Magnetic Cable 4-Pin Delivers 2A Fast Charging & Stable Data Sync for Car/Dash Cam. Reliable, Efficient, Ready To Power Your Devices. Buy Now!

Introduction: Magnetic Cable 4-Pin Structure

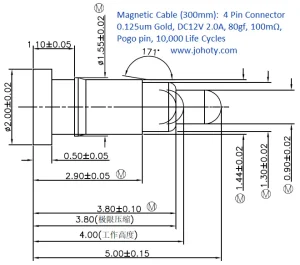

The core of Magnetic Cable APC0504-49915 and APC0504-49916 lies in their magnetic adsorption interface structure. This design is based on the modular contact point principle and is divided into four pins: VCC, GND, Data+, and Data -. The separation and independence of power and data channels can effectively reduce signal interference.

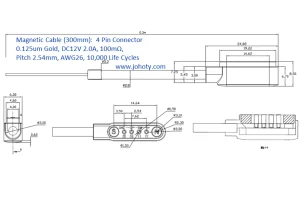

Pin configuration and layout: VCC/GND: 2A rated load, 5uin gold plating can improve conductivity and oxidation resistance. Data+/Data -: It is a USB 2.0 standard design that Johoty can update to achieve USB 3.1, 3.2, 4.0. The magnetic cable adopts a symmetrical wiring structure. It achieves high-speed differential signal transmission and is compatible with mainstream transmission protocols.

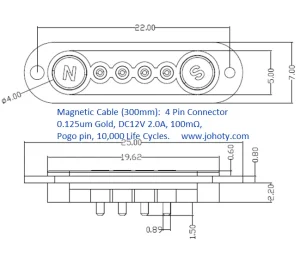

Magnetic adsorption structure; Using N52 neodymium iron boron magnets, the Curie temperature is about 310℃~340℃ high and the magnetic stability is maintained. The positive and negative poles maintain strong magnetism and are not easily demagnetized when used in high-temperature environments of stable magnetic performance in automobiles. Cooperate with directional card slot design to avoid misalignment insertion and have self-correction function. The contact surface adopts circular floating spring contacts to reduce mechanical wear and enhance earthquake resistance.

Modular anti misoperation design: Bipolar magnets, S and Z magnetic interfaces support 360 ° rotation but only magnetic contact in one direction. Magnetic Cable APC0504-49915 and APC0504-49916 have mandatory anti reverse plug design, suitable for mobile/fixed devices.

Balancing Current and Stability: 2A Fast Charging of Magnetic Cable

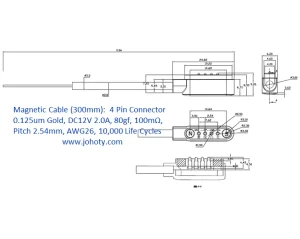

2A current carrying capacity is not simply a numerical parameter. It is a systematic engineering trade-off based on wire diameter (AWG1-30), copper conductor cross-sectional area, core resistance, and heat dissipation performance. To avoid heat concentration, the two power lines in the 4-pin interface independently carry positive and negative currents. Reducing pressure drop while minimizing single point heat accumulation at connection ports.

Internal conductor structure: The wire core adopts multiple strands of oxygen free copper thin wires. Diameter 0.0159mm2 × 144 stranded structure, low resistance, bending resistance. The measured average resistance is less than 0.0424Ω when the line length is 1 meter Meet the requirement of controlling the voltage drop within 0.3V throughout the 2A charging process and maintaining a voltage range of 5V±0.3V.

Overload and temperature rise test: Continuous 2A charging test at an ambient temperature of 25℃, with a temperature rise of <8℃ within 1 hour. Extreme test with uninterrupted charging for 4 hours, with a peak surface temperature of <48℃, without any protective circuit breakers or performance degradation. High temperature nylon-66 is used, with a heat resistance of 100-120℃. In terms of structural layout, air conduction channels are arranged around the magnetic attraction plate. Prevent plastic fatigue or metal oxidation caused by overheating.

Joint stability: After >10,000 cycles of magnetic attraction, there is no virtual connection or increased contact resistance in the connector, maintaining stable power output.

Stable synchronization: data transmission and protocol compatibility of magnetic cable

The magnetic connection is often criticized for its stability in data transmission. Johoty’s magnetic cable 4-pin solves this problem through pogo pin design and material processing.

Differential signal path optimization: Data+/Data – uses equal length and equal resistance path wiring to reduce signal delay mismatch. Adopting a low-noise plastic coating to reduce EMI.

USB 2.0 compatibility testing; The measured data transmission rate of 480 Mbps is stable and meets the standard. Compatibility with embedded development boards: Raspberry Pi, Arduino, STM32, etc. The average speed of a large file transfer test on multiple platforms (Windows/macOS/Linux) is 42-44 MB/s, with no packet loss.

Anti-interference capability: Connector shielding layer is connected to GND to form a complete circuit shielding In high car engine compartments. The measured packet loss rate is less than 0.1%.

Engineering level durability: Materials, design, and reliability of Magnetic Cable

The industrial design standards for magnetic cable refer to MIL-STD-202 and IEC 60512 standards. It emphasizes connection reliability, wear resistance, and multi-environmental adaptability.

Exterior material: TPE/nylon woven double-layer sheath. High and low temperature resistance (-20℃ to 80℃), bending resistance (over 10,000 times), and corrosion resistance (no abnormalities found after 72 hours of salt spray testing). Internal shielding layer: aluminum foil + woven double-layer shielding structure, effectively isolating external interference signals.

Mechanical performance: Under a bending radius of 5cm, it has undergone 10,000 cycles of bending, and its function is intact. The lifespan of the magnetic connection is over 10,000 times, and the magnetic attraction force is controlled within 8N to ensure the stability of user operation.

Optimization of joint structure: High-strength engineering housing integrated die-casting molding, anti-slip texture design enhances the sense of operation. Elastic silver alloy material is used at the contact point to improve elastic recovery force and contact stability.

Practical cases in the fields of automotive, power systems, and industrial control

Power connection between dash cam and DVR:

Many onboard recording devices require long-term operation, and stable power supply is key. Requires a continuous and stable power supply of 5V and 1.5-2A current. The equipment often has hidden wiring, which isn’t convenient for frequent connection. The installation space is narrow and requires quick docking.

Use the magnetic interface of Magnetic Cable to achieve blind insertion connection. In case of collision or disassembly, there is no need to forcefully unplug, reducing socket wear and tear. Automatic alignment and anti-reverse connection, suitable for multi vehicle environments. Reduce labor costs, improve installation stability, and facilitate later maintenance.

Car camera power supply and data synchronization:

The surround view system and reversing camera need to synchronously transmit image data and power supply. Video signals are sensitive to power interference. Frequent vibration makes ordinary joints prone to loosening.

In the 4-pin structure, there are two wires for power supply, which fit a serial port or low-speed data communication (such as UART). Adopting magnetic connection to alleviate stress concentration. The video signal is more stable and there are no frame loss issues with power supply. Maintain reliable physical connections in mechanical bumpy environments.

Intelligent distribution terminal data acquisition interface:

Some switch stations or smart meter boxes contain independent sensor modules. The control module requires a regular power supply and debugging, and fixed welding connections can’t work.

Replace traditional USB with magnetic connection, integrating power on and parameter transmission into one interface. The joint has water and dust resistance capabilities and meets outdoor usage standards. Greatly improve the debugging efficiency of on-site engineers, reduce the risk of plugging errors and arc pulling.

Temporary maintenance portable device power interface:

Power operation and maintenance personnel need to bring small testing equipment into the primary equipment area. Standard power interfaces are mostly open type and unsafe. Strong magnetic and lightning strike areas can easily damage standard plugs.

Equipped with instant disconnection function (detachment in case of pulling), it is very suitable for high electromagnetic field areas and has a compact structure. The UK high-performance electric sports car customer company uses magnetic cables for operation and testing equipment, with no contact faults for 3 years.

End power cable for industrial robots:

Placing the end effector of the robot frequently and plugging it incausing joint wear. The standard connector cable has a high breakage rate.

Use Johoty’s 4-pin magnetic cable to power the end module. The plug has no hard contact with the body and maintains connection by a magnetic field. Plug and unplug lifespan>10000 times, with a 70% decrease in wire breakage rate. Hot plug testing is available during robot operation.

PLC control box testing interface:

The PLC control box of the French customer’s automated production line requires external handheld device debugging. The USB and DC interfaces are not unified, and the number of interface insertions and removals is limited, resulting in a high incidence of damage caused by mis-operation.

Connect the touch terminal using a magnetic 4-pin interface. Can quickly locate the connector and avoid incorrect insertion direction. The automation company of the French client and his client have set the magnetic suction port as the standard debugging interface. Extend the lifespan of debugging tools and reduce the frequency of equipment maintenance.

Why do top engineers and R&D leaders choose Johoty?

In the development process of the magnetic cable 4-pin, Johoty was not market-oriented, but engineering problem-oriented.

Design logic driven by engineering requirements: Joint design originates from feedback from frontline engineers on the need for quick disconnection on site Joint development of material selection and supply chain, customized high elasticity alloys and fatigue resistant woven layers.

Empirical data supports selection: Over 16 European and American power companies and security equipment vendors have passed their stability tests. Collaborate with high-performance sports cars in the UK to conduct interface aging experiments and data integrity verification.

Expert feedback: “In our long-term vehicle data collection tasks, we almost couldn’t find a magnetic cable that could be so stable in environments with severe vibration and temperature differences. Johoty’s magnetic connection solution saved us nearly 40% of maintenance costs. ”- German VP R&D

If your company is deploying edge collection, industrial automation control, and in vehicle AI terminals. You are still struggling with the fragility and maintenance issues of traditional cable connections. We welcome further discussion with you on the practical application of Johoty’s magnetic cable in your system.