2 Pin Connector Description:

Catalogs of 2 Pin Connector:

2 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: ≥15mΩ, Custom. |

| Rated current: 0.1A~100A, Custom. | |

| Rated voltage: 3.3V ~1,000V, Cusotm. | |

| Electrical insulation impedance: >100MΩ, Custom. | |

| Working frequency: From MHz to GHz, Custom. | |

| Mechanical: | Contact force: ≥15gf, Custom. |

| Pitch: ≥1.50mm Custom. | |

| Waterproof: IP65, IP66, IP67, IP68, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Plug and unplug: 10,000 ~ 200,000 times, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

| Materials: | Contact materials: Copper, copper alloys (phosphor copper), gold, etc. |

| Housing materials: Stainless steel, aluminum alloy, plastic (PPS, PBT, nylon), etc. | |

| Insulation materials: PI, PTFE, PBT, Nylon, etc. | |

| Spring materials: Gold-plated copper, phosphor copper, music steel, and, stainless steel, etc. | |

| Ball materials: Steel, zirconium, ceramic, Custom. | |

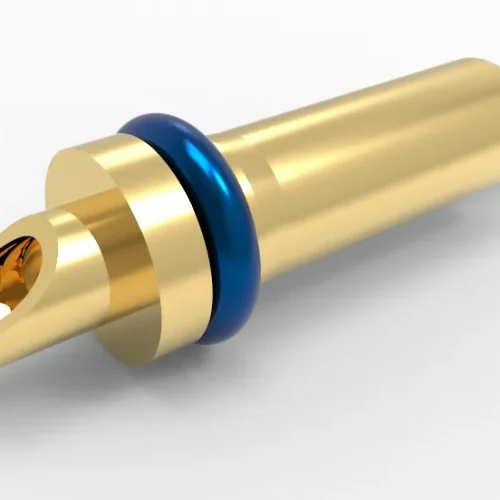

| Sealing materials: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating materials: Gold, silver, tin, nickel, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering materials: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: Polyurethane, silicone, rubber, etc. | |

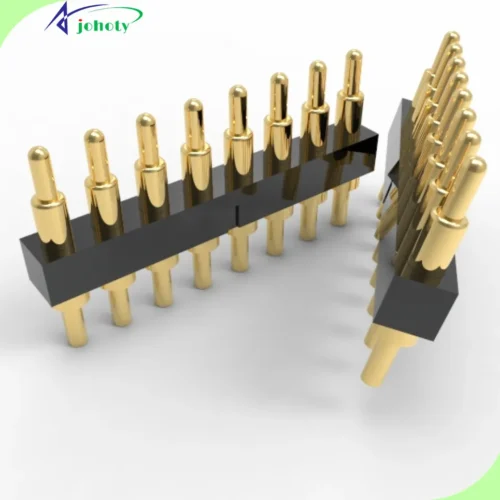

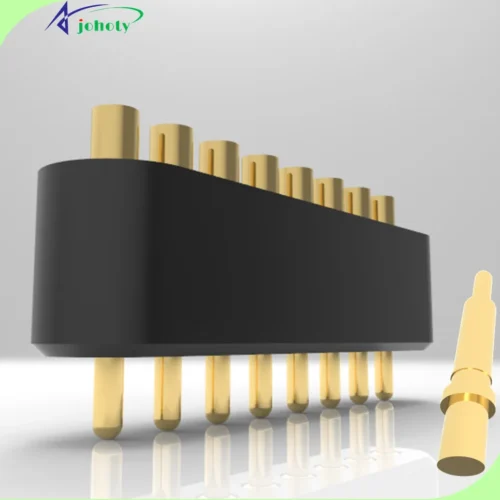

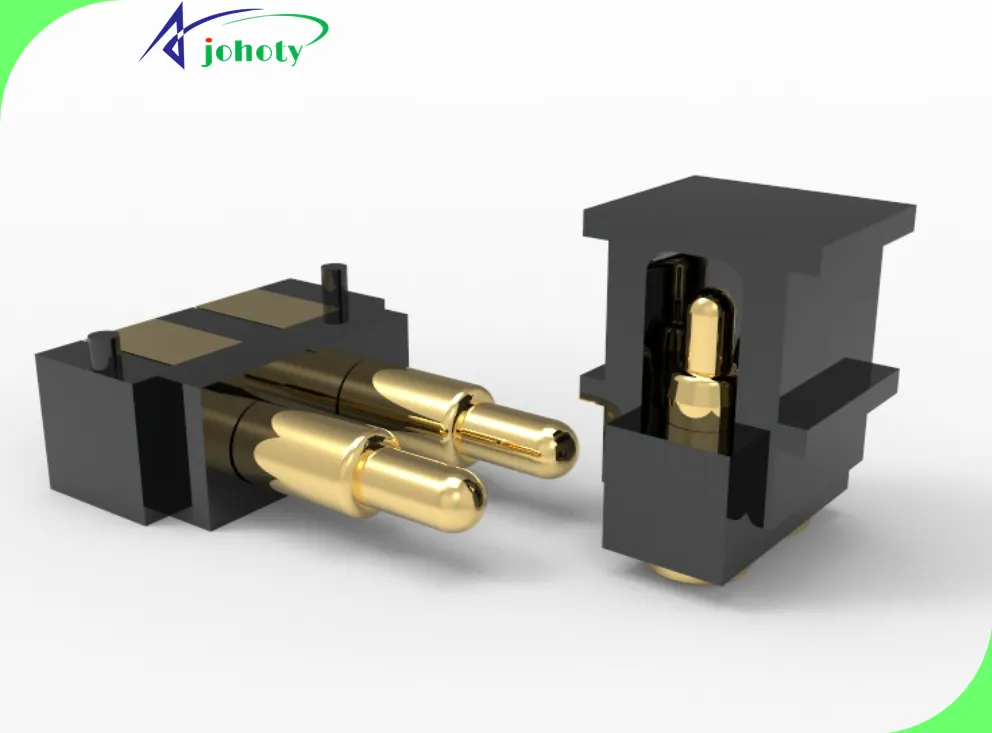

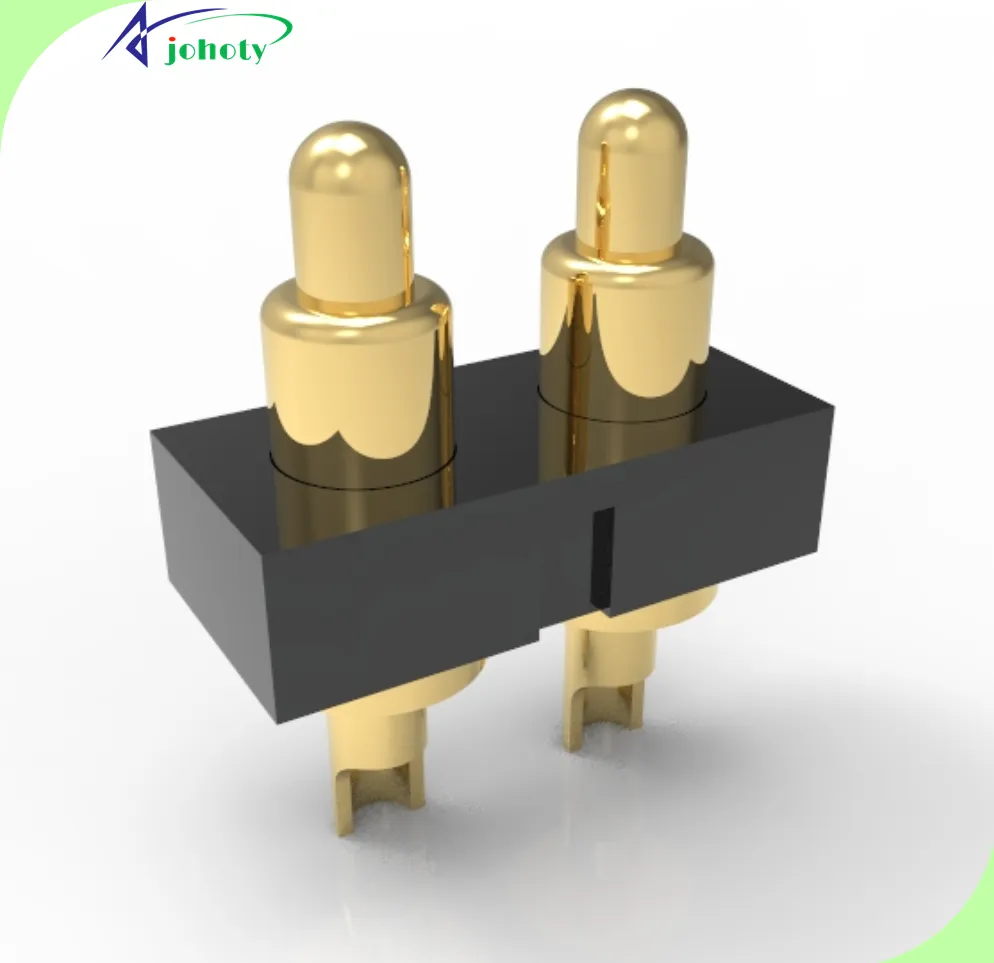

| Installation: | Surface mount: Automated production line, SMT. |

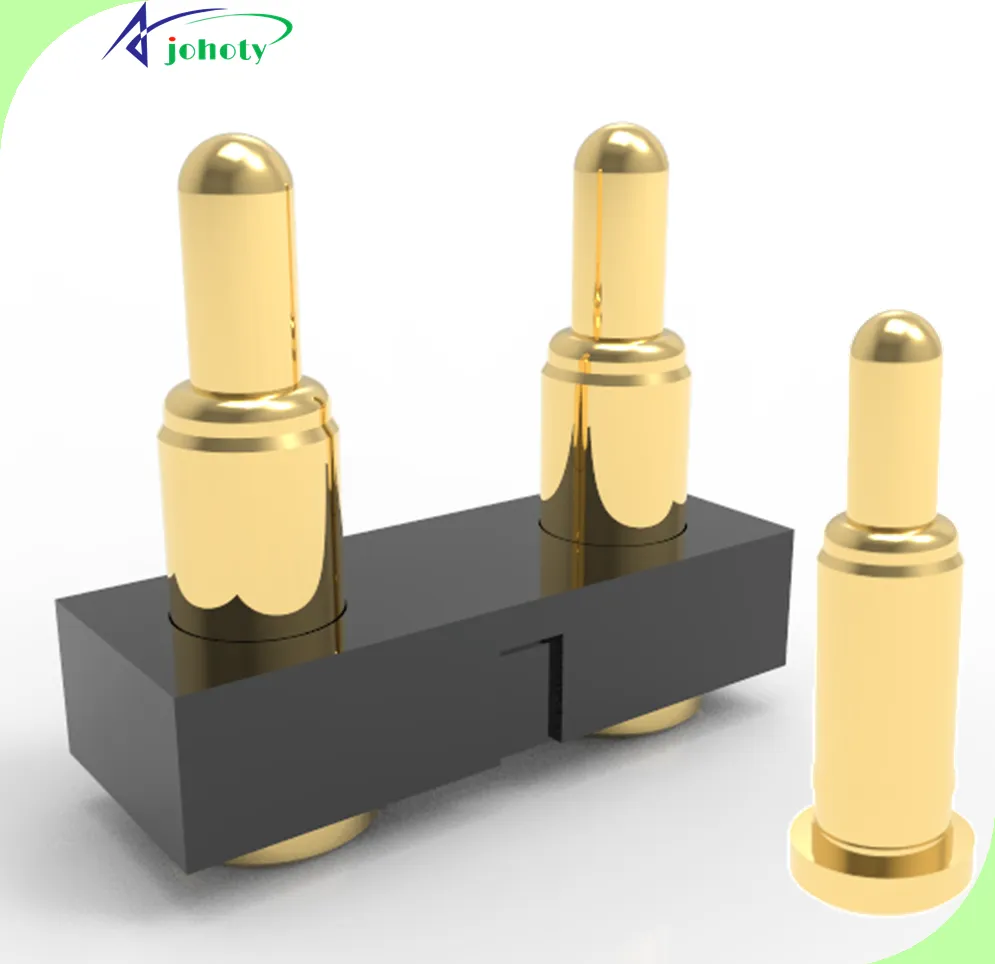

| Through-hole installation: High current, resistant to mechanica stress. | |

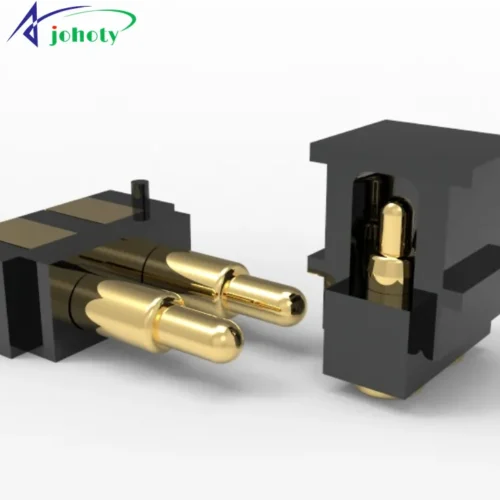

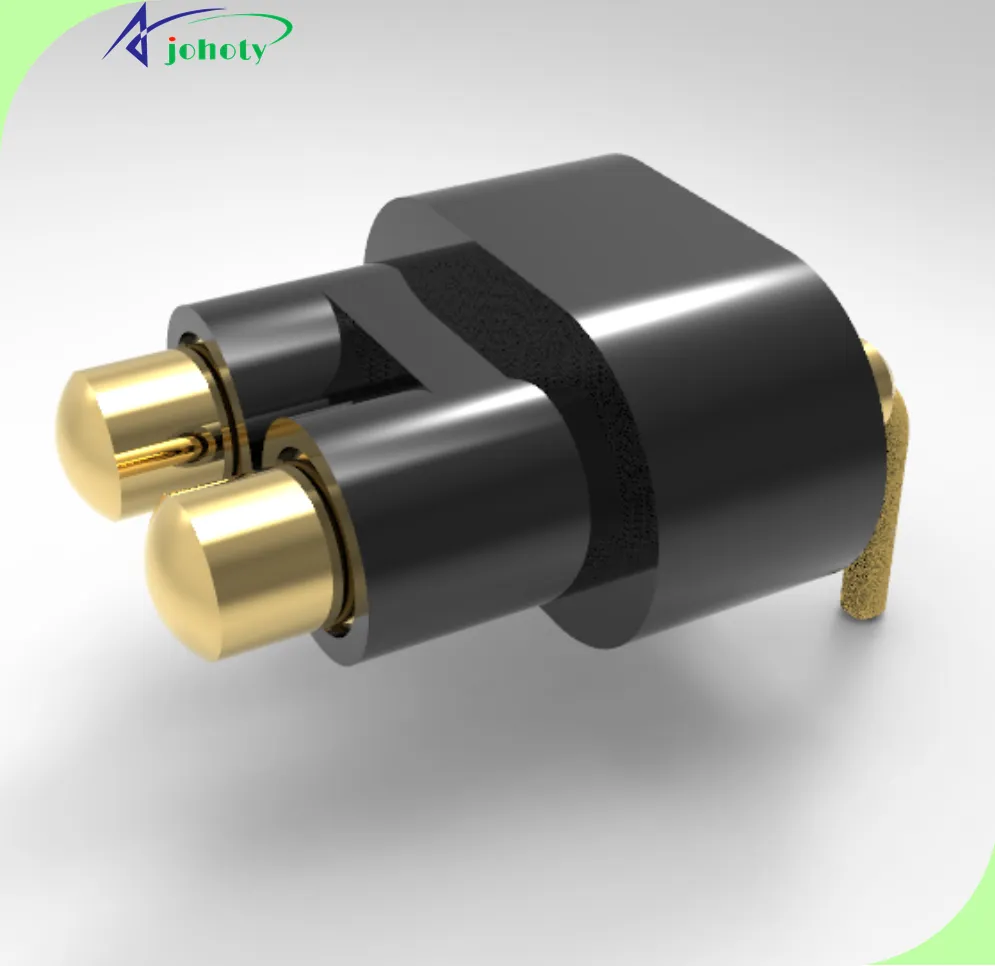

| Right Angle installation: Limited space or a dynamic connection. | |

| Soldering installation: High current. | |

| Spring installation: Anti-vibration, anti-impact, high-vibration. | |

| Embedded installation: High waterproof and sealing requirements. | |

| Quick installation/disassembly: Testing equipment. | |

| Locking installation: Additional mechanical fixation force. | |

| Slot installation: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 2 Pin Connector?

2 pin connector has wide pitch and male & female for power and signals, flexible custom, Johoty is trustworthy!

2 Pin Connector Benefits:

Simplify Design and Installation

Efficient Transmission and Stability

High Cost-effectiveness

Wide Applicability

2 Pin Connector Applications:

Portable Medical Devices

Intelligent Handheld Tools

Outdoor Lighting Equipment

Consumer Electronic Devices

Solar Panel Connection

Aerospace Equipment

Drone Power System

Wearable Devices

2 Pin Connector Advantages:

Compact Design, Saving Space

Male and Female End Design, More Flexible Connection

Quick Connection, Easy to Replace

High Security, Anti Misconnection Function

FAQ

2 pin connectors are waterproof and dustproof through specific designs and sealing materials that are IP-rated. This usually involves the use of O-rings, sealing gaskets, and special housing designs. This is to prevent water and dust from entering the pogo pin connector’s interior.

For guaranteed reliability in severe conditions, the 2 pin connector is constructed with premium-grade materials. They are corrosion-resistant, waterproof, dustproof, high-temperature-resistant, and UV-resistant. Specific measures include the use of IP67 or IP68 waterproof designs, chemical-resistant metal plating, high-performance plastic, and rubber materials.

- The subsequent criteria ought to be taken into account when choosing the suitable 2 pin connector:

- Electrical requirements: rated current, rated voltage, and signal type.

- Environmental conditions: temperature range, need for water and dust resistance, chemical exposure, etc.

- Mechanical requirements: plugging and unplugging frequency, vibration, and shock resistance.

- Certification requirements: UL, CE, RoHS, REACH, etc.

Common materials include beryllium copper, tellurium copper, phosphorous copper, stainless steel, copper alloys (brass), or aluminum. Plastics (e.g. polycarbonate, nylon), rubber, or thermoplastic elastomers. Surface treatments may include gold, silver, tin,platinum, palladium, and rhodium ruthenium plating. This is intended to augment conductivity and improve resistance against corrosion.