Right Angle Connector, 6 Innovative Solutions for Pogo Pin, Designed to Enhance Reliability, Precision, Efficiency in Your Engineering Project

Introduction

Right angle connector is becoming a key player in driving efficient connectivity solutions in modern electronic design. As an engineer, have you ever been troubled by achieving stable and precise connections in a limited space? Have you encountered difficulties such as reduced performance or shortened lifespan due to poor contact or limited space? The right angle connector, with its unique design, is the innovative choice to solve this problem.

So, how to ensure maximum connection efficiency in the smallest space? How can we ensure that the right angle connector remains stable and reliable in high-frequency and high-precision applications? Johoty delves into 6 innovative solutions for right angle connector based on pogo pins or pogo pin connector. We help you understand how to optimize connection design, improve engineering reliability and work efficiency. Through this article, you will learn how to leverage the advantages of right angle pogo pin in various engineering challenges. Realize more precise electrical transmission, more efficient space utilization, and significantly improve overall performance.

These 6 solutions are based on the latest technological innovations, fully consider the practical needs of engineers. Explore together how to optimize your design and improve the success rate of engineering projects through the right angle pogo pin.

Breakthrough design, flexible layout from multiple angles. Why choose Right Angle Connector based on Pogo Pins?

In circuit board layouts with limited space, maximizing every inch of space often becomes major challenges in design. Design difficulty of right angle pogo pin is greater on narrow circuit boards. Traditional right angle connector often occupies too much space due to its large size, which affects overall design and signal transmission effect of circuit board. So, how can we solve this problem?

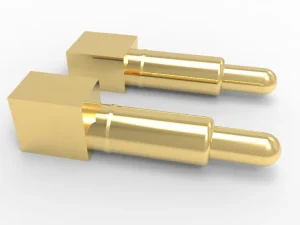

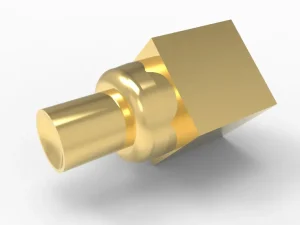

Breakthrough design, Right Angle Pogo Pins:

The right angle connector based on pogo pins is an important innovation over traditional right angle connector. Johoty’s patented design ensures connection stability and optimizes design dimensions. In this way, it can solve technical bottleneck of difficult installation of traditional right angle connector. Compared to traditional connectors, right angle pogo pin takes up less space. It can be flexibly arranged in corners of circuit board to ensure maximum utilization of limited space.

Space optimization and performance improvement:

Device internal space is limited. How to avoid wasting every inch of space in high-density designed circuit boards? Compact design of right angle connector maximizes device utilization of internal space without affecting signal quality. According to Johoty’s research, using right angle pogo pin can save up to 25% of circuit board space. Meanwhile, within the same space, this pogo pin connector can improve signal stability by 20%. This design can improve device compactness, enhances its overall performance.

Addressing technical challenges and improving design efficiency:

Choosing right angle connector without sacrificing connection stability can easily achieve efficient design of circuit boards. In space constrained designs, it can help engineers overcome traditional right angle connector being too large in size and difficult to install. For engineers, various complex designs become more flexible and efficient.

Right Angle Connector Based on Pogo Pins: Electrical Reliability in Precise Contact and High Frequency Applications

In high-frequency, poor contact often leads to unstable signal transmission and equipment failure. This is a significant challenge for communication and medical devices that require high-precision connectivity. How to ensure the stability of high-frequency data transfer and reduce signal attenuation and loss? It has become core connection issue for designers and engineers.

Technical difficulties and challenges

Traditional connectors are prone to signal attenuation in high-frequency applications due to poor contact. At extremely high data transmission rates, minor contact issues can lead to equipment failure or significant performance degradation. Uneven contact surface can easily lead to unstable electrical contact, thereby affecting the reliability of the entire system.

Innovative Solutions

Johoty’s pogo pins solve the problem of poor contact in traditional connectors by providing more precise contact surfaces. Pogo pins have excellent performance in high-frequency applications and are suitable for high-speed data transfer needs. Through precision designed contacts, pogo pins ensure stability, reliability and safety of electrical contacts. In high-frequency applications, it can minimize signal attenuation and loss to the greatest extent possible.

For wireless communication devices, Johoty’s right angle connector can effectively maintain a stable signal transfer. In high-speed data transfer, pogo pin connector provides higher contact accuracy. It reduces data loss and transfer delay caused by poor contact. According to customer data, signal transfer loss of pogo pin connectors is about 20% lower than that of traditional connectors. After 3 years of tracking, Johoty’s Italian customer has confirmed that it can significantly improve communication quality.

Engineer Value

For engineers, choosing right angle connector based on pogo pins can significantly improve system stability and data transfer speed. In communication equipment, medical instruments, precision instruments, high-precision connector can ensure high-frequency data reliability and reduce failure rate.

Why Choose Pogo Pin Right Angle Connector for Your High-Durability Needs?

Equipment stability and lifespan are crucial in engineering design. When frequent connector contact is required, the durability of traditional connectors often becomes a bottleneck. This always leads to frequent equipment failures and significant increase in maintenance costs. So, how can we ensure right angle connector maintains stable performance and high reliability under high-intensity use?

Technical difficulties and challenges:

Traditional connectors are prone to wear and tear at contact points due to friction, corrosion, or metal fatigue during prolonged repeated connection. This always leads to unstable connections, significantly shortens device’s lifespan. In some critical applications, device failure is possibly caused by this performance degradation.

Innovative solutions:

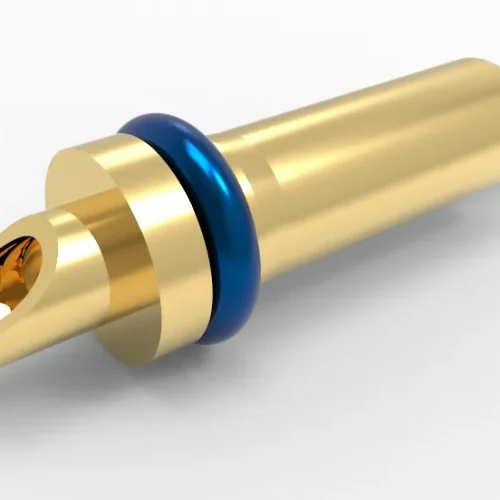

Johoty’s pogo pin based right angle connector utilizes advanced materials and finishing. We use high-performance brass, tellurium copper, beryllium copper, stainless steel, etc. Strengthen contact performance and wear resistance of pogo pins through gold plating, palladium plating, and platinum plating. The combination of high-quality materials and processing technology allows right angle pogo pin to withstand up to 200,000 operation cycles. This far exceeds standard lifespan of 10,000 cycles for traditional connectors.

Engineer value:

Extend product lifespan: By using more durable materials and finishing, Johoty’s right angle connector significantly extends the device’s lifespan. You don’t need to frequently replace connectors, reducing repairs and replacements costs.

Reduce maintenance costs: Due to right angle connector maintain efficient and stable connections during repeated connection, device operation is more stable. Reduced equipment downtime and maintenance costs caused by connector issues.

Ensure long-term stable operation of equipment: With high-strength durability and long-lasting contact, your equipment can work in demanding environments. And it can maintain good electrical performance and improve equipment overall reliability.

Fine-tuned contact force of Right Angle Connector reduces contact resistance

In high-speed and high-frequency applications, contact resistance directly affects signal quality and transmission efficiency. Engineers often face high contact resistance, leading to equipment instability, signal distortion, and short circuits. How to effectively reduce contact resistance and improve the reliability of connectors?

Difficulty and Challenge: Contact Resistance Influence

Contact resistance on connector contact surface determines current efficiency. When contact resistance is too high, the current will be limited, resulting in signal attenuation, interference or signal loss. It is severe in high-precision medical instruments, automotive electronics, communication equipment, where low contact resistance is crucial for stable operation.

Innovative solution: precise control of contact force

Johoty’s pogo pin based right angle connector utilizes precise contact force control technology. By optimizing elasticity and contact force of pogo pin, ensure connector contact resistance is minimized every time it is connected. Experimental data shows contact resistance is as low as 5mΩ, which is lower 15 mΩ of standard pogo pins. Through precise manufacturing, the contact force of pogo pins can be maintained consistently. Each connection has the same electrical performance, greatly improving signal transmission stability.

Engineer Value: Enhancing Equipment Reliability and Performance

Johoty’s right angle connector ensures low contact resistance and consistency in electrical performance. It is suitable for precision electronic devices with high requirements on connector stability. By reducing contact resistance, it improves signal quality, reduces the incidence of equipment failures, and extends equipment service life.

If your product needs to maintain stability in high-speed signal transfer, Johoty’s pogo pins based right angle connector is ideal choices. By finely controlling contact force and resistance, Johoty’s right angle pogo pin can bring significant performance improvements to your products. It can ensure the stable operation of your equipment in harsh environments.

Why Choose Pogo Pins-Based Right Angle Connector? Vibration and shock resistant design for a more adaptable work environment!

Aerospace, automotive, and industrial control equipment is often exposed to vibration and shock. Ordinary connectors often suffer from poor contact or loosening, seriously affecting stability and performance. How to solve this challenge? The answer is Johoty’s right angle connector, which is designed for high vibration environments and provides excellent vibration and shock resistance.

Technical difficulties and challenges:

In industrial or outdoor environments where vibration is high, connectors can face poor contact and loosening. This often leads to interruption of signal transmission and failure of equipment to work properly. In high vibration environments, the stability of the connector directly determines the performance of the equipment. Spacecraft and automotive equipment can vibrate up to 1,000 Hz, requiring connectors to withstand extreme vibration shock.

Innovative solutions:

Johoty’s right angle connector’s vibration-resistant design utilizes a unique spring contact and reinforced pin structure. It maintains perfect contact on uneven surfaces. This prevents the poor contact that occurs with traditional connectors during vibration and shock, and Johoty’s test data shows that our right angle pogo pin can withstand vibration shocks of up to 5,000G. It ensures signal stability and meets demands extreme environments. Customers from aerospace, automotive and industrial automation often order it.

Value for engineers:

High reliability: The anti-vibration design ensures that the right angle connector remains stable under prolonged high-frequency vibration and shock.

Wide applicability: It is commonly used in high vibration and shock aerospace, automotive, and industrial control with stable operation.

Space and Cost Saving: right angle pogo pin effectively reduces the space occupied in the design and enhances the ease of installation and cost effectiveness.

Modular customization to meet personalized needs, why choose the Right Angle Connector based on Pogo Pins?

Engineers often face the need for customized connections for specific applications. Traditional connectors often rely on standard specifications and cannot meet the requirements of personalized design. This affects system overall performance and increases design cycle and cost. In limited space or high-density connections, standard connectors cannot provide sufficient flexibility and accuracy.

Innovative solutions:

Johoty’s modular customized right angle pogo pin provides engineers with a fully tailored solution. Customers can customize right angle pogo pin with different specifications, sizes, and functions. In devices with limited space, perfect adaptation can be achieved in high-frequency and high-voltage environments. By precise design optimization, right angle connector can meet clients’ project unique requirements.

Modular connectors can reduce system integration time by up to 25%, while customized design can improve system stability and reliability by 30%. In complex and demanding engineering projects, right angle connectors can provide higher design freedom and system performance.

Engineer value:

Flexible design: Modular customization allows designers to make personalized choices based on applications, ensuring the flexibility and scalability of the system.

Enhance system integration: Through customized solutions, the right angle connector helps customers effectively solve connectivity issues. Reducing the risk of incompatibility and improving the overall stability of the system.

Improve production efficiency: Customized services can reduce the need for repeated adjustments caused by selecting standard connectors, shortening design and production cycles. The right angle connector can directly improve the work efficiency of engineers.

Conclusions:

Faced with complex electrical connection challenges, Johoty’s right angle connector, Six innovative solutions were presented. They are designed specifically for engineers and fill technological gap. Effectively helped engineers solve multiple technical problems in prototype, small batch trial production, and mass production. Johoty thoroughly analyzed each innovation to ensure it provides stable and reliable performance in various high demand environments.

High density right angle connectors can effectively optimize circuit board space, suitable for engineers with high requirements for space and design. The multi contact technology greatly improves pogo pin contact stability. Significantly enhanced the reliability of the connector during long-term use and reduced poor contact. Our right angle connector’s shock resistant design ensures stable operation in high vibration or impact environments. At the same time, it can maintain excellent electrical contact performance and perfectly adapt to industrial equipment.

Johoty has further broken through automatic docking, reducing human insertion and removal errors, ensuring connection accuracy and consistency. The antioxidant coating provides strong corrosion resistance, and the right angle connector is suitable for long-term use in extreme environments. This pogo pin connector ensures the longevity of guest devices in harsh weather conditions. Its low resistance design optimizes current transmission efficiency and reduces the heat generated by excessive current. The right angle connector ensures electrical system stability and safety.

These are all Johoty’s profound research and development accumulation of pogo pin connectors and precise insights into engineering requirements. We believe that as an engineer, you will definitely find the perfect solution to your project challenges in our right angle connector. Contact Johoty immediately to explore how to integrate these 6 innovative technologies of right angle connector into your design. Drive the success of your project and achieve more efficient, flexible, and reliable connectivity solutions.