6 Pin Magnetic Connector, Engineered For Stability, Speed, N52, Pitch 2.2mm, 50mΩ, Reliable Power And Data Transfer. Request Sample Pairs Now.

Introduction: Why do engineers love the 6 pin Magnetic Connector in engineering?

6 pin magnetic connector has become a core technological consideration in the rapidly developing era of information and electrification, the modularity, pluggable, reliability, and anti-interference of electronic systems. The magnetic connector has features that engineers love, such as automatic alignment, foolproof plugging, and low contact impedance. It is receiving attention and gradually applying to high-demand medical devices, wearable devices, industrial automation, unmanned systems, power tools.

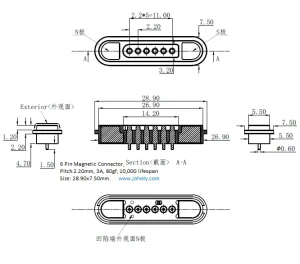

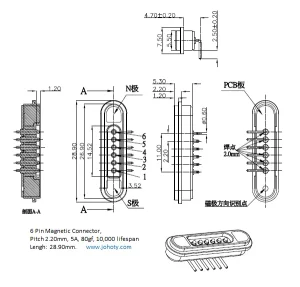

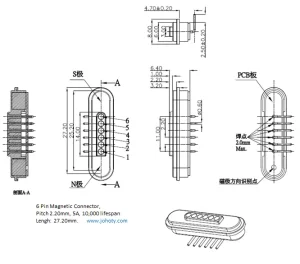

This article focuses on Johoty’s 6 pin magnetic connector APC0506-49949 and APC0506-49950. Carrying current up to 3A, contact resistance as low as 50mΩ, supporting synchronous transmission of power and data signals. The article will systematically analyze its engineering value from six dimensions. Including physical structure, electrical performance, materials science, reliability analysis, typical applications, and engineering interface design.

Structural design: Layout and magnetic coupling of 6 pin magnetic connector

Pin configuration logic: 2-pin power supply (V+/GND), 4-pin data (TX+/TX -/RX+/RX – or I2C/SPI signals), supporting bidirectional high-speed communication.

Magnetic structure analysis: The 6 pin magnetic connector adopts embedded neodymium iron boron (NdFeB, N52) strong magnetic material and cylindrical alignment structure. Providing automatic adsorption and self-positioning, it can effectively solve insertion and removal errors and poor connections.

Contact surface shape: APC0506-49949 and APC0506-49950 have male pogo pins and female contact pins. They are both at least 5uin gold-plated contacts, using copper alloy pins and metal ring structures. Improve the durability and contact stability of automatic docking.

Electrical characteristics: 3A carrying capacity and 50mΩ low impedance of 6 pin magnetic connector

Current carrying analysis: 3A continuous current design, Johoty considers the temperature rise caused by contact resistance (P=I^2R). We can effectively control the temperature rise below 30℃ at room temperature. At the same time, copper alloy pogo pins and 5 μm gold coating are used to ensure thermal conductivity and structural heat dissipation rationality. Based on the customer’s needs, these pogo pins can upgrade the continuous current to 5A.

Contact resistance testing and modeling: Accurately measure 50mΩ contact resistance using 4-wire method. The influencing factors include spring force, contact area, surface treatment process (gold/nickel plating), environmental oxidation, etc.

EMI/ESD characteristic evaluation: Multi pin design helps to achieve differential signal transmission and improve anti-interference ability. Ground PIN configuration can also assist in improving ESD capability (±8kV air discharge, ±6kV contact discharge).

Materials and Processes: From Gold Plating to Spring Force Curve Design

Contact material selection: High conductivity copper alloy HBi59 + 0.125μm thick gold coating (up to 5μm). Can maintain low contact resistance ≤50mΩ and corrosion resistance after 10,000 contact cycles.

Spring force calculation: Finite element analysis (FEA) is used to design the deformation curve of the spring needle. Ensure that the pressing force is controlled within the range of 80gf ± 20gf at a working stroke of 1.00mm. It has a full stroke of 1.10mm, which ensures contact and avoids damage to the PCB.

Environmental resistance test: Passed high and low temperature cycles of -25℃~+80℃, salt spray test for 24 hours, and wet heat aging (80℃/85%RH). Industrial-grade reliability is a favorite among many engineers.

Standards and Compatibility: Differences and Similarities between 6 pin magnetic connector and USB, PoGo, Magsafe.

Compared with USB connectors, USB places more emphasis on universality and protocol control. This magnetic connector emphasizes modularity, quick disassembly, high reliability, and mechanical protection.

Similarities and differences with Magsafe connectors: Although structurally similar, Magsafe is primarily designed for low-power charging. magnetic connector is more widely adopted in signal and power applications.

Complementary to industrial pogo pin connector: Magnetic connector can be seen as an upgraded form of adding magnetic positioning and module foolproofing on pogo pins. It is suitable for embedded systems with limited space and difficult visual guidance.

Application Analysis: Implementation in Medical, Automation, and Unmanned Equipment

Medical wearable devices: ECG recorders, continuous blood glucose monitors, require high reliability, low contact resistance, and anti-misconnection. 6 pin magnetic connector has gradually replaced Micro USB.

Industrial robot end tool replacement: The robot arm module quick change system uses a magnetic connector to achieve blind insertion and anti-vibration. Improving production efficiency and equipment lifespan.

Unmanned equipment/AGV charging station: In the automatic docking system, the magnetic structure is suitable for precise positioning in non-human environments. It has certain resistance to sediment and water vapor.

Reliability engineering perspective: FMEA of 6 pin magnetic connector MTBF, life analysis

Common failure mechanisms: spring fatigue, oxide layer formation, contact point displacement, magnetic attraction attenuation, etc. Both accelerated aging testing and physical modeling are for prediction.

Life modeling and simulation: Use Matlab/ANSYS for structural thermal electrical linkage simulation. Predictable plug-in life curve and thermal stability boundary of 6 pin magnetic connector.

MTBF (Mean Time Between Failures): Industrial grade magnetic connector can achieve >10,000 contact. If used in a good environment, it can achieve 50,000 connections. It can easily achieve a MTBF of >100,000 hours. Johoty knows that the key lies in the design of elastic fatigue and contact stability.

Engineering design suggestions and interface integration strategies for 6 pin magnetic connector

PCB board design suggestion: add positioning holes, maintain flatness, and control the gold plating thickness above 15μin. Designing the key signal lines as differential line pairs, paying attention to impedance matching.

Suggestion for shell fit and male-female docking tolerance: adopt a foolproof guiding design with a buffer structure. In this way, the pin alignment tolerance of APC0506-49949 and APC0506-49950 during magnetic adsorption is <±0.30mm.

Collaborative design with power/communication modules: It is recommended to use peripheral circuits of USB adapter chips and SPI/I2C isolation modules. This can reduce false triggering and signal loss.

Future development trend: High frequency, high voltage, and intelligent recognition of 6 pin magnetic connector

High frequency and high-speed signals: To adapt to high-speed differential signal transmission such as PCIe/HDMI, optimize the pogo pin shape, install shielding shells, and impedance control.

High voltage module: The demand for 24V~48V systems in medical and industrial equipment is increasing, and restructuring the high-voltage structure and insulation system.

Intelligent recognition function: EEPROM or 1-Wire protocol chips can achieve automatic recognition and parameter loading of module insertion, promoting the intelligence of Johoty’s magnetic connector.

Conclusion: The endpoint of connectors is the starting point of platform based collaborative capabilities

6 pin magnetic connector goes far beyond just connecting based on its value. It is more reflected in the improvement of engineering collaboration processes, modular design concepts, and system robustness. Facing the highly modular, intelligent, and unmanned system architecture of the future, it will evolve from components to interface platforms. A 6 pin magnetic connector can effectively build the underlying infrastructure for future engineering systems. If you need 6 pin magnetic connector of APC0506-49949/APC0506-49950, please contact Johoty now!