Aerospace Connectors With 5N Pogo Pin Force; 1.00mm Pitch 5μm Gold Plating, 10mΩ Low Resistance, Proven High Vibration for UAVs and Avionics!

Introduction:

Aerospace connectors are the invisible core of today’s avionics system integrity. Aerospace connectors with pogo pins are small in size and lightweight. Undertaking the stable transmission task of signals and power directly affects the reliability of the entire system. Johoty learned during communication with guests that UAVs often face complex flight postures and extreme environments. However, traditional connectors are unable to meet the multiple requirements of high-frequency signals, mechanical shock, electrical performance, and compact structure.

This article will introduce the structure, electrical performance, material processing, environmental adaptability, and system adaptation of aerospace connectors. Systematically analyze specific specifications of miniature pogo pin connectors: a highly reliable pogo pin connector solution with 5N force, 1.00mm pitch, 5 μm gold plating, 10mΩ contact resistance, and MIL-STD vibration testing. Provide content analysis with sufficient technical logic and detailed data for high-end customers.

Structural mechanism of aerospace connectors:

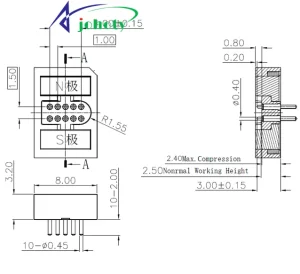

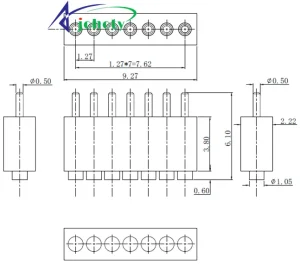

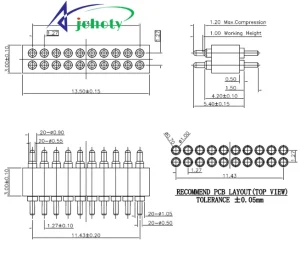

The core components of mechanical constraints and matching pogo pin connector in miniaturized design. It includes spring, plunger, and external barrel. The structure must achieve high-frequency reliable docking in a very small space. The setting of 5N elasticity is not arbitrarily selected, but based on the vibration spectrum of the drone system (20Hz~2kHz). At the same time, it also includes the micro dynamic displacement analysis of the plug-in contact surface.

Within this range, 5N can ensure stable contact under continuous vibration. It will not cause local stress concentration or fatigue damage to solder joints on PCB pads. Johoty found the stability of this force value in finite element simulation modeling analysis. The minimum contact resistance fluctuation curve is observed within the rebound modulus range of aviation-grade beryllium copper (BeCu) springs.

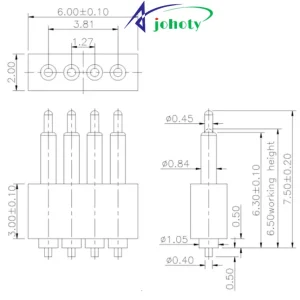

Engineers can design a 1.00mm pitch, but there is no standard 1.27mm or 2.54mm pitch. They often face four main contradictions: wiring density, contact redundancy, crosstalk prevention, and PCB manufacturability. 1.00mm is the most commonly used pitch in aviation electronics, which can maintain sufficient air insulation distance.

It can also achieve compact packaging of up to 128 bit signal interfaces. At the same time, it has natural compatibility with the MIL-DTL-83513 micro interface standard. Adaptation or updates can be made without changing the system motherboard layout.

Electrical performance of aerospace connectors:

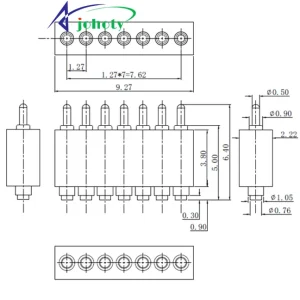

The boundary condition between 10mΩ internal resistance and signal integrity: It is a key indicator for achieving high signal integrity and low power consumption in pogo pin connectors. UAVs extensively utilize CAN bus, I²C, SPI, PWM, and high-speed ADC sensing systems. A small change in internal resistance may cause drift in the rise/fall time of the pulse width modulation signal edge. This further affects the stability of servo control or the linear consistency of data acquisition.

Verify the signal retention of aerospace connectors and simulate a 1GHz sine signal channel under different pressure drop conditions. The results showed that at room temperature of 25℃, the insertion loss (S21) in its S parameter remained within -0.28dB. The reflection loss (S11) is below -18dB. This effectively indicates that it has extremely low reflection interference in typical transmission paths.

In addition, a 10m Ω contact resistance at 5V and 2A only results in a unit contact power consumption of 20mW. Compared to the traditional 20~30m Ω spring needle structure, it can reduce energy consumption by more than 35%. The optimization of power supply efficiency in long endurance unmanned aerial vehicles has a significant effect.

Material of aerospace connectors:

The design of 5 μm gold plating and multi-layer metallurgical structure: The core determining the performance of pogo pin lies in its contact surface coating process. Johoty uses a 5 μm Au thickness coating, with a bottom layer of Ni shielding and a diffusion transition layer in the middle. Build good electrochemical stability.

The setting of a thickness of 5μm is based on the ASTM B488-01 standard. Compared to the common 0.76-2.5μm, it has a lower oxidation rate in high humidity and high salt environments. After 1,000 hours of continuous exposure to humid heat at 85℃ and 95%RH, the fluctuation amplitude of contact resistance is less than 3.5%. Far below the allowable range of 10% fluctuation for aviation grade connectors.

In terms of material selection, Plunger uses high-strength BeCu with a yield strength of > 1.2 GPa and excellent creep resistance. The spring part is made of SUS631 stainless steel or SWP-B, which has excellent rebound and fatigue limits. Barrel is a precision phosphor bronze that provides excellent dimensional tolerance control and resistance to electromagnetic interference.

Environmental adaptability of aerospace connectors:

Long-term validation of high vibration and extreme temperature and humidity: Aerospace connectors have undergone full cycle testing based on MIL-STD-202/810 for high vibration. Including 20~2000Hz three-axis sine vibration for 12 hours, with a 30g impact of 24 times per axis. -Thermal cycling at 55℃~125℃ for 1,000 times and salt spray experiment for 240 hours.

It is worth noting that after 10,000 consecutive automatic insertion and extraction experiments, the contact impedance remained within the initial range of ± 1.8mΩ. Has excellent plug-in reliability and contact stability. This is crucial in the modular quick-release structure of fixed-wing tactical UAVs or electro-optical radar systems.

System integration of aerospace connectors:

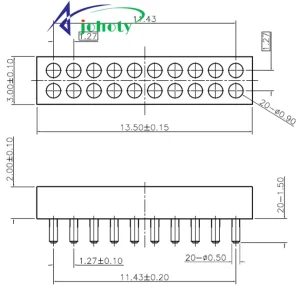

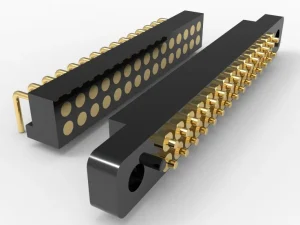

Scalability for modular avionics platforms. At the system integration level, the structure of the best aerospace connectors is highly compatible with mainstream avionics backplane and hot-swappable modules. 1.00mm pitch facilitates component replacement and supports blind mating structural design. Ensure docking accuracy through mechanical guide slots to avoid pin misalignment and failure.

Aerospace connectors are commonly used in UAV cluster communication, cabin-mounted inertial navigation modules, energy conversion modules, and task load subsystems. This connector supports a parallel pogo array and has good EMI protection, passing the IEC 61000 immunity test. Can operate normally under high-power radio interference conditions.

Future challenges for aerospace connectors:

Evolve towards higher frequency and intelligent integration. At present, UAV systems perform well in <1GHz, but in the future, UAV will gradually develop towards frequencies above 28GHz. How aerospace connectors maintain mating reliability, achieve lower insertion loss, higher SNR, and smaller spatial layout, will become key designs.

At the same time, the system platform is evolving towards software hardware decoupling, intelligent recognition, and module self-management. Aerospace connectors will also develop towards integrating EEPROM identity recognition, hot swappable power management, and digital protocol negotiation. It is no longer just a physical conductive device, but a node with electrical intelligent recognition.

Conclusion:

In complex avionics systems, aerospace connectors are not isolated components, but miniature keypoints that couple the system. Johoty describes a highly reliable pogo pin connector with 5N spring force, 1.00mm signal pitch, 5μm Au coating, and 10mΩ internal resistance. Has demonstrated the ability to adapt to extreme conditions: materials science, electrical design, process manufacturing, and system integration.

In the future, aerospace connectors will continue to assume the responsibility of micro interfaces in flight control, power scheduling, and data exchange. Lay a solid connection foundation for the systematic and intelligent evolution of aerial platforms. If you need Johoty’s high reliability aerospace connectors, please contact our CFT team.