12 Pin Connector Description:

12 Pin Connector Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact resistance: 15 mΩ ~ 200 mΩ, Custom. |

| Rated current: 1.0 A to 60 A, Custom. | |

| Rated voltage: 12 V to 230 V, Custom. | |

| Insulation impedance: ≥100 MΩ, Custom. | |

| EMI: Support. Custom. | |

| Transfer speed: Up to 5Gbps | |

| Working frequency: From MHz to GHz, Custom. | |

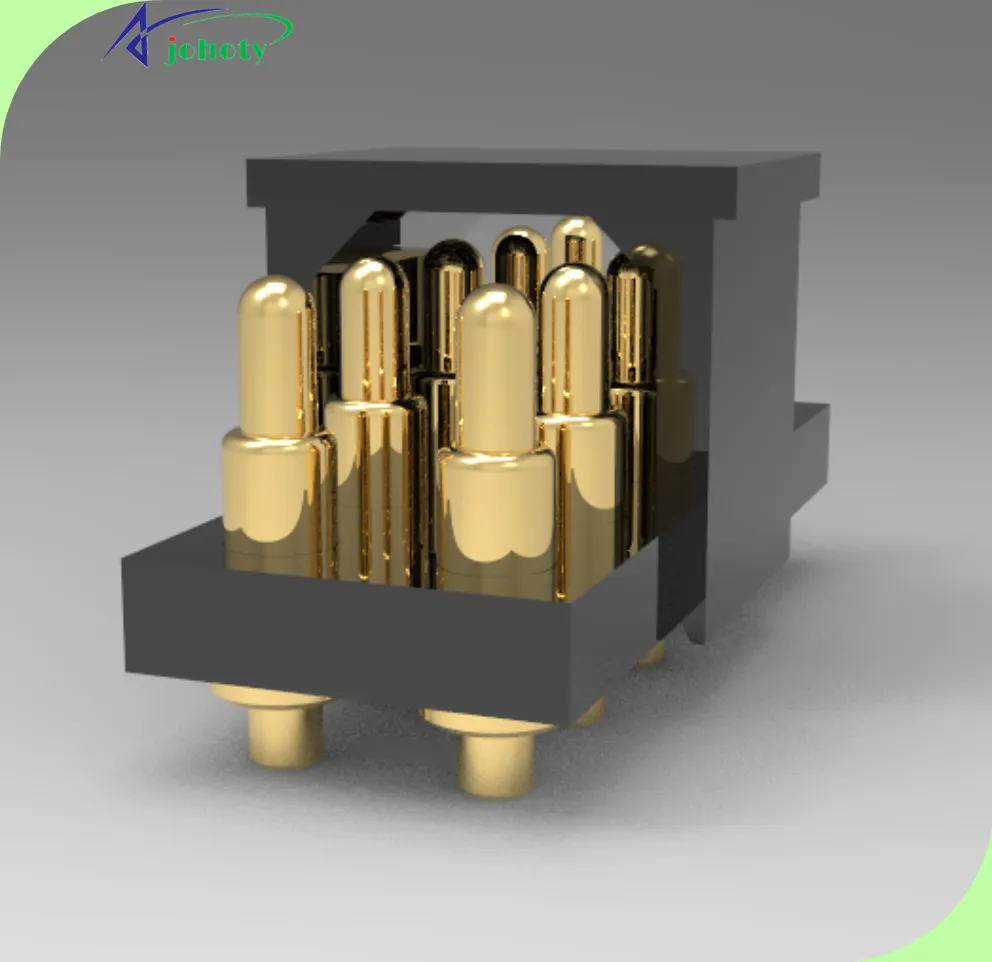

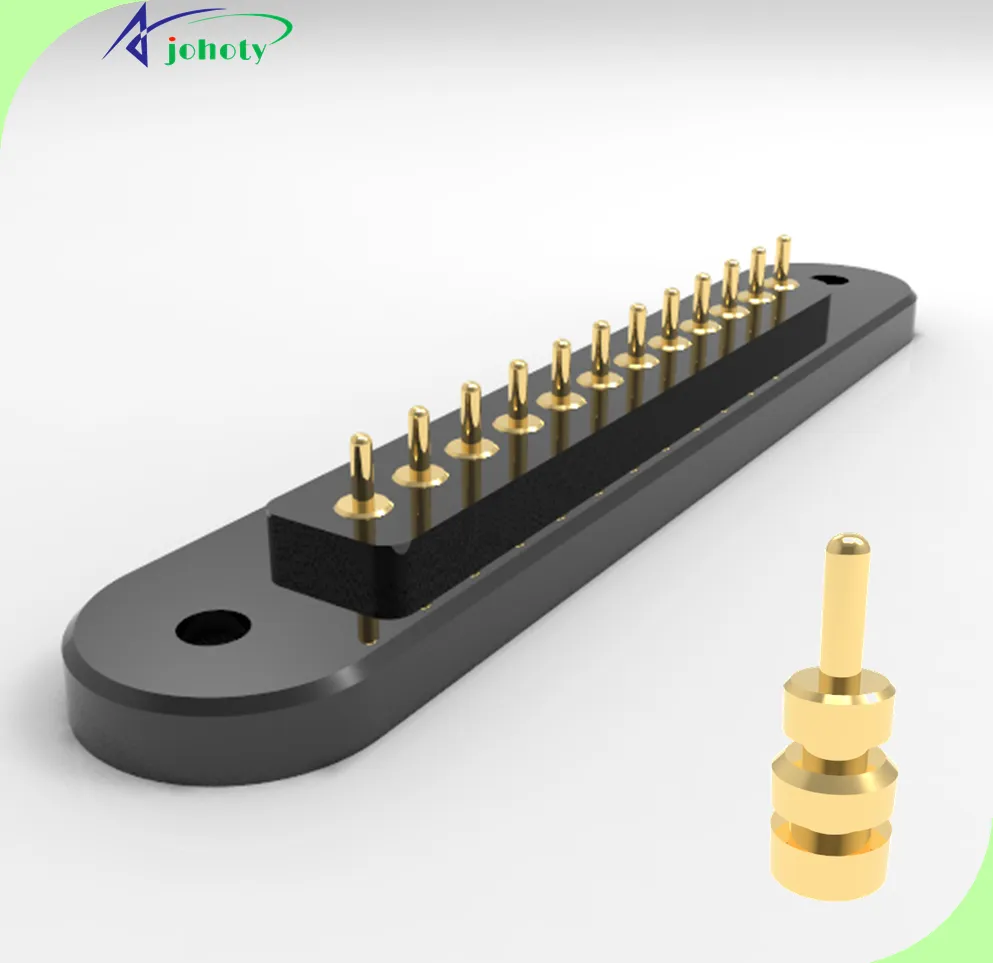

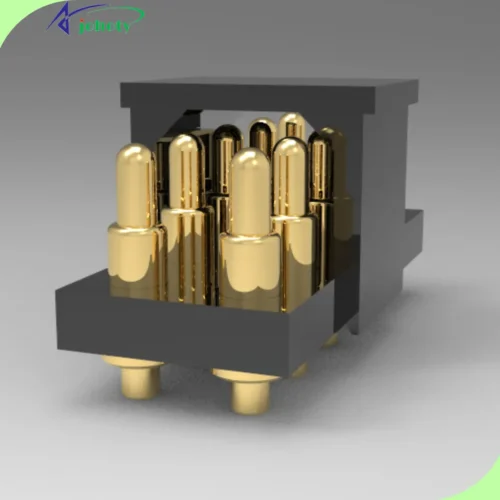

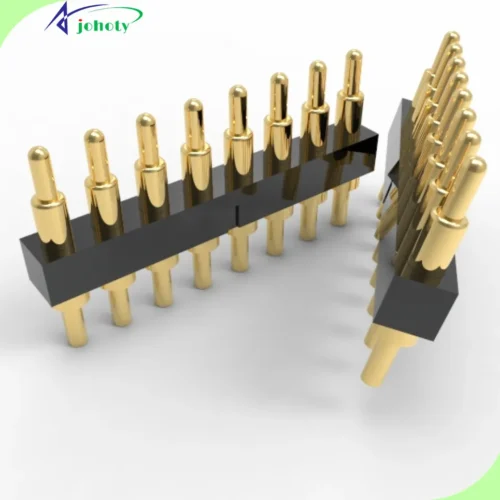

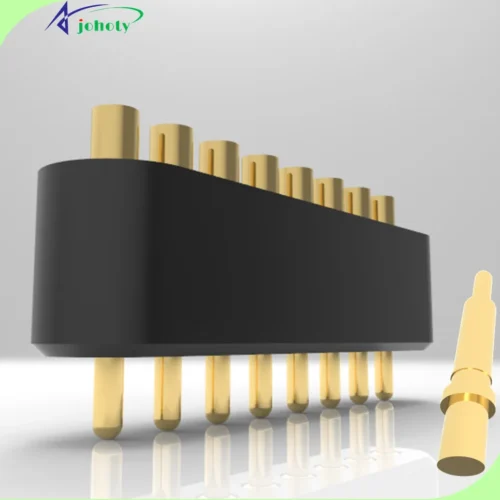

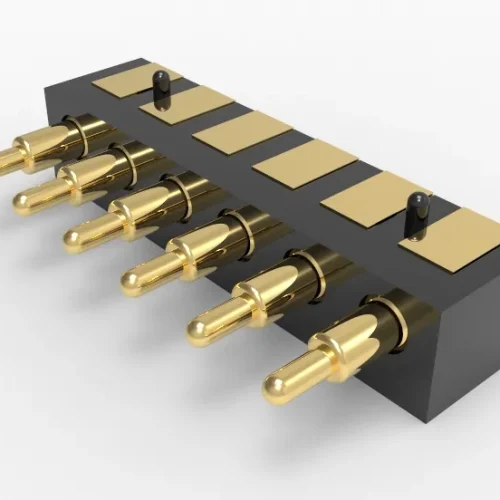

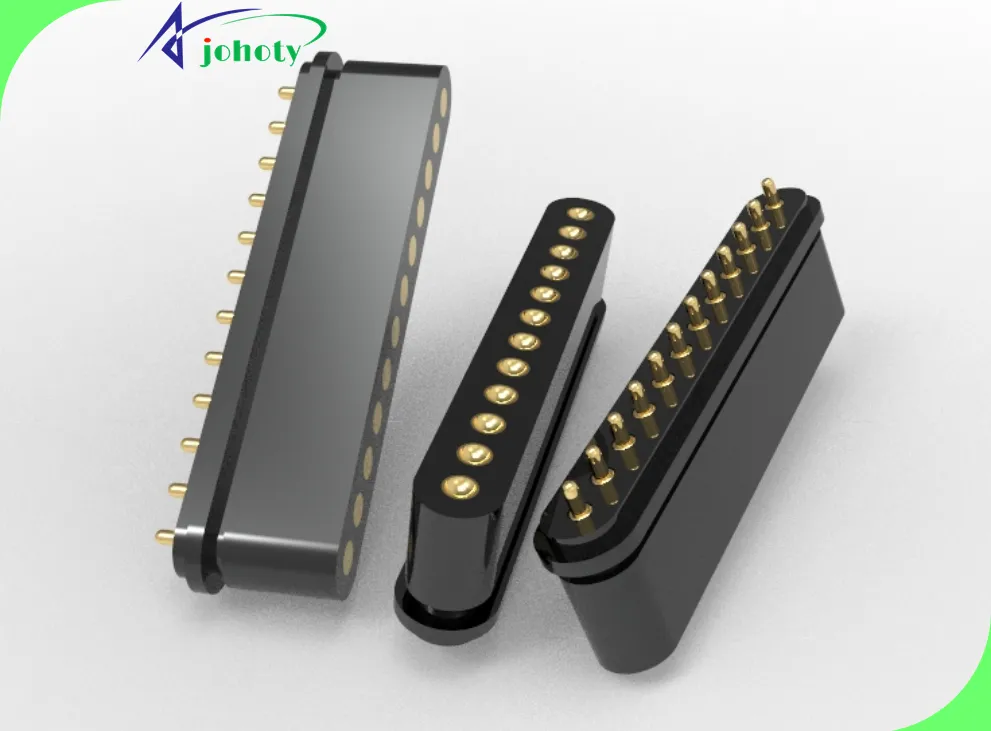

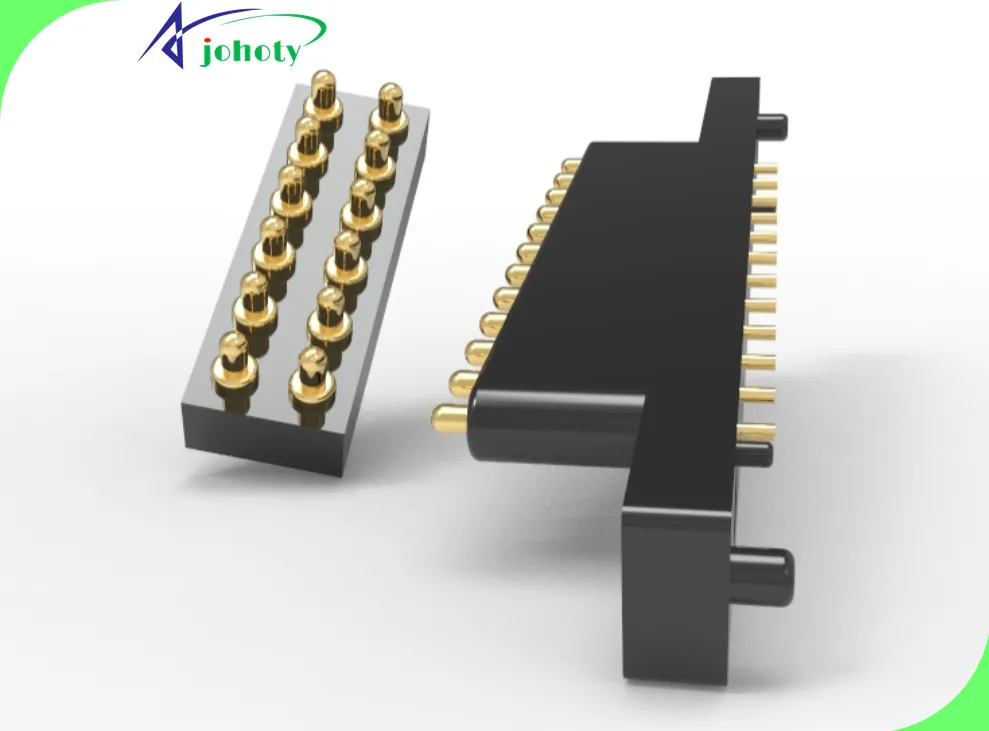

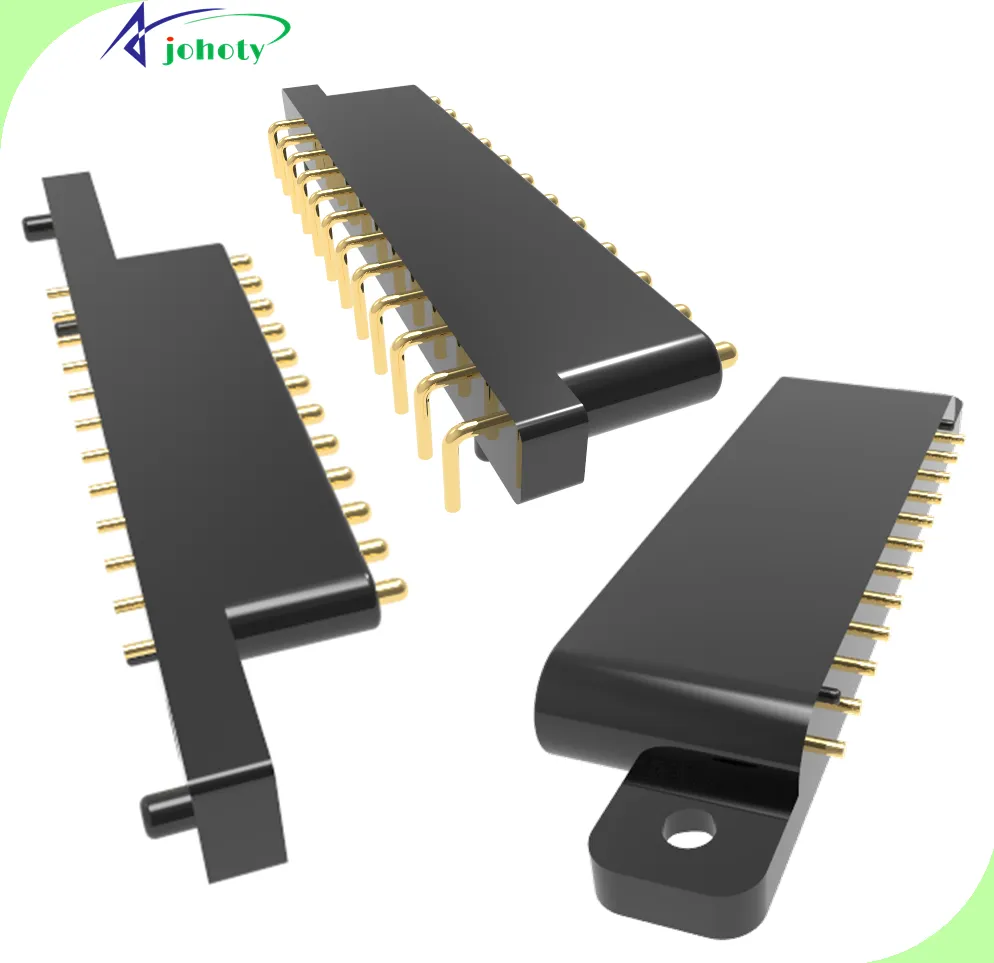

| Mechanical: | Shapes: 12-pins, single/dual rows, Rectangle, Round, SMT, DIP, Solder-cup, Right-Angle, Bending- type, Custom. |

| Spring force: ≥40gf, Custom. | |

| Pitch: 1.50mm~3.50mm, Custom. | |

| Stroke: ≥0.40mm, Custom. | |

| Length: ≥3.60mm, Custom. | |

| Barrer diameter: ≥1.20mm, Custom. | |

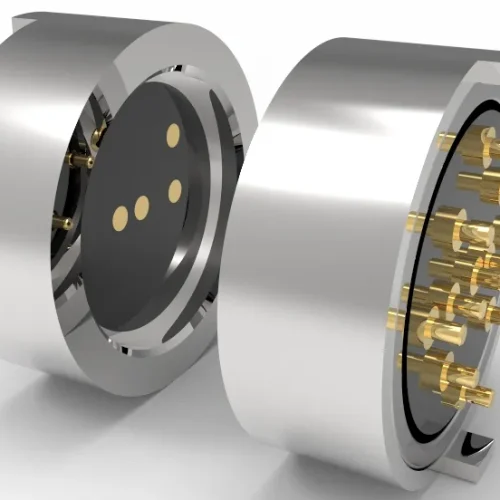

| Waterproof: IP65, IP66, IP67, IP68, female preferred, Custom. | |

| Impact resistance: 10G to 50G, Custom. | |

| Vibration resistance: 10G to 50G, Custom. | |

| Life cycles: >10,000 times, Custom. | |

| Hardness: 20 HRC to 60 HRC, Custom. | |

| Working temperature: -40°C ~ +85°C (some: -55°C ~ +125°C). | |

| Storage temperature: -40°C ~ +100°C (some: -55°C ~ +150°C). | |

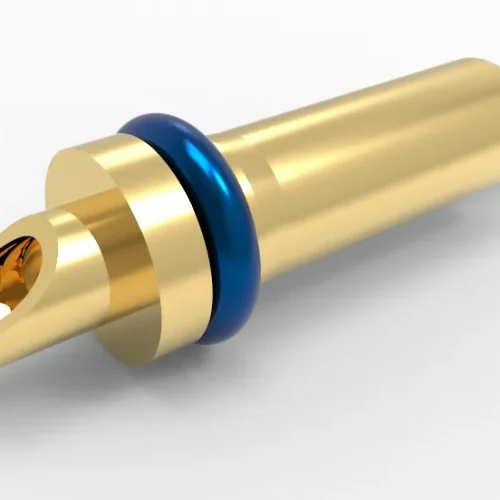

| Materials: | Plunger/Barrer: Brass, copper alloys (beryllium copper, tellurium copper), stainless steel, etc. |

| Housing Plastics (nylon, PA66, PTE, PPS, PBT), stainless steel, aluminum alloy, etc. | |

| Spring: Gold-plated, music steel, stainless steel, etc. | |

| Ball: Steel, zirconium, ceramic, Custom. | |

| Sealing: Silicone, rubber (fluoro rubber, EPDM), polyurethane, etc. | |

| Coating: >1.5u”, Gold, silver, nickel, composite plating, Pd, Pt, Ru, Rh, passivation treatment, etc. | |

| Soldering: Tin, lead-free solder, silver solder, etc. | |

| Insulation material: PI, PTFE, PBT, Nylon, Polyurethane, silicone, rubber, etc. | |

| Eco-friendly: RoHS, REACH, ASTM B488, ASTM B733, etc. | |

| Flammability rating: UL94 V-0, etc. | |

| Installation: | Surface mount: SMT, vertical, automated production line. |

| Through-hole: Stable, high current, mechanical stress resistance. | |

| Right Angle: Bent tail pin, surface mounting, limited space or a dynamic connection. | |

| Soldering: High current. | |

| Spring: Anti-vibration, anti-impact, high-vibration. | |

| Embedded: High waterproof and sealing requirements. | |

| Quick: Testing equipment. | |

| Locking: Screws, nut, additional mechanical fixation force. | |

| Slot: High requirements for connection stability. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

Why Choose Johoty’s 12 Pin Connector?

Johoty’s 12 Pin Connector has IP67,IP68, EMI, safe delivery, flexible custom at the best prices. Johoty is trustworthy!

12 Pin Connector Benefits:

Efficient Current Transmission

Reliable Signal Transfer

Durability and Long Lifespan

Multi Functionality and Flexibility

12 Pin Connector Applications:

Laser Range Finder

Microscope System

High-end Audio Equipment

Aerospace Communication Equipment

Medical Imaging Equipment

Precision Measuring Instruments

High precision Sensor System

Quantum Computer

12 Pin Connector Advantages:

High-density Design

Precise Contact Force

High-temperature Resistance

High Durability

Waterproof and Dustproof

Strong Compatibility

FAQ

Johoty accept T/T bank transfers, PayPal, WeChat transfer, cash. Regardless of the payment method, we must ensure the safety of the customer’s funds and carefully verify the business invoice (PI or CI), bank account, and signature confirmation with the customer.

Johoty’s prices vary depending on your purchase quantity and requirements. it is from $0.10 to $100.00, or higher. you can enjoy more favorable prices based on bulk purchases.

Yes, Johoty can offer sliding scale discounts, with discount rates ranging from 1% to 5% depending on your order volume. Sure, Johoty’s CFT team always pushes to get the best price and the biggest discounts for your’s long-term business.

While ensuring high quality, our 12 pin connector is more advantageous at price compared to similar competitors. We can offer detailed comparisons based on its specifications and performance.