Waterproof Magnetic Connector Meets IP67 Standard, Delivers 99.9% Conductivity, Ensures Reliable Operation in Extreme Industrial Environments

Introduction: Importance of Waterproof Magnetic Connector in Industrial Applications

As a key connecting component of modern industrial equipment, the waterproof magnetic connector is responsible for the core duties of electrical signal and power transmission. With the rapid popularization of Industry 4.0, intelligent manufacturing, and outdoor equipment, the protective performance of connectors has been unprecedentedly improved and valued. Connectors not only need to meet high-precision electrical performance, but also need to ensure stable operation of the system in harsh environments such as dust, moisture, salt spray, and high and low temperatures.

The dust and waterproof standards defined by the IP67 rating provide a strict reference for connector design, which can withstand short-term immersion and completely prevent dust from entering. APC0504-31853 and APC0504-31854 are 4-pin waterproof magnetic connectors designed for this standard. Intended to provide secure and reliable connectivity solutions for high-end industrial automation, medical equipment, outdoor intelligent terminals, and other fields.

According to the IEC 60529 standard, the IP67 rating test includes soaking in water at a depth of 1 meter for 30 minutes without water entering the interior. Ensure that the performance of the connector does not degrade in extremely humid environments.

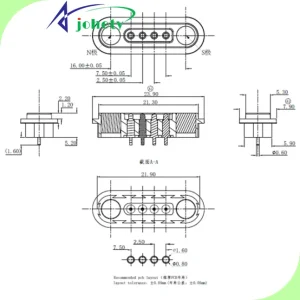

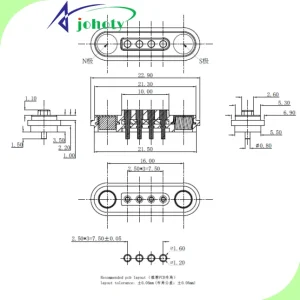

Parameters of 4-pin IP67 Waterproof Magnetic Connectors APC0504-31853 and APC0504-31854.

These two waterproof magnetic connectors adopt a 4-pin design, optimized for transmitting control signals and low-power power. The core technical parameters are as follows:

Electrical performance: Its rated voltage is 12V, rated current is 3A, and it can transmit various industrial signals and power. The contact resistance of both male and female terminals is less than 50mΩ, ensuring stable signal transmission and low energy consumption.

Protection design: Based on the design concept of IP68, it can comprehensively achieve stable protection of IP67. APC0504-31854 features a multi-layer sealing ring design and injection molding. Using high-performance silicone material to effectively block the infiltration of dust and moisture.

Magnetic connection principle: Equipped with high-performance neodymium magnet N52, the magnetic distribution of the S and Z poles effectively prevents errors. The magnetic attraction is strong and uniform, with a maximum pulling force of up to 400gf. The connection between the male and female ends APC0504-31853 and APC0504-31854 is stable and quickly positioned. The elasticity of APC0504-31853 is 80gf ± 20Gf when working stroke 1.00mm.

Material selection: Pogo pins are made of brass alloy plated with nickel, balancing conductivity and corrosion resistance. The housing is made of high-strength and high-temperature resistant nylon, suitable for working environments ranging from -40℃ to +85℃. And it complies with RoHs, REACH, ASTM

Mechanical lifespan: The design lifespan exceeds 10000 insertion and extraction cycles, with almost no wear and tear, and can operate stably for a long time. Johoty can increase its lifespan to 200,000 cycles through effective optimization.

Size and weight: APC0504-31853 has a size of 23.90×7.90×5.20mm and a pitch of 2.50mm. This waterproof magnetic connector is compact and lightweight. It’s easy to integrate in small spaces without affecting the mechanical structure design.

Key Performance Testing of Waterproof Magnetic Connector

IP67 waterproof test: During the standard test of 30 minutes underwater at 1 meter, no moisture entered the interior of the connector, and the electrical performance was stable without any abnormalities.

Temperature cycling test: The connector undergoes 50 cycles from -40℃ to+85℃ without significant changes in electrical parameters. Therefore, we determine that it can adapt to different climatic environments.

Salt spray corrosion test: After 96 hours of continuous salt spray environment testing, there are no corrosion marks on the surface and inside of the connector. The waterproof magnetic connector can adapt well to the demanding requirements of marine and coastal industrial applications.

Plug and unplug life test: After more than 5,000 plug and unplug cycles, the contact resistance only slightly increases by <0.5mΩ, and the magnetic attraction force remains above 95%. It has excellent mechanical and electrical stability. Can you confirm what the customer often says, that even if the equipment is broken, APC0504-31853 and APC0504-31854 can still be used.

Practical application feedback: APC0504-31853 and APC0504-31854 are commonly used in industrial automation control systems, outdoor intelligent monitoring equipment, and medical devices. The customer reported that equipment overall stability has improved by about 20%, and maintenance cycle has been extended.

Performance Influence of Design and Manufacturing Process of Waterproof Magnetic Connector

The performance advantages of the APC0504 series waterproof magnetic connector are inseparable from precise design and manufacturing process support:

High precision machining: CNC machining technology can ensure that the dimensional tolerance of the contact parts is ≤ 0.05mm, greatly reducing the risk of poor contact.

Surface treatment: The nickel plating thickness of the contacts reaches 5 microns or more, enhancing corrosion resistance and conductivity stability, and improving service life.

Magnetic circuit design: Optimize magnetic field distribution through finite element analysis (FEM), resulting in strong and uniform magnetic force. There will be no magnetic interference when connecting quickly.

Sealing structure: Multi-layer silicone sealing ring design, stable sealing performance. It can still maintain the IP67 protection level after mechanical fatigue testing.

Assembly automation: Introducing automated assembly lines and online electrical performance testing. The batch consistency and yield of this magnetic connector are very high.

Quality Management System: Compliant with ISO9001 standards, equipped with a comprehensive supply chain management and quality tracking system.

Reliability and Safety Analysis: Stability of Waterproof Magnetic Connector

Anti misplacement design: Two pairs of cylindrical magnets with S and Z poles effectively determine the direction of magnetic attraction connection. The concave contact surface of the male end rubber core and the convex contact surface of the female end. This dual anti misoperation measure and structure avoid incorrect insertion, improving installation efficiency and equipment safety.

Anti detachment mechanism: 400gf magnetic attraction combined with concave convex structure design, with no movement space in both forward and lateral directions. Ensure that the connection between the male and female ends does not loosen under severe vibration and impact environments.

Electrical safety certification: We have taken into account the risk of short circuits and arcs when designing. In terms of UL and electrical safety standards, APC0504-31853 and APC0504-31854 are both of very high quality.

Low failure rate: Long term monitoring data on site shows a failure rate of less than 0.01%. Without accidental damage to pogo pins or magnets on male and female ends, there is almost no wear and tear. They can downtime risks, reduce maintenance costs significantly.

Easy maintenance: Modular design of APC0504-31853 and APC0504-31854, as well as optimized design of tail pin into SMT and solder cups. Very convenient for your on-site quick replacement and maintenance, reducing downtime.

How to evaluate and select high-performance waterproof magnetic connectors?

APC0504-31853 and 31854 series provide complete technical documentation and test reports to meet the strict technical review requirements of procurement experts. When selecting a waterproof magnetic connector, procurement decision-makers need to pay attention to the following key indicators:

Technical parameter verification: Verify IP protection level certification, magnetic attraction, rated current and voltage, and life test reports.

Third party certification: Priority should be given to water-based magnetic connectors equipped with independent laboratory testing and certification to ensure verifiable performance.

Production Qualification: Evaluate the supplier’s quality management system, with priority given to Johoty that complies with ISO9001 and ISO14001.

Supply chain stability: Pay attention to supply cycle, batch consistency, and professionalism of CFT team for the waterproof magnetic connector.

Compliance and Environmental Protection: Ensure that the waterproof magnetic connector complies with RoHS and REACH, suitable for your procurement compliance.

Conclusion: The irreplaceable value of waterproof magnetic connectors in high-reliability industrial applications

4-pin IP67 waterproof magnetic connector APC0504-31853 and APC0504-31854, with high standard design, rigorous testing validation, and advanced manufacturing processes. They maintain electrical connection stability and safety in complex and harsh environments. Many engineers are favort their excellent waterproof and dustproof, and mechanical reliability. Provided a solid connection foundation for industrial automation, intelligent devices, and medical fields.

Looking towards the future, Johoty’s continuous technological innovation and strict quality management will drive continuous advancement of waterproof magnetic connector. Assisting in the digital transformation of industry and the development of intelligent manufacturing has become an indispensable key component for high-end equipment.