Waterproof Connectors Designed with Pogo Pins: Show You the Best IP67 5-pin Solutions Trusted by Engineers for Durability and Tight Sealing.

Introduction: Real Challenge of Waterproof Connectors, why do engineers urgently need reliable IP67 5-Pin Pogo Pin Connector?

Waterproof connectors are becoming a must-have in the design of industrial, medical, and outdoor wearable devices. But why are truly reliable water proof connectors so difficult to find? They are commonly used in high-frequency plugging, sweat erosion, rainwater erosion, and salt spray environments. However, conventional connectors are prone to poor contact, oversized dimensions, looseness, inappropriate shape, metal corrosion, and sealing failure.

Are engineers tired of repeatedly replacing faulty interfaces? Does the design of waterproof connectors really consider continuous stability in extreme environments? Is the IP67 protection standard sufficient to cope with real-life working conditions? Why is pogo pin + magnetic attraction + IP67 currently perfect solution that can balance repeated connection, corrosion resistance, fast docking, long lifespan?

Johoty will show you the optimal solution for this industry based on a 5-pin IP67 magnetic connector. We will provide engineers with practical selection criteria based on product drawings, specifications, dimensions, and application cases.

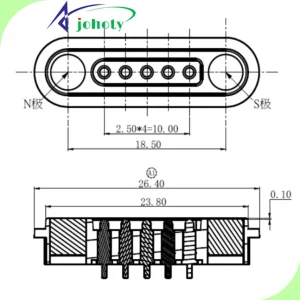

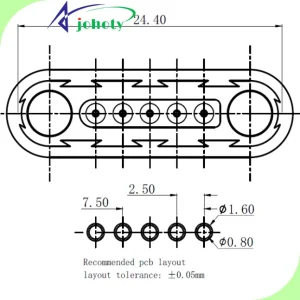

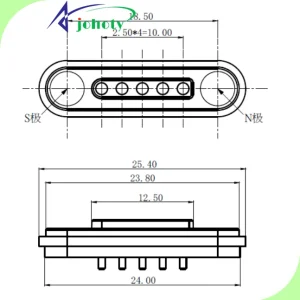

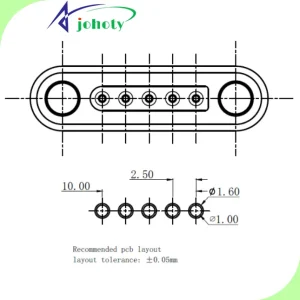

5 pin Waterproof Connector: APC0505-37691

Let’s show you a trusted 5 pin waterproof connector: APC0505-37691. It belongs to the category of waterproof connectors and has waterproof sealing and fast connection characteristics. Widely used in prototypes, automotive waterproof connectors, industrial equipment, and outdoor environments.

Spring plunger stroke design

Plunger material: high elasticity brass, surface gold-plated. Gold plating 5u” ensures low contact impedance and wear resistance.

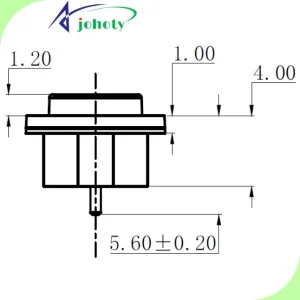

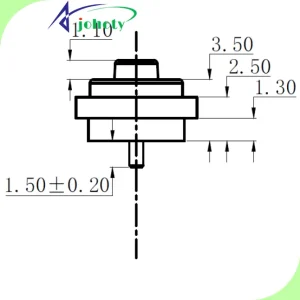

Stroke: The effective travel of the plunger is 1.00mm. Standard stroke is 0.30-2.00mm for pogo pins. Sure, Johoty can flexibly customize the working stroke if pogo pin length has no limit. It is easy to get good elasticity and contact pressure.

Contact impedance: ≤50mΩ, can greatly reduce signal loss and heat generation.

Life cycle: ≥10,000 insertions and removals, suitable for high-frequency usages.

Waterproof rubber ring (sealing ring)

Material selection: Silicone Rubber meets IP67 standard and has a temperature resistance range of -40°C to+125°C.

Sealing structure: Multi layer lip design, combined with the fit of the plug and socket housing. It can achieve 360° no dead angle waterproofing with IP67, even IP68 waterproof. Injection molding is commonly used for pogo pins and rubber cores with at least two chamfered tube bodies. This combination of technology and high-temperature waterproof adhesive can effectively achieve IP67 or IP68

Pressure resistance performance: withstand pressure in 1 meter underwater for >30 minutes without any water seepage.

Design of Magnetic Force

Magnet type: High performance neodymium iron boron (NdFeB) magnet, ensuring fast adsorption and stable locking. The strongest magnetic N52 material, cylindrical, track circular, etc. can flexibly match the shape of customer products.

Adsorption force test: The maximum adsorption force of a single connection point is ≥100gf, and the total adsorption force of the five plungers is ≥600gf. The connection is stable and has high shock resistance.

Anti-detachment mechanism: The combination of magnetic force and structural buckle prevents accidental disconnection. At the same time, S and Z pole magnets can achieve anti reverse insertion and effectively prevent errors.

Barrel design

Material: Aviation grade engineering plastic, compliant with RoHS and REACH, anodized, corrosion-resistant and wear-resistant.

Structural features: Multi-layer protection design, equipped with dust-proof mesh and buffer pad, enhancing mechanical strength and environmental adaptability.

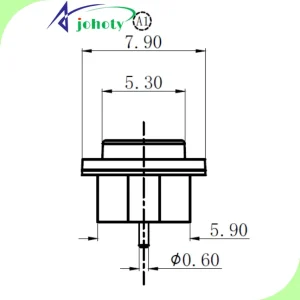

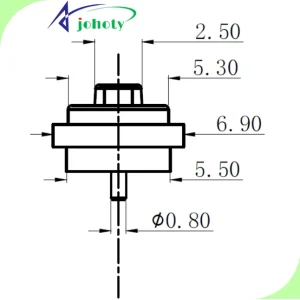

Size: Pitch 2.50mm, length 26.40mm, width 7.90mm, elasticity 80gf ± 20Gf. Meets the design requirements of compact waterproof circular connectors.

Installation method: through-hole installation, can also be flexibly customized for panel installation. Adapt to different engineering structural spaces.

Performance Test of Waterproof Connectors

Waterproof performance test:

APC0505-37691/APC0505-37692 adopts a sealed design and meets the IP67 protection level standard.

Test method: Immerse the 5-pin magnetic pogo pin connector sample APC0505-37692 into a 1-meter deep water tank for 30 minutes.

Test results: After soaking, there is no water infiltration inside the connector, and the contact points are dry. There is no significant decrease in insulation resistance (maintained at ≥1000MΩ).

Comparative analysis: Ordinary water proof circular connectors and water proof wire connectors often use O-rings and silicone seals. Magnetic pogo pin connector has high-precision mechanical fit and double sealing. Structurally reducing the risk of seal fatigue and improving long-term waterproof reliability.

Electrical performance testing:

Contact resistance: The initial contact resistance is below 50 m Ω, which meets industry standards.

Temperature cycling test: Under temperature cycling from -40℃ to 85℃, the contact resistance of the connector does not change by more than 5 mΩ, indicating strong electrical connection stability.

Current carrying capacity: The rated current of a single pin can reach 3A, and the total current carrying capacity of 5 pins can reach 15A. The male end can reach a stable 5A current. Satisfy the needs of medium to high power automotive electronics and are suitable for automotive water proof connectors applications.

Life test:

Insertion and extraction lifespan: 10,000 insertion and extraction cycles have been tested, and the insertion and extraction force remains stable. The average change in contact resistance is less than 10%, and there is no mechanical deformation or poor contact phenomenon.

Corrosion resistance: in salt spray test of ASTM B117, after 48 hours of spray test, connector surface is free of rust and the electrical performance is free of significant decline.

Structural differences and advantages:

This water proof connector adopts a magnetic pogo pin structure, which automatically aligns and contacts through magnetic force during connection. Avoiding the complex mechanical buckles and threads of traditional waterproof circular connectors, simplifying operations, and improving assembly efficiency.

The internal spring plunger design allows for small axial and radial offsets. Improve the mechanical tolerance of connections and reduce the risk of contact failure caused by vibration.

The dual waterproof sealing structure includes high-precision sealing rings and plastic part gap design. Prevent moisture infiltration and improve durability. Meet the waterproof, electrical, and mechanical lifespan requirements in harsh environments.

Applications of Johoty 5-pin Magnetic Waterproof Connectors

Medical wearable devices: ECG monitoring devices require APC0505-37691 to have high sealing and stability to ensure continuous and accurate data collection.

Outdoor GPS navigation device: In changing outdoor environments, APC0505-37692 needs to ensure waterproof and dustproof performance, and support all-weather operation.

Industrial handheld terminal: used for industrial field data acquisition, APC0505-37691/APC0505-37692 can withstand mechanical vibration and liquid immersion.

Structural differences and technical data support

Magnetic connection design: Utilizing magnetic force to achieve fast and error free insertion and removal, reducing mechanical wear and extending service life. Through laboratory plug and unplug testing, the connector can maintain a contact resistance of ≤ 5mΩ after more than 10,000 plug and unplug cycles.

Multi layer sealing structure: Combined with dual silicone sealing rings and gaskets, it achieves IP67 level protection. Waterproof depth up to 1 meter, time 30 minutes. The structural materials used are high-strength engineering plastics and copper alloy contacts, which are corrosion-resistant and have excellent electrical conductivity.

Standardized 5-pin single row: easy to be compatible with multiple electronic modules, with signal and power separated to reduce interference and ensure signal stability. Compared to ordinary waterproof wire connectors, Johoty connectors have a 30% longer salt spray resistance time and a 20% higher electrical performance retention rate in corrosion resistance testing.

Selected Engineer Evaluations:

German medical equipment company R&D engineer: We ultimately chose Johoty based on its magnetic connection design, which brings about efficient disassembly and high reliability. This is important and critical in precise application of medical equipment.

CTO of Swiss industrial grade GPS manufacturing plant: Outdoor GPS products face complex environments, and Johoty waterproof connectors have multiple layers of sealing and materials. Our equipment still works stably after soaking in rainwater multiple times.

Norwegian Industrial Handheld Terminal Procurement Manager: Compared to other brands of waterproof circular connectors, Johoty performs better in structural design and durability. Significantly reduced on-site maintenance frequency, with a very high cost-effectiveness.

Waterproof Connectors FAQ

How to ensure the stability of magnetic connection without affecting EMI?

Johoty 5-pin magnetic waterproof connector uses high-performance neodymium magnets to achieve reliable adhesion. There is mechanical stability during the connection process. EMI suppression performance of Johoty connectors meets the FCC Class B standard for EMI. Magnetic structure does not introduce significant additional electromagnetic noise, without impact on signal integrity.

Shielding layer structure: Connector housing is embedded with a metal shielding layer to form a closed shielding cover. It can effectively block external EMI.

Grounding design: Shielding layer is well grounded with the equipment casing and ground wire, further reducing electromagnetic radiation and conducted interference.

Signal line isolation: The distribution of power and signal lines in the 5-pin is reasonable, reducing the risk of mutual interference.

Is the waterproof rating tested before or after assembly?

The waterproof performance test of Johoty magnetic waterproof connectors is after assembly. The production process will conduct component level waterproof material testing and dimensional tolerance control at critical stages. Johoty can ensure the final assembly quality.

The integrity of the seal depends on the assembly state: the waterproof structure includes the fit between the sealing ring, sealant, and connector body. Only after the connection is completed can a continuous and effective protective layer be formed.

IP level standard testing basis: According to IEC 60529 standard, the connector is subjected to immersion testing as a whole after assembly. IP67, Water depth of 1 meter, 30 minutes, verify sealing performance.

Can magnetic waterproof connectors transmit both power and signals simultaneously?

In the Johoty 5-pin design, the internal pins of the connector support multifunctional signal and power transmission. When the signal line is fully loaded on the power line, the signal-to-noise ratio (SNR) remains above 60dB without significant signal distortion.

Multi pin division of labor is clear: some pins are specifically used for transmitting power, with a maximum support current of 5A. The remaining pins can transmit analog or digital signals to ensure signal stability.

Signal integrity design: Using differential signal design or shielding separation technology to reduce interference from power lines to signal lines.

Compatible with a variety of application requirements: meet the needs of medical equipment, automotive electronics, industrial automation, etc. for power and signal simultaneous interpreting.

How to ensure a secure connection by soldering the PCBA end?

Johoty ensures the soldering strength and electrical performance of waterproof connectors at the PCBA end. After 500 vibration tests and thermal cycling tests, the solder joints did not break and the resistance value remained stable at ≤ 10m Ω.

Choose appropriate pad design: The pad area should meet the mechanical strength requirements, and it is generally recommended that the pad size be greater than 2.5mm × 1.5mm to increase the solder adhesion area.

Adopting wave soldering or reflow soldering process: ensuring uniform distribution of solder, no virtual soldering or cold soldering phenomenon.

Strengthening mechanical structure: Positioning holes or support columns on the PCBA, combined with adhesive or mechanical buckles, to reduce the mechanical stress borne by solder joints.

Selection of solder paste and optimization of welding parameters; Select high-quality solder paste, adjust the reflow temperature curve to ensure tight bonding of solder joints.

Conclusions:

Johoty focuses on providing high-quality IP67 grade 5-pin pogo pin water proof connectors. They often support industrial, automotive, medical, and other fields. Our waterproof connectors combine excellent waterproof performance and electrical stability. It is the preferred and perfect choice for engineers and procurement experts. Whether it’s waterproof circular connectors or automotive waterproof connectors, Johoty can meet the most demanding requirements.

We look forward to all technical experts and decision-makers contacting Johoty to explore more waterproof connectors solutions. Jointly promote technological innovation and reliable connectivity.