Waterproof Connector is Vital for Reliability. Top 5 Benefits of Pogo Pin Connector, Offering Engineers Durability, Precision, Cost-efficiency

Introduction

The demand for waterproof connector is increasing in devices operating in complex and extreme environments. As one of the solutions, the selection of a waterproof connector is crucial for the long-term stability and security of the device. Traditional connectors may malfunction due to moisture, dust, and harsh weather conditions, thereby increasing maintenance and replacement costs. The pogo pin waterproof connector has excellent waterproof performance, reliability, and high-frequency connection capability. It has become an ideal choice for engineers to tackle these challenges.

Choosing a waterproof connector that can provide stable connections and withstand extreme environments is a core issue that engineers must address during the design process. What unique advantages can pogo pin waterproof connector bring to engineers? How can it ensure efficient electrical transmission and extend the service life of equipment while meeting waterproof requirements? These questions are answered by Johoty in this article.

This article will analyze 5 major advantages of waterproof connectors based on pogo pins. Help engineers fully understand the unique performance of this connection solution and assist them in choosing the most suitable connector solution. Whether you are developing high-frequency electronics or complex industrial equipment. This article will provide you with practical insights to help you make the best decisions when choosing waterproof connectors.

Why choose a waterproof connector based on pogo pins? Ultimate waterproof performance

Waterproof requirements in harsh environments

In the engineering design of outdoor equipment, medical instruments, and industrial automation control systems, they often face the test of harsh environments. The working environment with high humidity, high temperature, or frequent contact with water sources places extremely high demands on the waterproof performance of connectors. If the selected connector cannot effectively resist moisture intrusion, it will lead to equipment failure, performance degradation, and even catastrophic equipment damage. Therefore, as an engineer, choosing a waterproof connector with excellent waterproof performance is crucial for the long-term stability of the equipment.

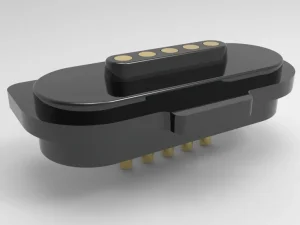

Precision sealing design and high-performance materials

Pogo Pin connectors excel in waterproofing due to their precise design and high-performance materials. The sealing design adopts high-density rubber sealing rings, which can effectively block moisture from entering the interior of the connector, preventing poor electrical contact or short circuit. At the same time, corrosion-resistant stainless steel or titanium alloy is used inside the connector, further enhancing its corrosion resistance in humid environments. Through these technological innovations, pogo pin connectors can easily meet the protection requirements of IP67 and higher levels. In harsh environments, waterproof connectors can still work stably for a long time.

Widely used to ensure long-term stability of equipment

The waterproof performance of pogo pin connectors has been validated and proven in multiple fields. Sports cameras, smartwatches, or other wearable devices in outdoor equipment need to function properly in rain, sweat, and moisture. The waterproof design based on the pogo pin connector ensures that the device maintains a high degree of waterproofness throughout its entire lifecycle. Continuous exposure to water sources and high humidity environments will not affect performance due to moisture intrusion.

In the field of medical instruments, pogo pin connectors have also demonstrated their irreplaceable advantages. Medical equipment often needs to be used in high humidity operating rooms or emergency rooms, and even in contact with patients’ bodily fluids. The Pogo pin connector provides ultimate waterproof performance, ensuring that the device is not affected by moisture in these environments. The waterproof connector based on pogo pins ensures accuracy, reliability, and high performance of medical instruments.

High reliability and durability: extending the service life of equipment

Focus on long-term stability and durability

High frequency connection and disconnection often pose significant challenges to the performance of connectors. Conventional connectors are prone to poor contact, oxidation, and wear under frequent operation The water proof connector based on Pogo Pin has significant advantages in design. Its precise elastic contact design can withstand long-term high-frequency operations, ensuring stable electrical connections. In harsh environments such as high temperatures, humidity, dust, etc., waterproof connector can effectively prevent external interference and ensure the continuous operation of the equipment.

Durability and wear resistance

Pogo Pin connectors have excellent wear resistance and oxidation resistance, making them suitable for long-term high-frequency operation. Spring contact design can provide stable pressure during the contact process, reduce mechanical damage, and extend the service life of the contact point. More importantly, the housing of the waterproof connector adopts high waterproof sealing design. Under humidity or water immersion, the connector can still maintain excellent performance, greatly improving the operational reliability of the equipment.

Proving efficient and stable performance in extreme environments

According to multiple experimental data, the waterproof connector based on pogo pins can pass 50,000 high-frequency connection and disconnection tests. At the same time, the test can still maintain stable electrical performance. Under extreme high humidity, high temperature, or low temperature conditions, there was no significant increase in contact resistance. It can still ensure stable signal transmission and electrical contact. In addition, the metal material on the surface of the connector oxidizes extremely slowly under salt spray and corrosive gases. The antioxidant test shows that it maintains excellent corrosion resistance.

Waterproof connector based on Pogo Pins: precise electrical transfer, ensuring signal stability and transfer accuracy

In high-frequency applications, the accuracy of signal transfer is crucial for ensuring the stable operation of equipment. In medical equipment, precision instruments, and wireless communication systems, the performance of the system is directly determined by the stability of the signal. This is precisely where the waterproof connector based on pogo pins demonstrates its unique advantages. It can provide extremely precise electrical transfer, ensuring signal stability and transfer accuracy.

The importance of precise transfer

Johoty’s customers and engineers always consider maintaining electrical transfer accuracy in high-speed data transfer, RF signals, and high-frequency circuits. Any small transfer error can affect the overall performance of the device. It may even cause system crashes or communication failures. In communication, we will understand that these are the core considerations that engineers must take into account when designing efficient and reliable systems. Therefore, it is very important to choose waterproof connector that can provide stable contact and precise electrical transfer.

Elastic Design of Pogo Pin Connector

Pogo pin connector is often designed with precision springs to achieve reliable contact performance. This type of connector with elastic design can self adjust and maintain a constant contact pressure. It can avoid signal attenuation caused by poor contact. In complex working environments, the contact points of waterproof connector can remain stable. There is a unique advantage in the accuracy of electrical transfer.

Specifically, the pogo pin connector adopts a spring design. Its contact points can adapt to different pressure changes, ensuring efficient signal transfer. Pogo pin connectors are commonly used in high-speed data transfer, RF signals, and precision circuits.

Ideal choice for high-precision equipment

Waterproof connector is widely used in fields that require high-precision electrical transfer. In medical equipment, any small interference from electrical signals can have an impact on diagnostic results. Therefore, pogo pin connectors provide critical support for medical devices by ensuring stable and precise electrical transfer.

In wireless communication and precision instruments, equipment often requires high-speed and stable signal transfer. Any signal loss or attenuation can lead to a decrease in device performance. A waterproof connector based on pogo pins can effectively avoid this problem. It can ensure stable signal transfer while ensuring long-term reliable operation of equipment in extreme environments.

Simplified design and convenient installation: waterproof connector improves production efficiency

Johoty’s customers and engineers often face the challenge of balancing complex design with production efficiency. Reducing design complexity and improving installation convenience can save engineering time and enhance overall production efficiency. This is a huge advantage brought by waterproof connector based on pogo pins. It provides engineers with a more simplified and convenient solution.

Simplify design and improve installation convenience

When designing circuit boards, engineers consider electrical performance, simplify the design, and reduce assembly difficulty. Complex designs can increase production and assembly costs, affecting clients’ product’s market competitiveness. Improving installation convenience can significantly reduce assembly time and error rates, and enhance production efficiency.

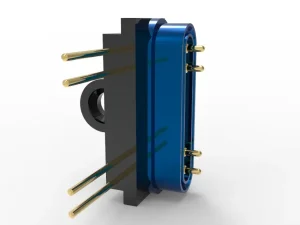

The waterproof connector adopts a modular design, and each pogo pin can be independently connected. It does not require too many complex circuits or welding processes. This reduces the difficulty of circuit board design and makes product assembly simpler and faster. By reducing the complexity of design, engineers can focus on improving product performance instead of tedious installation process.

Modular design and optimization of contact point arrangement

The modular design of pogo pin connector allows each connector unit to be freely combined according to requirements. This can reduce the complex circuit planning required in traditional connector designs. By optimizing the number and arrangement of contact points, pogo pin connector can help simplify circuit board design. This can reduce the burden on the circuit board and improve assembly efficiency.

In addition, the precise insertion and removal design of the pogo pin connector ensures a very smooth installation process. This can reduce electrical failures caused by improper assembly. Based on this design, the installation of the water proof connector becomes more intuitive and convenient. Engineers can complete various installations in short time and furtherly improve production efficiency.

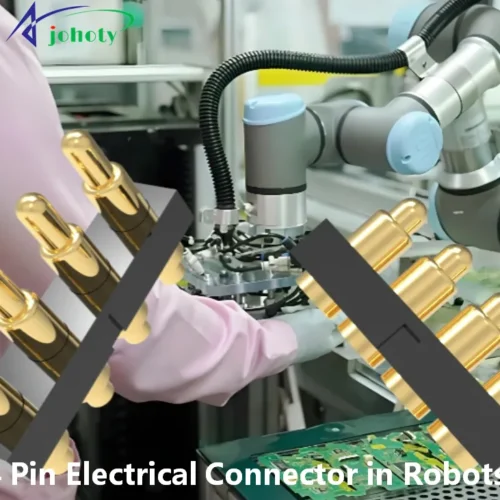

Case: Reducing design complexity and optimizing production processes

The German medical equipment manufacturer introduced Johoty’s pogo pins based waterproof connector in 2024. The customer successfully reduced the design complexity of the circuit board and significantly improved the production efficiency of the product. By simplifying the connection design, the customer’s production team has reduced assembly time by approximately 30%. This convenient installation method also reduces the probability of errors and greatly improves production quality.

An Italian consumer electronics brand also uses Johoty’s pogo pin connector. By optimizing circuit design, production costs have been successfully reduced and the time to market for the product has been shortened. This efficient connection method improves the market response speed for customers. Waterproof connector also helps customers gain an advantage in a fiercely competitive market.

Cost effective waterproof connector: a cost-effective solution

Cost effectiveness is a crucial consideration for engineers or bosses in mass production. How to achieve optimal performance at the lowest cost is the core goal of every customer at Johoty. The waterproof connector based on pogo pins has become an ideal choice among many engineering projects.

Long term cost-effectiveness:

During large-scale production, waterproof connector based on pogo pins can provide lower unit costs. Because the pogo pin connector simplifies the complex mechanical assembly processes in traditional connection methods, such as screw connections or welding. Compared to these traditional connectors, the production process of Pogo Pin connectors is more efficient, reducing manual operations and waste during the production process. Therefore, as the output increases, the unit cost will significantly decrease, thereby saving a lot of budget for the engineering project.

High cost-effective technological advantages:

Pogo pin connector adopts spring contact technology, which can provide extremely reliable electrical connections. This design not only ensures the high performance of the connector, but also performs excellently in terms of waterproofing and durability. It also avoids the problem of poor contact that may occur with various traditional connectors. Despite its superior performance, the cost of Pogo Pin connectors is lower than many similar waterproof connector. Compared with metal welded connectors, it greatly reduces component and maintenance costs. Engineers can fully guarantee system stability and long-term service life,

Market comparison:

Compared to other waterproof connector, the price of Pogo Pin connectors is often more competitive. Traditional connectors that use complex sealing structures and welding processes have higher manufacturing and maintenance costs. The Pogo Pin connector, due to its simple and efficient structure, can provide a more cost-effective solution. Help customers achieve significant economic benefits in production costs and system maintenance.

Reduce overall system costs:

In industrial production, engineers are increasingly focusing on controlling overall system costs during the design phase. The waterproof connector based on Pogo Pin can help the system ensure high performance and reliability, reducing overall costs. The low-cost Waterproof connector can meet performance requirements and effectively reduce the production cost of the final product. It has significant advantages in enhancing client’s product market competitiveness.

Improve production efficiency, minimize maintenance costs:

The design of pogo pin connector aims to improve production efficiency. The simple installation method and efficient electrical connection can save a lot of time and resources in the production process. In this way, mass production is more efficient, reducing the difficulty of maintenance and repair, and further lowering the cost of the product lifecycle.

Conclusion: Why choose Johoty’s waterproof connector based on pogo pins?

Choosing the appropriate waterproof connector is to ensure system long-term reliability and stability. In order to optimize project costs and improve production efficiency. As described in this article, the waterproof connector based on pogo pin has excellent cost-effectiveness, simplified design, high performance assurance, and lower production and maintenance costs. Based on Johoty’s selection of over 1,000 customers, waterproof connector has become an excellent choice in engineering design.

How can engineers make the best choice?

If you are looking for a cost-effective waterproof connector that is competitive in mass production and has excellent waterproof performance, Johoty’s pogo pin based waterproof connector is undoubtedly the preferred choice worth considering. The balance between performance and cost is crucial in the design process. Johoty is committed to providing solutions that best meet the needs of engineers.

How does Johoty meet your needs or target?

The pogo pin waterproof connector provided by Johoty meets strict quality standards and has been validated multiple times in practical applications. It can maintain excellent performance in harsh environments and complex industrial systems. Our CFT team can provide customized waterproof connector solutions according to your demand project requirements. Help you reduce production costs, improve system efficiency, and ensure long-term reliability.

Contact us immediately and let Johoty provide the most reliable waterproof connector solution for your project. Assist you in achieving success in future engineering projects!