How to Make a Magnet Charger? Saving money is essential for business success. This blog helps boost equipment maintenance efficiency and lower maintenance costs, achieving maximum operational benefits.

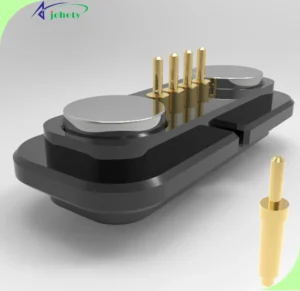

How to Make a Magnet Charger? What is a magnetic charger? is a charger that uses magnetism to connect and charge devices. Typically, it consists of two parts. A magnetic attachment for your device and a magnetic charging base that connects to the power source.

When the device is near the charging base, the magnetic connector is attracted to the base, initiating charging. This design offers a convenient charging experience, requiring no plugging and unplugging of charging cables. Just place the device on the charging base to start charging.

Introduction to How to Make a Magnet Charger?

First:

In today’s rapidly evolving tech landscape, businesses demand higher performance and efficiency from their equipment. Traditional charging solutions often struggle to meet the needs of modern, efficient automation and continuous operation. The Pogo Pin magnet charger is becoming the top choice in numerous industries.

Thanks to its outstanding electrical performance, rapid docking capabilities, and durability. From medical devices to industrial robots, the Pogo Pin magnet charger optimizes the charging process. And, significantly improves overall operational efficiency and equipment lifespan.

Second:

This article intends to provide tech manufacturers with a comprehensive guide. It is on how to design and manufacture an efficient and reliable Pogo Pin magnet charger from scratch. Whether you’re looking to improve the charging efficiency of existing products or enhance your market competitiveness through innovative technology. This article will provide the key information and practical tips you need.

We’ll start by discussing the basic components of the Pogo Pin magnet charger. Delving into design considerations, material selection, and manufacturing processes. And how to ensure the product meets the highest performance standards through precision engineering.

Additionally, we’ll share some successful industry application cases to depict how these theories are applied in practice. Are you ready to dive into the detailed process of making this revolutionary charging device? Let’s get started.

Design Principles and Material Selection on How to Make a Magnet Charger?

Design Principles

1. Efficient Performance and Compatibility:

- We consider the charging efficiency of the Pogo Pin magnet charger and its compatibility with various devices. Including adaptability to different voltage and current requirements.

- We always ensure easy integration into customer’s existing product lines without extensive modifications.

2. Durability and Reliability:

- Considering extreme conditions in industrial environments, it’s highly resistant to wear and corrosion.

- Ensure long-term stable physical and electrical connections, even under high-frequency use or vibration environments.

3. Safety and Compliance with Standards:

- All designs must comply with international safety standards and industry regulations, including electromagnetic compatibility and user safety.

- Adopt an anti-misoperation design to ensure the safe use of the magnet charger under any operating conditions.

4. Ease of Manufacturing and Scalability:

- It is conducive to mass production, considering the cost efficiency and simplicity of manufacturing processes.

- Choose components and structures that can be produced through automated production to reduce labor costs and complexity.

Material Selection

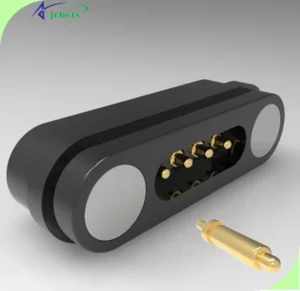

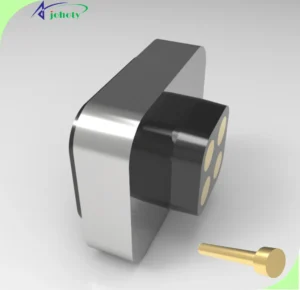

1. Pogo Pin Materials:

- Spring steel: Used for Pogo Pin springs, must possess good elasticity and durability to maintain long-term resilience and stable electrical performance.

- Copper or brass: Typically chosen as the conductive core of Pogo Pins, often gold or nickel-plated for improved conductivity and corrosion resistance.

2. Housing Materials:

- High-strength plastic: Such as polycarbonate, used for housing materials, is known for its lightweight, high strength, and good electrical insulation properties.

- Metal housing: In applications requiring higher mechanical strength or shielding performance, aluminum or stainless steel housing may be chosen.

3. Magnet Materials:

- Rare-earth magnets (such as neodymium): Suitable for applications requiring strong magnetic attraction to ensure stability and automatic alignment of the charging interface.

4. Insulation and Protection Materials:

- Silicone or polyurethane: Used for insulation of cables and interfaces, enhancing temperature resistance and waterproofing, suitable for use in harsh environments.

Guideline on How to Make a Magnet Charger?

Design and Prototyping:

- Design Stage: Firstly, precise design using CAD is necessary to ensure the magnet charger meets electrical and mechanical performance requirements. Considerations include magnetic distribution, contact resistance, durability, and dimensional accuracy.

- Prototype Testing: Once designed, prototypes are created using 3D printing or rapid prototyping techniques for physical testing and adjustments.

Material Selection:

- Choosing appropriate materials is crucial. Typically, Pogo Pins use copper or stainless steel as base materials. Possibly gold or nickel-plated for enhanced conductivity and corrosion resistance.

Precision Machining:

- Utilize CNC machining to precisely craft metal materials for magnet charger bodies and spring pins. These parts must meet strict tolerance standards to ensure optimal mechanical performance and electrical contact.

Assembly:

- Assemble Pogo Pin components, including springs, pins, and moving contacts, it is in the magnet charger housing. During assembly, ensure all parts are properly aligned for optimal electrical performance and mechanical stability.

Magnetic Integration:

- Integrate magnets, often using rare-earth magnets, such as neodymium, for their strong magnetic properties. Precise control of magnet position and polarity is necessary for effective magnetic attraction.

Electrical Performance and Durability Testing:

- Conduct a series of tests, including resistance testing, and connection/disconnection cycle testing. And environmental adaptability testing, such as temperature and humidity testing. It is to ensure products meet technical and safety standards.

Quality Control:

- Samples from each production batch undergo quality inspection. Including visual inspection, dimensional measurement, and functionality testing. This ensures each magnet charger meets design specifications.

Use Case about How to Make a Magnet Charger?

Background:

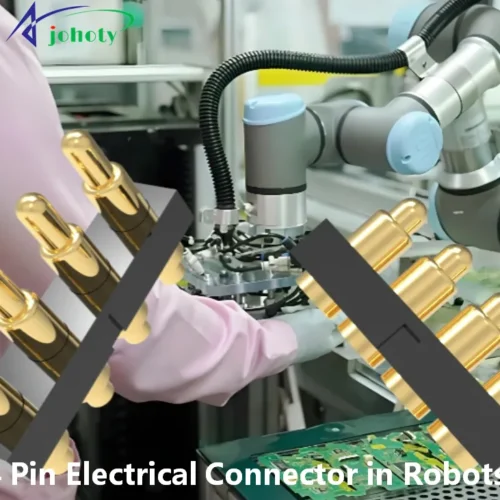

The robots produced by the client are mainly used for highly precise manufacturing tasks, such as assembling small electronic components. The robots require frequent and rapid charging. However traditional plug-in charging interfaces often suffer from poor contact and charging interruptions due to wear and alignment issues.

Objectives:

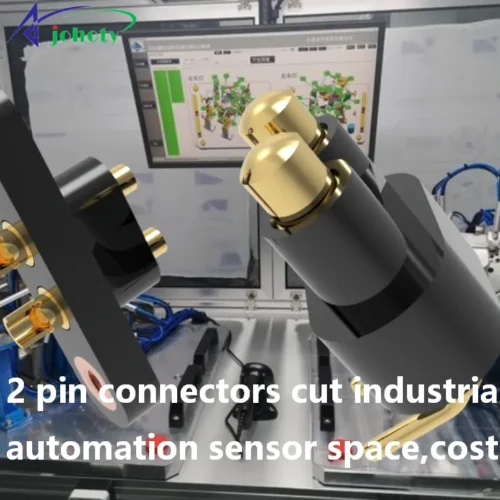

Enhance charging reliability: Reduce physical wear and alignment issues by using our Pogo Pin magnet charger.

Increase production efficiency: Achieve faster charging cycles and reduce robot downtime.

Extend equipment lifespan: Reduce interface wear to lengthen the equipment’s overall lifespan.

Solution:

1. Design and Implementation:

- Charger interface design: Design magnetic charging interfaces with Pogo Pins, providing resilient contact. While magnetic attraction ensures automatic and precise docking.

- Magnet selection and layout: Select high-performance rare-earth magnets and carefully design magnet layouts. It is to maximize magnetic attraction and ensure connection stability.

2. Technical Implementation:

- Automatic docking technology: Robots automatically align and connect to the magnet charger via magnetic force when approaching the charging station.

- Fast charging technology: Utilize efficient power management systems to shorten charging times and increase robot operating cycles.

3. Testing and Optimization:

- Performance testing: Conduct multiple rounds of testing, including long-term operation tests and environmental adaptability tests. Such as temperature and humidity impact tests.

- Optimization: Adjust magnet strength and Pogo Pin configuration based on test results to achieve optimal charging performance.

Achievements:

- Improved efficiency: Average robot charging time reduced by 30%, effectively enhancing production line operation efficiency.

- Reduced maintenance costs: The non-physical contact nature of the interface greatly reduces maintenance costs and part replacement frequency.

- Enhanced system stability: Increased reliability of the charging interface reduces downtime caused by charging issues.

Performance Testing and Validation About How to Make a Magnet Charger

Testing Objectives

- Electrical Performance Testing: Ensure the stability and efficiency of the magnet charger under different voltage and current conditions.

- Mechanical Durability Testing: Validate the physical durability of Pogo Pin and magnet interfaces, including insertion and removal cycles and vibration resistance.

- Environmental Adaptability Testing: Evaluate the magnet charger’s performance in extreme temperatures, humidity, and corrosive environments.

Testing Methods

1. Electrical Performance Testing

- Continuity Testing: Check the electrical continuity of Pogo Pins to ensure no disconnection.

- Voltage and Current Testing: Measure voltage and current under standard and extreme operating conditions to verify the magnet charger’s electrical stability.

- Insulation Impedance Testing: Ensure insulation effectiveness between magnet charger components meets safety standards.

2. Mechanical Durability Testing

- Insertion and Removal Cycle Testing: Simulate repeated connection and disconnection operations to evaluate the physical durability of Pogo Pins.

- Vibration Testing: Test the structural integrity and functional retention of the magnet charger under simulated transportation or usage environments.

3. Environmental Adaptability Testing

- High and Low-Temperature Testing: Test the magnet charger’s performance under extreme temperature conditions, including heating and freezing cycles.

- Humidity Testing: Test the magnet charger’s moisture resistance and withstand corrosion in high humidity.

- Salt Spray Testing: Evaluate the magnet charger’s corrosion resistance and long-term stability in salt-containing environments.

Verification Process

- Internal Audit: Preliminary testing conducted by our engineering team to address obvious design flaws.

- Third-Party Certification: Standardized testing conducted by independent laboratories to obtain necessary certifications (such as CE, and UL standards).

- Customer Trials: Selected customers conduct on-site testing, collect usage feedback, and further optimize the product.

Analysis of Test Results and Improvement

- Data Analysis: Thoroughly record and analyze all test data to determine performance baselines and any deviations.

- Problem Identification and Solutions: Identify potential performance issues based on test results and develop improvement measures.

- Iterative Design: Adjust design and manufacturing processes based on test feedback to enhance the overall performance and reliability of the product.

Conclusion

We’ve delved deeply into every critical step in this article from concepts to final manufacturing. Showcasing the entire process of manufacturing efficient and reliable Pogo Pin magnet chargers. Through careful design principles, selecting the highest quality materials, and conducting rigorous performance testing and validation.

We ensure that our magnet charger meets the stringent requirements of modern, efficient automation equipment. It is crucial in improving equipment operational efficiency and reducing maintenance costs.

Our magnet charger prioritizes durability and compatibility, fitting for diverse industries and applications. From medical devices to industrial robots, providing unparalleled charging efficiency and safety.

Through continuous optimization and innovation, we are committed to driving your business forward. We ensure that our technical solutions keep pace with the times and lead industry standards.

To experience our technological achievements firsthand and learn how to apply these innovations to your products, we invite you to contact our professional CFT team.