon nanotubes to fill silicone gel for anisotropic conductivity, reducing volume by 40%

Dynamic mechanical stress challenge

According to ASTM F2878 standard, wearable device connectors need to withstand 2 million bending cycles. Traditional copper alloy fracture risk: Recall of dynamic ECG patches due to wire breakage. The application of liquid metal (Ga In Sn alloy) connectors in flexible circuits has led to a bending life exceeding 5 million times

The Paradox of Preventing Misinsertion and Fast Connection

After the implementation of ISO 80369 standard, the misplacement rate of anesthesia machine connectors decreased by 72%, but the insertion and extraction force increased by 3N. The magnetic suction connection solution is facing EMI interference issues: MRI compatible ventilators are therefore delayed in launch for 6 months. Acoustic coding recognition technology achieves millisecond level pairing.

Miniaturization and high-density interconnection

Using Utah electrode array technology, the neural electrode array requires a 128 channel connector diameter<2mm. TSV technology enables connector density to reach 240 pin/mm², but heat dissipation becomes a new bottleneck. Heterogeneous integrated packaging is breaking through the limitations of traditional connector forms.

Balance equation between cost and reliability

The use of military grade connectors for civilian medical purposes has resulted in BOM costs exceeding the standard. Reliability mathematical model: MTBF=exp [(0.03 x material grade+0.7 x process control) -0.5 x insertion and extraction times]. The alternative project has reduced costs by 58% through DOE optimization and passed IEC 60601-1 testing.

Integration of data link and power transmission

The surgical navigation system requires USB 3.0 (5Gbps) and 20W power supply for cable transmission. The hybrid modulation technology achieves a coaxial transmission efficiency of 92%, while the traditional scheme only achieves 68%.

The latest Qi2 standard provides new possibilities for wireless connectivity of implantable devices.

The best 6 Pogo Pin connector solutions for Medical Connectors

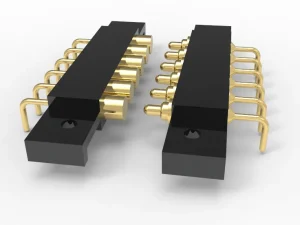

High plug-in life type: medical connectors used for high-frequency testing and diagnostic interfaces

In high reliability testing and diagnostic applications, medical connectors are not consumables, but the cornerstone of system stability. Designed for use requiring high-frequency plugging, high signal integrity, and extremely low contact resistance. Truly solving 3 major challenges of durability, precision, and customization in traditional medical interfaces.

Ultra high plug-in life: >200,000 cycles, using thickened gold plating and reinforced spring structure, the performance is very stable in high-frequency testing.

Specially designed for medical equipment: used for precise interface requirements, ECG, ultrasound probes, wearable devices, intelligent monitoring terminals, etc.

Support high-speed signal transmission and analog detection: configurable to high frequency above 5GHz, meeting the requirements of complex physiological signals or high-speed diagnostic signal transmission.

Miniaturization + modular solutions are optional: precision micro-plunger design, suitable for portable medical devices and wearable medical IoT scenarios.

Fully support OEM/ODM projects: from structural co-construction, material selection to mass production sampling, the entire process provides professional support for medical customer standards.

Miniaturized Pogo Pin Arrays for Next-Gen Wearable Medical Connectors

How to achieve efficient, stable, and repeatable signal/power transmission in a very small space in wearable medical devices? Miniature pogo pin connector that balances size, reliability, comfort, and biocompatibility. It is the ideal interface choice for new generation of various intelligent medical devices.

Ultra small package: The diameter of a single Pogo Pin can be as low as 0.5mm, supporting high-density layout, making it easy to embed into ultra small wearable terminals.

High frequency/low impedance reliable connection: meets the needs of medical grade data transmission, supports high-speed acquisition of heart rate/EEG/blood oxygen signals, stable connection impedance, and low signal attenuation.

Flexible fit and comfortable wearing: Suitable for skin contact products, with controllable plunger pressure and support for curved/movable structural connections, without affecting the user’s wearing experience.

Corrosion resistant and biocompatible materials are available: coatings such as gold and palladium nickel can be selected to meet long-term wear and sweat corrosion environments; Compliant with medical material standards such as ISO 10993.

Sealed Waterproof Pogo Pin Connector As Best Medical Connectors

How to achieve long-term reliable, liquid resistant, and structurally stable electrical connections in the increasingly miniaturized and high-frequency trend of wearable medical and in vivo/in vitro diagnostic devices? The waterproof pogo pin connector adopts a sealing ring design highly compatible with silicone and PC materials and an ultrasonic welding structure. It can achieve true structural waterproofing, electrical stability, and biological friendliness.

IP67, IP68 waterproof: Specially designed medical grade sealing ring, compatible with silicone coating and PC shell structure, ensuring reliable operation even in harsh usage scenarios such as sweat, rinsing, and liquid splashing.

Ultrasonic welding process: Achieving structural sealing without threads or glue, improving air tightness and assembly consistency, suitable for mass medical grade assembly.

Flexible and high elasticity Pogo Pin structure: Suitable for dynamic wearing, frequent insertion and removal, maintaining low contact resistance and stable antioxidant performance, ensuring accurate transmission of key physiological data.

Material biocompatibility certification support: All materials can be selected as needed and certified according to ISO 10993, USP Class VI, etc., suitable for long-term skin application or short-term invasive use.

Autoclavable Pogo Pin Connector for Medical Sterilization Environments

In the medical industry, medical connectors are not only transmission media, but also key components that determine equipment durability and compliance. Pogo pin connector with high temperature resistance and sterilization is designed for high-pressure steam sterilization (Autoclave) environments. It can meet the high requirements of stable performance, no deformation, and no oxidation of medical devices in repeated sterilization cycles.

Support high-pressure steam sterilization: temperature ≥134℃, pressure ≥2.0 bar. The structural material can stably withstand 134℃ and a 30 minute sterilization cycle, meeting the mainstream sterilization process standards in Europe and America.

High temperature resistant spring plunger structure design: selected high-temperature alloy spring material + medical grade high-performance plastic to ensure elasticity and contact reliability after repeated sterilization.

Anti-corrosion coating & long-life design: Adopting high-temperature resistant gold plating, gold nickel plating or composite electroplating to prevent electrochemical corrosion in high humidity and high temperature environments.

Airtight fit & cleaning design: The structure has strong sealing, making it easy to clean and sterilize, meeting the strict requirements of medical regulations for controlling hygiene blind spots.

Support customized modular plunger holder structure: flexible adaptation to one-time or multiple sterilization equipment, widely supports multi pogo pin combination design.

Integrated Magnetic Pogo Pin Connector for Effortless Charging & Docking

How to achieve fast, safe, and error-tolerant charging connections in today’s increasingly intelligent portable diagnostic terminals and wearable medical devices? Magnetic pogo pin connector, integrating spring pin structure and magnetic automatic docking function, no need for precise insertion and removal, close to the suction and positioning. It provides the ultimate convenient charging and data docking experience for medical products.

Magnetic positioning and automatic docking: Equipped with a high-performance N52 magnet design, the connector automatically adheres and aligns. It can quickly complete the connection even when the line of sight is unclear or the hand is inconvenient to operate.

Integrated structure of spring plu and magnetic attraction: Precise Pogo Pin design ensures stable current transmission, suitable for dual-channel scenarios of charging and data synchronization.

Support medical grade fast charging and low resistance transmission: maximum support 50A current, low contact resistance 5 mΩ, meeting the needs of long-term power supply and fast charging.

User-friendly experience design: fast insertion and high tolerance for blind insertion, improving the user experience and maintenance efficiency of wearable or portable devices.

Compact structure, can be encapsulated in silicone/plastic shell modules: supports medical grade material encapsulation, compatible with IP67 or IP68 waterproof design and high-frequency use.

Why choose Johoty as your medical connector supplier?

High-quality, reliable, and innovative medical connectivity solutions

In the medical industry, medical connectors are tools for transmitting electrical current and are critical components for ensuring the safe and efficient operation of medical equipment. As a professional supplier of customized medical connectors, Johoty has leading technology, excellent quality control, and customized solutions. Winning the trust of global high-quality medical device manufacturers.

High standard quality assurance

Our medical connectors comply with strict certification requirements such as ISO 13485, FDA, CE, etc. Each pogo pin connector undergoes 23 strict quality inspections and can operate stably in high temperature, high humidity, and corrosive environments.

Innovative design to meet diverse needs

From Pogo Pin with high temperature resistance and long plug-in life to shielded connectors with EMI interference resistance, supporting USB, HDMI, Data transmission and charging. Johoty is able to provide personalized customized solutions based on customer needs.

Deep technical strength and engineering support

Johoty has an R&D team with over 20 years of experience, which can provide customers with support in selection, technical consultation, and optimization design. Assist clients in quickly resolving technical difficulties in the project.

Strict environmental and biocompatibility testing

Our Pogo pin connector complies with biocompatibility standards such as ISO 10993 and USP Class VI. It ensures safety and harmlessness to human body when it is used in medical devices. Compliant with environmental regulations and suitable for long-term wear or internal devices.

Global supply chain and fast delivery

Johoty has a powerful factory for CNC manufacturing, assembly, and 23 quality control processes, DHL, FedEx, UPS, TNT, and SF Express. We can provide customers with stable supply chain support to ensure fast delivery. No matter where you are from or where your projects are located, Johoty can provide you with a quick response and efficient service.

Focus on customer needs and build long-term partnerships

Johoty is not only a factory, manufacturer, and supplier, but also a trusted partner for you. Our goal is to help you improve the performance and user experience of medical devices through efficient and reliable pogo pin connector solutions. Johoty is committed to building long-term and stable relationships with our valued clients in the world. We always provide you with timely and reliable solutions in the field of medical connectors.

Conclusions:

Accurate, reliable, and cost-effective medical connectors are never a universal replacement, but stem from Johoty’s ultimate control over details. Johoty medical connectors are designed based on rigorous standards, aimed at meeting the highest precision requirements and extreme applications. We are well aware of the strict performance requirements of engineers. That is why Johoty’s medical connectors not only meet, but even exceed industry standards, providing solid support for your project. Contact Johoty immediately to become your reliable partner and help your project succeed!