Right Angle Pogo Pin Ensures a Low-Profile Fit with Stable Contact, Perfect for Tight Spaces | Compact Boards. See Real-World Solutions Now

Introduction: Why has right angle pogo pin become new benchmark for compact board design?

How to achieve reliable, low impedance, and wear-resistant connections on a high-density PCB smaller than a fingernail cover? This is all engineers’ challenge in RF modules, UAVs, EVs, micro-sensing systems, and intelligent medical devices.

Right angle pogo pin has a compact layout structure that can be vertically turned horizontally. It is becoming an ideal connector for resolving the contradiction between space and stability. Johoty CFT team has found through hundreds of practical projects that right angle pogo pins can greatly reduce Z-axis stacking thickness in confined spaces. It exhibits stunning engineering reliability in terms of thermal cycling, current continuity, and assembly tolerance compensation.

This article will conduct a systematic analysis around the right angle pogo pin. Including its structural advantages, electrical performance, application cases, selection criteria, and industry trends. And add its key experimental data, failure analysis, and real-world feedback. To show you a trustworthy, usable as well as professional technical reading experience.

Structural principle of right angle pogo pin is to horizontally output the plunger for low tolerance vertical docking

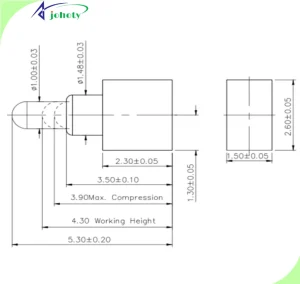

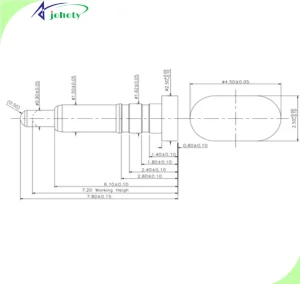

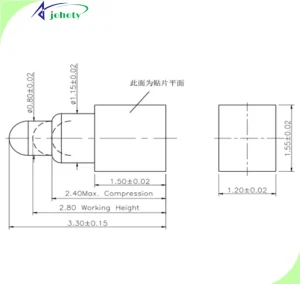

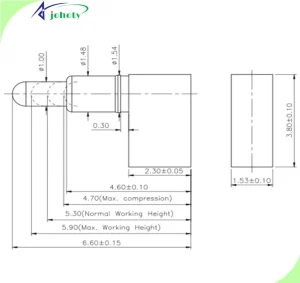

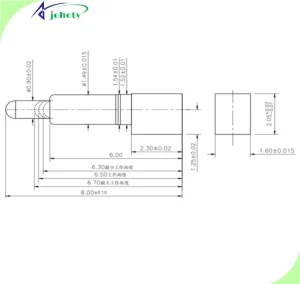

The definition of a right angle pogo pin is: the pogo pin soldering surface is installed vertically from the PCB soldering end. Its contact end is connected to the tested end or docking component in a 90°turning manner. This corner design is achieved through the built-in slanted piston structure or inverted Barrel. When the lateral offset is less than ±0.20mm, achieve stable and low voltage drop electrical contact.

Johoty’s standard specification right angle pogo pin underwent structural fatigue testing under 10,000 lateral compressions. The contact resistance is always maintained between 8.3~10.2mΩ, far below the recommended value of IPC standard <20mΩ.

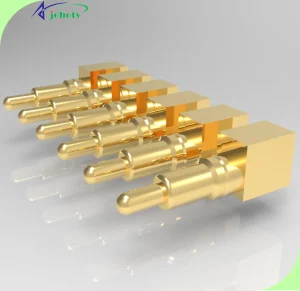

Compared to traditional vertical pogo pins, the right angle structure effectively compresses the thickness of spatial axial stacking. Greatly reduces the vertical packaging burden in compact products. It is suitable for horizontal interconnection between two parallel PCBs or FPC boards.

Stability of electrical performance: 10mΩ contact impedance of right angle pogo pin

Contact structure of a right angle pogo pin generally consists of three parts: Barrel, Spring, and Plunger. It often requires sufficient overlap of the contact surfaces under lateral force. Johoty always uses a gold beveled plunger and low stiffness nickel plated gold springs. On the basis of ensuring an initial contact force as low as 5gf, the following performance is achieved:

- Contact resistance: average 9.6mΩ, stability ±0.5mΩ (under continuous current test conditions of 40A).

- Response time: <10ns, suitable for high-speed signal transmission.

- Plug and unplug lifespan: ≥100,000 times (@2Hz cycle frequency).

Johoty’s actual test comparison data shows that right angle structure is more stable than traditional vertical structure. It is contaminated during lateral insertion and removal, and the probability of resistance fluctuation decreases by about 42%. The reason is that lateral contact surface is usually located in a horizontal zone with less sedimentary pollution.

Core application of right angle pogo pin: it is not usable, but the optimal solution

Precision signal connections in high-density modules (UAV, electric vehicle BMS):

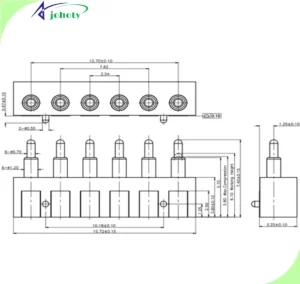

High current and small signal parallel transmission are required between module boards of EV BMS. The right angle pogo pin can achieve:

- Module embedding depth is only 2.50mm.

- Horizontal docking error automatically absorbs ±0.30mm.

- Mount FPC and motherboard connection ports without additional fixtures.

Micro charging connection for implantable medical devices (Smart Capsule, neural stimulator):

The right angle pogo pin features a low profile, low heat generation, and anti-oxidation gold plating design. It has been successfully deployed in multiple micro medical devices. This pogo pin connector can work in applications where charging current is <3.0A and the ambient temperature is <40℃. Its thermal expansion compensation performance is stable, saving customers about 25% of cooling component costs.

Robot arm signal feedback module in industrial automation:

Most automated joints have only a few millimeters of internal space during extreme sports. The right angle pogo pin can achieve horizontal bending and axial rebound. When the repeated high-speed crimping exceeds 200 times per hour, it reduces misconnection rate by 41% compared to traditional terminal connectors.

Selection of right angle pogo pins: professional balance of size, current, elasticity, and corrosion resistance

To facilitate quick selection for clients, Johoty has summarized the following key parameter recommendations:

Size selection: Total length <5.00mm, plunger elongation not exceeding 1.20mm.

Current specification: Recommended between 3~10A, and can be extended to 50A when connected in parallel.

Spring force range: Initial contact force of 2~5gf, full compression force <80gf.

Coating recommendation: A gold layer of ≥0.5μm is a basic industrial standard. Suggest adding a 0.1μm palladium cobalt layer for electrical spark resistance applications.

In addition, we encourage customers to use Johoty’s customized spring force designs. Design a minimum energy consumption model based on product usage frequency and docking materials. In this way, the right angle pogo pin maintains stable contact even during frequent insertion or slight sliding.

How to avoid micro solder through and metal fatigue in the right angle pogo pin?

Johoty assisted a German medical client in conducting a round of extreme durability testing in 2023. One group of right angle pogo pins was soaked in physiological saline solution at 37 ℃ for 60 days. It still maintains over 98% electrical performance integrity. In the failure analysis, we found that the following engineering strategies are crucial:

- We need to adopt a controllable elastic fatigue attenuation design. In this way, pogo pins can avoid the decrease in contact force caused by the spring memory effect.

- The diagonal position of the plunger tip should avoid machining burrs of <30μm. Otherwise, the topper tip can easily cause detachment or adhesion of metal debris.

- The coating needs to undergo a salt spray test for 96 hours to verify that there are no corrosion points. Johoty’s standard right angle pogo pins have all passed.

Right angle pogo pin moves from connection to dynamic tolerance absorption in future board level interconnects

Miniaturization, application of high-frequency electrical signals and flexible materials is becoming increasingly widespread. Right angle pogo pin is being redefined as an intelligent connectivity node with self-regulating capabilities. It has:

- 3D spring force self-adjusting structure (allowing for slight angle changes).

- Nickel carbide alloy replaces traditional copper materials to enhance fatigue strength.

- Magnetic guidance structure integration reduces blind insertion errors.

Johoty R&D and CFT team believe that right angle pogo pin will replace traditional FPC connectors. It is in dynamic module splicing and thermal redundancy systems with multi board structures in vehicles. Become a key node for inter-board interconnection in the next 10 years.

Conclusions:

The right angle pogo pin is just a connector. But Johoty believes it is the cartilage of an engineering system, an adaptive channel between modules. What it solves is not whether it can be powered on, but:

- How to maintain the purity of electrical signals in extreme space?

- How to achieve zero assembly error during frequent plugging and unplugging?

- In complex mechanical environments, How to achieve electrical redundancy?

- How to integrate aesthetics and efficiency in low profile structures?

If your product structure has reached the boundary, if you are pursuing the ultimate assembly between millimeters. Please follow Johoty’s right angle pogo pin and our customized industry solutions for numerous manufacturers.