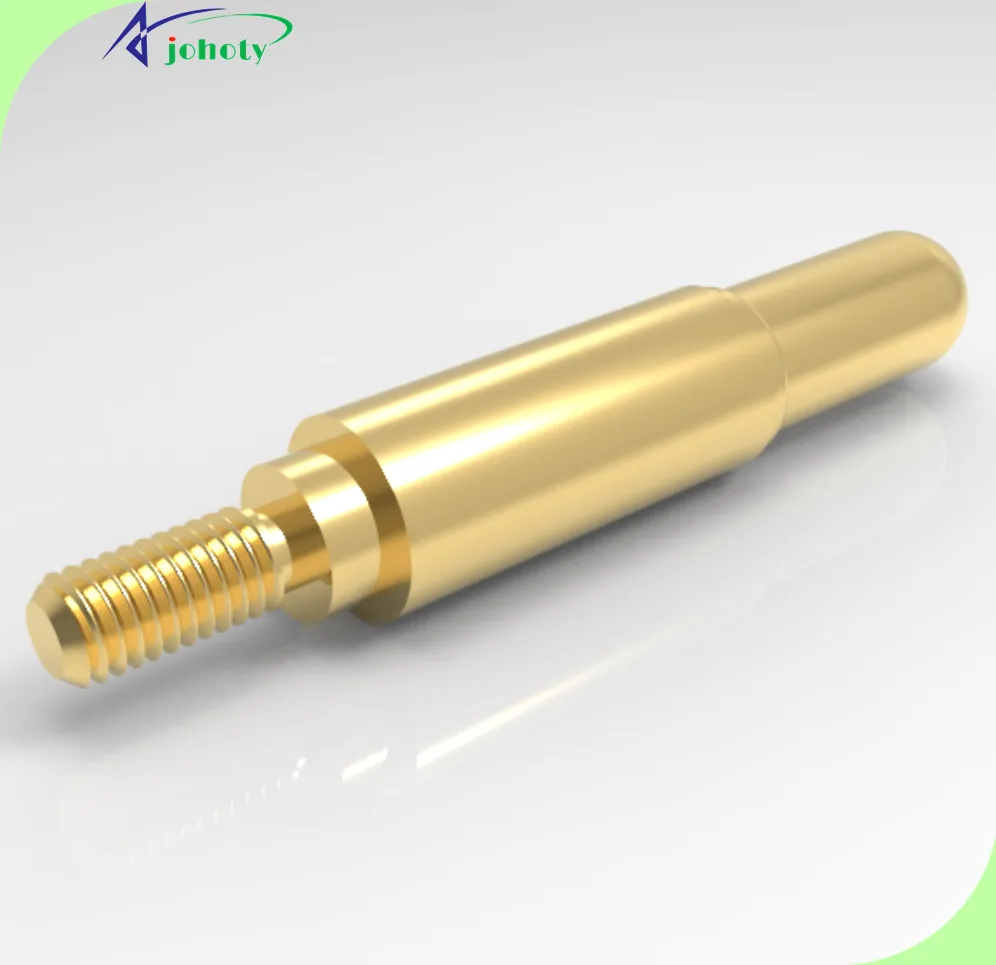

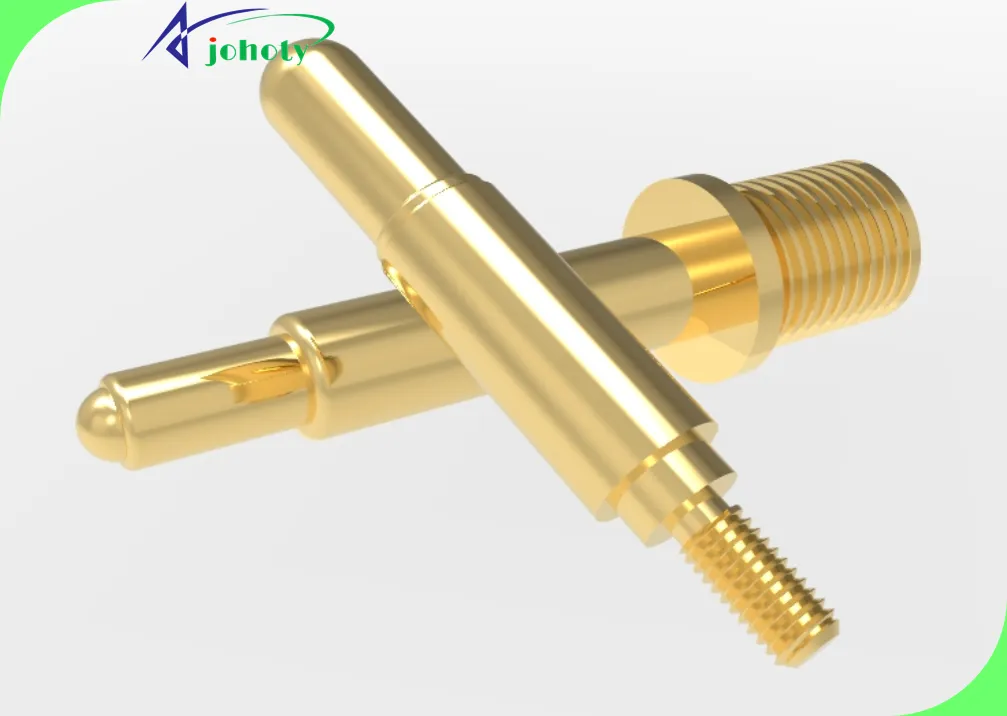

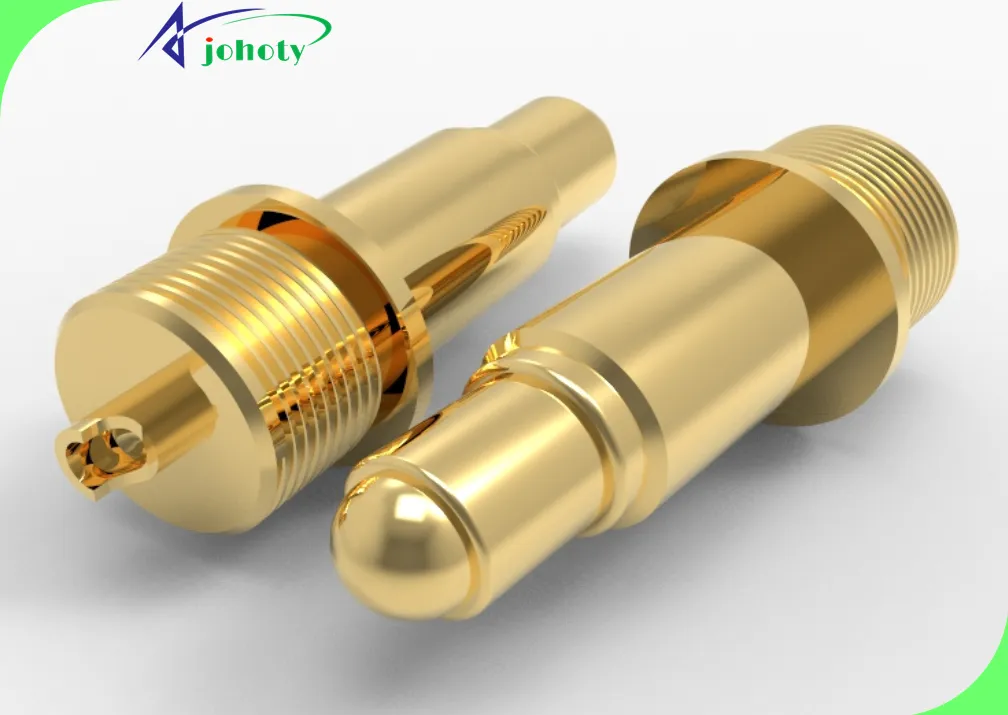

Threaded Pogo Pins Description:

Threaded Pogo Pins Datasheet:

| Items | Details |

|---|---|

| Electrical: | Contact Resistance: ≥ 15 mΩ, Custom. |

| Current Rating: 0.5A – 120A, Custom. | |

| Voltage Rating: 3.3V – 220V, Custom. | |

| Mechanical: | Diameter: M1.2-M10, 0.50 mm to 20.00 mm, Custom. |

| Length: 6.00 mm to 70.00 mm, Custom. | |

| Spring Force: 70 gf – 3,000 gf | |

| Working stroke: 0.50 mm to 15.00 mm, Custom. | |

| Full stroke: 0.50 mm to 15.00 mm, Custom. | |

| Durability (Life Cycle): 10,000 ~ 500,000 cycles. | |

| Operating Temperature: -40°C to +125°C | |

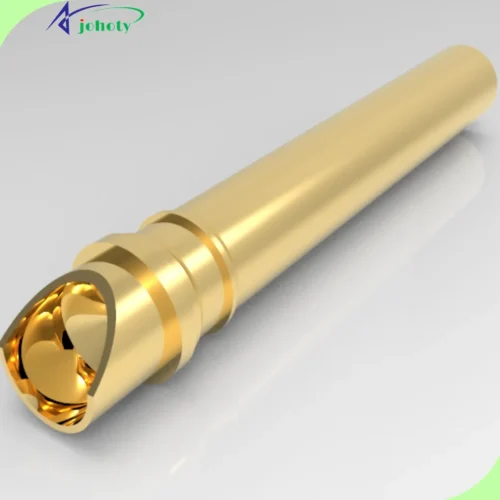

| Materials: | Plunger: Brass, tellurium copper, or beryllium copper. ≥ 0.25um. Plating of gold, Ag, Pd, Pt, Rh, Ru, Custom. |

| Barrel: Brass, beryllium copper, tellurium Copper, Glating of gold, Ag, Pd, Pt, Rh, Ru, Custom. | |

| Spring: Stainless steel, music wire, Custom. | |

| Installation: | Install methods: Manual, automated, snap-in, embedded, nut-fixed, end-face installation. |

| Threaded shapes: Male, female, fine, coarse, triangular, extended, serrated, round thread. Custom. | |

| Threaded diameter: M1.0, M1.2, M1.5, M2.0, M2.5, M3.0, M4.0, M5.0, M6.0, M8,0. Custom. | |

| Pitch: 0.2mm, 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 1.0mm, 1.25mm, 1.5mm. Custom. | |

| Special thread: Self locking thread, waterproof thread, high temperature resistant thread. Custom. | |

| Package: | Bulk, T&R(tape and reel), tray, tube, blister, plastic bag, Custom. |

| Applications: | Consumer Electronics: Optional. |

| Medical Devices: Optional. | |

| Automotive Industry: Optional. | |

| Testing and Measurement: Optional. | |

| Wearable Technology: Optional. | |

| Communication Devices: Optional. | |

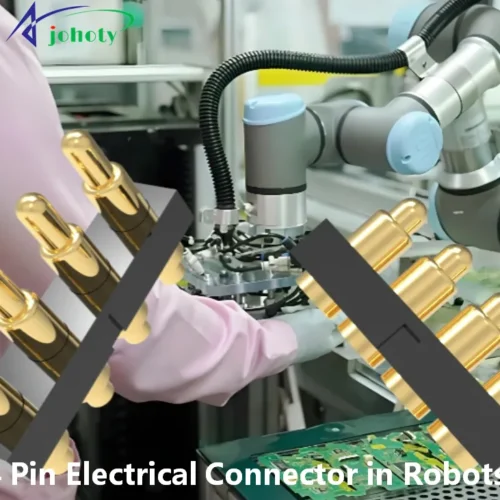

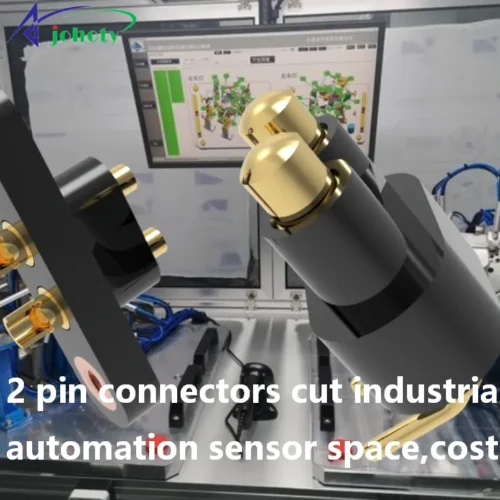

| Industrial Automation: Optional. | |

| Power Supply Systems: Optional. | |

| Military and Aerospace: Optional. | |

| PCB Connectivity: Optional. |

Why Choose Johoty’s Threaded Pogo Pins ?

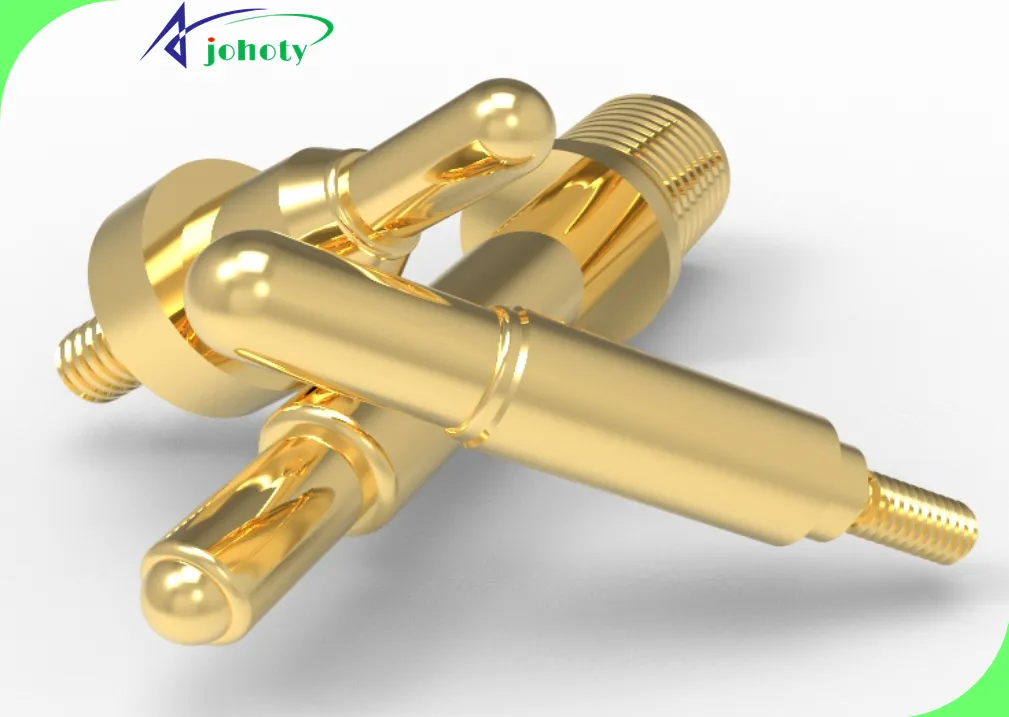

Johoty’s threaded pogo pins have optional 8 shapes for 6 install methods, flexible custom. Johoty is trustworthy!

Threaded Pogo Pins Benefits:

Flexible Customized, Support Personalized Product Development

Enhance Connection Stability and Provide Reliable Performance

High Compatibility, Meet the Connection Needs of Various Devices

We help you provide flexible installation options to improve electrical performance and transfer efficiency. Improve equipment maintenance efficiency and reduce downtime. Extend the service life of connectors and reduce duplicate purchases. Save design and development time & reduce development costs. Suitable from consumer electronics to industrial machinery.

Cost-benefit Optimization, Reduce Excess Inventory and Resource Waste

Johoty helps you reduce inventory management complexity and lower warehousing costs. Simplify procurement processes for time and cost savings. Improve inventory flexibility and reduce the proportion of stagnant inventory. Reduce resource waste, and minimize rework costs. Reduce changeover time and costs. And decrease overall operating costs and increase profit margins.

Threaded Pogo Pins Applications:

Electrical Connection of Precision Instruments

Battery Charging for Wearable Devices

Modular Design of Unmanned Aerial Vehicles

Automotive Electronic Systems

Integrated Interface of Smart Home Devices

Industrial Robot Signal Transmission

Medical Equipment Module Docking

Probe Interface of Electronic Testing Equipment

Threaded Pogo Pins Advantages:

Compatible with Multiple Devices, Extremely Adaptable

Threaded pogo pins can adapt to various types of device interfaces due to their diverse thread specifications. You can find suitable thread types for your designs or devices. Engineers no longer have to worry about interface mismatches! This adaptability can simplify the installation process and reduce the maintenance difficulty between different devices. Imagine how convenient it is to have equipment quickly connected, whether you are in a laboratory or at a technology exhibition!

Excellent Seismic Performance, More stable Connection

The threaded design gives pogo pins strong seismic resistance, ensuring a secure connection even in high vibration. Engineers can use it with peace of mind to make complex robots or drones. It’s like no matter how much your safe shakes, the door won’t automatically open! Thread design protects the stability of circuit connections and is the best choice for devices with high-performance requirements.

High Conductivity, Efficiency Improvement

The material and design of threaded pogo pins ensure efficient current conduction without power outages or current losses. Engineers particularly need this reliable conductivity when manufacturing high-performance products. Just like how Johoty uses the most precise 6-axis CNC to produce pogo pins that strictly meet your drawing requirements, making it easy to see high-end and highly efficient at a glance!

Easy Installation, Time and Labor savings

Compared to other complex connectors, the installation process of threaded pogo pins is very simple. Engineers only need to gently twist to complete the fixation, and no longer have to worry about the connector falling off. Imagine it’s as easy as unscrewing a bottle of cola! This humanized design greatly saves time and effort, making it very suitable for large-scale production and rapid assembly projects.

FAQ

Threaded pogo pins offer smaller sizes, higher connection reliability, and longer lifespan while being easy to install and maintain. Their affordability positions them as a prime option across various applications.

Competitive pricing is available, and discounts are offered depending on the volume of your order and any customization preferences. Please contact our CFT team for quotations and more information.

We can provide customized designs and manufacturing services according to customer requirements. Including working strokes, sizes, spring force, shapes, materials, electrical characteristics, etc.

Yes, we provide samples for customers to test and evaluate. Please contact our CFT team for samples and technical support.