Wire to Board Connector Solutions Using Pogo Pins Offer 10 Engineering-driven Benefits for Reliability, Space, Modularity, Discover Them Now!

Introduction:

Wire to board connector is one of the core interfaces that every electronic engineer cannot avoid in system design. However, are there better solutions for wire to board connector when facing space constraints, lifespan, high-frequency connections, vibration environments? Traditional solution of wire to board connector often has high insertion force, unstable contact, and high assembly difficulty.

Is there a way to achieve high customization while improving connection reliability and maintainability? Pogo pin technology in wire to board connector is becoming an emerging trend in high-end manufacturing and precision equipment. Data shows that connectors using pogo pins can achieve 5-10 times longer insertion lifespan than traditional connectors. At the same time, it far exceeds conventional structures in terms of spatial adaptability and module flexibility.

Johoty is delving into top 10 professional advantages of wire to board connector based on pogo pins based on engineers. Covering key structural design, electrical performance, reliability, maintenance efficiency, and automation compatibility. Are you looking for a more advanced, reliable, and flexible connectivity solution? Please continue reading to fully understand how pogo pins can completely reshape the engineering imagination of wire to board connector.

Pogo pin in wire to board connector achieves true zero insertion force, unleashing automation potential:

In high-speed automated assembly scenarios, traditional wire to board connector generally relies on plug and play coordination. The insertion force can reach 30-70N, often causing fatigue and fragility of the connector components. It also significantly increases the difficulty of robotic arm positioning and mounting errors, greatly limiting automation efficiency. And Johoty’s wire to board connector based on pogo pins achieves true zero insertion force. The contact force is controlled between 0.2-0.6N, and spring structure adapts to tolerance changes. Effectively reduce mechanical wear by over 90% and extend connection life by more than 10,000 cycles.

This structural innovation is highly suitable for non vertical plug-in connection solutions of slide rail, magnetic suction, and horizontal docking. Perfectly compatible with typical automation processes such as pick and place and modular assembly lines. After replacing with the Johoty pogo pin wire to board connector, Israeli equipment manufacturers have increased their mounting efficiency by 27%. Client’s repair rate has decreased by over 60%, equipment maintenance cycle has been reduced from quarterly to annual.

Johoty’s pogo pin adopts a beryllium copper core and gold plating structure, with a contact resistance as low as 30mΩ. It supports stable transmission of currents ≥3A, fully meeting the needs of highly reliable industrial equipment, power tools, and medical modules. For engineers who prioritize reliability, automation efficiency, and long-term cost optimization, it is very helpful and valuable. The wire to board connector based on Johoty pogo pins is reshaping the connector design paradigm.

Solving Micro-space Challenge: Layout Freedom of Pogo Pin in Ultra Compact Wire to Board Connector.

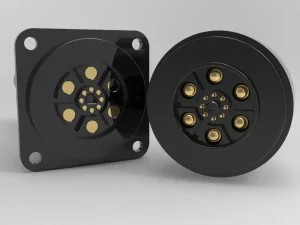

In high-density and miniaturized electronic design, traditional wire to board connector faces dual challenges of dimensional rigidity and directional limitations. In smart wearables, medical detection, and microsensors, conventional pin connectors are difficult to meet structural flexibility and space requirements. Johoty’s wire to board connector based on pogo pins has zero insertion force and customizable orientation, giving clients unprecedented layout freedom.

Pogo pin structure supports 360° placement in any direction and can achieve a minimum pitch of 1.00mm. The space occupied by a single pogo pin is only 1/3 of that of traditional connectors It can achieve highly reliable connections in a packaging space of less than 10mm³. Johoty’s German medical equipment client has applied our pogo pin wire to board connector to fingertip blood oxygen modules. Overall size has been reduced by 21%, and the module can be slid and replaced, greatly simplifying user maintenance experience.

Johoty pogo pins can easily match complex multi-layer PCBs, high-low misalignment, and multi-mode stacking. It breaks the wiring restrictions of traditional connectors that must be plugged in, truly unleashing design imagination. Combination of flexibility and compactness is a key breakthrough for realizing next generation of wearable devices and intelligent edge modules.

Johoty is well aware of engineer’s need to meticulously calculate every cubic millimeter. This is precise value of Johoty’s wire to board connector reshaping spatial logic through pogo pin technology. If looking for connection breakthrough for highly integrated devices, you may want to start redefining your connection method with Johoty.

Wire to board connector uses pogo pins to achieve dynamic connections and adapt to multi axis moving structures:

System design of multi axis moving parts includes nozzle modules for 3D printers, slide rail systems for CNC equipment, and rotating structures for electric tools. Traditional wire to board connector is prone to poor contact, interrupted conductivity. And even mechanical damage during dynamic connections due to rigid insertion and removal limitations. Johoty’s pogo pin based wire to board connector has high elasticity, self adjustment, and multi-point contact. It provides engineers with an ideal solution for maintaining electrical stability during continuous motion.

Johoty pogo pin has a dynamic displacement tolerance of up to ± 1.2mm and a constant contact force of 3-5N. In complex Z-axis reciprocating motion and X-Y offset vibration, it can maintain a stable contact resistance of <50mΩ. Our Swiss automation client has adopted Johoty pogo pin wire to board connector in their laser module. Equipment lifespan has been increased by 3 times, interruption rate of electrical signals has been reduced to 0.02% during dynamic processes.

More importantly, wire to board connector doesn’t require an additional locking structure. It can achieve dynamic connection through sliding, simplifying machine’s overall structural complexity. Significantly reduces pulling stress of moving parts on the wiring harness. Suitable for automation equipment with high-frequency start-stop and multi-axis linkage.

Johoty pogo pin breaks the design bottleneck of static connections. Transforming wire to board connector from assembly components to dynamic cores. This is exactly connection technology that modern motion control systems need. Johoty told you who are seeking an optimal solution for mechanical and electrical coordination. This is both a connection optimization and a design concept innovation.

Highly fatigue resistant: The Pogo pin in the Wire to Board connector has a contact life of over 100,000 times

The fatigue life of connectors in industrial automation, military equipment, and medical systems is often a key indicator that determines the maintenance cycle and stability of the system. Traditional wire to board connectors are prone to elastic fatigue, surface wear, and even metal migration after multiple uses. The typical lifespan is between 3,000 and 5,000 cycles, which severely limits the availability of equipment under high-frequency maintenance or periodic connections. Johoty’s pogo pin based wire to board connector has a mechanical lifespan of over 1000 cycles. After special design, it can achieve a lifespan of 200,000 times or even higher.

The Johoty pogo pin is made of high hardness gold-plated beryllium copper brass, paired with a spiral spring structure. Stable contact resistance of<40m Ω can be maintained under a contact force of 50gf. After fatigue testing verification, it can withstand at least 10,000-300,000 complete compression cycles without significant performance degradation. Compared to traditional pin type wire to board connectors, its lifespan is increased by up to 20 times.

Suitable for regular module replacement, frequent start stop testing, mobile terminal connection, etc. The military portable radar adopts the Johoty pogo pin wire to board connector. The connector replacement cycle has been extended from every 6 months to 3 years, significantly reducing operational risks and maintenance costs.

Johoty understands that the customer’s definition of reliability is not just one successful connection, but thousands of stable connections. Therefore, we have injected true industrial grade toughness into wire to board connectors through 23 rigorous tests. If you are designing a product that cannot fail, this connectivity technology cannot be ignored.

Pogo Pins of wire to board connector supports blind insertion, simplifying assembly process:

Traditional wire to board connector requires precise alignment between plug and socket, and even slight deviations can cause pin damage or signal failure. The problem is very prominent in automated assembly and space constrained applications. Johoty’s pogo pin structure introduces a self aligning design, which automatically compensates for the deviation of insertion force through an elastic plunger tip. Realize automatic correction of content differences within a range of ± 0.5mm, and increase assembly fault tolerance by up to 73%. On site engineers don’t need complex alignment fixtures or rely on skilled technicians. This can significantly reduce labor costs and assembly time.

Johoty conducted detailed research on 3 large equipment manufacturers in Europe. After adopting pogo pin wire to board connector, assembly efficiency increased by 32% and failure rate decreased by 41%. In complex multi-layer assembly, there is no need for directional restrictions on insertion, making system design more flexible. Reduce the footprint of circuit boards and provide space for the miniaturization of industrial equipment.

In addition, Johoty’s pogo pin has undergone 50,000 plug and unplug life tests. It can maintain a contact resistance fluctuation of <30 mΩ, ensuring stable long-term signal transmission. It’s crucial under high frequency and vibration, highly favored by medical, automation, new energy engineers in Europe and America.

Breaking through welding limitations: pogo pins enable truly replaceable wire to board connector.

European and American customers often demand Johoty’s modular design. Our pogo pin wire to board connector, which requires no soldering, is becoming a key component in solving the challenges of on-site maintenance and flexible integration. Traditional wire to board connector require permanent connection through soldering. This limits the replaceability of components, increases maintenance difficulty, and system downtime.

Johoty adopts a high-precision spring needle structure to achieve true plug and unplug electrical connections. Compared to traditional welding connections, pogo pins support zero tool replacement of parts, reducing assembly and disassembly time by up to 85%. Provides high flexibility for remote devices, modular robots, and replaceable sensors.

Our Italian customer’s original system replacement of the main control module requires 4 hours of hot disassembly, welding, and testing. After customers switched to Johoty pogo pin wire to board connector, the single replacement time was reduced to less than 30 minutes. Maintenance efficiency increased by 8 times, saving over $100,000 in annual downtime costs.

The pogo pin in the wire to board connector has superior anti vibration and anti impact capabilities:

Johoty’s wire to board connectors have excellent vibration and impact resistance in high dynamic engineering vehicles, aviation electronics, and wearable devices. Traditional welded or rigid structural connectors often experience unstable signals due to micro vibrations or impacts. The pogo pin automatically compensates for micro displacement through its spring-loaded flexible structure, achieving reliable contact. According to third-party accelerated fatigue testing, the Johoty pogo pin maintained a contact resistance fluctuation of<5 mΩ after 10,000 vibration cycles and 50G impact load conditions. Far superior to standard metal pin connectors with fluctuations up to 15 mΩ.

In wearable devices that frequently encounter displacement interference, Johoty’s pogo pin can continuously and stably connect within a ± 0.2mm axial floating range. This can greatly enhance the dynamic adaptability of wire to board connectors. Under simulated bumpy driving and airdrop impact, the signal interruption frequency of traditional connectors is more than three times that of pogo pins.

Choosing Johoty’s pogo pin wire to board connector provides higher anti-interference performance. It is a precise guarantee for system reliability and engineering stability. Engineers have high requirements for connection reliability, and vibration resistance is the most important performance.

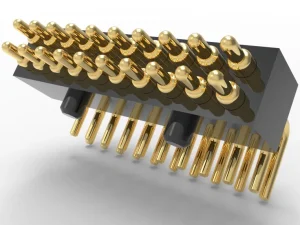

Pogo pin provides multi-point contact and optimizes electrical redundancy design in wire to board connector:

The wire to board connector based on pogo pins greatly improves the stability and fault tolerance of electrical connections through a multi-point redundant contact structure. Traditional single point metal PINs are prone to oxidation, contamination, or micro displacement, which may cause signal loss or power interruption. Johoty’s pogo pin can achieve 2-6 pin parallel contact, even if a single pin is damaged, the remaining pins can still maintain a low impedance path. This can significantly improve the MTBF of the system.

At a working current of 1A, the contact resistance of the Johoty pogo pin remains stable at<20m Ω, which is lower than the average value of 35-50m Ω for traditional single PIN connectors Under redundant configuration, the volatility is reduced by over 60%. High power integrity and signal integrity are often required in servers, industrial control boards, and medical equipment wire to board connector. Johoty’s pogo pin Redundant design provides structural support to prevent single point failure and enhance system reliability.

Johoty’s multi-point contact design optimizes electrical redundancy structure, enhances connection stability and fault tolerance. Becoming an irreplaceable wire to board connector solution in modern high-performance modular design. This design concept that starts from system level reliability hits the pain point that engineers are most concerned about.

Wire to board connector supports customized pogo pin length and stroke, perfectly matching irregular structure.

In complex electronic design, traditional wire to board connectors are often limited by their fixed size. It is difficult to adapt to connection requirements of irregular plates or non-standard shells. And Johoty’s wire to board connector based on pogo pins completely breaks this technological bottleneck. One of our biggest advantages is that we support customized pogo pin length and stroke, including all mechanical and electronic parameters. It can achieve a stroke of 0.10mm to 10mm and a maximum length variation of 150mm. Perfectly matching multi-layer stacking, high-low misalignment, and even inclined structures, unleashing great freedom in product design.

Compared to traditional rigid PIN connectors, Johoty’s pogo pin uses adjustable springs. Under positional deviation of ± 0.1mm, contact success rate can maintain at >95%, significantly improving connection fault tolerance in irregular structures. Combined with Johoty’s 5-axis CNC, pitch accuracy control can reach ± 0.02mm, and precise matching can be achieved under complex shapes. Suitable for high customization requirements in industrial automation, medical equipment, and wearable electronics.

Engineers generally focus on structural adaptation and connection reliability, and Johoty provides structural 3D fitting analysis and dynamic travel simulation. Every wire to board connector selection is supported by data and reliable solutions. Johoty is not only your flexible supplier, but also your engineering partner in structural design challenges.

Pogo pin structure is lightweight and can easily integrate EMI shielding solutions, optimizing electromagnetic compatibility of wire to board connector:

EMC is a key focus of high reliability electronic system design. Johoty’s wire to board connector based on pogo pins is lightweight and highly integrated. It provides breakthrough solutions for medical, aviation, military, and other industries with high EMC requirements. The core advantage is the easy integration of EMI shielding design. Suppress radio frequency radiation and conducted interference through a 360° metal shielding cover or an independently grounded pogo pin.

The radiation emission value of Johoty shielded wire to board connector at 1GHz can be reduced by up to 38dB μV/m compared to traditional unshielded connectors. The EMI control effect is better than 80% of similar products on the market. In multi-channel high-speed signals or high-voltage pulses, it can ensure signal integrity and system stability. Johoty’s pogo pin structure can quickly discharge stray currents through a dual path of shielding and ground spring pins.

The elasticity and miniaturization of pogo pins enable the placement of complete shielding structures in limited spaces. Avoid EMI exposure issues of traditional connectors in space limited environments. Johoty provides customers with EMC simulation modeling and prototype validation to ensure that wire to board connectors pass CE/FCC at the system level.

Conclusions:

Many engineers pursue designs that are high-density, compact, and highly reliable. The wire to board connector based on pogo pins is rapidly becoming the preferred choice for engineers in Europe and America. The top 10 key dimensions shown above can comprehensively lead traditional solutions.

Johoty deeply understands the strict standards that engineers have for wire to board connector. We provide data support and engineering delivery for material selection, stroke design, contact reliability, and shielding integration. Johoty is not selling connectors, but helping you solve design problems and improve overall system performance.

If you are looking for a wire to board connector that can truly solve the complex structure and high-performance connection needs, please feel free to contact Johoty. We use expertise, flexibility, practical experience to make every connection more reliable and intelligent.