Automatic Test Equipment (ATE), Pogo Pins ensure high reliability testing with their efficiency, precision, reliability, and long lifespan. Choosing Pogo Pins enhances ATE performance, reducing maintenance costs while increasing production efficiency. Explore further details to optimize your testing process.

Automatic Test Equipment (ATE), Pogo pins guarantee efficient, precise, and reliable test results with outstanding connectivity performance. Their durable design extends lifespan and significantly reduces maintenance frequency and costs, thus enhancing overall test reliability. Opting for Pogo Pins elevates your ATE system to unprecedented levels of performance and stability.

The performance and reliability of Automatic Test Equipment (ATE) are paramount. Engineers continuously seek methods to enhance testing efficiency and precision, ensuring product quality and production consistency. In this endeavor, Pogo Pins have emerged as critical components in ATE testing.

They are leveraging their exceptional connectivity performance and durable design. Pogo pins significantly enhance testing efficiency and accuracy and ensure the long-term reliability of testing systems. This article delves into the advantages of applying Pogo Pins in ATE. Showcasing how they bring revolutionary improvements to your testing process.

Introduction, Automatic Test Equipment, Pogo Pins Ensure ATE High Reliability

- In electronic manufacturing and testing, reliable testing equipment is essential to guarantee product excellence. However, data shows that over 30% of test failures are attributed to unstable connections and poor contacts. These issues increase testing time and costs and impact production efficiency and product reliability.

- Automatic Test Equipment (ATE) assumes a pivotal role in this endeavor. ATE greatly enhances testing efficiency and accuracy through automated testing processes, becoming a core tool in the electronics industry. However, traditional connectors often struggle to meet the high-intensity and high-precision testing requirements.

In such a context

- Pogo Pins emerge as an innovative connectivity solution. With their outstanding connectivity performance and durable design, Pogo Pins significantly enhance the reliability and efficiency of ATE. They not only ensure high-precision connections for each test but also reduce maintenance and replacement frequencies. Thereby substantially lowering testing costs.

- This article will delve into the application advantages of Pogo Pins in ATE. Showcasing how they revolutionize the ATE testing process, bringing higher productivity and quality assurance to the electronics industry.

Ultimate Test Solutions of Automatic Test Equipment, Pogo Pins Ensure ATE High Reliability

Dive into ATE Testing of Automatic Test Equipment

- In the realm of electronic manufacturing and testing, Automatic Test Equipment (ATE) stands as a crucial tool. ATE ensures rigorous quality inspection for every electronic product before leaving the factory by executing automated testing procedures.

- The primary functions of ATE include functional testing of circuit boards and components. Pinpoint potential fault points, and validate product performance and reliability.

Role of ATE in Electronic Manufacturing and Testing

- Boosting Production Efficiency: Automatic Test Equipment can automatically conduct numerous repetitive tests, significantly reducing the time and manpower costs of manual testing. Thereby enhancing the overall efficiency of production lines.

- Ensuring Product Quality: Through stringent automated testing, Automatic Test Equipment ensures that every product meets design specifications and quality standards. Mitigating the chance of faulty products reaching consumers.

- Fault Detection and Prevention: Automatic Test Equipment can quickly identify faults in circuit boards or components. Helping engineers take corrective measures promptly to stave off the worsening of potential issues.

Key Aspects of Automatic Test Equipment Performance

1. Efficiency:

- Automatic Test Equipment can complete many complex tests in a short time, significantly improving production efficiency.

Automated testing processes reduce human intervention, lowering error rates.

2. Precision:

- High-precision testing equipment can capture subtle electrical signal changes, ensuring the accuracy of test results.

Precise test data assists engineers in optimizing product design and production processes.

3. Reliability:

- Reliable Automatic Test Equipment systems can operate stably under various environmental conditions, ensuring the continuity and consistency of testing.

- Reliable test results enhance the overall quality and market competitiveness of products.

4. Lifespan:

- The durability of ATE systems directly impacts their lifespan and maintenance costs.

- Long-lasting ATE equipment reduces replacement frequency, lowering long-term operating costs.

Role of Pogo Pins in Automatic Test Equipment

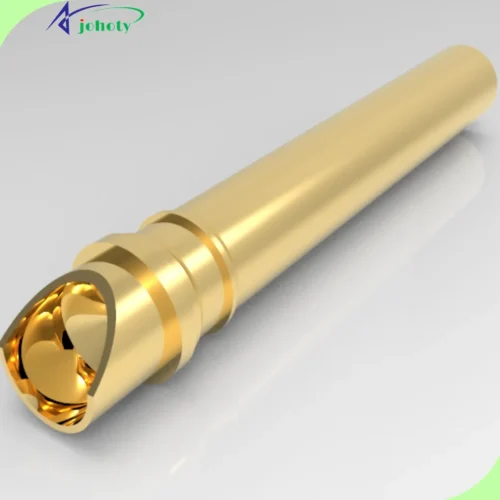

- Pogo pins, as a type of spring-loaded connector, emerge as the ideal choice in ATE testing. This is due to their efficiency, precision, reliability, and long lifespan.

- Pogo Pins can provide stable electrical connections, assuring the exactitude and consistency of every test. While reducing connector wear and replacement frequency during the testing process. Thereby significantly enhancing the overall performance and lifespan of ATE systems.

The Key Advantages of Pogo Pins in Automatic Test Equipment

Efficiency

- The application of Pogo Pins in Automatic Test Equipment (ATE) significantly enhances testing efficiency. Traditional test connectors may require additional time and manpower for connection and disconnection. Whereas the spring-loaded design of Pogo Pins streamlines this process, making it quick and simple.

- They can automatically adjust connection pressure, ensuring swift and accurate connections every time, thereby reducing test preparation time and cycles. This efficient connection method speeds up the testing process and significantly boosts productivity. Facilitating quicker product launches for clients.

Precision

- Pogo Pins are meticulously designed with precision in mind. They employ high-precision manufacturing processes to ensure perfect contact with the test object for each pin. This precise connection provides stable electrical contact, ensuring accurate transmission of test signals while avoiding signal loss and interference.

- Additionally, the spring-loaded mechanism of Pogo Pins provides constant contact pressure. It maintains consistent test results even during frequent connections and disconnections. This high-precision performance ensures more reliable measurement results for ATE testing, providing engineers with accurate test data.

Reliability

- The outstanding reliability of Pogo Pins under various testing conditions is a significant contributor to their extensive popularity. They can maintain stable performance in extreme environments, unaffected by external conditions.

- This stability is crucial for ensuring the continuity and consistency of ATE testing. Whether in laboratory environments or batch testing on production lines, Pogo Pins can provide stable and reliable connections. Reducing interruptions and errors caused by connector failures during the testing process.

Longevity

- The durability and long lifespan of Pogo Pins are another key advantage widely adopted in ATE testing. They are made from high-quality materials and advanced manufacturing processes, exhibiting excellent wear resistance and fatigue resistance.

- Even during high-frequency connection and disconnection operations, Pogo Pins can maintain good performance, reducing the frequency of replacement and maintenance. The long lifespan of Pogo Pins lowers the long-term operating costs of testing equipment. Furthermore, it boosts the general reliability and longevity of ATE systems.

Success Story: How Pogo Pins Enhance Performance and Reliability of Automatic Test Equipment?

1. Consumer Electronics Testing

A French consumer electronics company encountered issues with low testing efficiency and frequent connector replacements during the production process. Traditional test connectors couldn’t handle the high frequency of connection and disconnection.

Resulting in frequent production line interruptions, and affecting overall productivity. The client decided to adopt our Pogo Pins as ATE test connectors.

Results:

- Efficiency Improvement: Testing time was reduced by 30%, a significant decrease in production line downtime.

- Accuracy Enhancement: Significant improvement in test data accuracy, with a 20% decrease in error rate and non-detective failure rate.

- Reliability Enhancement: Pogo Pins demonstrated stable performance under high-frequency operations, with no connection failures.

- Cost Savings: Reduced replacement and maintenance frequency led to a 15% decrease in overall testing costs.

2. Automotive Electronics Testing

A UK automotive electronics manufacturer required rigorous testing of Electronic Control Units (ECUs) in extreme environments. Traditional connectors couldn’t maintain stable operation in such environments, affecting testing reliability and product quality. Eventually, the client opted for our Pogo Pins for testing.

Results:

- High Reliability: Pogo Pins maintained stable connections in extreme environments, with no disconnections or signal distortion during testing.

- Longevity: The durable design of Pogo Pins reduced replacement frequency, extending the lifespan of testing equipment.

Consistency: Improved consistency in test results, with a 10% increase in product pass rate.

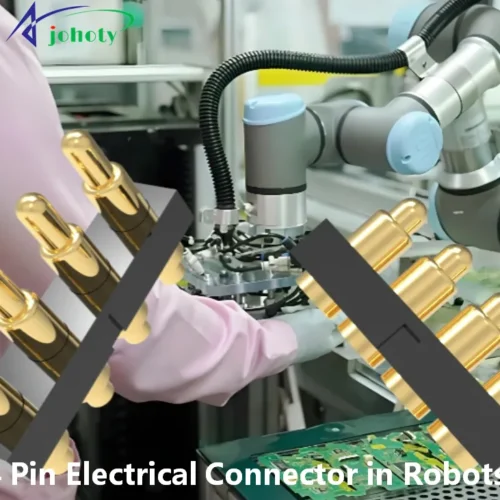

3. Key Factors in Enhancing Performance of Automatic Test Equipment

A leading global semiconductor company based in the United States faces significant challenges in its complex chip testing processes. Chip testing demands high precision and stability, requirements that traditional test connectors fail to meet. This results in inconsistent test results and high product failure rates.

The client decided to utilize Johoty’s Pogo Pins for ATE testing, aiming to leverage their efficiency, precision, and reliability. Hope to enhance testing performance.

Implementation Process:

- Test Preparation: Introducing Pogo Pins to replace existing connectors and recalibrating testing equipment.

- Test Execution: Using Pogo Pins for connections in multiple batches of chip testing, observing their performance.

- Data Analysis: Comparing the differences between Pogo Pins and traditional connectors in terms of testing efficiency, precision, and reliability.

Results:

- Efficiency Improvement: Pogo Pins significantly streamlined the testing process, reducing the time per test cycle. Productivity increased by 25%, enabling the client to bring their products to market faster.

- Accuracy Enhancement: Pogo Pins ensured high precision with every connection. Significantly improving the consistency and accuracy of test results, and reducing the error rate by 50%.

- Reliability Enhancement: Pogo Pins performed excellently in various testing environments, with no connection failures, ensuring the continuity and consistency of testing.

- Cost Savings: Due to the longevity and high reliability of Pogo Pins, replacement and maintenance costs were significantly reduced. The client saved over 20% of testing costs in the first year.

By adopting Johoty’s Pogo Pins, the client resolved bottlenecks in testing, and greatly improved the ATE system’s overall performance. Ultimately achieving dual enhancements in product quality and production efficiency.

How to Choose the Best Pogo Pins for Automatic Test Equipment?

1. Customized Services:

- It’s advisable to choose suppliers who offer customized services, such as Johoty, as your most reliable partners. Customize the size, shape, and material of Pogo Pins according to specific testing requirements to ensure optimal compatibility and performance.

2. Material Selection:

- Spring Material: High-quality stainless steel or beryllium copper springs can provide stable contact pressure and long life. Choosing corrosion-resistant and fatigue-resistant materials guarantees consistent operation across diverse environments.

- Tip Material: Tip materials such as palladium-nickel, gold plating, or silver plating offer better conductivity and wear resistance.

3. Design and Specifications:

- Size and Shape: Select appropriate Pogo Pins based on DUT’s size and shape to ensure precise connections and stable signal transmission. Pay attention to the tip shape, e.g., flat, pointed, ball, claw, cup, etc., and its impact on connections.

- Spring Force: Choose the appropriate spring force according to testing requirements. The higher spring force can ensure stable connections but may also increase mechanical stress, requiring careful consideration.

4. Electrical Performance:

- Conductivity: Choose Pogo Pins with high conductivity to ensure low resistance and stable electrical signal transmission.

- Current Capacity: Ensure that Pogo Pins can withstand the required current during testing to avoid overheating and electrical faults.

5. Environmental Adaptability:

- Temperature Range: Ensure that Pogo Pins can maintain stable performance within the expected operating temperature range. Choose materials resistant to high or low temperatures to accommodate diverse harsh environments.

- Durability: Select Pogo Pins with high wear resistance and long life for frequent operations to reduce replacement frequency and maintenance costs.

Conclusion, Automatic Test Equipment, Pogo Pins Ensure ATE High Reliability

Pogo Pins provide unparalleled efficiency, precision, and reliability for Automatic Test Equipment (ATE) testing. This renders them the perfect option for improving testing efficiency. If you aim to boost the performance of your Automatic Test Equipment system, Johoty’s Pogo Pins are undoubtedly indispensable core components.